高等学校化学学报 ›› 2023, Vol. 44 ›› Issue (5): 20220730.doi: 10.7503/cjcu20220730

收稿日期:2022-11-25

出版日期:2023-05-10

发布日期:2023-01-09

通讯作者:

苗政培,田新龙

E-mail:zpmiao92@hainanu.edu.cn;tianxl@hainanu.edu.cn

基金资助:

LI Ruisong, MIAO Zhengpei( ), LI Jing, TIAN Xinlong(

), LI Jing, TIAN Xinlong( )

)

Received:2022-11-25

Online:2023-05-10

Published:2023-01-09

Contact:

MIAO Zhengpei, TIAN Xinlong

E-mail:zpmiao92@hainanu.edu.cn;tianxl@hainanu.edu.cn

Supported by:摘要:

中空纳米结构具有比表面积大、 传质可控和活性位点明确等优势, 其结构设计与电催化应用在能源 转化与储存领域引起了广泛关注. 特别是中空贵金属纳米材料用于氧还原催化时, 中空内腔引入到贵金属 纳米结构, 不仅暴露更多的活性位点, 还能减少贵金属的用量, 这将为贵金属催化剂的大规模应用提供一个理想的研发平台. 本文综合评述了近年来中空贵金属的合成策略及其氧还原催化应用. 首先, 回顾了中空贵金属在氧还原催化剂研制中的优势与意义; 然后, 介绍了近期关于中空贵金属的制备策略(硬模板法、 软模板法、 自模板和无模板法等)及其优势; 最后, 分析了中空贵金属在氧还原领域所面临的挑战, 并对其设计进行了展望.

中图分类号:

TrendMD:

李瑞松, 苗政培, 李静, 田新龙. 中空贵金属纳米材料氧还原催化的研究进展. 高等学校化学学报, 2023, 44(5): 20220730.

LI Ruisong, MIAO Zhengpei, LI Jing, TIAN Xinlong. Research Progress on Hollow Precious Metal-based Nanostructures for Oxygen Reduction Reaction. Chem. J. Chinese Universities, 2023, 44(5): 20220730.

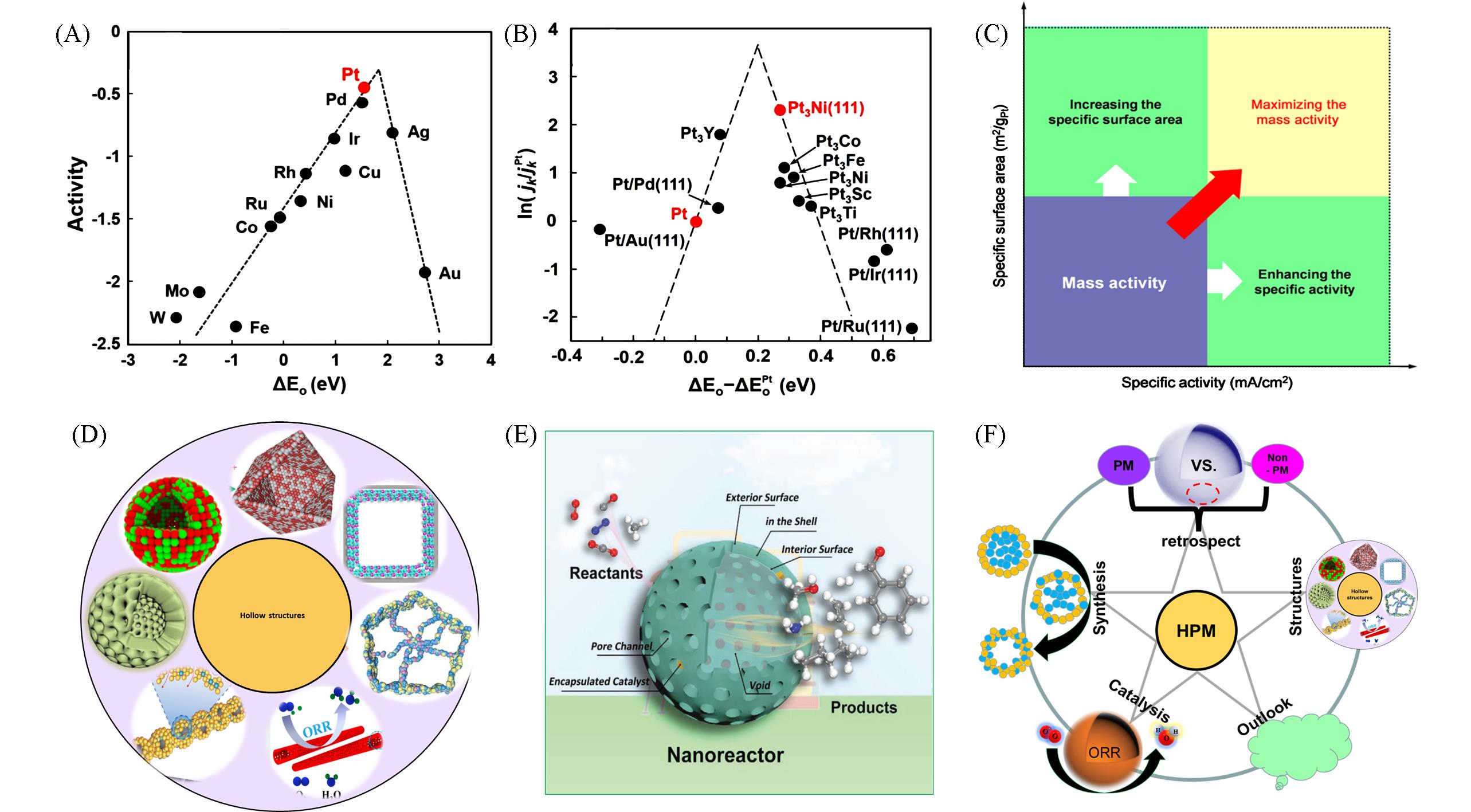

Fig.1 Activities of different metals toward ORR plotted as a function of the oxygen binding energy(A)[26], kinetic current densities(based on pure Pt) of different binary alloys as a function of the oxygen adsorption energy relative to pure Pt as(ΔEo-ΔEoPt)(B)[28], schematic illustration for maximizing the MA of PM⁃based nanostructures(C)[34], main structures of HPMs for recent progress, including nanocages, nanotubes, mesoporous nanocages, nanochains and nanoframes(D), schematic diagram of hollow nanostructure as nanoreactors(E)[36], schematic illustration of this review including retrospect, synthesis, structure, catalysis and outlook(F)(A) Copyright 2004, American Chemical Society; (B) Copyright 2018, Wiley-VCH; (C) Copyright 2017, American Chemical Society; (E) Copyright 2019, Wiley-VCH.

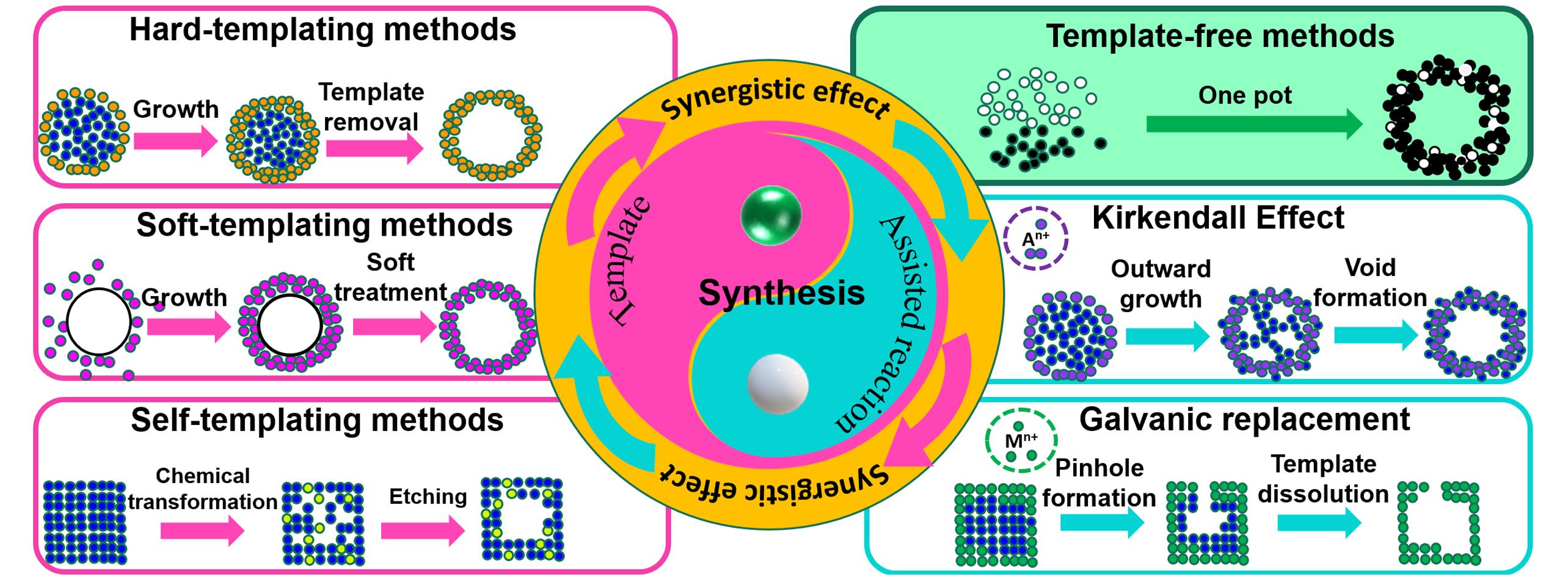

Fig.2 Essential and schematic plots of synthetic methodologies for hollow structures concluding hard⁃, soft⁃, and self⁃templating methods, as well as assisted kirkendall effect and galvanic replacement reaction

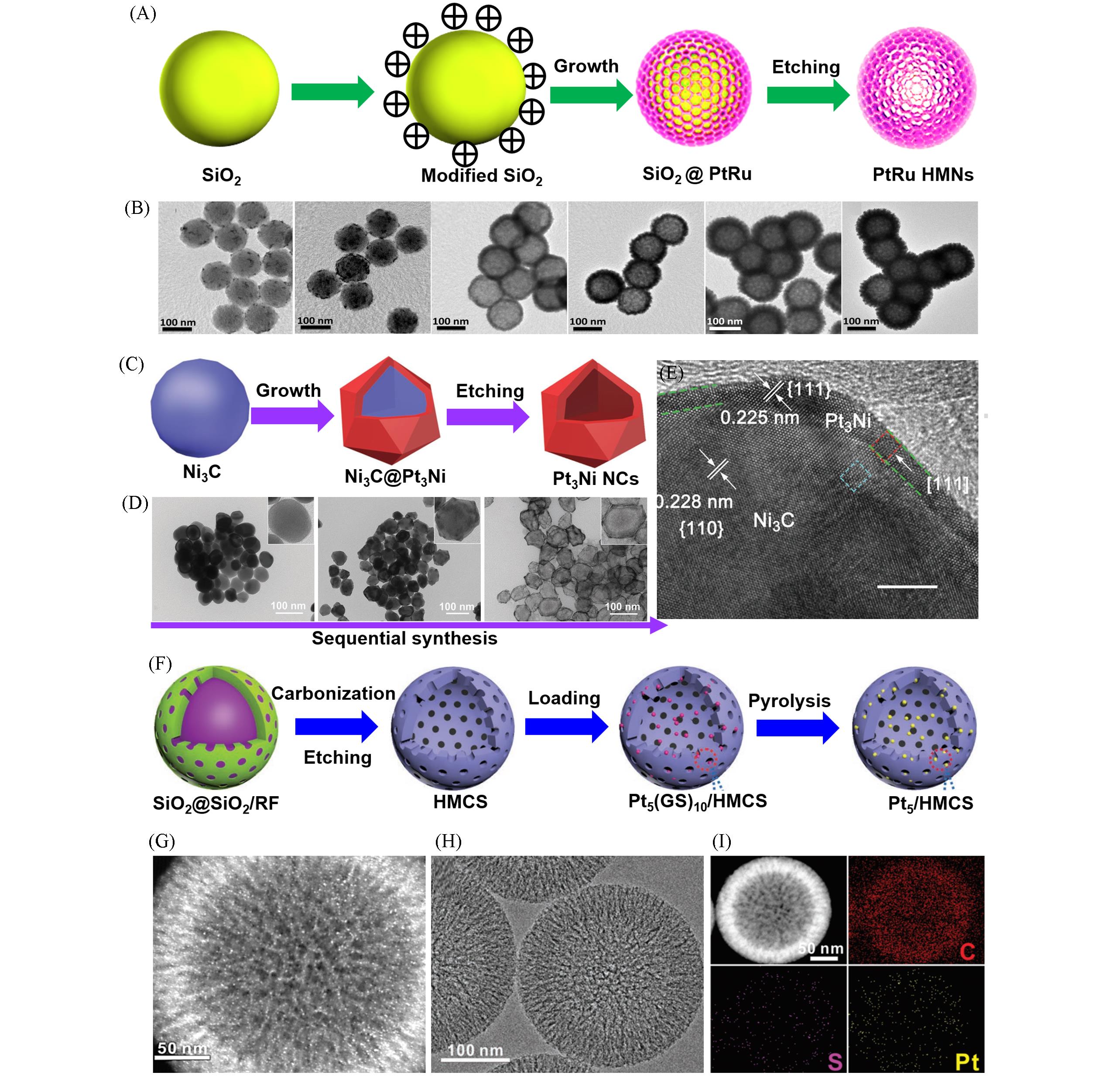

Fig.3 Hard⁃templating method for synthesizing HPMs: schematic illustration for synthesizing hollow Pt⁃Ru nanostructures(A), TEM images during the preparation process(B)[50], schematic illustration for synthesizing hollow Pt3Ni nanostructures(C), corresponding TEM images(D), high⁃ resolution TEM image of Ni3C@Pt3Ni particle(E)[56], schematic illustration for synthesizing Pt5/HMCS(F), SEM image(G), TEM image(H) and EDS mappings(I) of Pt5/HMCS[57](A, B) Copyright 2013, Wiley-VCH; (C—E) Copyright 2022, Wiley-VCH; (F—I) Copyright 2020, Wiley-VCH.

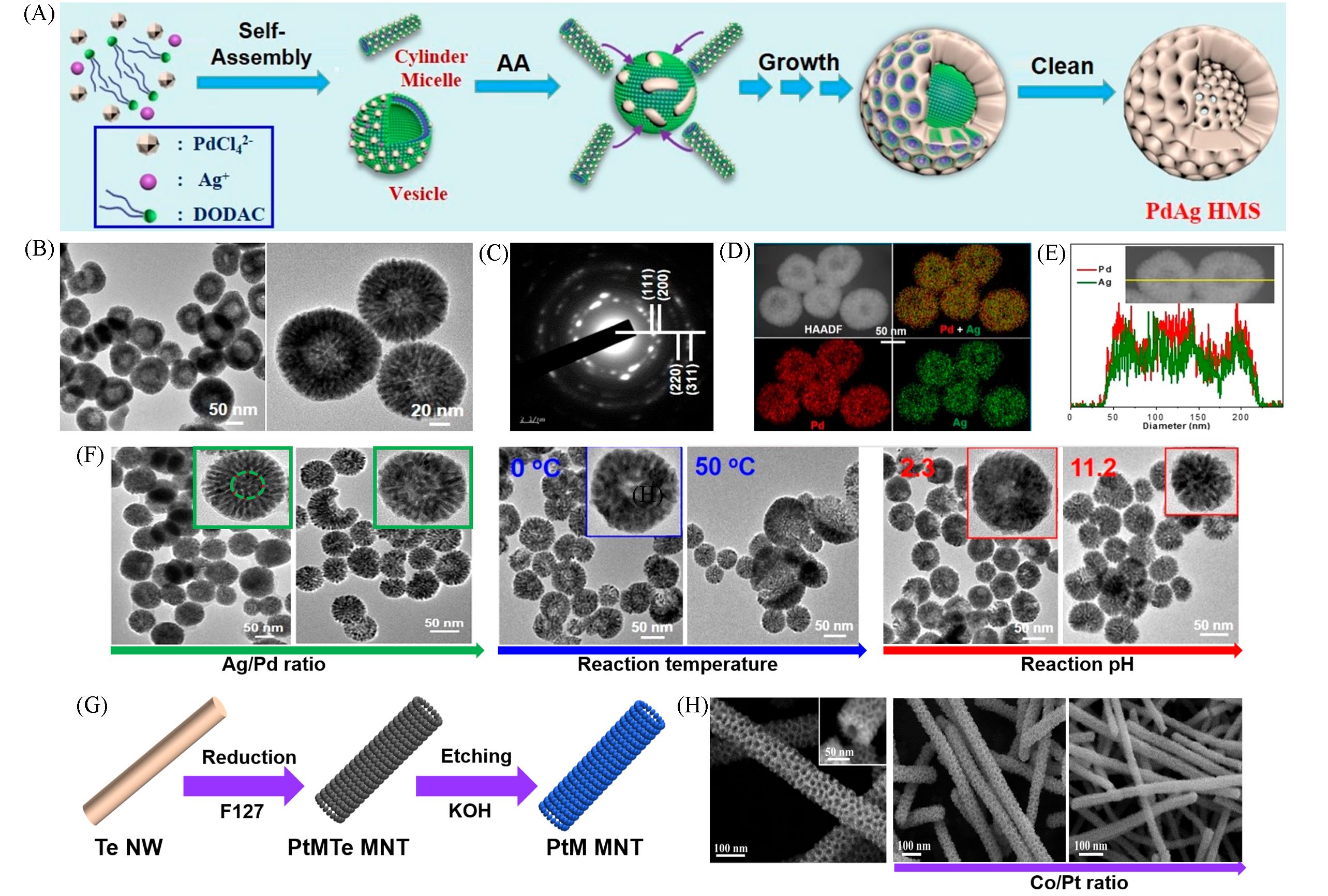

Fig.4 Soft⁃templating method for synthesizing HPMs: schematic illustration for synthesizing hollow PdAg nanostructure(A), TEM image(B), selective area electron diffraction pattern(C), dark⁃field scanning transmission electron microscopy and EDS mapping(D), line scan profiles(E), the morphology change based on different Ag/Pd ration, temperature and pH of PdAg HMNs(F)[62], schematic illustration for synthesizing hollow PtCo and PtNi nanostructures(G), different morphologies of PtCo MNT with mesoporous nanotube structures at different metallic ratio(H)[64]

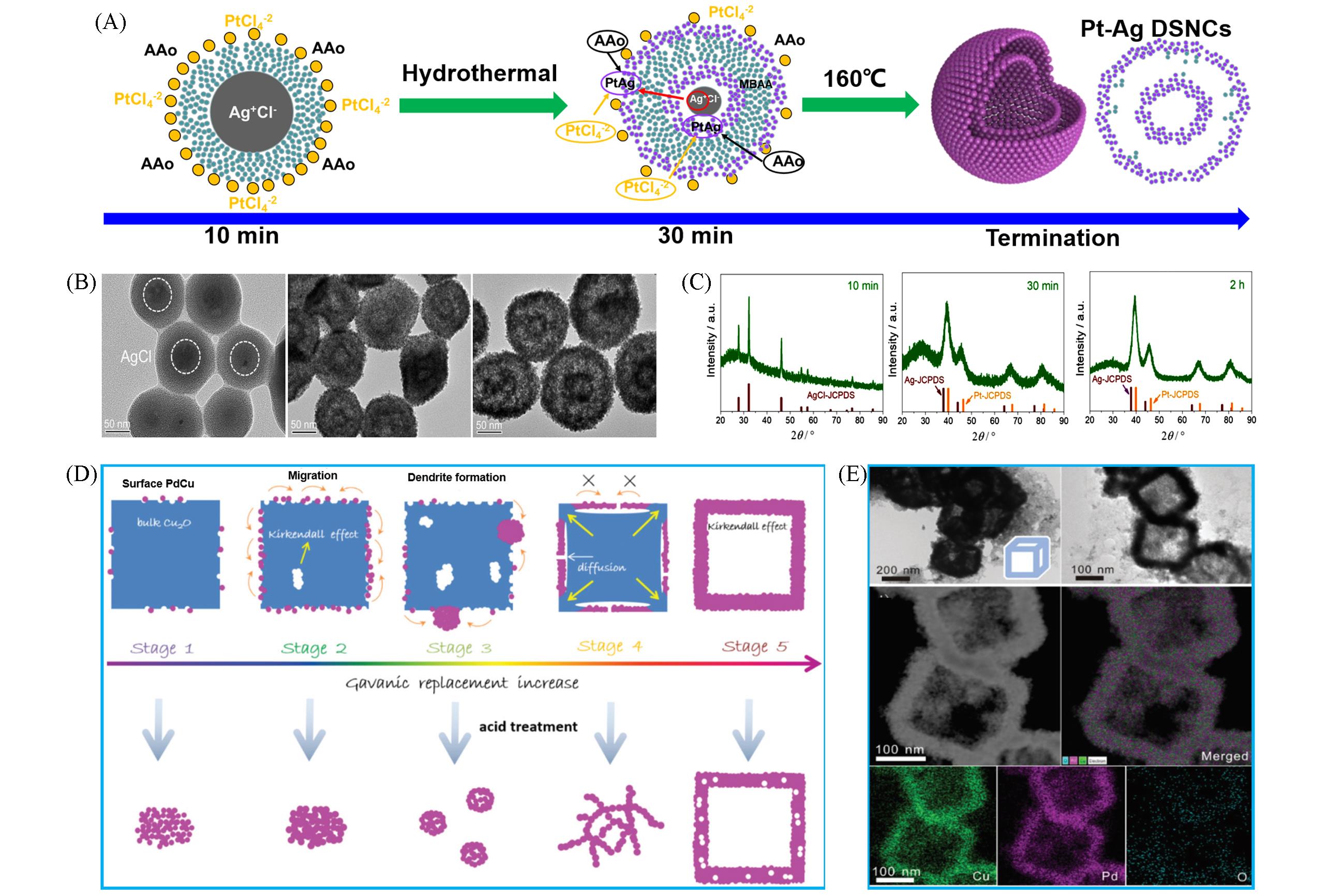

Fig.5 Self⁃templating method for synthesizing HPMs: schematic illustration for synthesizing(A), TEM images(B), X⁃ray diffraction patterns with different crystals during preparation process(C) of hollow Pt⁃Ag nanostructures[25], schematic illustration for synthesizing hollow PdCu nanoboxes(D), corresponding TEM images and EDS mapping(E)[67]

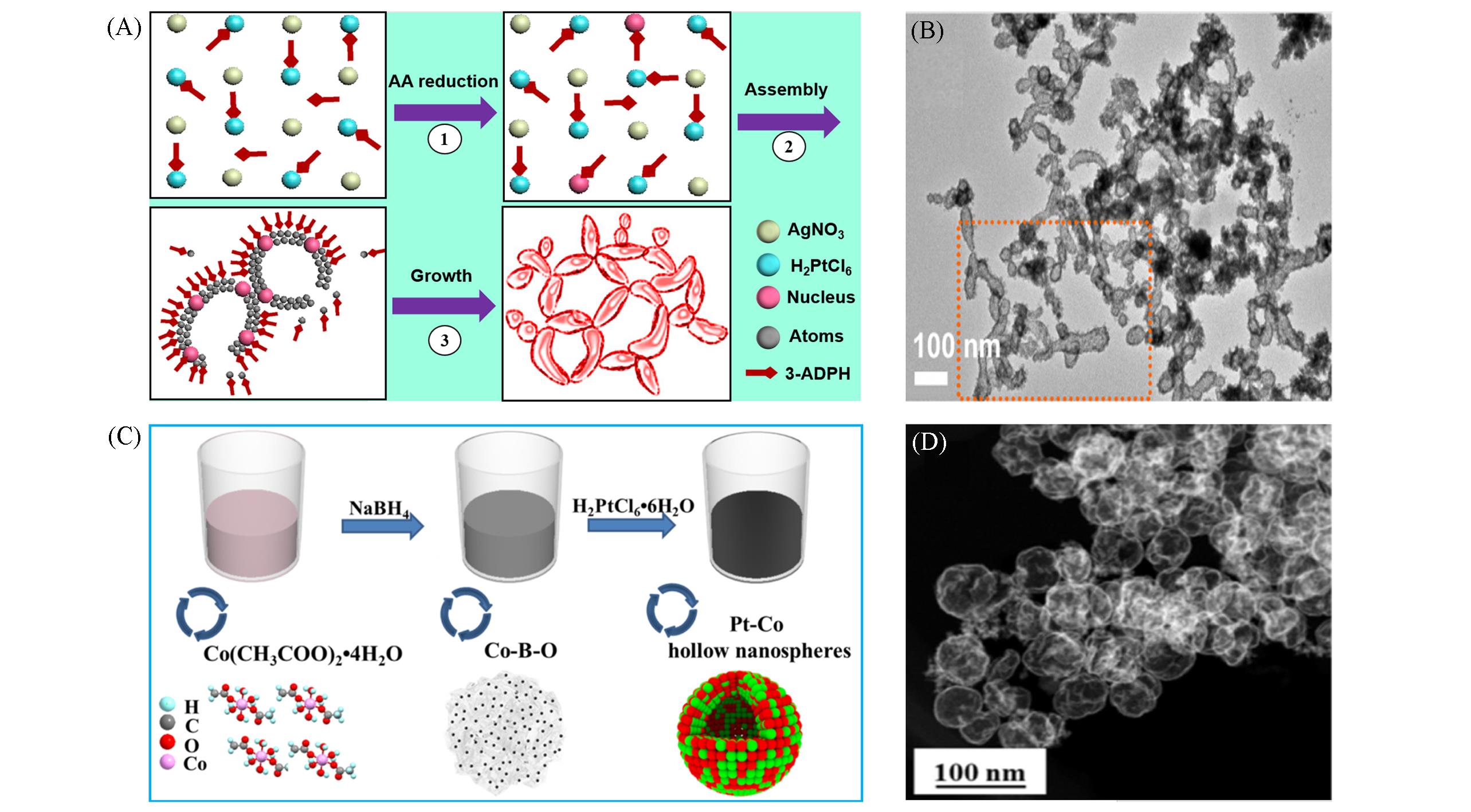

Fig.6 Template⁃free method for synthesizing HPMs: schematic illustration for synthesizing hollow Pt⁃Ag nanochains by one⁃pot strategy(A), TEM image for nanochains(B)[68], schematic illustration for synthesizing hollow PdCo nanospheres with Co⁃B⁃O as intermedium(C), TEM image for nanospheres(D)[71](A, B) Copyright 2017, Elsevier; (C, D) Copyright 2020, Elsevier.

| Structure | Composition | Synthesis strategy | Mass activity/(A·mg | Ref. |

|---|---|---|---|---|

| Mesoporous nanocages | PtPdNi | Pd cores, selective etching | 1.140 | [ |

| Nano⁃hollow spheres | PdCuMoNiCo | One⁃pot solvothermal method | 0.882 | [ |

| Nanocages | Pt⁃Ag | Ag nanocubes, galvanic replacement | 0.640 | [ |

| Nanoframes | Pt3Ni | PtNi3 polyhedra, erosion | — | [ |

| Hollow tesseracts | Pd⁃Pt | Pd⁃Pt alloy nanocubes, Oxygen reaction | 1.860 | [ |

| Double⁃shelled nanocages | Pt⁃Ag | One⁃pot self⁃templated strategy | — | [ |

| Hollow nanostructures | Pt/Ag | AgCl nanoparticles, galvanic replacement | — | [ |

| Nanoframes | PtNi | PtNi rhombic dodecahedron nanoparticles, oxidative etching | 0.920 a | [ |

| Hollow nanoparticles | Pt⁃Ni | Sacrificial SiO2 template | 0.490 | [ |

| Nanocages | Pt | Pd icosahedral seeds, HNO3 oxygen | 1.120 | [ |

| Mesoporous nanocages | S, P⁃PtPd | SiO2 as template | 0.560 | [ |

| Hollow nanospheres | PdCu | Soft template method | 0.370 | [ |

| Hollow nanospheres | Pd4S | A self⁃templating process | 0.160 | [ |

| Holey nanotubes | Pt | PtII ⁃dimethylglyoxime complex, Ostwald ripening | — | [ |

| Hollow nanochain | PtAg | One⁃pot co⁃reduction method | 0.370 | [ |

| Hollow nanocubes | PtNi | Eutectic salt⁃mediated pyrolysis strategy, Kirkendall effect | 2.020 | [ |

| Hollow nanochains | PtNi | Ni nanosponges, galvanic replacement | 0.340 a,b | [ |

| Nanorings | PtPdCo | Colloidal chemistry method | 3.580 b | [ |

| Hollow tetrapods | Pt | Pd cores, chemical etching | 0.800 | [ |

| Superlong nanotubes | Pt | Pd nanowire, etching | 2.090 | [ |

| Nanocages | Pt⁃Ni⁃P | SiO2 spheres as template | 1.210 | [ |

| Ultrathin nanoring | PdPtCu | A sequential reduction method | 1.970 | [ |

| Core/shell⁃nanotubes | Pd/PtFe | Pd nanowire, galvanic dissolution | 2.710 | [ |

| Hollow nanochains | PtNi | Pt⁃Ni bunched nanospheres, etching | 3.520 | [ |

| Hollow nanochains | Pd⁃Au | Co nanochains, galvanic replacement | 0.287 a,b,c | [ |

| Hollow nanospheres | PdAu | Cobalt nanoparticles as templates | 0.153 b,c | [ |

| Nanoframes | Pt⁃Cu⁃Mn | A simple wet⁃chemical approach | 1.450 b | [ |

Table 1 Synthetic strategies and corresponding catalytic applications of HPMs

| Structure | Composition | Synthesis strategy | Mass activity/(A·mg | Ref. |

|---|---|---|---|---|

| Mesoporous nanocages | PtPdNi | Pd cores, selective etching | 1.140 | [ |

| Nano⁃hollow spheres | PdCuMoNiCo | One⁃pot solvothermal method | 0.882 | [ |

| Nanocages | Pt⁃Ag | Ag nanocubes, galvanic replacement | 0.640 | [ |

| Nanoframes | Pt3Ni | PtNi3 polyhedra, erosion | — | [ |

| Hollow tesseracts | Pd⁃Pt | Pd⁃Pt alloy nanocubes, Oxygen reaction | 1.860 | [ |

| Double⁃shelled nanocages | Pt⁃Ag | One⁃pot self⁃templated strategy | — | [ |

| Hollow nanostructures | Pt/Ag | AgCl nanoparticles, galvanic replacement | — | [ |

| Nanoframes | PtNi | PtNi rhombic dodecahedron nanoparticles, oxidative etching | 0.920 a | [ |

| Hollow nanoparticles | Pt⁃Ni | Sacrificial SiO2 template | 0.490 | [ |

| Nanocages | Pt | Pd icosahedral seeds, HNO3 oxygen | 1.120 | [ |

| Mesoporous nanocages | S, P⁃PtPd | SiO2 as template | 0.560 | [ |

| Hollow nanospheres | PdCu | Soft template method | 0.370 | [ |

| Hollow nanospheres | Pd4S | A self⁃templating process | 0.160 | [ |

| Holey nanotubes | Pt | PtII ⁃dimethylglyoxime complex, Ostwald ripening | — | [ |

| Hollow nanochain | PtAg | One⁃pot co⁃reduction method | 0.370 | [ |

| Hollow nanocubes | PtNi | Eutectic salt⁃mediated pyrolysis strategy, Kirkendall effect | 2.020 | [ |

| Hollow nanochains | PtNi | Ni nanosponges, galvanic replacement | 0.340 a,b | [ |

| Nanorings | PtPdCo | Colloidal chemistry method | 3.580 b | [ |

| Hollow tetrapods | Pt | Pd cores, chemical etching | 0.800 | [ |

| Superlong nanotubes | Pt | Pd nanowire, etching | 2.090 | [ |

| Nanocages | Pt⁃Ni⁃P | SiO2 spheres as template | 1.210 | [ |

| Ultrathin nanoring | PdPtCu | A sequential reduction method | 1.970 | [ |

| Core/shell⁃nanotubes | Pd/PtFe | Pd nanowire, galvanic dissolution | 2.710 | [ |

| Hollow nanochains | PtNi | Pt⁃Ni bunched nanospheres, etching | 3.520 | [ |

| Hollow nanochains | Pd⁃Au | Co nanochains, galvanic replacement | 0.287 a,b,c | [ |

| Hollow nanospheres | PdAu | Cobalt nanoparticles as templates | 0.153 b,c | [ |

| Nanoframes | Pt⁃Cu⁃Mn | A simple wet⁃chemical approach | 1.450 b | [ |

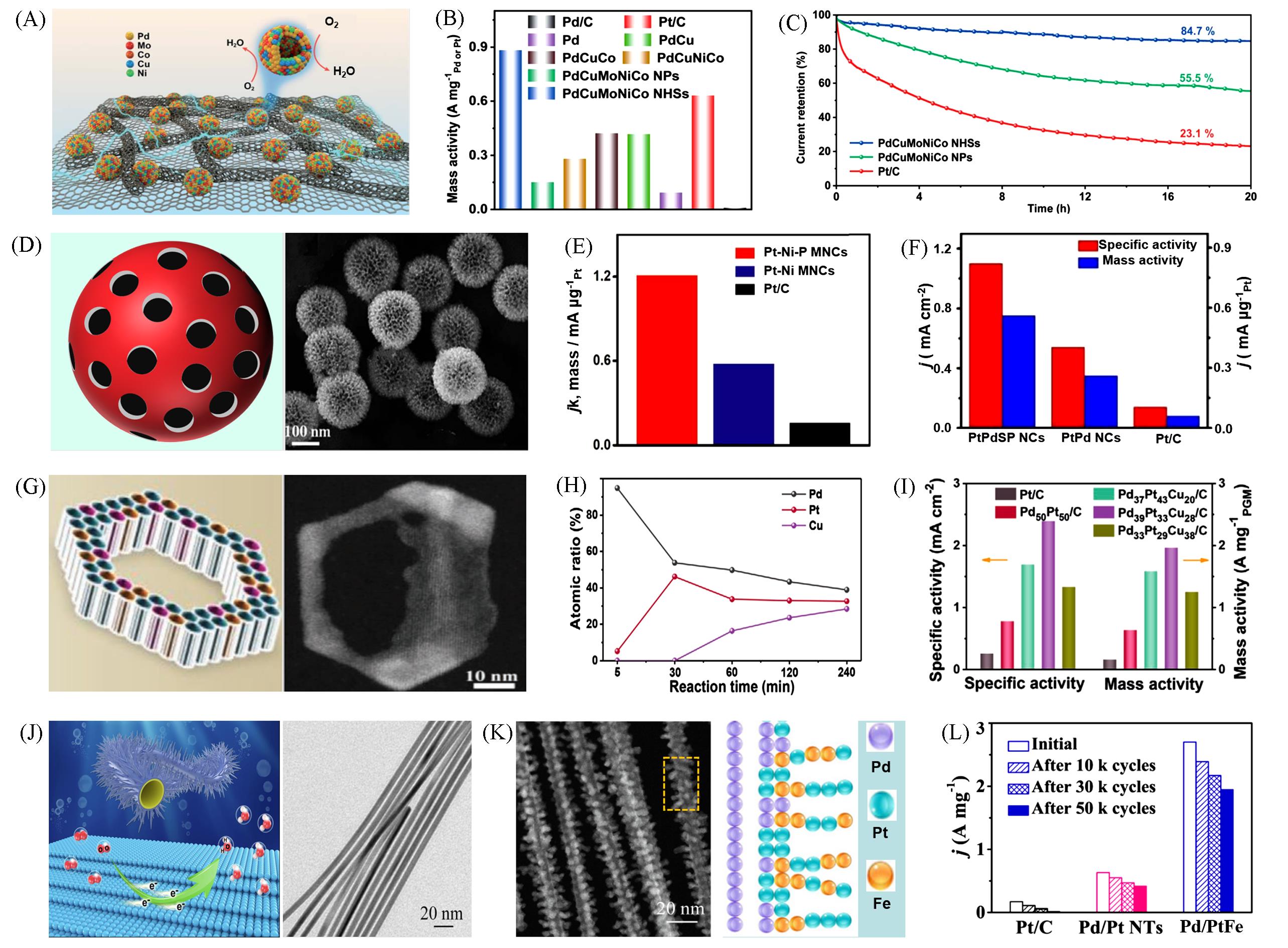

Fig.7 PdCuMoNiCo with hollow nanosphere structures(A), corresponding MA of hollow PdCu, PdCuCo, PdCuNiCo, and PdCuMoNiCo nanospheres for ORR in 0.1 mol/L KOH(B), long⁃term stability of PdCuMoNiCo hollow nanospheres and nanoparticles(C)[15], Pt⁃Ni⁃P with hollow nanocage structures(D), corresponding MA of Pt⁃Ni and Pt⁃Ni⁃P in 0.1 mol/L HClO4(E)[80], MA of S, P co⁃ doing PtPd nanocage in 0.1 mol/L HClO4(F)[51], PdPtCu with nanoring structures(G), controlling compositions for Pd, Pt and Cu in PdPtCu by reaction times(H), corresponding MA in 0.1 mol/L KOH(I)[81], spiny Pd/PtFe with core/shell nanotube structures(J), corresponding TEM images(K) and MA(L) in 0.1 mol/L HClO4[82](A—C) Copyright 2021, the Royal Society of Chemistry; (D, E) Copyright 2019, the Royal Society of Chemistry; (F) Copyright 2020, the Royal Society of Chemistry; (G—I) Copyright 2021, Wiley-VCH; (J—L) Copyright 2021, Elsevier.

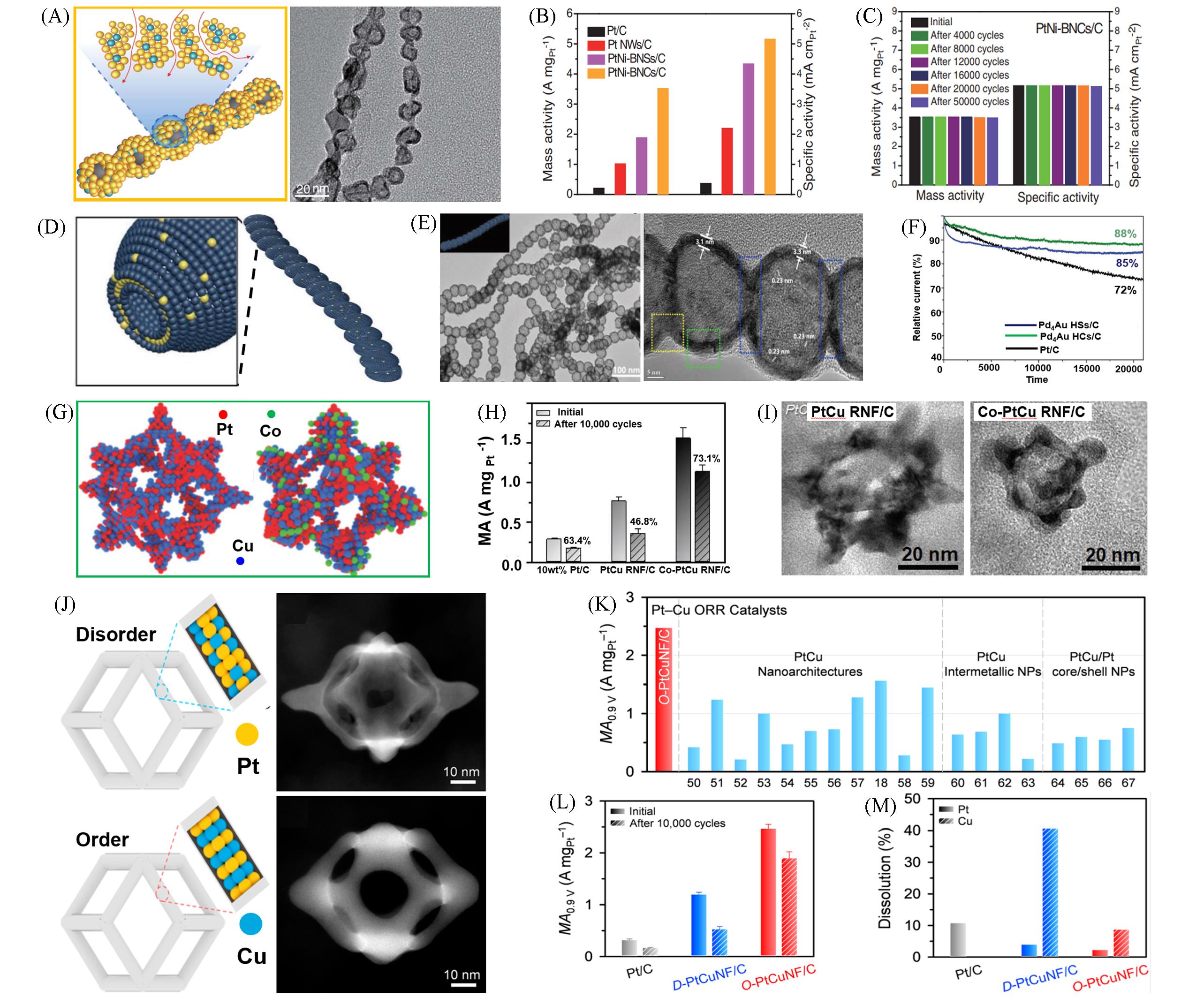

Fig.8 Pt⁃Ni bunched nanocages with 1D form(A), corresponding ORR activity in 0.1 mol/L HClO4(B), ORR stability of the optimized PtNi nanochains in 0.1 mol/L HClO4(C)[83], hollow Pd4Au nanochains(D), TEM images(E), ORR stability in 0.1 mol/L KOH(F)[84], Co⁃PtCu nanoframe(G), corresponding ORR activity and stability(H), TEM images of PtCu NF and Co⁃PtCu NF after running stability test(I)[101], disorder and order PtCu nanoframe(J), ORR activity compared with recent PtCu catalysts(K), ORR activity and stability in 0.1 mol/L HClO4(L), dissolution of Pt and Cu in D⁃PtCu NF and O⁃PtCu NF after running stability test(M)[105](A—C) Copyright 2019, AAAS; (D—F) Copyright 2020, Wiley-VCH; (G—I) Copyright 2018, Wiley-VCH; (J—M) Copyright 2020, American Chemical Society.

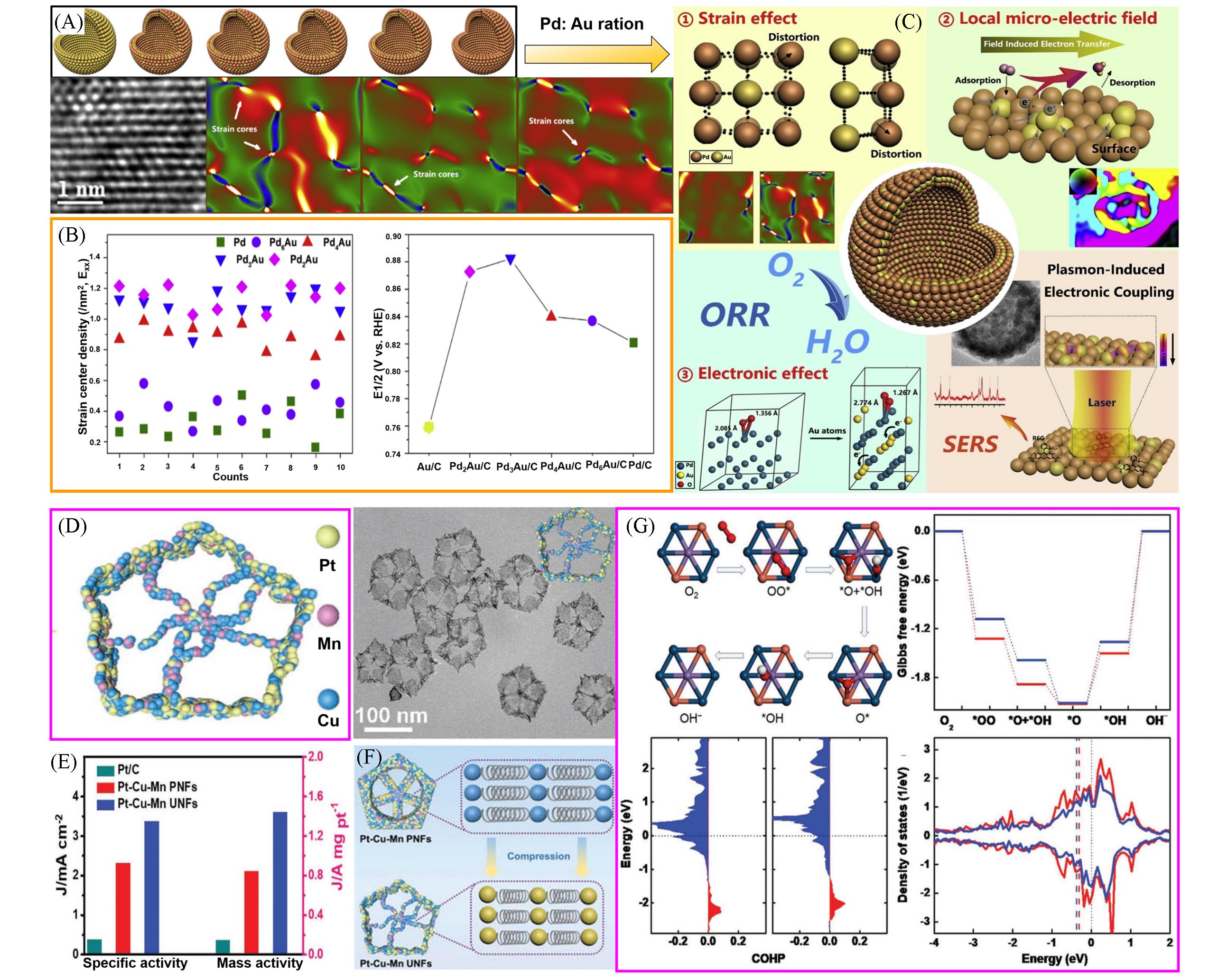

Fig.9 A series of hollow PdAu nanospheres with different ratios of Pd and Au, and corresponding high⁃ resolution TEM images(A), strain center density for hollow PdAu nanospheres and corresponding ORR activity in 0.1 mol/L KOH(B), the mechanisms for ORR performance enhancement(C)[85], ultrafine Pt⁃Cu⁃Mn nanoframes(D), corresponding ORR activities in 0.1 mol/L KOH solution(E), compression strain for the two nanoframes of Pt⁃Cu⁃Mn(F), density functional theory(DFT) based on d⁃band center for strain effect toward ORR enhancement(G)[86](A—C) Copyright 2020, Elsevier; (D—G) Copyright 2020, Wiley-VCH.

| 1 | Stamenkovic V., Mun B. S., Mayrhofer K. J. J., Ross P. N., Markovic N. M., Rossmeisl J., Greeley J., Nørskov J. K., Angew. Chem. Int. Ed., 2006, 118(18), 2963—2967 |

| 2 | Han Y., Wang Y., Xu R., Chen W., Zheng L., Han A., Zhu Y., Zhang J., Zhang H., Luo J., Chen C., Peng Q., Wang D., Li Y., Energ. Environ. Sci., 2018, 11(9), 2348—2352 |

| 3 | Chen J., Qian G., Chu B., Jiang Z., Tan K., Luo L., Li B., Yin S., Small, 2022, 18(12), 2106773 |

| 4 | Yoshida T., Kojima K., Electrochem. Soc. Interface, 2015, 24(2), 45 |

| 5 | Koenigsmann C., Wong S. S., Energ. Environ. Sci., 2011, 4(4), 1161—1176 |

| 6 | Li Y., Sun Y., Qin Y., Zhang W., Wang L., Luo M., Yang H., Guo S., Adv. Energy Mater., 2020, 10(11), 1903120 |

| 7 | Tian X., Lu X. F., Xia B. Y., Lou X. W., Joule, 2020, 4(1), 45—68 |

| 8 | Huang L., Zaman S., Tian X., Wang Z., Fang W., Xia B. Y., Acc. Chem. Res., 2021, 54(2), 311—322 |

| 9 | Liu M., Zhao Z., Duan X., Huang Y., Adv. Mater., 2019, 31(6), 1802234 |

| 10 | Wu T., Sun M., Huang B., InfoMat, 2020, 2(4), 715—734 |

| 11 | Zeng X., Zhao Y., Hu X., Stucky G. D., Moskovits M., Small Structures, 2021, 2(4), 2000138 |

| 12 | Zhao M., Wang X., Yang X., Gilroy K. D., Qin D., Xia Y., Adv. Mater., 2018, 30(48), 1801956 |

| 13 | Dubau L., Asset T., Chattot R., Bonnaud C., Vanpeene V., Nelayah J., Maillard, F., ACS Catal., 2015, 5(9), 5333—5341 |

| 14 | Wang H., Li Y., Deng K., Li C., Xue H., Wang Z., Li X., Xu, Y., Wang L., ACS Appl. Mater. Interfaces, 2019, 11(4), 4252— 4257 |

| 15 | Zuo X., Yan R., Zhao L., Long Y., Shi L., Cheng Q., Liu, D., Hu C., J. Mater. Chem. A, 2022, 10(28), 14857—14865 |

| 16 | Yang X., Roling L. T., Vara M., Elnabawy A. O., Zhao M., Hood Z. D., Bao S., Mavrikakis M., Xia Y., Nano Lett., 2016, 16(10), 6644—6649 |

| 17 | Chen C., Kang Y., Huo Z., Zhu Z., Huang W., Xin H. L., Snyder J. D., Li D., Herron J. A., Mavrikakis M., Chi M., More K. L., Li Y., Markovic N. M., Somorjai G. A., Yang P., Stamenkovic V. R., Science, 2014, 343(6177), 1339—1343 |

| 18 | Ouyang Y., Cao H., Wu H., Wu D., Wang F., Fan X., Yuan W., He M., Zhang L. Y., Li C. M., Appl. Catal. B: Environ., 2020, 265, 118606 |

| 19 | Chen S., Zhao J., Su H., Li H., Wang H., Hu Z., Bao J., Zeng J., J. Am. Chem. Soc., 2021, 143(1), 496—503 |

| 20 | Zhu J., Wei M., Meng Q., Chen Z., Fan Y., Hasan S. W., Zhang X., Lyu D., Tian Z. Q., Shen, P. K., Nanoscale, 2020, 12(47), 24070—24078 |

| 21 | Li C., Wang M., Ren L., Sun H., Inorg. Chem. Front., 2022, 9(7), 1467—1473 |

| 22 | Li H. H., Yu S. H., Adv. Mater., 2019, 31(38), 1803503 |

| 23 | Sun L., Lv H., Feng J., Guselnikova O., Wang Y., Yamauchi Y., Liu B., Adv. Mater., 2022, 34(31), 2201954 |

| 24 | Yang T. H., Ahn J., Shi S., Wang P., Gao R., Qin D., Chem. Rev., 2021, 121(2), 796—833 |

| 25 | Yao W., Jiang X., Li M., Li Y., Liu Y., Zhan X., Fu G., Tang Y., Appl. Catal. B: Environ., 2021, 282, 119595 |

| 26 | Nørskov J. K., Rossmeisl J., Logadottir A., Lindqvist L., Kitchin J. R., Bligaard T., Jónsson H., J. Phys. Chem. B, 2004, 108(46), 17886—17892 |

| 27 | Strasser P., Koh S., Anniyev T., Greeley J., More K., Yu C., Liu Z., Kaya S., Nordlund D., Ogasawara H., Toney M. F., Nilsson A., Nat. Chem., 2010, 2(6), 454—460 |

| 28 | Greeley J., Stephens I. E. L., Bondarenko A. S., Johansson T. P., Hansen H. A., Jaramillo T. F., Rossmeisl J., Chorkendorff I., Nørskov J. K., Nat. Chem., 2009, 1(7), 552—556 |

| 29 | Cao L., Zhao Z., Liu Z., Gao W., Dai S., Gha J., Xue W., Sun H., Duan X., Pan X., Mueller T., Huang Y., Matter, 2019, 1(6), 1567—1580 |

| 30 | Li X., Huang Y., Chen Z., Hu S., Zhu J., Tsiakaras P., Kang S. P., Chem. Eng. J., 2023, 454, 140131 |

| 31 | Mo Y., Feng S., Yu T., Chen J., Qian G., Luo L., Yin S., J. Colloid Interface Sci., 2022, 607, 1928—1935 |

| 32 | Feng Q., Wang X., Klingenhof M., Heggen M., Strasser P., Angew. Chem. Int. Ed., 2022, 61(36), e202203728 |

| 33 | Polani S., MacArthur K. E., Klingenhof M., Wang X., Paciok P., Pan L., Feng Q., Kormányos A., Cherevko S., Heggen M., Strasser P., ACS Catal., 2021, 11(18), 11407—11415 |

| 34 | Xia Y., Yang X., Acc. Chem. Res., 2017, 50(3), 450—454 |

| 35 | Chen J., Li H., Fan C., Meng Q., Tang Y., Qiu X., Fu G., Ma T., Adv. Mater., 2020, 32(30), 2003134 |

| 36 | Zhu W., Chen Z., Pan Y., Dai R., Wu Y., Zhuang Z., Wang D., Peng Q., Chen C., Li Y., Adv. Mater., 2019, 31(38), 1800426 |

| 37 | Wang J., Cui Y., Wang D., Adv. Mater., 2019, 31(38), 1801993 |

| 38 | Zhang W., Yang J., Lu X., ACS Nano, 2012, 6(8), 7397—7405 |

| 39 | Zhao M., Lyu Z., Xie M., Hood Z. D., Cao Z., Chi M., Xia Y., Small Methods, 2020, 4(5), 1900843 |

| 40 | Wang Y., Chen S., Wang X., Rosen A., Beatrez W., Sztaberek L., Tan H., Zhang L., Koenigsmann C., Zhao J., ACS Appl. Energ. Mater., 2020, 3(1), 768—776 |

| 41 | Au L., Chen Y., Zhou F., Camargo P. H. C., Lim B., Li Z. Y., Ginger D. S., Xia Y., Nano Res., 2008, 1(6), 441—449 |

| 42 | Wang J. X., Ma C., Choi Y., Su D., Zhu Y., Liu P., Si R., Vukmirovic M. B., Zhang Y., Adzic R. R., J. Am. Chem. Soc., 2011, 133(34), 13551—13557 |

| 43 | Han L., Liu H., Cui P., Peng Z., Zhang S., Yang J., Scientific Reports, 2014, 4(1), 6414 |

| 44 | González E., Arbiol J., Puntes V. F., Science, 2011, 334(6061), 1377—1380 |

| 45 | Wang X., Feng J. I., Bai Y., Zhang Q., Yin Y., Chem. Rev., 2016, 116(18), 10983—11060 |

| 46 | Wang Q., Mi B., Zhou J., Qin Z., Chen Z., Wang H., Molecules, 2022, 27(8), 2524 |

| 47 | He D. S., He D., Wang J., Lin Y., Yin P., Hong X., Wu Y., Li Y., J. Am. Chem. Soc., 2016, 138(5), 1494—1497 |

| 48 | Choi S., Oh M., Angew. Chem. Int. Ed., 2019, 58(3), 866—871 |

| 49 | Ataee⁃Esfahani H., Nemoto Y., Wang L., Yamauchi Y., Chem. Commun., 2011, 47(13), 3885—3887 |

| 50 | Ataee⁃Esfahani H., Liu J., Hu M., Miyamoto N., Tominaka S., Wu K. C. W., Yamauchi Y., Small, 2013, 9(7), 1047—1051 |

| 51 | Yin S., Xu Y., Liu S., Yu H., Wang Z., Li X., Wang L., Wang H., Nanoscale, 2020, 12(27), 14863—14869 |

| 52 | Yin S., Kumar R. D., Yu H., Li C., Wang Z., Xu Y., Li X., Wang L., Wang H., ACS Sustain. Chem. Eng., 2019, 7(17), 14867—14873 |

| 53 | Wang H., Qian X., Liu S., Yin S., Yu H., Xu Y., Li X., Wang Z., Wang L., Chem⁃Asian J., 2019, 14(17), 3019—3024 |

| 54 | Wang H., Lin G., Li X., Lu W., Peng Z., J. Colloid Interface Sci., 2019, 554, 396—403 |

| 55 | Fu Q. Q. Li H. H., Ma S. Y., Hu B. C., Yu S. H., Sci. China Mater., 2016, 59(2), 112—121 |

| 56 | Ding H., Wang P., Su C., Liu H., Tai X., Zhang N., Lv H., Lin Y., Chu W., Wu X., Wu C., Xie Y., Adv. Mater., 2022, 34(12), 2109188 |

| 57 | Wan X. K., Wu H. B., Guan B. Y., Luan D., Lou X. W., Adv. Mater., 2020, 32(7), 1901349 |

| 58 | Yan X., Hu X., Fu G., Xu L., Lee J. M., Tang Y., Small, 2018, 14(13), 1703940 |

| 59 | Bai Z., Xu P., Chao S., Yan H., Cui Q., Niu L., Yang L., Qiao J., Catal. Sci. Technol., 2013, 3(10), 2843—2848 |

| 60 | An L., Zhu M., Dai B., Yu F., Electrochimica Acta, 2015, 176, 222—229 |

| 61 | Liu Y., Goebl J., Yin Y., Chem. Soc. Rev., 2013, 42(7), 2610—2653 |

| 62 | Lv H., Sun L., Lopes A., Xu D., Liu B., J. Phys. Chem. Lett., 2019, 10(18), 5490—5498 |

| 63 | Lv H., Lopes A., Xu D., Liu B., ACS Central Sci., 2018, 4(10), 1412—1419 |

| 64 | Yin S., Wang Z., Qian X., Yang D., Xu Y., Li X., Wang L., Wang H., ACS Sustain. Chem. Eng., 2019, 7(8), 7960—7968 |

| 65 | Wang Q., Zhao D., Yu J., Shi L., Wang Y., Chen H., Nano Res., 2022,1—7 |

| 66 | Wang T. J., Sun H. Y., Xue Q., Zhong M. J., Li F. M., Tian X., Chen P., Yin S. B., Chen Y., Sci. Bull., 2021, 66(20), 2079— 2089 |

| 67 | Lu L., Wang B., Wu D., Zou S., Fang B., Nanoscale, 2021, 13(6), 3709—3722 |

| 68 | Wang A. J., Liu L., Lin X. X., Yuan J., Feng J. J., Electrochimica Acta, 2017, 245, 883—892 |

| 69 | Wang X., Sun M., Xiang S., Waqas M., Fan Y., Zhong J., Huang K., Chen W., Liu L., Yang J., Electrochimica Acta, 2020, 337, 135742 |

| 70 | Zhou S., Liao W., Wang Z., Chen M., Long J., Zhou Q., Wang Q., ACS Appl. Energ. Mater., 2022, 5(5), 6472—6480 |

| 71 | Wei M., Huang L., Huang S., Chen Z., Lyu D., Zhang X., Wang S., Tian Z. Q., Shen P. K., J. Catal., 2020, 381, 385—394 |

| 72 | Fu S., Zhu C., Song J., Engelhard M. H., He Y., Du D., Wang C., Lin Y., J. Mater. Chem. A, 2016, 4(22), 8755—8761 |

| 73 | Sun Y., Zhang X., Luo M., Chen X., Wang L., Li Y., Li M., Qin Y., Li C., Xu N., Lu G., Gao P., Guo S., Adv. Mater., 2018, 30(38), 1802136 |

| 74 | Li M., Yang A., Wang S., Wang Y., Huang Q., Cai B., Qiu X., Tang Y., J. Mater. Chem. A, 2021, 9(19), 11537—11544 |

| 75 | Tao L., Yu D., Zhou J., Lu X., Yang Y., Gao F., Small, 2018, 14(22), 1704503 |

| 76 | Zhou K., Li Y., Angew. Chem. Int. Ed., 2012, 51(3), 602—613 |

| 77 | Sun H., Xu X., Yan Z., Chen X., Cheng F., Weiss P. S., Chen J., Chem. Mater., 2017, 29(19), 8539—8547 |

| 78 | Wu J., Shan S., Cronk H., Chang F., Kareem H., Zhao Y., Luo J., Petkov V., Zhong C. J., J. Phys. Chem. C, 2017, 121(26), 14128—14136 |

| 79 | Balkan T., Küçükkeçeci H., Zarenezhad H., Kaya S., Metin Ö., J. Alloy. Compd., 2020, 831, 154787 |

| 80 | Deng K., Xu Y., Yang D., Qian X., Dai Z., Wang Z., Li X., Wang L., Wang H., J. Mater. Chem. A, 2019, 7(16), 9791—9797 |

| 81 | Li M., Tian F., Lin T., Tao L., Guo X., Chao Y., Guo Z., Zhang Q., Gu L., Yang W., Yu Y., Guo S., Small Methods, 2021, 5(6), 2100154 |

| 82 | Tao L., Xia Z., Zhang Q., Sun Y., Li M., Yin K., Gu L., Guo S., Sci. Bull., 2021, 66(1), 44—51 |

| 83 | Tian X., Zhao X., Su Y. Q., Wang L., Wang H., Dang D., Chi B., Liu H., Hensen E. J. M., Lou X. W., Xia B. Y., Science, 2019, 366(6467), 850—856 |

| 84 | Jiao W., Chen C., You W., Zhao X., Zhang J., Feng Y., Wang P., Che R., Adv. Energy Mater., 2020, 10(18), 1904072 |

| 85 | Jiao W., Chen C., You W., Chen G., Xue S., Zhang J., Liu J., Feng Y., Wang P., Wang Y.,Wen H., Che R., Appl. Catal. B: Environ., 2020, 262, 118298 |

| 86 | Qin Y., Zhang W., Guo K., Liu X., Liu J., Liang X., Wang X., Gao D., Gan L., Zhu Y., Zhang Z., Hu W., Adv. Funct. Mater., 2020, 30(11), 1910107 |

| 87 | Ma Z., Cano Z. P., Yu A., Chen Z., Jiang G., Fu X., Yang L., Wu T., Bai Z., Lu J., Angew. Chem. Int. Ed., 2020, 59(42), 18334—18348 |

| 88 | Wang Y., Wang D., Li Y., SmartMat, 2021, 2(1), 56—75 |

| 89 | Guo S., Dong S., Wang E., Chem⁃Eur. J., 2008, 14(15), 4689—4695 |

| 90 | Zhu Z., Zhai Y., Dong S., ACS Appl. Mater. Interfaces, 2014, 6(19), 16721—16726 |

| 91 | Ou L., Comput. Theor. Chem., 2014, 10(48), 69—76 |

| 92 | Bing Y., Liu H., Zhang L., Ghosh D., Zhang J., Chem. Soc. Rev., 2010, 39(6), 2184—2202 |

| 93 | Li J., Yin H. M., Li X. B., Okunishi E., Shen Y. L., He J., Tang Z. K., Wang W. X., Yücelen E., Li C., Gong Y., Gu L., Miao S., Liu L. M., Luo J., Ding Y., Nat. Energy, 2017, 2(8), 17111 |

| 94 | Suo Y., Zhuang L., Lu J., Angew. Chem., 2007, 119(16), 2920—2922 |

| 95 | Zamora Zeledón J. A., Stevens M. B., Gunasooriya G. T. K. K., Gallo A., Landers A. T., Kreider M. E., Hahn C., Nørskov J. K., Jaramillo T. F., Nat. Commun., 2021, 12(1), 620 |

| 96 | Li H. H., Cui C. H., Zhao S., Yao H. B., Gao M. R., Fan F. J., Yu S. H., Adv. Energy Mater., 2012, 2(10), 1182—1187 |

| 97 | Kang Y. S., Jung J. Y., Choi D., Sohn Y., Lee S. H., Lee K. S., Kim N. D., Kim P., Yoo S. J., ACS Appl. Mater. Interfaces, 2020, 12(14), 16286—16297 |

| 98 | Lin R., Cai X., Zeng H., Yu Z., Adv. Mater., 2018, 30(17), 1705332 |

| 99 | Rao P., Luo J., Li J., Huang W., Sun W., Chen Q., Jia C. M., Liu Z. X., Deng P. L., Shen Y. J., Tian X. L., Carbon Energy, 2022, 4(6), 1003—1010 |

| 100 | Niu H., Xia C., Huang L., Zaman S., Maiyalagan T., Guo W., You B., Xia B. Y., Chinese J. Catal., 2022, 43(6), 1459—1472 |

| 101 | Kwon T., Jun M., Kim H. Y., Oh A., Park J., Baik H., Joo S. H., Lee K., Adv. Funct. Mater., 2018, 28(13), 1706440 |

| 102 | Dhavale V. M., Kurungot S., ACS Catal., 2015, 5(3), 1445—1452 |

| 103 | Chen H. S., Benedetti T. M., Gonçales V. R., Bedford N. M., Scott R. W. J., Webster R. F., Cheong S., Gooding J. J., Tilley R. D., J. Am. Chem. Soc., 2020, 142(6), 3231—3239 |

| 104 | Zhou M., Li C., Fang J., Chem. Rev., 2021, 121(2), 736—795 |

| 105 | Kim H. Y., Kwon T., Ha Y., Jun M., Baik H., Jeong H. Y., Kim H., Lee K., Joo S. H., Nano Lett., 2020, 20(10), 7413—7421 |

| 106 | Xia Z., Guo S., Chem. Soc. Rev., 2019, 48(12), 3265—3278 |

| 107 | Eid K., Wang H., Malgras V., Alothman Z. A., Yamauchi Y., Wang L., J. Phys. Chem. C, 2015, 119(34), 19947—19953 |

| 108 | Ren Y., Li C., Li B., Gao F., Zhang X., Yang X., Li L., Lu Z., Yu X., Inorg. Chem. Front., 2021, 8(9), 2280—2287 |

| [1] | 王军, 杜石谦, 陶李. 高温聚合物电解质膜燃料电池催化剂的研究进展[J]. 高等学校化学学报, 2023, 44(5): 20220722. |

| [2] | 李轩, 亓帅, 周伟良, 李小杰, 景玲胭, 冯超, 蒋兴星, 杨恒攀, 胡琪, 何传新. 纤维基氧化还原电催化剂的研究进展[J]. 高等学校化学学报, 2023, 44(5): 316. |

| [3] | 杜磊, 刘兆清. 非贵金属催化剂在羟甲基糠醛电氧化增值中的应用[J]. 高等学校化学学报, 2023, 44(5): 20220710. |

| [4] | 鲍春竹, 向中华. 非热解共价有机聚合物基氧还原电催化材料[J]. 高等学校化学学报, 2023, 44(5): 20220715. |

| [5] | 王慧, 赵德偲, 杨乃亮, 王丹. 智能中空药物载体的门控设计[J]. 高等学校化学学报, 2023, 44(1): 20220237. |

| [6] | 朱科润, 任雯萱, 张威, 李伟. 单分散中空介孔结构的盐模板合成及形貌调控[J]. 高等学校化学学报, 2023, 44(1): 20220607. |

| [7] | 李姿若, 张红娟, 朱国勋, 夏伟, 汤静. 负载酞菁铁的氮掺杂中空碳球的电催化氧还原性能[J]. 高等学校化学学报, 2023, 44(1): 20220677. |

| [8] | 匡华艺, 陈晨. 贵金属纳米框架设计合成及电催化性能的研究进展[J]. 高等学校化学学报, 2023, 44(1): 20220586. |

| [9] | 杨庆凤, 吕良, 赖小勇. 中空MOFs材料制备及电催化应用的研究进展[J]. 高等学校化学学报, 2023, 44(1): 20220666. |

| [10] | 沈欣怡, 张森, 王树涛, 宋永杨. 聚合物中空微球的合成策略[J]. 高等学校化学学报, 2023, 44(1): 20220627. |

| [11] | 叶祖洋, 殷亚东. 基于刻蚀反应的纳米结构空心化[J]. 高等学校化学学报, 2023, 44(1): 20220656. |

| [12] | 刘双红, 夏思玉, 刘世奇, 李旻, 孙嘉杰, 钟永, 张锋, 白锋. 中空全固态Z型异质结光催化剂的研究进展[J]. 高等学校化学学报, 2023, 44(1): 20220512. |

| [13] | 程前, 杨博龙, 吴文依, 向中华. S掺杂Fe-N-C高活性氧还原反应催化剂[J]. 高等学校化学学报, 2022, 43(9): 20220341. |

| [14] | 楚宇逸, 兰畅, 罗二桂, 刘长鹏, 葛君杰, 邢巍. 单原子铈对弱芬顿效应活性位点氧还原稳定性的提升[J]. 高等学校化学学报, 2022, 43(9): 20220294. |

| [15] | 谷雨, 奚宝娟, 李江潇, 熊胜林. 单原子催化剂在氧还原反应中的分子级调控[J]. 高等学校化学学报, 2022, 43(5): 20220036. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||