高等学校化学学报 ›› 2020, Vol. 41 ›› Issue (4): 829.doi: 10.7503/cjcu20190549

收稿日期:2019-10-23

出版日期:2020-04-10

发布日期:2020-03-02

通讯作者:

段莉梅,刘景海

E-mail:duanlmxie@126.com;jhliu2008@sinano.ac.cn

基金资助:

WANG Xia,LIU Yanji,JIA Yongfeng,JI Lei,HU Quanli,DUAN Limei( ),LIU Jinghai(

),LIU Jinghai( )

)

Received:2019-10-23

Online:2020-04-10

Published:2020-03-02

Contact:

Limei DUAN,Jinghai LIU

E-mail:duanlmxie@126.com;jhliu2008@sinano.ac.cn

Supported by:摘要:

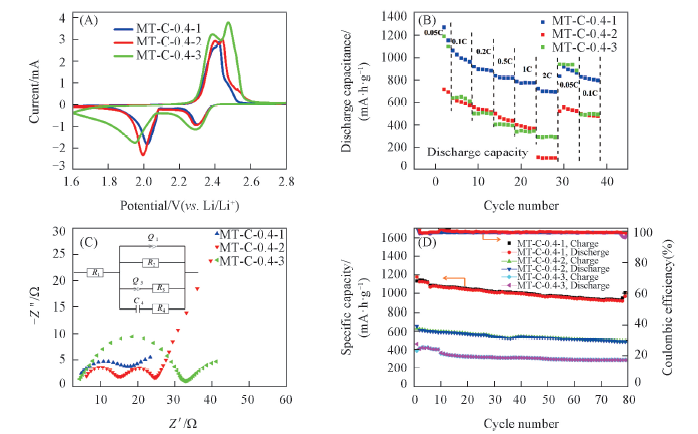

采用静电纺丝技术获得聚丙烯腈(PAN)纳米纤维, 选用聚乙烯吡咯烷酮(PVP)作为造孔剂, 在氮气气氛下1000 ℃高温碳化制备富介孔结构的含氮纳米碳纤维(MT-C). 研究结果表明, 当m(PVP)/m(PAN)为2∶1时, MT-C-0.4比表面积为190.8 m 2/g, 并且在0.05C倍率下首次放电比容量高达1269.4 mA·h/g, 在0.5C倍率下循环300周后比容量仍保持为658.3 mA·h/g, 每周容量衰减率为0.14%. 硫电极负载量为1 mg/cm 2时, MT-C表现出最佳的电化学性能.

中图分类号:

TrendMD:

王霞, 刘彦吉, 贾永锋, 吉磊, 胡全丽, 段莉梅, 刘景海. 含氮多孔纳米碳纤维的制备及对锂硫电池容量的提高. 高等学校化学学报, 2020, 41(4): 829.

WANG Xia, LIU Yanji, JIA Yongfeng, JI Lei, HU Quanli, DUAN Limei, LIU Jinghai. Preparative Chemistry of N-containing Porous Carbon Nanofibers for Capacity Improvement in Lithium-sulfur Battery †. Chem. J. Chinese Universities, 2020, 41(4): 829.

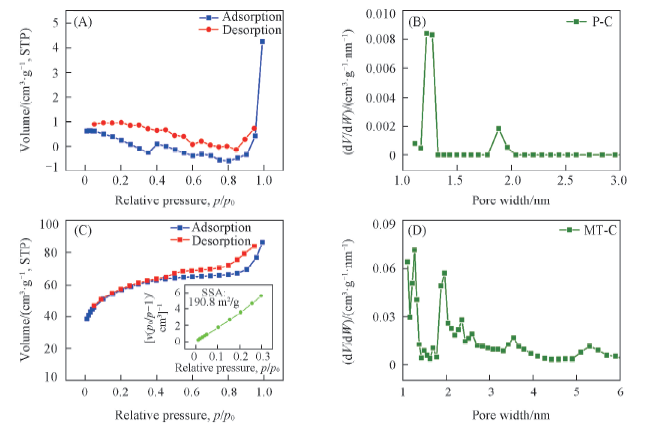

Fig.4 Nitrogen adsorption-desorption isotherms(A, C) and pore size distributions(B, D) for P-C(A, B) and MT-C-0.4(C, D)Insets: BET curves; SSA: specific surface area.

| Sample | Surface area/(m2·g-1) | Total-pore volume/(cm3·g-1) | Micropore volume/(cm3·g-1) | Average pore diameter/nm |

|---|---|---|---|---|

| MT-C-0.3 | 18.8 | 0.01 | 0.006 | 2.43 |

| MT-C-0.4 | 190.8 | 0.13 | 0.066 | 2.82 |

| MT-C-0.6 | 117.6 | 0.16 | 0.022 | 5.55 |

| MT-C-0.8 | 129.3 | 0.29 | 0.021 | 9.22 |

Table 1 Pore structure of carbon nanofibers with variable PAN contents

| Sample | Surface area/(m2·g-1) | Total-pore volume/(cm3·g-1) | Micropore volume/(cm3·g-1) | Average pore diameter/nm |

|---|---|---|---|---|

| MT-C-0.3 | 18.8 | 0.01 | 0.006 | 2.43 |

| MT-C-0.4 | 190.8 | 0.13 | 0.066 | 2.82 |

| MT-C-0.6 | 117.6 | 0.16 | 0.022 | 5.55 |

| MT-C-0.8 | 129.3 | 0.29 | 0.021 | 9.22 |

Fig.8 Electrochemical performances of MT-C-0.4/S with different S contents(A) CV curves, scan rate: 0.1 mV/s; (B) rate capabilities; (C) EIS curves. Inset in (C): model circuit; (D) cycling stability.

| [1] | Qie L., Chen W . M., Wang Z. H., Shao Q. G., Li X., Yuan L. X., Hu X. L., Zhang W. X., Huang Y. H., Adv. Mater., 2012, 24, 2047— 2050 |

| [2] | Ge Y. Q., Jiang H., Fu K., Zhang C. H., Zhu J. D., Chen C., Lu Y., Qiu Y. P., Zhang X. W., J. Power Sources, 2014, 272, 860— 865 |

| [3] | Chen Y. M., Li X. Y., Park K., Song J., Hong J. H., Zhou L. M., Mai Y. W., Huang H. T., Goodenough J. B., J. Am. Chem. Soc., 2013, 135, 16280— 16283 |

| [4] | Zhang Z., Jing H. K., Liu S., Li G. R., Gao X. P., J. Mater. Chem. A, 2015, 3, 6827— 6834 |

| [5] | Liu X., Huang J. Q., Zhang Q., Mai L., Adv. Mater., 2017, 29, 1601759 |

| [6] | Pan H., Wei X., Henderson W. A., Shao Y., Chen J., Bhattacharya P., Xiao J., Liu J., Adv. Energy Mater., 2015, 5, 1500113 |

| [7] | Lin L. L., Pei F., Peng J., Fu A., Cui J. Q., Fang X. L., Zheng N. F., Nano Energy., 2018, 54, 50— 58 |

| [8] | Meng X. B., Gao Q. M., Chem. J. Chinese Universities, 2014, 35 8), 1715— 1719 |

| ( 孟宪斌,高秋明.高等学校化学学报, 2014, 35(8), 1715— 1719) | |

| [9] | Pang Q., Liang X., Kwok C. Y., Nazar L. F., Nat. Energy, 2016, 1, 16132 |

| [10] | Rana M., Li M., Huang X., Luo B., Gentle L., Knibbe R., J. Mater. Chem. A, 2019, 7, 6596— 6615 |

| [11] | Wang J., Sun X. G., Chen W., Li X., Huang Y. P., Wei C. C., Hu H., Liang G. D., Chem. J. Chinese Universities, 2018, 39 8), 1782— 1789 |

| ( 王杰,孙晓刚,陈玮,李旭,黄雅盼,魏成成,胡浩,梁国东.高等学校化学学报, 2018, 39(8), 1782— 1789) | |

| [12] | Xiong S. Z., Xie K., Hong X. B., Chem. J. Chinese Universities., 2011, 32 11), 2645— 2649 |

| ( 熊仕昭,谢凯,洪晓斌.高等学校化学学报, 2011, 32(11), 2645— 2649) | |

| [13] | Fan L. L., Li M., Li X. F., Xiao W., Chen Z. W., Lu J ., Joule, 2019, 3, 361— 386 |

| [14] | He G., Mandlmeier B., Schuster J., Nazar L. F., Bein T., Chem. Mater., 2014, 26, 3879— 3886 |

| [15] | Rodríguez E., Camean I., Garcia R., Garcia A. B., Electrochim. Acta, 2011, 56, 5090— 5094 |

| [16] | Zhou X., Tang J., Yang J., Xie J., Huang B., J. Mater. Chem. A, 2013, 1, 5037— 5044 |

| [17] | Sun X., Wang X., Mayes R . T., Dai S., ChemSusChem, 2013, 5, 2079— 2085 |

| [18] | Sun F., Wang J., Chen H., Li W., Qiao W., Long D., Ling L., ACS Appl. Mater. Interfaces, 2013, 5, 5630— 5638 |

| [19] | Yan D., Teng B., Chem. Res. Chinese Universities, 2019, 35( 4), 654— 661 |

| [20] | Yang J., Xie J., Zhou X Y .,Zou Y. L., Tang J. J.,Wang S. C., Chen F., Wang L. Y J. Phys. Chem. C, 2014,118, 1800— 1807 |

| [21] | Zhou L., Lin X. J., Huang T., Yu A. S., Electrochimica Acta, 2014, 116, 210— 216 |

| [22] | Wu Y. Z., Balakrishna R., Reddy M. V., Nair A. S., Chowdari B. V. R., Ramakrishna S., J. Alloys Comp., 2012, 517, 69— 74 |

| [23] | Kim C., Jeong Y.I., Ngoc B. T. N., Yang K. S., Kojima M., Kim Y. A., Endo M., Lee J. W ., Small, 2007, 3, 91— 95 |

| [24] | Sun H.X. , Du H. R., Yu M. K., Huang K. F., Yu N., Geng B. Y ., Nano Res., 2019, 12,1937— 1942 |

| [25] | Wang D. D., Wang J. N., Chemical Engineering Journal, 2017, 314, 714— 726 |

| [26] | Chung S. H., Manthiram A., Adv. Mater., 2014, 26, 7352— 7357 |

| [27] | Zhou G. M., Pei S. F., Li L., Wang D. W., Wang S. G., Huang K., Yin L. C., Li F., Cheng H. M., Adv. Mater., 2014, 26, 625— 631 |

| [28] | Chen W., Lei T. Y., Qian T., Lv W. Q., He W. D., Wu C. Y., Liu X. J., Liu J., Chen B., Yan C. L., Xiong J., Adv. Energy Mater., 2018, 8, 1702889 |

| [29] | Xu R., Lu J., Amine K., Adv. Energy Mater., 2015, 5, 1500408 |

| [30] | Ji X. L., Nazar L. F., J. Mater. Chem., 2010, 20, 9821— 9826 |

| [31] | Barchasz C., Molton F., Duboc C., Leprêtre J. C., Patoux S., Alloin F., Anal. Chem., 2012, 84, 3973— 3980 |

| [32] | Su Y. S., Manthiram A., Nat. Commun., 2012, 3, 1166— 1172 |

| [33] | Song J. X., Gordin M. L., Xu T., Chen S. R., Yu Z. X., Sohn H., Lu J., Ren Y., Duan Y. H., Wang D. H., Angew. Chem. Int. Ed., 2015, 54, 4325— 4329 |

| [34] | Wang Z., Feng M., Sun H., Li G. R., Fu Q., Li H. B., Liu J., Sun L. Q., Mauger A., Julien C. M., Xie H. M., Chen Z. W., Nano Energy, 2019, 59, 390— 398 |

| [35] | Doerfler S., Strubel P., Jaumann T., Troschke E., Hippauf F., Kensy C., Schökel A., Althues H., Giebeler L., Oswald S., Kaskel S., Nano Energy, 2018, 54, 116— 128 |

| [36] | Tang C., Zhang Q., Zhao M. Q., Huang J. Q., Cheng X. B., Tian G. L., Peng H. J., Wei F., Adv. Mater., 2014, 26, 6100— 6105 |

| [37] | Cheon S. E., Ko K. S., Cho J. H., Kim S. U., Chin E. Y., Kim H. T., J. Electrochem. Soc., 2003, 150, A796— A799 |

| [38] | Lian P. C., Zhu X. F., Liang S. Z., Li Z., Yang W. S., Wang H. H., Electrochem. Acta, 2010, 55, 3909— 3914 |

| [39] | Liu C., Liu X. G., Tan J., Wang Q. F., Wen H., Zhang C. H., J. Power Sources, 2017, 342, 157— 164 |

| [40] | Luo W. B., Chou S. L., Wang J. Z., Zhai Y. C., Liu H. K ., Small, 2015, 11, 2817— 2824 |

| [41] | Yin Y. X., Xin S., Guo Y. G., Wan L. J., Angew. Chem. Int. Ed., 2013, 52, 13186— 13200 |

| [42] | Zhang S. S., J. Electrochem. Soc., 2012, 159, A920— A923 |

| [43] | Tan G. Q., Xu R., Xing Z. Y., Yuan Y. F., Lu J., Wen J. G., Liu C., Ma L., Zhan C., Liu Q., Wu T. P., Jian Z. L., Shahbazian-Yassar R., Ren Y., Miller D. J., Curtiss L. A., Ji X. L., Amine K., Nat. Energy, 2017, 2, 17090 |

| [44] | Qiao Q. Q., Zhang H. Z., Li G. R., Ye S. H., Wang C. W., Gao X. P., J. Mater. Chem. A, 2013, 1, 5262— 5268 |

| [45] | Gao X. P., Liu J., Ye S. H., Song D. Y., Zhang Y. S., J. Alloys Compd., 1997, 253 254, 515— 519 |

| [46] | Du C., Gao C. H., Yin G. P., Chen M., Wang L., Energy Environ. Sci., 2011, 4, 1037— 1042 |

| [1] | 吴玉, 李轩, 杨恒攀, 何传新. 钴单原子的双重限域制备策略及高效CO2电还原性能[J]. 高等学校化学学报, 2022, 43(9): 20220343. |

| [2] | 范建玲, 唐灏, 秦凤娟, 许文静, 谷鸿飞, 裴加景, 陈文星. 氮掺杂超薄碳纳米片复合铂钌单原子合金催化剂的电化学析氢性能[J]. 高等学校化学学报, 2022, 43(9): 20220366. |

| [3] | 韩付超, 李福进, 陈良, 贺磊义, 姜玉南, 徐守冬, 张鼎, 其鲁. CoSe2/C复合电催化材料修饰隔膜对高载量锂硫电池性能的影响[J]. 高等学校化学学报, 2022, 43(8): 20220163. |

| [4] | 郝宏蕾, 孟繁雨, 李若钰, 李迎秋, 贾明君, 张文祥, 袁晓玲. 生物质基氮掺杂多孔炭材料的制备及对水中亚甲基蓝的吸附性能[J]. 高等学校化学学报, 2022, 43(6): 20220055. |

| [5] | 尹肖菊, 孙逊, 赵程浩, 姜波, 赵晨阳, 张乃庆. 单原子催化剂在锂硫电池中的研究进展[J]. 高等学校化学学报, 2022, 43(5): 20220076. |

| [6] | 张诗昱, 何润合, 李永兵, 魏士俊, 张兴祥. 辐照交联制备低分子量聚丙烯腈纤维锂硫电池正极材料及其储硫机理[J]. 高等学校化学学报, 2022, 43(3): 20210632. |

| [7] | 侯从聪, 王惠颖, 李婷婷, 张志明, 常春蕊, 安立宝. N-CNTs/NiCo-LDH复合材料的制备及电化学性能[J]. 高等学校化学学报, 2022, 43(10): 20220351. |

| [8] | 马丽娟, 高升启, 荣祎斐, 贾建峰, 武海顺. Sc, Ti, V修饰B/N掺杂单缺陷石墨烯的储氢研究[J]. 高等学校化学学报, 2021, 42(9): 2842. |

| [9] | 陈铭苏, 张会茹, 张琪, 刘家琴, 吴玉程. 锂硫电池中钴磷共掺杂MoS2催化性能的第一性原理研究[J]. 高等学校化学学报, 2021, 42(8): 2540. |

| [10] | 耿传楠, 化五星, 凌国维, 陶莹, 张辰, 杨全红. 锂硫电池中的催化作用: 材料与表征[J]. 高等学校化学学报, 2021, 42(5): 1331. |

| [11] | 刘志刚, 李家宝, 杨剑, 马浩, 王赪胤, 郭鑫, 汪国秀. 新型石墨化氮化碳/锡/氮掺杂碳复合物的制备及储钠性能[J]. 高等学校化学学报, 2021, 42(2): 633. |

| [12] | 李锐, 孙晓刚, 邹婧怡, 何强. 含羟基磷灰石纳米线复合夹层的高性能锂硫电池[J]. 高等学校化学学报, 2020, 41(8): 1866. |

| [13] | 吴桐, 丛丽娜, 孙立群, 谢海明. 氧缺位结构介孔二氧化钛/聚乙烯复合隔膜在锂硫电池中的应用[J]. 高等学校化学学报, 2020, 41(7): 1661. |

| [14] | 熊俊宇, 王姗姗, 许颜清, 胡长文. 原子级分散Fe-N-C温和条件下选择性氧化催化特性[J]. 高等学校化学学报, 2020, 41(6): 1262. |

| [15] | 秦春萍, 王先流, 唐寒, 易兵成, 刘畅, 张彦中. 含骨脱细胞基质电纺纤维的成骨性能[J]. 高等学校化学学报, 2020, 41(4): 780. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||