高等学校化学学报 ›› 2018, Vol. 39 ›› Issue (5): 941.doi: 10.7503/cjcu20170756

夏坤, 王艺, 周丹, 黄哲, 伍忠汉, 夏清华

收稿日期:2017-11-22

出版日期:2018-04-08

发布日期:2018-04-08

作者简介:联系人简介: 周 丹, 女, 博士, 教授, 博士生导师, 主要从事分子筛类孔材料的合成、 表征及应用方面的研究. E-mail: d.zhou@hubu.edu.cn;夏清华, 男, 博士, 教授, 博士生导师, 主要从事新材料的开发及催化方面的研究. E-mail: xiaqh518@aliyun.com

基金资助:XIA Kun, WANG Yi, ZHOU Dan*, HUANG Zhe, WU Zhonghan, XIA Qinghua*

Received:2017-11-22

Online:2018-04-08

Published:2018-04-08

Contact:

ZHOU Dan,XIA Qinghua

Supported by:摘要:

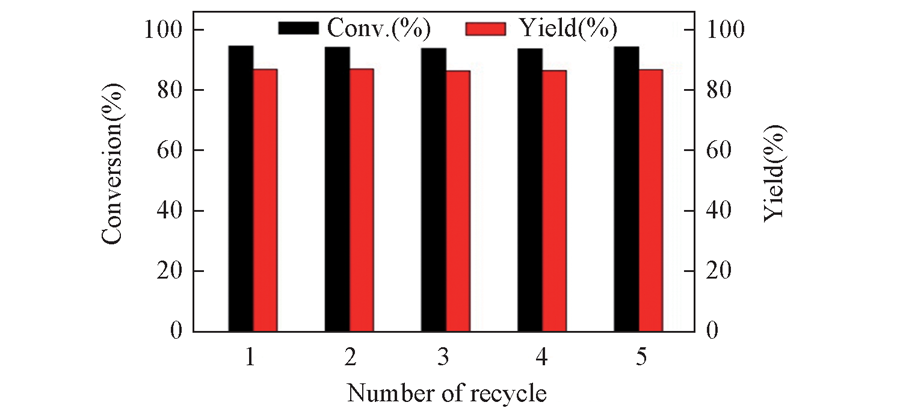

构建了用于催化空气环氧化α-蒎烯合成α-环氧蒎烷的高效、 节能、 绿色催化反应体系. 首先, 采用转动水热晶化模式合成了SAPO-5分子筛前驱体. 相比于静态水热晶化模式, 转动水热晶化模式可以显著缩短分子筛成核时间和晶化时间, 同时可有效减小晶粒尺寸并显著提高晶粒尺寸的均一性. 进一步对SAPO-5分子筛前驱体进行改性制得CoSAPO-5分子筛催化剂, 并对反应溶剂、 催化剂用量、 反应温度和反应时间进行了优化. 在获得的最优催化反应条件下, α-蒎烯转化率可达96.5%, α-环氧蒎烷产率可达89.0%. 催化剂循环实验结果表明, 该催化剂是稳定的、 可多次循环使用的多相催化剂.

中图分类号:

TrendMD:

夏坤, 王艺, 周丹, 黄哲, 伍忠汉, 夏清华. CoSAPO-5分子筛的快速合成及高效催化α-蒎烯与空气环氧化反应. 高等学校化学学报, 2018, 39(5): 941.

XIA Kun,WANG Yi,ZHOU Dan,HUANG Zhe,WU Zhonghan,XIA Qinghua. Rapid Synthesis of CoSAPO-5 Zeolite and Efficiently Catalytic Epoxidation of α-Pinene with Air†. Chem. J. Chinese Universities, 2018, 39(5): 941.

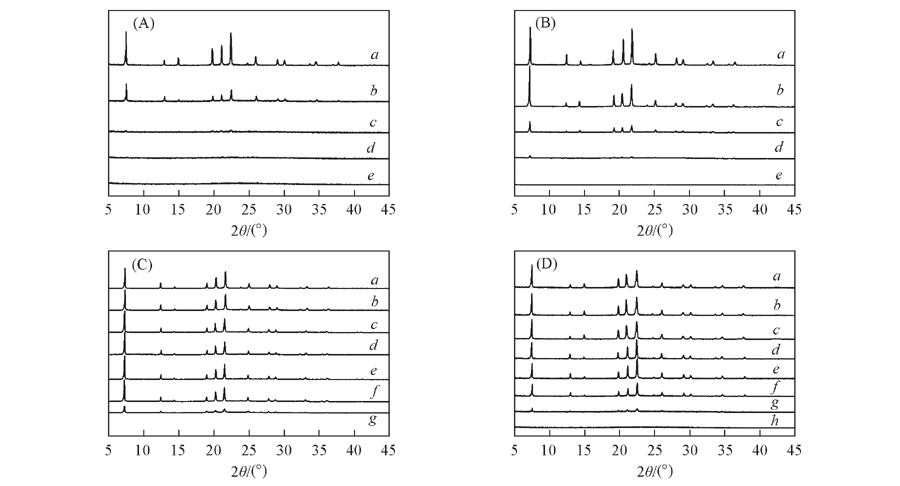

Fig.2 XRD patterns of SAPO-5 samples prepared under static(A) and at rotating rates of 56 r/min(B), 120 r/min(C) and 140 r/min(D), respectively Note:Reaction time/h: a. 24; b. 12; c. 8; d. 6; e. 4; f. 3; g. 2; h. 1.

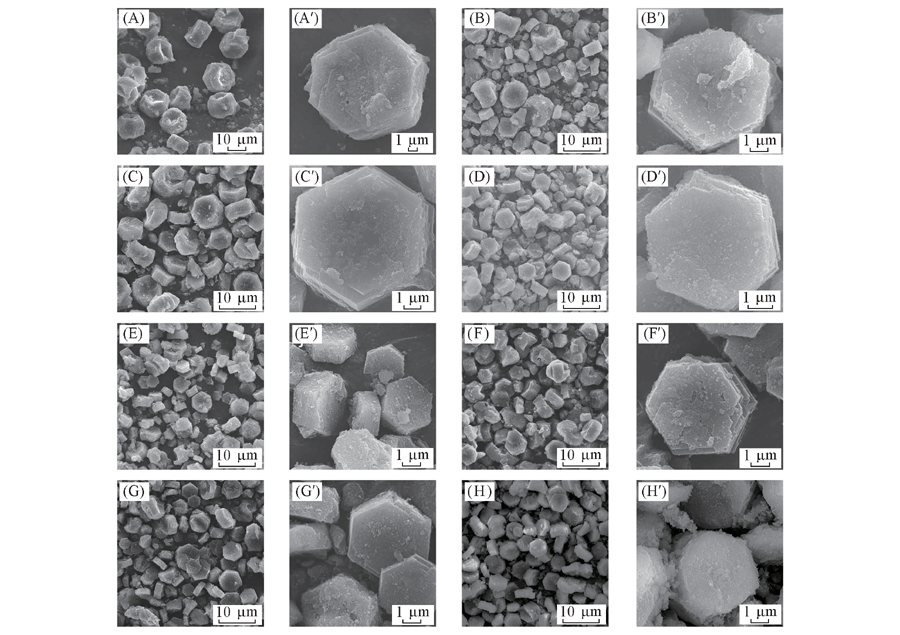

Fig.3 SEM images of SAPO-5 samples prepared under static and rotating conditions with different magnifications Note:A), (A') SAPO-5-Static-24; (B), (B') SAPO-5-56-24; (C), (C') SAPO-5-56-12; (D), (D') SAPO-5-120-12; (E), (E') SAPO-5-140-24; (F), (F') SAPO-5-140-12; (G), (G') SAPO-5-140-4; (H), (H') SAPO-5-140-3.

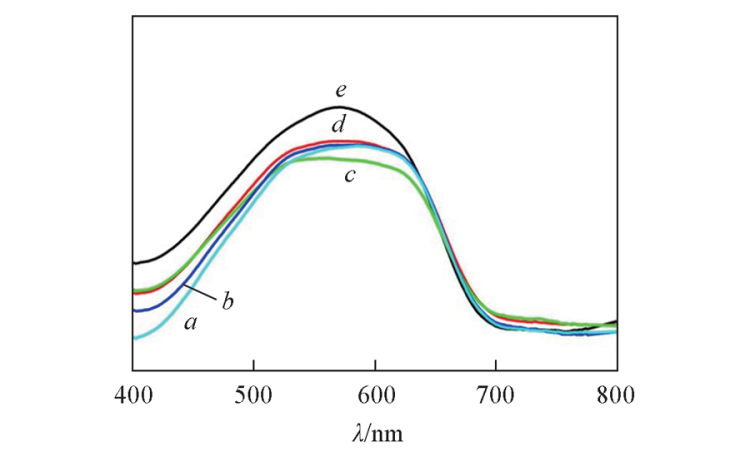

Fig.5 UV-Vis spectra of CoSAPO-5 samples prepared under static and rotating conditions Note:a. CoSAPO-5-Static-24; b. CoSAPO-5-140-3; c. CoSAPO-5-140-4; d. CoSAPO-5-140-12; e. CoSAPO-5-140-24.

| Sample | Mass fraction of Co(%) | Sample | Mass fraction of Co(%) |

|---|---|---|---|

| CoSAPO-5-Static-24 | 0.421 | CoSAPO-5-140-12 | 0.711 |

| CoSAPO-5-140-3 | 0.545 | CoSAPO-5-140-24 | 0.738 |

| CoSAPO-5-140-4 | 0.696 |

Table 1 ICP characterization results of CoSAPO-5 samples

| Sample | Mass fraction of Co(%) | Sample | Mass fraction of Co(%) |

|---|---|---|---|

| CoSAPO-5-Static-24 | 0.421 | CoSAPO-5-140-12 | 0.711 |

| CoSAPO-5-140-3 | 0.545 | CoSAPO-5-140-24 | 0.738 |

| CoSAPO-5-140-4 | 0.696 |

| Sample | Relative crystallinity(%) | Sample | Relative crystallinity(%) |

|---|---|---|---|

| SAPO-5-Static-24 | 76.7% | SAPO-5-140-12 | 96.3% |

| SAPO-5-140-3 | 81.1% | SAPO-5-140-24 | 100% |

| SAPO-5-140-4 | 87.5% |

Table 2 Relative crystallinity of SAPO-5 samples prepared under rotation and static conditions

| Sample | Relative crystallinity(%) | Sample | Relative crystallinity(%) |

|---|---|---|---|

| SAPO-5-Static-24 | 76.7% | SAPO-5-140-12 | 96.3% |

| SAPO-5-140-3 | 81.1% | SAPO-5-140-24 | 100% |

| SAPO-5-140-4 | 87.5% |

| Catalyst | Conversion(%) | Selectivity(%) | Yield(%) |

|---|---|---|---|

| CoSAPO-5-Static-8 | 15.3 | 92.3 | 14.6 |

| CoSAPO-5-Static-12 | 19.2 | 92.6 | 17.7 |

| CoSAPO-5-Static-24 | 90.2 | 92.4 | 83.3 |

| CoSAPO-5-56-8 | 22.6 | 92.9 | 21.0 |

| CoSAPO-5-56-12 | 91.5 | 92.2 | 84.4 |

| CoSAPO-5-56-24 | 92.1 | 92.5 | 85.1 |

| CoSAPO-5-120-3 | 93.7 | 92.3 | 86.5 |

| CoSAPO-5-120-4 | 93.9 | 92.4 | 86.8 |

| CoSAPO-5-120-8 | 94.3 | 92.2 | 86.9 |

| CoSAPO-5-120-12 | 93.8 | 92.5 | 86.8 |

| CoSAPO-5-140-3 | 96.5 | 92.2 | 89.0 |

| CoSAPO-5-140-4 | 96.3 | 92.3 | 88.9 |

| CoSAPO-5-140-8 | 95.9 | 92.1 | 88.3 |

| CoSAPO-5-140-12 | 96.0 | 92.2 | 88.5 |

Table 3 Epoxidation of α-pinene with air over various CoSAPO-5 catalysts*

| Catalyst | Conversion(%) | Selectivity(%) | Yield(%) |

|---|---|---|---|

| CoSAPO-5-Static-8 | 15.3 | 92.3 | 14.6 |

| CoSAPO-5-Static-12 | 19.2 | 92.6 | 17.7 |

| CoSAPO-5-Static-24 | 90.2 | 92.4 | 83.3 |

| CoSAPO-5-56-8 | 22.6 | 92.9 | 21.0 |

| CoSAPO-5-56-12 | 91.5 | 92.2 | 84.4 |

| CoSAPO-5-56-24 | 92.1 | 92.5 | 85.1 |

| CoSAPO-5-120-3 | 93.7 | 92.3 | 86.5 |

| CoSAPO-5-120-4 | 93.9 | 92.4 | 86.8 |

| CoSAPO-5-120-8 | 94.3 | 92.2 | 86.9 |

| CoSAPO-5-120-12 | 93.8 | 92.5 | 86.8 |

| CoSAPO-5-140-3 | 96.5 | 92.2 | 89.0 |

| CoSAPO-5-140-4 | 96.3 | 92.3 | 88.9 |

| CoSAPO-5-140-8 | 95.9 | 92.1 | 88.3 |

| CoSAPO-5-140-12 | 96.0 | 92.2 | 88.5 |

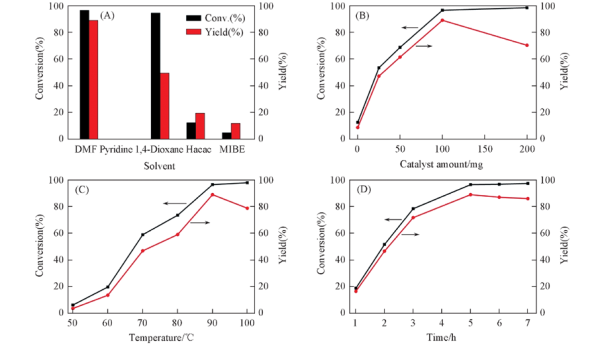

Fig.6 Effects of solvent(A), catalyst amount(B), reaction temperature(C) and time(D) on the epoxidation of α-pinene over CoSAPO-5-140-3 Note:Reaction conditions:α-pinene: 3 mmol; solvent: 10.0 g; flow rate of dry air: 40 mL/min; catalyst: 0—200 mg; CHP: 0.3 mmol; reaction temperature: 50—100 ℃; reaction time: 1—7 h.

| Alkene | Epoxide | Conversion(%) | Selectivity(%) | Yield(%) |

|---|---|---|---|---|

| 98.6 | 83.7 | 82.5 | ||

| 84.4 | 85.1 | 71.8 | ||

| 61.8 | 100 | 61.8 | ||

| 42.5b | 62.5b | 26.6 | ||

| 4.1 | 100 | 4.1 |

Table 4 Epoxidation of different substrates over Co-SAPO-5-140-3 catalystsa

| Alkene | Epoxide | Conversion(%) | Selectivity(%) | Yield(%) |

|---|---|---|---|---|

| 98.6 | 83.7 | 82.5 | ||

| 84.4 | 85.1 | 71.8 | ||

| 61.8 | 100 | 61.8 | ||

| 42.5b | 62.5b | 26.6 | ||

| 4.1 | 100 | 4.1 |

Fig.7 Recycling tests of CoSAPO-5-140-3 catalyst Note:Reaction conditions:α-pinene: 3 mmol; DMF: 10.0 g; catalyst: 100 mg; CHP: 0.3 mmol; time: 5 h; temperature: 90 ℃; flow rate of air: 40 mL/min.

| [1] | Xia Q.H., Ge H. Q., Ye C. P., Liu Z. M., Su K. X., Chem. Rev., 2005, 105, 1603—1662 |

| [2] | Chu X., Zhou D., Li D., Xia K., Gan N., Lu X.H., Nie R. F., Xia Q. H., Micropor. Mesopor. Mater., 2016, 230, 166—176 |

| [3] | Kubi<inline-formula><mml:math xmlns:mml="http://www.w3.org/1998/Math/MathML" id="Mml1-0251-0790-39-5-941"><mml:mtable frame="none" columnlines="none" rowlines="none"><mml:mtr><mml:mtd><mml:maligngroup/><mml:mrow><mml:mover><mml:mrow><mml:mi mathvariant="normal">c</mml:mi></mml:mrow><mml:mrow><mml:mi mathvariant="normal">˙</mml:mi></mml:mrow></mml:mover></mml:mrow></mml:mtd></mml:mtr></mml:mtable></mml:math></inline-formula>ka D., Kubi<inline-formula><mml:math xmlns:mml="http://www.w3.org/1998/Math/MathML" id="Mml2-0251-0790-39-5-941"><mml:mtable frame="none" columnlines="none" rowlines="none"><mml:mtr><mml:mtd><mml:maligngroup/><mml:mrow><mml:mover><mml:mrow><mml:mi mathvariant="normal">c</mml:mi></mml:mrow><mml:mrow><mml:mi mathvariant="normal">˙</mml:mi></mml:mrow></mml:mover></mml:mrow></mml:mtd></mml:mtr></mml:mtable></mml:math></inline-formula>kov�� I., <inline-formula><mml:math xmlns:mml="http://www.w3.org/1998/Math/MathML" id="Mml3-0251-0790-39-5-941"><mml:mtable frame="none" columnlines="none" rowlines="none"><mml:mtr><mml:mtd><mml:maligngroup/><mml:mrow><mml:mover><mml:mrow><mml:mi mathvariant="normal">C</mml:mi></mml:mrow><mml:mrow><mml:mi mathvariant="normal">˙</mml:mi></mml:mrow></mml:mover></mml:mrow></mml:mtd></mml:mtr></mml:mtable></mml:math></inline-formula>ejka [J]., Catal. Rev., 2013, 55, 1—78 |

| [4] | Monteiro J., Veloso C., Top. Catal., 2004, 27, 80—169 |

| [5] | Milchert E., Goc W., Meissner E., Myszkowski J., [J]. Chem. Techmol. Biotechmol., 1994, 61(3), 251—254 |

| [6] | Solati Z., Hashemi M., Ebrahimi L., Catal. Lett., 2011, 141, 163—167 |

| [7] | Li K., Zhou D., Deng J.J., Lu X. H., Xia Q. H., J. Mol. Catal. A: Chem., 2014, 387, 31—37 |

| [8] | Zhou D., Zhang T.J., Xia Q. H., Zhao Y. R., Lv K. X., Lu X. H., Nie R. F., Chem. Sci., 2016, 7, 4966—4972 |

| [9] | Wang L., Sun J., Meng X.J., Zhang W. P., Zhang J., Pan S. X., Shen Z., Xiao F. S., Chem. Commun., 2014, 50, 2012—2014 |

| [10] | Qi B., Lu X.H., Zhou D., Xia Q. H., Tang Z. R., Fang S. Y., Pang T., Dong Y. L., J. Mol. Catal. A: Chem., 2010, 322, 73—79 |

| [11] | Shan Z.C., Wang H., Meng X. J., Liu S. Y., Wang L., Wang C. Y., Li F., Lewis J. P.,Xiao F. S., Chem. Commun., 2011, 47, 1048—1050 |

| [12] | Tang B., Lu X.H., Zhou D., Lei J., Niu Z. H., Fan J., Xia Q. H., Catal. Commun., 2012, 21, 68—71 |

| [13] | Wei X.L., Lu X. H., Zhang T. J., Chu X., Zhou D., Nie R.F., Xia Q. H., Micropor. Mesopor. Mater., 2015, 214, 80—87 |

| [14] | Zhou D., Tang B., Lu X.H., Wei X. L., Li K., Xia Q. H., Catal. Commun., 2014, 45, 124—128 |

| [15] | Wang Z., Yu J.H., Xu R. R., Chem. Soc. Rev., 2012, 41, 1729—1741 |

| [16] | Chang X.W., Yan W. F., Shi W., Xu R. R., Chem. [J]. Chinese Universities, 2018, 39(1), 12—18 |

| (常晓文, 闫文付, 师唯, 徐如人. 高等学校化学学报, 2018, 39(1), 12—18) | |

| [17] | Liu R., Zha F., Yang A.M., Chang Y., Chem. [J]. Chinese Universities, 2016, 37(5), 964—971 |

| (刘蓉, 查飞, 杨爱梅, 常玥. 高等学校化学学报, 2016, 37(5), 964—971) | |

| [18] | Liu N., Wang J.Q., Chen B. H., Li Y. X., Zhang R. D., Chem. [J]. Chinese Universities, 2016, 37(10), 1817—1825 |

| (刘宁, 王继琼, 陈标华, 李英霞, 张润铎. 高等学校化学学报, 2016, 37(10), 1817—1825) | |

| [19] | Li Y., Yu J.H., Chem. Rev., 2014, 114, 7268—7316 |

| [20] | Xu R.R., Pang W. Q., Yu J. H., Huo Q. S., Chen J. S., Chemistry of Zeolites and Related Porous Materials, John Wiley & Sons,(Asia) Pte Ltd., 2007 |

| [21] | Zhou D., Chen L., Yu J.H., Li Y., Yan W. F., Deng F., Xu R. R., Inorg. Chem., 2005, 44, 4391—4397 |

| [22] | Zhou D., Lu X.H., Xu J., Yu A. A., Li J. Y., Deng F., Xia Q. H., Chem. Mater., 2012, 24, 4160—4165 |

| [23] | Xi D.Y., Sun Q. M., Chen X. X., Wang N., Yu J. H., Chem. Commun., 2015, 51, 11987—11989 |

| [24] | Li M., Zeng C.F., Zhang L. X., CrystEngComm, 2012, 14, 3787—3792 |

| [25] | Shen W.L., Li X., Wei Y. X., Tian P., Deng F., Han X. W., Bao X. H., Micropor. Mesopor. Mater., 2012, 158, 19—25 |

| [1] | 姚伊婷, 吕佳敏, 余申, 刘湛, 李昱, 李小云, 苏宝连, 陈丽华. 等级孔微孔-介孔Fe2O3/ZSM-5中空分子筛催化材料的制备及催化苄基化性能[J]. 高等学校化学学报, 2022, 43(8): 20220090. |

| [2] | 李志光, 齐国栋, 徐君, 邓风. Sn-Al-β分子筛酸性在葡萄糖转化反应中作用的固体NMR研究[J]. 高等学校化学学报, 2022, 43(6): 20220138. |

| [3] | 陈玮琴, 吕佳敏, 余申, 刘湛, 李小云, 陈丽华, 苏宝连. 有机杂化介孔Beta分子筛的合成及在苯甲醇烷基化反应中的应用[J]. 高等学校化学学报, 2022, 43(6): 20220086. |

| [4] | 李加富, 张凯, 王宁, 孙启明. 分子筛限域单原子金属催化剂的研究进展[J]. 高等学校化学学报, 2022, 43(5): 20220032. |

| [5] | 孟祥龙, 杨歌, 郭海玲, 刘晨光, 柴永明, 王纯正, 郭永梅. 纳米分子筛的合成及硫化氢吸附性能[J]. 高等学校化学学报, 2022, 43(3): 20210687. |

| [6] | 魏李娜, 彭莉, 朱锋, 顾鹏飞, 顾学红. 中空纤维Au-CeZr/FAU催化膜的制备及在富氢气氛CO选择性氧化反应中的应用[J]. 高等学校化学学报, 2022, 43(10): 20220175. |

| [7] | 罗强强, 金少青, 孙洪敏, 杨为民. 液相酸溶液后补钛合成Ti-MWW分子筛[J]. 高等学校化学学报, 2021, 42(9): 2742. |

| [8] | 李海勃, 肖长发, 江龙, 黄云, 淡宜. MCM-41分子筛负载氯化铝催化丙烯酸甲酯与1-辛烯共聚[J]. 高等学校化学学报, 2021, 42(9): 2974. |

| [9] | 李奕川, 朱国富, 王宇, 柴永明, 刘晨光, 何盛宝. 基底表面性质与前驱液化学环境对原位定向构筑钛硅分子筛膜的影响[J]. 高等学校化学学报, 2021, 42(9): 2934. |

| [10] | 张旭, 阙家乾, 侯月新, 吕佳敏, 刘湛, 雷坤皓, 余申, 李小云, 陈丽华, 苏宝连. 等级孔介孔-微孔TS-1分子筛单晶的合成及催化氯丙烯环氧化性能[J]. 高等学校化学学报, 2021, 42(8): 2529. |

| [11] | 王磊, 孙毯毯, 闫娜娜, 马超, 刘晓娜, 田鹏, 郭鹏, 刘中民. 利用适用于SAPO-34的有机结构导向剂合成SSZ-13分子筛[J]. 高等学校化学学报, 2021, 42(6): 1716. |

| [12] | 王冶, 张晓思, 孙丽婧, 李冰, 刘琳, 杨淼, 田鹏, 刘仲毅, 刘中民. 有机硅烷辅助合成特殊形貌SAPO分子筛[J]. 高等学校化学学报, 2021, 42(3): 683. |

| [13] | 李健, 于明明, 孙源, 冯文华, 冯兆池, 吴剑峰. 水溶液pH对甲烷低温氧化制备甲醇的影响[J]. 高等学校化学学报, 2021, 42(3): 776. |

| [14] | 王勇, 董彪, 孙娇, 董德录, 孙连坤. 基于分子筛模板的银/硅铝无定形结构复合材料的合成及光谱性质[J]. 高等学校化学学报, 2021, 42(10): 3233. |

| [15] | 闻嘉丽, 张钧豪, 姜久兴. 超大孔分子筛, 十年再回顾[J]. 高等学校化学学报, 2021, 42(1): 101. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||