高等学校化学学报 ›› 2020, Vol. 41 ›› Issue (12): 2561.doi: 10.7503/cjcu20200708

• 庆祝《高等学校化学学报》复刊40周年专栏 • 上一篇 下一篇

沈明辉1,2, 魏延泽1,2, 徐楠2, 王祖民2, 杨乃亮2,3, 于然波1, 王丹2,3

收稿日期:2020-09-24

出版日期:2020-12-10

发布日期:2020-12-09

基金资助:SHEN Minghui1,2, WEI Yanze1,2, XU Nan2, WANG Zumin2, YANG Nailiang2,3, YU Ranbo1, WANG Dan2,3

Received:2020-09-24

Online:2020-12-10

Published:2020-12-09

Supported by:摘要:

异质中空结构是指壳层由不同成分组成的空心微纳结构. 通过对异质中空结构的表面性质和传质过程进行调控, 可以调控经过中空结构的物质及能量. 目前, 异质中空结构在太阳能转化、 气体传感、 电化学储能和药物运输等领域展示出了优异的性能, 对异质中空结构的设计与构建已成为新型多功能先进材料研究的前沿领域. 本文总结了异质中空结构的种类、 特征和性能优势, 重点描述了各类异质中空结构的制备方法, 并探讨了异质中空结构微纳材料面临的挑战及发展趋势.

中图分类号:

TrendMD:

沈明辉, 魏延泽, 徐楠, 王祖民, 杨乃亮, 于然波, 王丹. 异质中空结构微纳材料的构建. 高等学校化学学报, 2020, 41(12): 2561.

SHEN Minghui, WEI Yanze, XU Nan, WANG Zumin, YANG Nailiang, YU Ranbo, WANG Dan. Construction of Hetero⁃hollow Structure Micro⁃/Nanomaterials. Chem. J. Chinese Universities, 2020, 41(12): 2561.

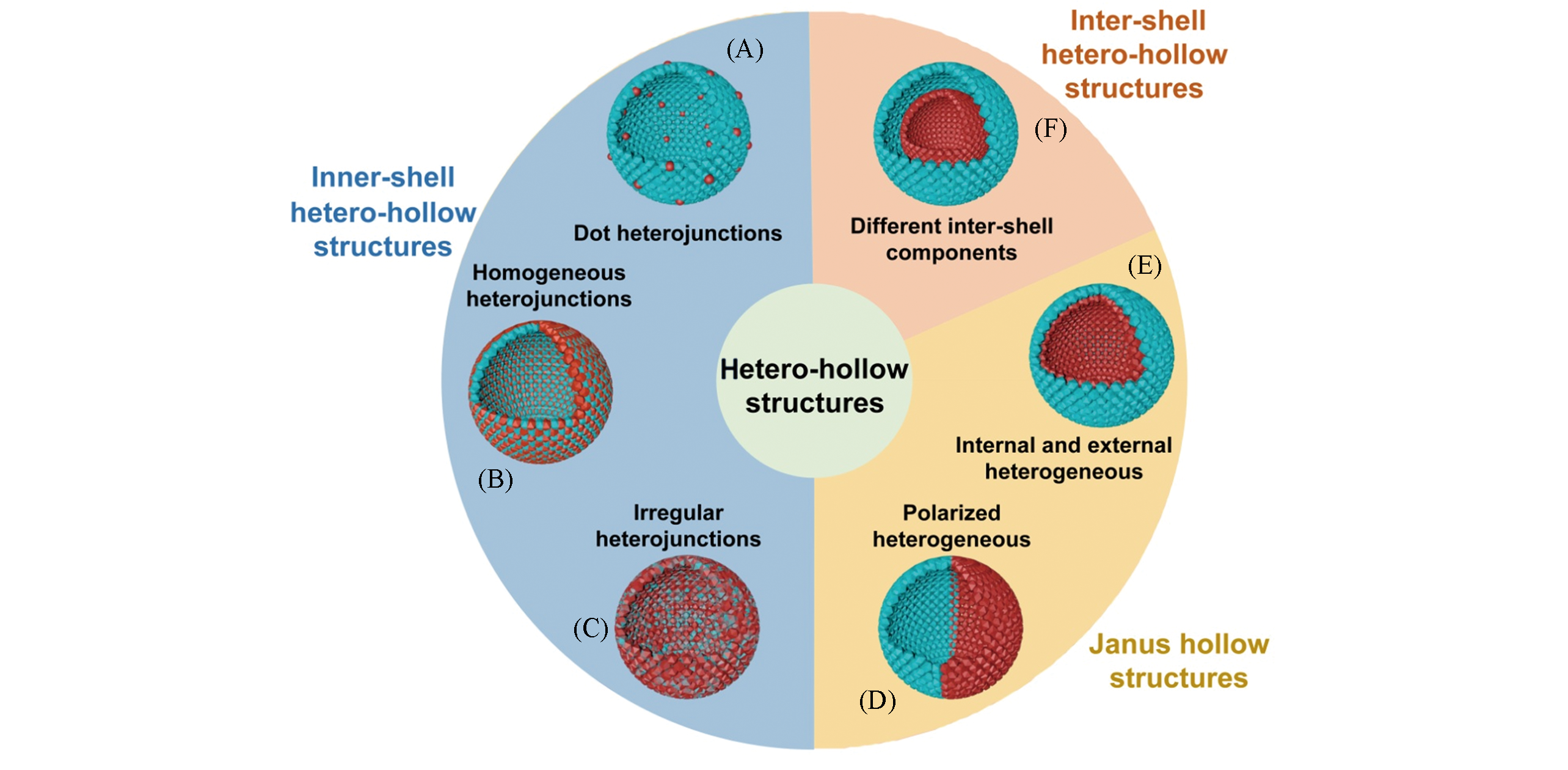

Fig.1 Illustration of different types of hetero?hollow structuresInner?shell hetero?hollow structures: (A) dot heterojunctions; (B) homogeneous heterojunctions; (C) irregular heterojunctions. Janus hollow structures: (D) polarized heterogeneous Janus; (E) internal and external heterogeneous Janus. Inter?shell hetero?hollow structures: (F) different inter?shell components.

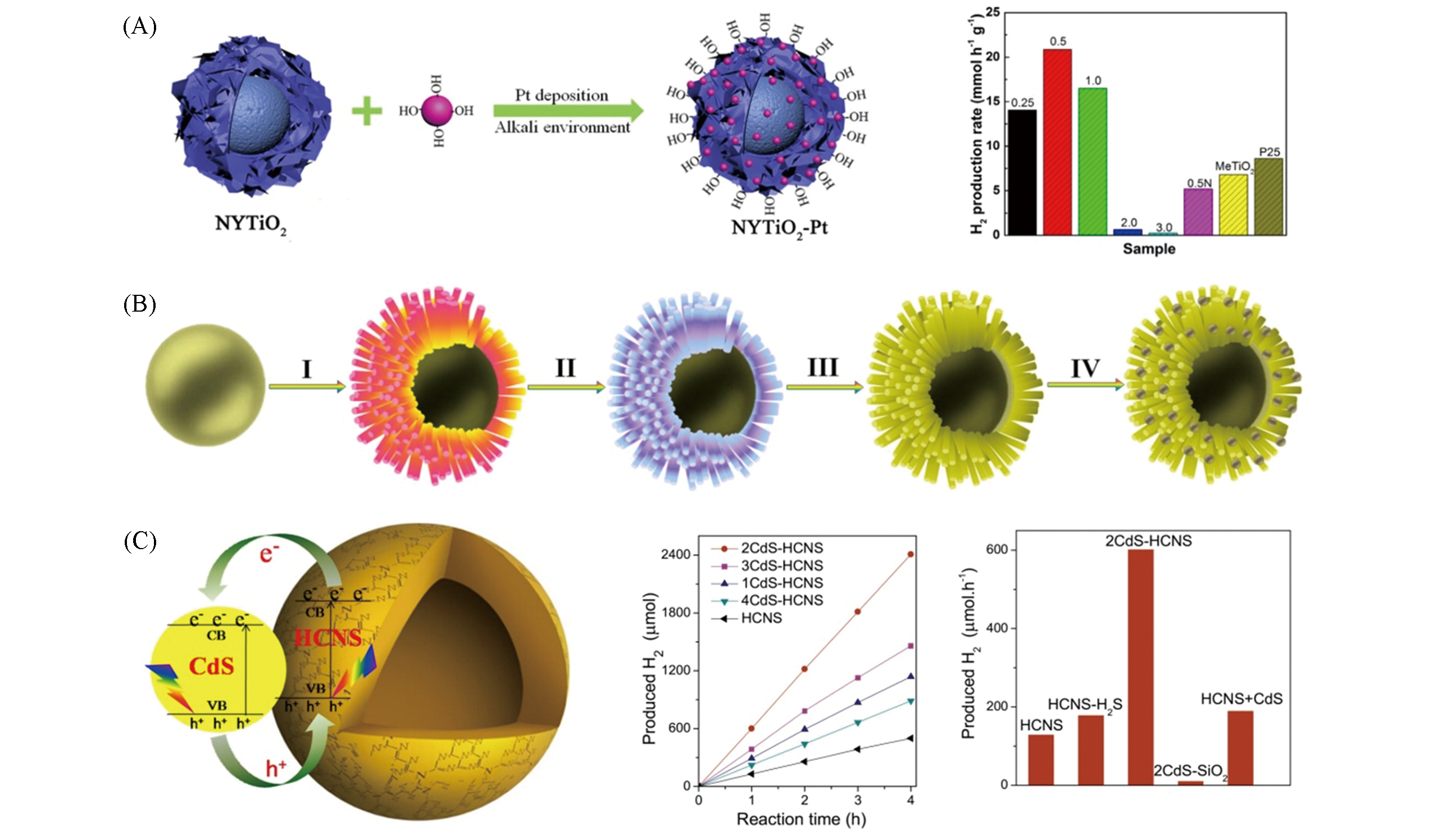

Fig.2 Construction of hollow structures with dot heterojunctions(A) Pt deposition and NaOH?modification process of NY?TiO2 and H2 production rates of all the samples[38]; Copyright 2017, Elsevier. (B) Schematic illustration of the fabrication process of hierarchical CQDs/H?γ?TaON hollow urchin heterostructures: (Ⅰ) in situ hydrothermal treatment; (Ⅱ) thermal nitridation; (Ⅲ) hydrogenation; (Ⅳ) oil bath reflux[23]; Copyright 2015, Else- vier. (C) Schematic illustration of CdS?HCNS heterojunction system, Photocatalytic hydrogen evolution by CdS?HCNS photocatalysts under visible light irradiation(λ>420 nm) with different amounts of CdS QDs and some reference samples of HCNS, HCNS?H2S, CdS?SiO2, physically?mixed HCNS and CdS[39]. Copyright 2015, Elsevier.

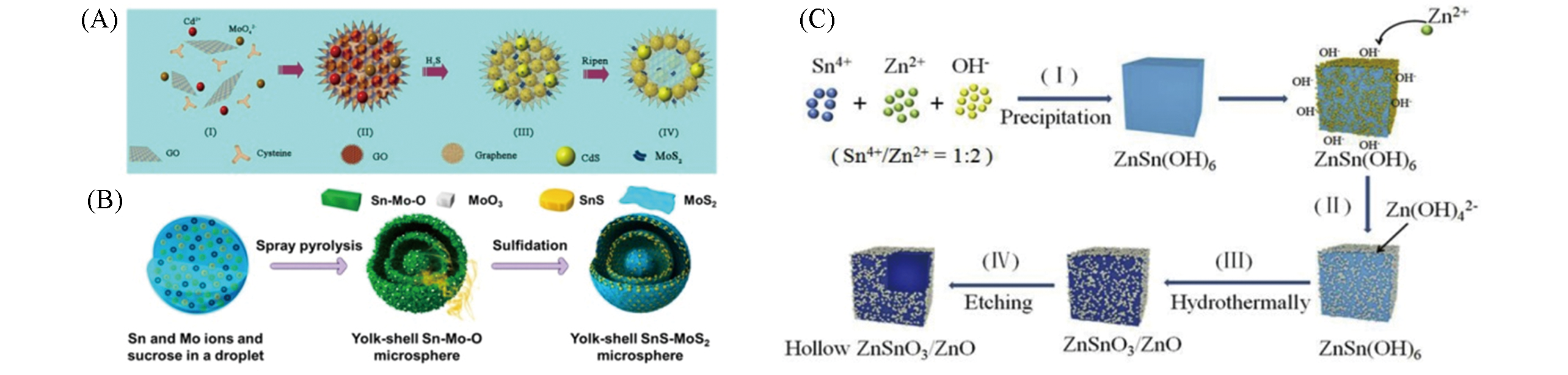

Fig.3 Construction of hollow structures with homogeneous heterojunctions(A) Schematic illustration of the growth mechanism of CdS/MoS2/graphene hollow spheres[25]; Copyright 2015, Elsevier. (B) Illustration of the formation mechanism of the yolk?shell SnS?MoS2 composite microsphere by the spray pyrolysis and subsequent sulfidation process[40]; Copyright 2015, American Chemical Society. (C) Schematic illustration for the formation of solid ZnSnO3/ZnO and hollow ZnSnO3/ZnO[41]; Copyright 2019, Elsevier.

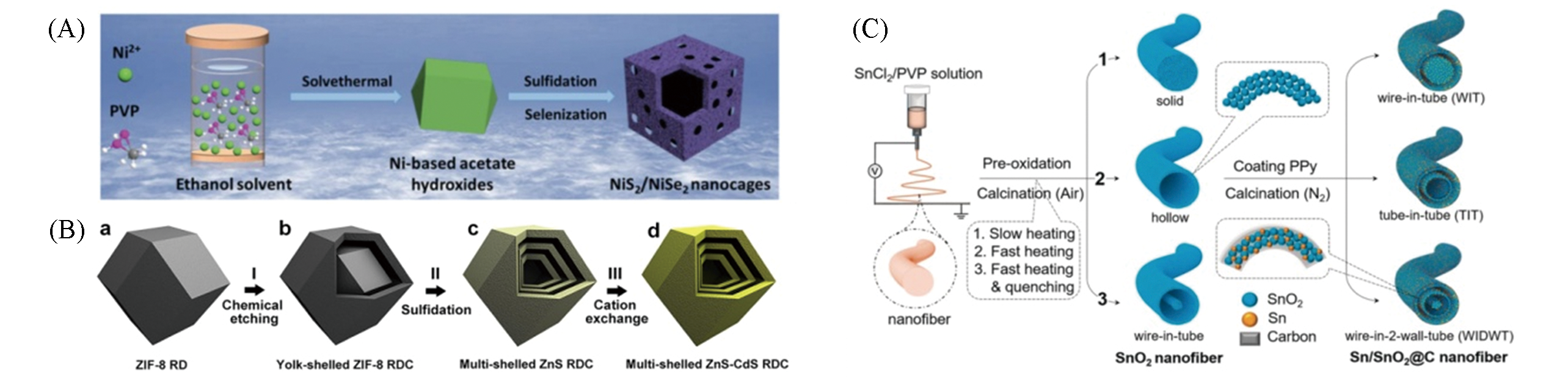

Fig.4 Construction of hollow structures with irregular heterojunctions(A) Schematic illustration of the synthesis of tetrahedral NiS2/NiSe2 heterocages[44]. Copyright 2019, Wiley?VCH. (B) Schematic illustration of the formation process of multi?shelled ZnS?CdS RDCs[26]. Copyright 2018, Elsevier. (C) Fabrication scheme of multi?wall Sn/SnO2@C hollow nanofibers[45]. Copyright 2019, Wiley?VCH.

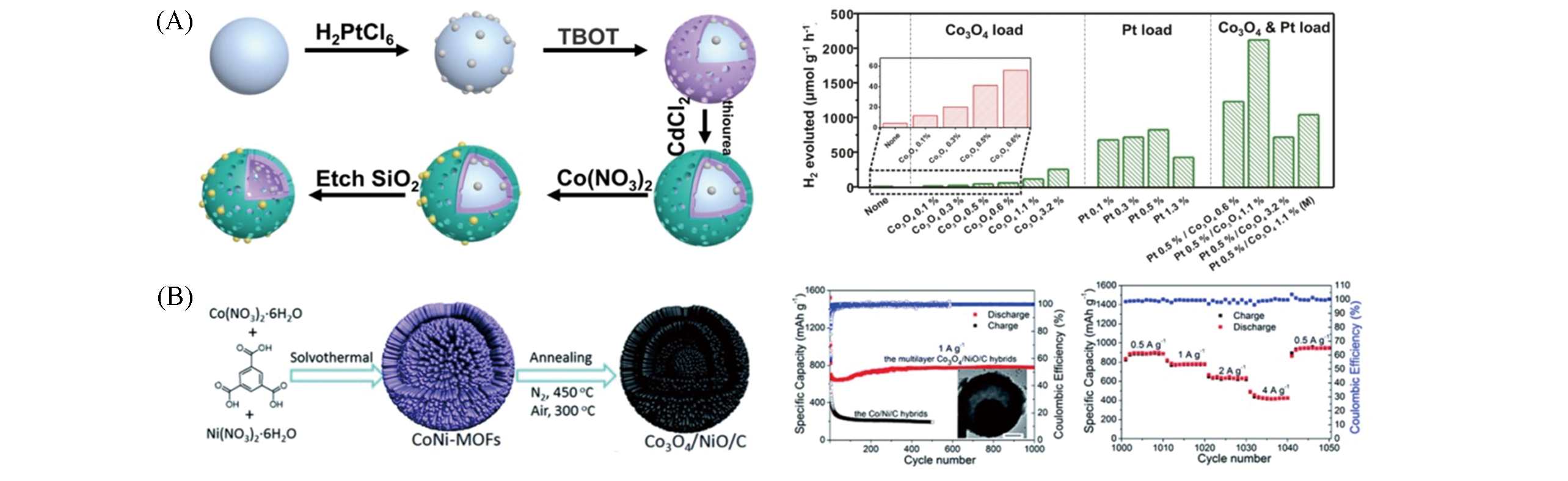

Fig.5 Construction of hollow structures with multiple heterojunctions(A) Schematic of the synthesis process of Pt/TiO2/CdS/Co3O4 composite hollow spheres and hydrogen evolution speed of hollow spheres with different co?catalysts loaded on[46]. Copyright 2017, Elsevier. (B) Schematic of the fabrication process for the multilayered Co3O4/NiO/C hybrids, Long?term cycling performance and coulombic efficiencies of the multilayered Co3O4/ NiO/C electrodes at 1 A/g. The inset shows a TEM image of the multilayered Co3O4/NiO/C hybrids after 200 cycles at a current density of 1 A/g(scale bar: 2 μm), Discharge?charge capacities and coulombic efficiencies at current rates of 0.5, 1, 2, 4 and 0.5 A/g[47]. Copyright 2017, Royal Society of Chemistry.

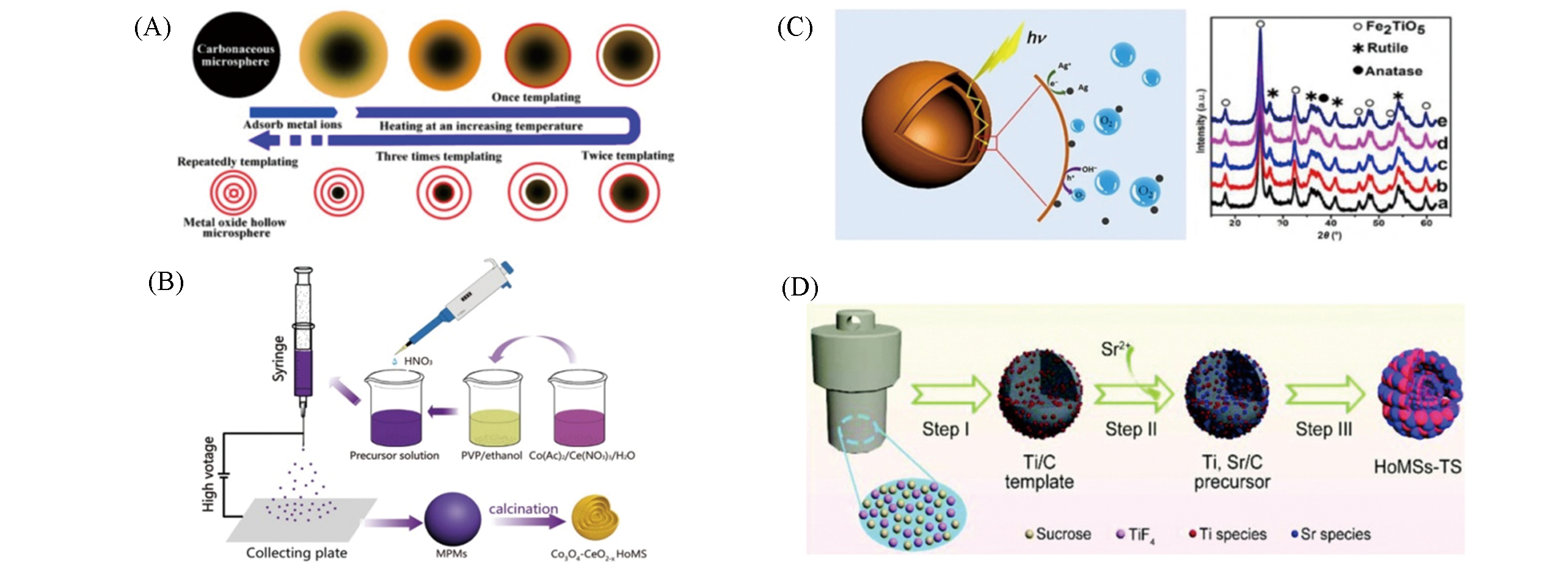

Fig.6 Synthesis of heterogeneous HoMSs based on sequential template method(A) Illustration of the sequential templating approach to multiple?shell hollow metal oxide microsphere synthesis[50]. Copyright 2011, Wiley?VCH. (B) Illustration for the preparation of Co3O4?CeO2-x HoMS by electrostatic spray[62]. Copyright 2019, Wiley?VCH. (C) TiO2/Fe2TiO5 HoMSs Catalytic reaction mechanism and XRD[63]. Copyright 2017, Springer. (D) Schematic illustration of the synthesis process for TiO2?SrTiO3 HoMSs[65]. Copyright 2019, Royal Society of Chemistry.

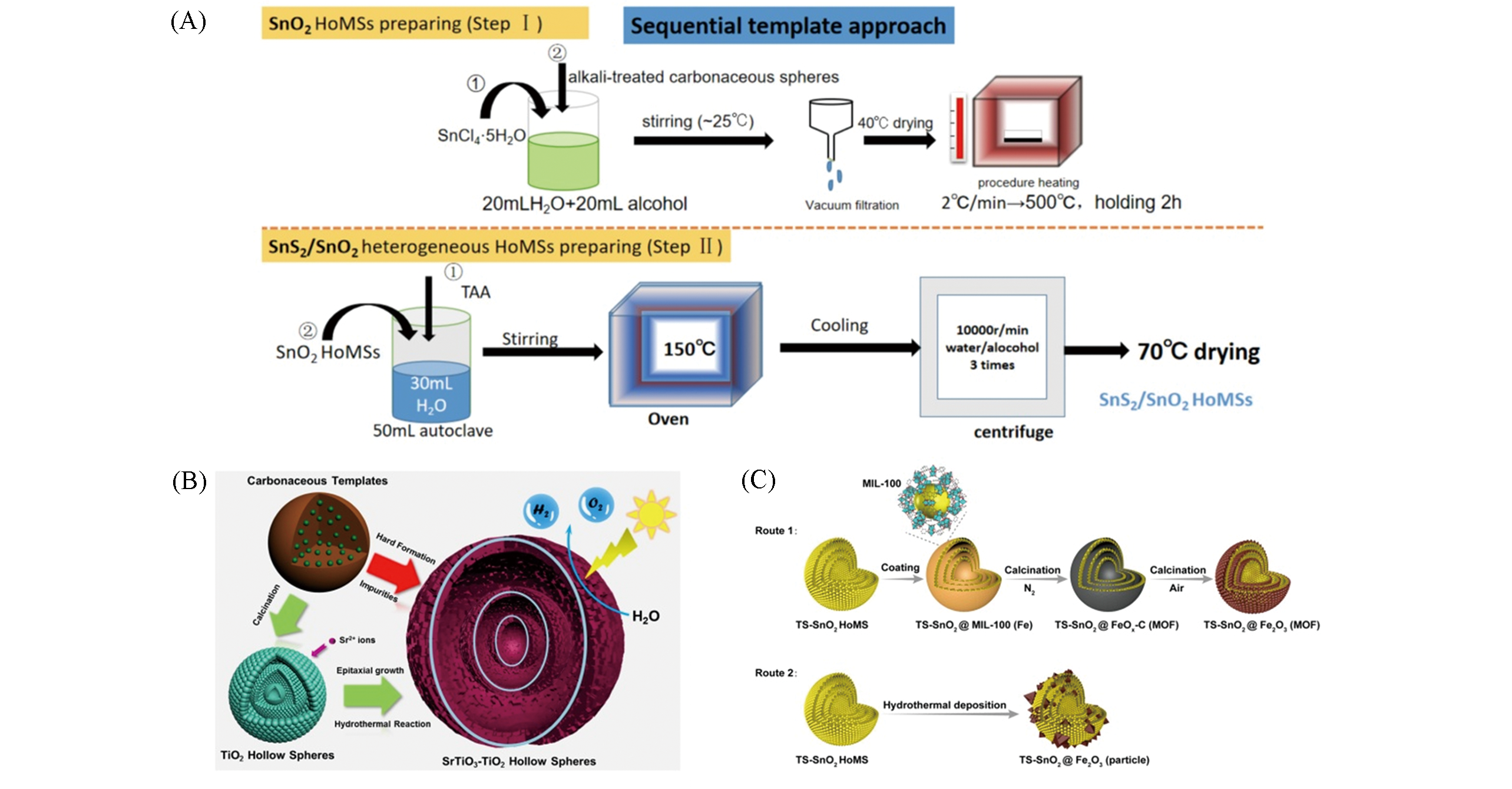

Fig.7 Synthesis of heterogeneous HoMSs based on sequential template method and post?treatment(A) Synthesis routes for the preparation of SnS2?SnO2 heterogeneous hollow multi?shelled structures(HoMSs)[66]. Copyright 2019, Wiley?VCH. (B) Synthetic route of SrTiO3?TiO2 hollow multi?shelled structures from hydrothermal reaction[67]. Copyright 2018, Wiley?VCH. (C) Synthesis procedure of HoMS with MOFs evolutive casing(Route 1) and with hydrothermal deposition method(Route 2)[68]. Copyright 2018, Wiley?VCH.

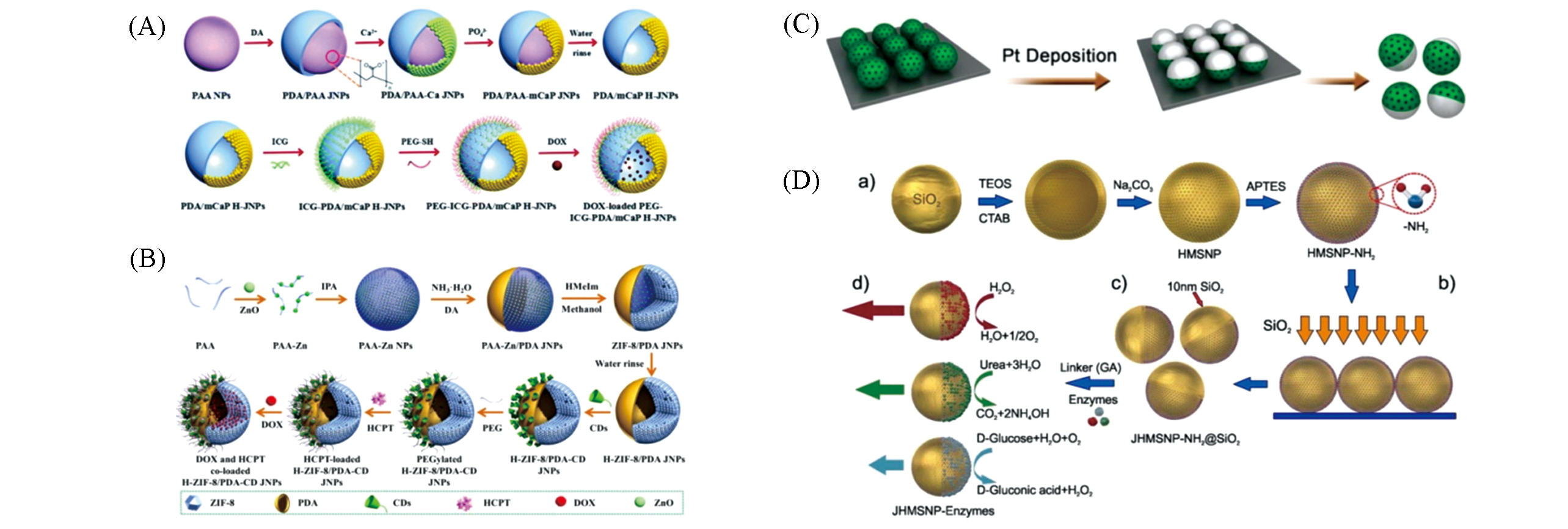

Fig.8 Construction of polarized heterogeneous Janus hollow structures(A) Schematic showing the controlled synthesis of PEG?ICG?PDA/mCaP H?JNPs and biofunctionalization of multifunctional H?JNPs[10]. Copyright 2017, Royal Society of Chemistry. (B) Schematic illustration of fabricating the H?ZIF?8/PDA?CD JNPs for the application of synergistic dual?drug chemotherapy and photothermal therapy in vitro and in vivo[75]. Copyright 2019, Elsevier. (C) Schematic illustration of the Pt?CuS synthesis procedures[77]. Copyright 2019, American Chemical Society. (D) Fabrication of enzymatic hollow mesoporous silica Janus nanomotors[80]. Copyright 2015, American Chemical Society.

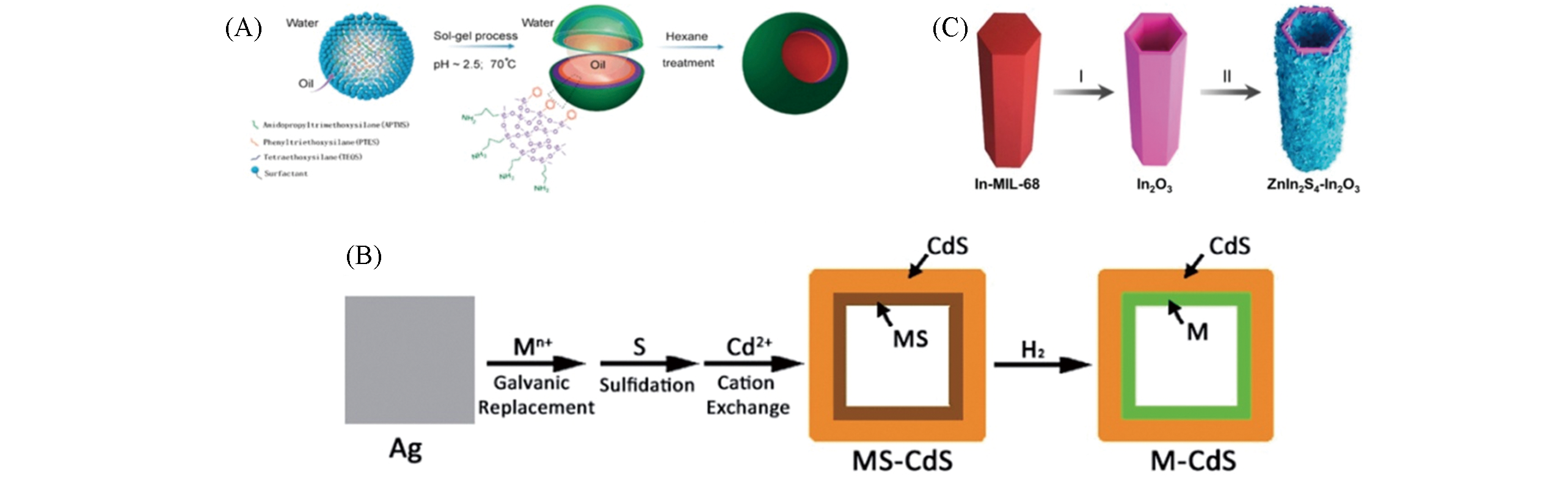

Fig.9 Construction of Internal and external heterogeneous Janus hollow structures(A) Illustrative fabrication of the Janus hollow spheres by emulsion interfacial self?assembled sol?gel process[82]. Copyright 2011, Royal Society of Chemistry. (B) General synthetic approach of M?CdS double shell hollow nanocubes(M=Pt, Au, and Pd)[84]. Copyright 2016, Royal Society of Chemistry. (C) Schematic illustration of the synthetic process of sandwich?like ZnIn2S4?In2O3 hierarchical tubular heterostructures: (I) thermal annealing in air, (II) growth of ZnIn2S4 nanosheets[85]. Copyright 2018, American Chemical Society.

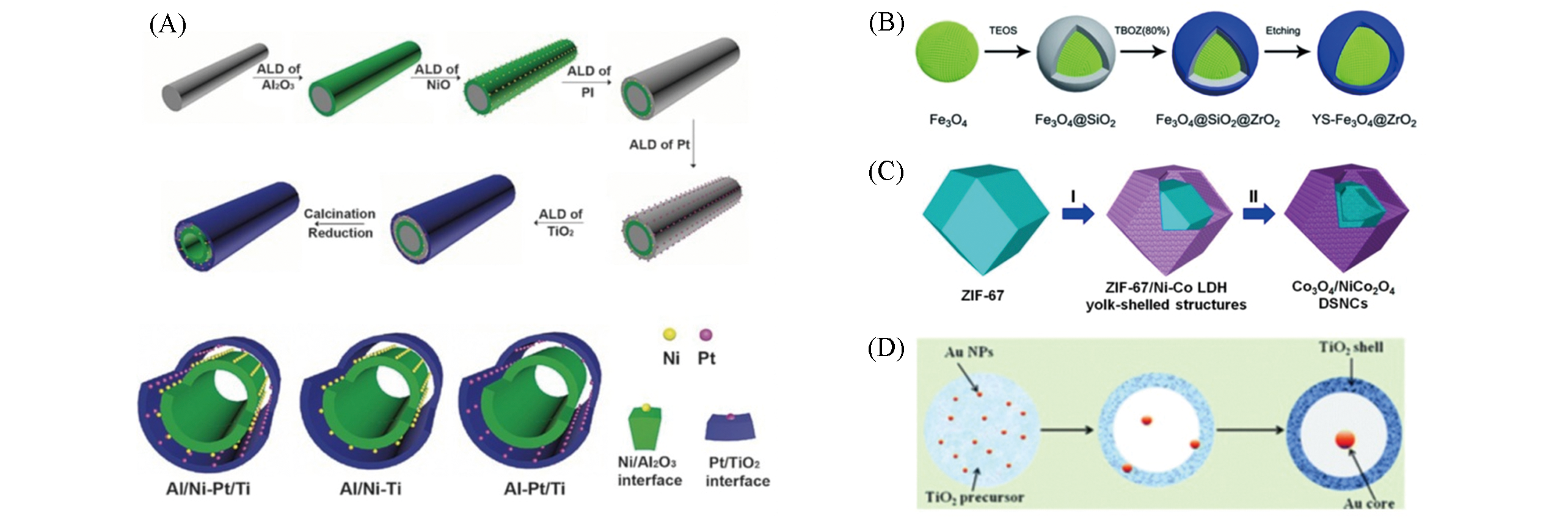

Fig.10 Construction of intershell hetero?hollow structures(A) Schematic illustration of the procedure for the synthesis of the tandem catalyst with both Ni/Al2O3 and Pt/TiO2 interfaces and semi?sectio?nal views of different catalysts for comparison[86]. Copyright 2016, Wiley?VCH. (B) Schematic illustration of the synthesis procedure in pre? paring YS(yolk?shell) Fe3O4@ZrO2 microspheres[87]. Copyright 2014, Royal Society of Chemistry. (C) Schematic illustration of the formation process of Co3O4/NiCo2O4 DSNCs. Step I: transformation of ZIF?67 into ZIF?67/Ni?Co LDH yolk?shelled structures by a facile etching and deposition process. Step II: formation of Co3O4/NiCo2O4 DSNCs by annealing the yolk?shelled structures in air[92]. Copyright 2015, American Chemical Society. (D) Illustrations of formation process of Au@TiO2 hollow submicrospheres[94]. Copyright 2012, Royal Society of Chemistry.

| 1 | Gleiter H., Prog. Mater. Sci., 1989, 33(1), 233—239 |

| 2 | Chen M., Ye C., Zhou S., Wu L., Adv. Mater., 2013, 25(37), 5343—5351 |

| 3 | Hu F., Zhang Y., Chen G., Li C., Wang Q., Small, 2015, 11(8), 985—993 |

| 4 | Qi J., Lai X., Wang J., Tang H., Ren H., Yang Y., Jin Q., Zhang L., Yu R., Ma G., Su Z., Zhao H., Wang D., Chem. Soc. Rev., 2015, 44(19), 6749—6773 |

| 5 | Zhou L., Zhuang Z., Zhao H., Lin M., Zhao D., Mai L., Adv. Mater., 2017, 29(20), 1602914 |

| 6 | Low J., Yu J., Jaroniec M., Wageh S., Al⁃Ghamdi A. A., Adv. Mater., 2017, 29(20), 1601694 |

| 7 | Zong L., Cui P., Qin F., Zhao K., Wang Z., Yu R., Mater. Res. Bull., 2017, 86, 44—50 |

| 8 | Wei J., Zhou M., Long A., Xue Y., Liao H., Wei C., Xu Z. J., Nano⁃Micro Lett., 2018, 10(4), 75 |

| 9 | Miller D. R., Akbar S. A., Morris P. A., Sens. Actuators B: Chem., 2014, 204, 250—272 |

| 10 | Zhang M., Zhang L., Chen Y., Li L., Su Z., Wang C., Chem. Sci., 2017, 8(12), 8067—8077 |

| 11 | Yang Y., Liu X., Li X., Zhao J., Bai S., Liu J., Yang Q., Angew. Chem. Int. Ed., 2012, 51(36), 9164—9168 |

| 12 | Wang X., Feng J., Bai Y., Zhang Q., Yin Y., Chem. Rev., 2016, 116(18), 10983—11060 |

| 13 | Oh M. H., Yu T., Yu S. H., Lim B., Ko K. T., Willinger M. G., Seo D. H., Kim B. H., Cho M. G., Park J. H., Science, 2013, 340(6135), 964—968 |

| 14 | Pei F., An T., Zang J., Zhao X., Fang X., Zheng M., Dong Q., Zheng N., Adv. Energy Mater., 2016, 6(8), 1502539 |

| 15 | Xia X., Wang Y., Ruditskiy A., Xia Y., Adv. Mater., 2013, 25(44), 6313—6333 |

| 16 | Chen T., Colver P. J., Bon S. A., Adv. Mater., 2007, 19(17), 2286—2289 |

| 17 | Han M. G., Foulger S. H., Chem. Commun., 2005, (24), 3092—3094 |

| 18 | Xiong S., Zeng H. C., Angew. Chem. Int. Ed., 2012, 51(4), 949—952 |

| 19 | Xu X., Nosheen F., Wang X., Chem. Mater., 2016, 28(17), 6313—6320 |

| 20 | Zhao H., Chen J. F., Zhao Y., Jiang L., Sun J. W., Yun J., Adv. Mater., 2008, 20(19), 3682—3686 |

| 21 | Sharma B. L., Purohit R. K., Semiconductor Heterojunctions, Elsevier Science Press, Holland, 2015 |

| 22 | Wang H., Zhang L., Chen Z., Hu J., Li S., Wang Z., Liu J., Wang X., Chem. Soc. Rev., 2014, 43(15), 5234—5244 |

| 23 | Hou J., Cheng H., Yang C., Takeda O., Zhu H., Nano Energy, 2015, 18, 143—153 |

| 24 | Wang T., Kou X., Zhao L., Sun P., Liu C., Wang Y., Shimanoe K., Yamazoe N., Lu G., Sens. Actuators B: Chem., 2017, 250, 692—702 |

| 25 | Yu X., Du R., Li B., Zhang Y., Liu H., Qu J., An X., Appl. Catal. B: Environ., 2016, 182, 504—512 |

| 26 | Zhang P., Guan B. Y., Yu L., Lou X. W., Chem, 2018, 4(1), 162—173 |

| 27 | De Gennes P. G., Rev. Mod. Phys., 1992, 64(3), 645—648 |

| 28 | Walther A., Müller A. H. E., Chem. Rev., 2013, 113(7), 5194—5261 |

| 29 | Lee K. J., Yoon J., Lahann J., Curr. Opin. Colloid In., 2011, 16(3), 195—202 |

| 30 | Guo W., Wang Y., Li Q., Wang D., Zhang F., Yang Y., Yu Y., ACS Appl. Mater. Interfaces, 2018, 10(17), 14993—15000 |

| 31 | Li S., Cai J., Wu X., Zheng F., Lin X., Liang W., Chen J., Zheng J., Lai Z., Chen T., Zhu L., Appl. Catal. B: Environ., 2014, 160/161, 279—285 |

| 32 | Lv X., Zhu Y., Jiang H., Zhong H., Yang X., Li C., Dalton Trans., 2014, 43(40), 15111—15118 |

| 33 | Wang Y., Guo W., Yang Y., Yu Y., Li Q., Wang D., Zhang F., Electrochim. Acta, 2018, 262, 1—8 |

| 34 | Khan I. U., Serra C. A., Anton N., Li X., Akasov R., Messaddeq N., Kraus I., Vandamme T. F., Int. J. Pharm., 2014, 473(1/2), 239—249 |

| 35 | Wang J., Wan J., Yang N., Li Q., Wang D., Nat. Rev. Chem., 2020, 4(3), 159—168 |

| 36 | Wei Y., Wan J., Yang N., Yang Y., Ma Y., Wang S., Wang J., Yu R., Gu L., Wang L., Wang L., Huang W., Wang D., Natl. Sci. Rev., 2020, 7(11), 1638—1646 |

| 37 | Shi J., Chem. Rev., 2013, 113(3), 2139—2181 |

| 38 | Jin J., Wang C., Ren X. N., Huang S. Z., Wu M., Chen L. H., Hasan T., Wang B. J., Li Y., Su B. L., Nano Energy, 2017, 38, 118—126 |

| 39 | Zheng D., Zhang G., Wang X., Appl. Catal. B: Environ., 2015, 179, 479—488 |

| 40 | Choi S. H., Kang Y. C., ACS Appl. Mater. Interfaces, 2015, 7(44), 24694—24702 |

| 41 | Yan Y., Liu J., Zhang H., Song D., Li J., Yang P., Zhang M., Wang J., J. Alloys Compd., 2019, 780, 193—201 |

| 42 | Sun L., Han X., Jiang Z., Ye T., Li R., Zhao X., Han X., Nanoscale, 2016, 8(26), 12858—12862 |

| 43 | Xiong Y., Xu W., Zhu Z., Xue Q., Lu W., Ding D., Zhu L., Sens. Actuators B: Chem., 2017, 253, 523—532 |

| 44 | Yang Y., Kang Y., Zhao H., Dai X., Cui M., Luan X., Zhang X., Nie F., Ren Z., Song W., Small, 2020, 16(1), 1905083 |

| 45 | Gao S., Wang N., Li S., Li D., Cui Z., Yue G., Liu J., Zhao X., Jiang L., Zhao Y., Angew. Chem. Int. Ed., 2020, 59(6), 2465—2472 |

| 46 | Wang Z., Wu W., Xu Q., Li G., Liu S., Jia X., Qin Y., Wang Z. L., Nano Energy, 2017, 38, 518—525 |

| 47 | Wang Y., Kong M., Liu Z., Lin C., Zeng Y., J. Mater. Chem. A, 2017, 5(46), 24269—24274 |

| 48 | Cai J., Wu X., Li S., Zheng F., ACS Sustain. Chem. Eng., 2016, 4(3), 1581—1590 |

| 49 | Li S., Cai J., Wu X., Liu B., Chen Q., Li Y., Zheng F., J. Hazard. Mater., 2018, 346, 52—61 |

| 50 | Lai X., Li J., Korgel B. A., Dong Z., Li Z., Su F., Du J., Wang D., Angew. Chem. Int. Ed., 2011, 50(12), 2738—2741 |

| 51 | Mao D., Wan J., Wang J., Wang D., Adv. Mater., 2019, 31(38), 1802874 |

| 52 | Chen M., Wang J., Tang H., Yang Y., Wang B., Zhao H., Wang D., Inorg. Chem. Front., 2016, 3(8), 1065—1070 |

| 53 | Dong Z., Lai X., Halpert J. E., Yang N., Yi L., Zhai J., Wang D., Tang Z., Jiang L., Adv. Mater., 2012, 24(8), 1046—1049 |

| 54 | Dong Z., Ren H., Hessel C. M., Wang J., Yu R., Jin Q., Yang M., Hu Z., Chen Y., Tang Z., Zhao H., Wang D., Adv. Mater., 2014, 26(6), 905—909 |

| 55 | Li H., Ma H., Yang M., Wang B., Shao H., Wang L., Yu R., Wang D., Mater. Res. Bull., 2017, 87, 224—229 |

| 56 | Wang F., Wang J., Ren H., Tang H., Yu R., Wang D., Inorg. Chem. Front., 2016, 3(3), 365—369 |

| 57 | Wang J., Tang H., Zhang L., Ren H., Yu R., Jin Q., Qi J., Mao D., Yang M., Wang Y., Liu P., Zhang Y., Wen Y., Gu L., Ma G., Su Z., Tang Z., Zhao H., Wang D., Nat. Energy, 2016, 1(5), 16050 |

| 58 | Wang J., Yang N., Tang H., Dong Z., Jin Q., Yang M., Kisailus D., Zhao H., Tang Z., Wang D., Angew. Chem. Int. Ed., 2013, 52(25), 6417—6420 |

| 59 | Xu S., Hessel C. M., Ren H., Yu R., Jin Q., Yang M., Zhao H., Wang D., Energy Environ. Sci., 2014, 7(2), 632—637 |

| 60 | Ren H., Yu R., Wang J., Jin Q., Yang M., Mao D., Kisailus D., Zhao H., Wang D., Nano Lett., 2014, 14(11), 6679—6684 |

| 61 | Ren H., Yu R., Qi J., Zhang L., Jin Q., Wang D., Adv. Mater., 2019, 31(10), 1805754 |

| 62 | Wang H., Mao D., Qi J., Zhang Q., Ma X., Song S., Gu L., Yu R., Wang D., Adv. Funct. Mater., 2019, 29(15), 1806588 |

| 63 | Waqas M., Wei Y., Mao D., Qi J., Yang Y., Wang B., Wang D., Nano Res., 2017, 10(11), 3920—3928 |

| 64 | Zong L., Xu J., Jiang S., Zhao K., Wang Z., Liu P., Zhao H., Chen J., Xing X., Yu R., Adv. Mater., 2017, 29(9), 1604377 |

| 65 | Jiang S., Zhao K., Al⁃Mamun M., Zhong Y. L., Liu P., Yin H., Jiang L., Lowe S., Qi J., Yu R., Wang D., Zhao H., Inorg. Chem. Front., 2019, 6(7), 1667—1674 |

| 66 | You F., Wan J., Qi J., Mao D., Yang N., Zhang Q., Gu L., Wang D., Angew. Chem. Int. Ed., 2020, 59(2), 721—724 |

| 67 | Wei Y., Wang J., Yu R., Wan J., Wang D., Angew. Chem. Int. Ed., 2019, 58(5), 1422—1426 |

| 68 | Zhang J., Wan J., Wang J., Ren H., Yu R., Gu L., Liu Y., Feng S., Wang D., Angew. Chem. Int. Ed., 2019, 58(16), 5266—5271 |

| 69 | Wang J., Wan J., Wang D., Acc. Chem. Res., 2019, 52(8), 2169—2178 |

| 70 | Wang Z., Yang N., Wang D., Chem. Sci., 2020, 11(21), 5359—5368 |

| 71 | Wei Y., Yang N., Huang K., Wan J., You F., Yu R., Feng S., Wang D., Adv. Mater., 2020, 32(44), 2002556 |

| 72 | Liang F., Zhang C., Yang Z., Adv. Mater., 2014, 26(40), 6944—6949 |

| 73 | Mock E. B., Zukoski C. F., Langmuir, 2010, 26(17), 13747—13750 |

| 74 | Skelhon T. S., Chen Y., Bon S. A., Langmuir, 2014, 30(45), 13525—13532 |

| 75 | Li S., Zhang L., Liang X., Wang T., Chen X., Liu C., Li L., Wang C., Chem. Eng. J., 2019, 378(15), 122175 |

| 76 | Perro A., Reculusa S., Ravaine S., Bourgeat⁃Lami E., Duguet E., J. Mater. Chem., 2005, 15(35/36), 3745—3760 |

| 77 | Liang S., Deng X., Chang Y., Sun C., Shao S., Xie Z., Xiao X., Ma P., Zhang H., Cheng Z., Lin J., Nano Lett., 2019, 19(6), 4134—4145 |

| 78 | Sridhar V., Park B. W., Sitti M., Adv. Funct. Mater., 2018, 28(25), 1704902 |

| 79 | Wu Y., Lin X., Wu Z., Mohwald H., He Q., ACS Appl. Mater. Interfaces, 2014, 6(13), 10476—10481 |

| 80 | Ma X., Jannasch A., Albrecht U. R., Hahn K., Miguel⁃Lopez A., Schaffer E., Sanchez S., Nano Lett., 2015, 15(10), 7043—7050 |

| 81 | Jin Z., Fan H., Soft Matter, 2014, 10(46), 9212—9219 |

| 82 | Liang F., Liu J., Zhang C., Qu X., Li J., Yang Z., Chem. Commun., 2011, 47(4), 1231—1233 |

| 83 | Chen Y., Yang H., Zhang C., Wang Q., Qu X., Li J., Liang F., Yang Z., Macromolecules, 2013, 46(10), 4126—4130 |

| 84 | Choi W., Park G., Bae K. L., Choi J. Y., Nam K. M., Song H., J. Mater. Chem. A, 2016, 4(35), 13414—13418 |

| 85 | Wang S., Guan B. Y., Lou X. W. D., J. Am. Chem. Soc., 2018, 140(15), 5037—5040 |

| 86 | Ge H., Zhang B., Gu X., Liang H., Yang H., Gao Z., Wang J., Qin Y., Angew. Chem. Int. Ed., 2016, 55(25), 7081—7085 |

| 87 | Yu M., Liang C., Liu M., Liu X., Yuan K., Cao H., Che R., J. Mater. Chem. C, 2014, 2(35), 7275—7283 |

| 88 | Zhang H., Zhang X., Yang X., J. Colloid Interface Sci., 2010, 348(2), 431—440 |

| 89 | Yue Q., Li J., Zhang Y., Cheng X., Chen X., Pan P., Su J., Ahmed A., Abdulaziz A., Deng Y., Zhao D., J. Am. Chem. Soc., 2017, 139(43), 15486—15493 |

| 90 | Zhou H. C., Long J. R., Yaghi O. M., Chem. Rev., 2012, 112(2), 673—674 |

| 91 | Ren H., Yu R., Inorg. Chem. Front., 2019, 6(9), 2239—2259 |

| 92 | Hu H., Guan B., Xia B., Lou X. W., J. Am. Chem. Soc., 2015, 137(16), 5590—5595 |

| 93 | Lu Y., Yu L., Wu M., Wang Y., Lou X. W. D., Adv. Mater., 2018, 30(1), 1702875 |

| 94 | Du J., Qi J., Wang D., Tang Z., Energy Environ. Sci., 2012, 5(5), 6914—6918 |

| [1] | 曹舒杰, 李泓君, 管文丽, 任梦田, 周传政. 硫代磷酸酯寡聚核苷酸的立体控制合成研究进展[J]. 高等学校化学学报, 2022, 43(Album-4): 20220304. |

| [2] | 常丽颖 凌鑫宇 陈和祺 王雪 刘涛. 基因编辑在线粒体疾病中的应用[J]. 高等学校化学学报, 2022, 43(Album-4): 20220363. |

| [3] | 姚青, 俞志勇, 黄小青. 单原子催化剂的合成及其能源电催化应用的研究进展[J]. 高等学校化学学报, 2022, 43(9): 20220323. |

| [4] | 王茹玥, 魏呵呵, 黄凯, 伍晖. 单原子材料的冷冻合成[J]. 高等学校化学学报, 2022, 43(9): 20220428. |

| [5] | 韦春洪, 蒋倩, 王盼盼, 江成发, 刘岳峰. 贵金属Pt促进Co基费托合成催化剂的原子尺度结构分析[J]. 高等学校化学学报, 2022, 43(8): 20220074. |

| [6] | 金睿明, 穆晓清, 徐岩. 生物-化学法合成黑色素前体5, 6-二羟基吲哚[J]. 高等学校化学学报, 2022, 43(8): 20220134. |

| [7] | 张昕昕, 许狄, 王艳秋, 洪昕林, 刘国亮, 杨恒权. CO2加氢制低碳醇CuFe基催化剂中的Mn助剂效应[J]. 高等学校化学学报, 2022, 43(7): 20220187. |

| [8] | 周紫璇, 杨海艳, 孙予罕, 高鹏. 二氧化碳加氢制甲醇多相催化剂研究进展[J]. 高等学校化学学报, 2022, 43(7): 20220235. |

| [9] | 鲁聪, 李振华, 刘金露, 华佳, 李光华, 施展, 冯守华. 一种新的镧系金属有机骨架材料的合成、 结构及荧光检测性质[J]. 高等学校化学学报, 2022, 43(6): 20220037. |

| [10] | 宋颖颖, 黄琳, 李庆森, 陈立妙. CuO/BiVO4光催化剂的制备及光催化CO2还原性能[J]. 高等学校化学学报, 2022, 43(6): 20220126. |

| [11] | 李祎頔, 田晓春, 李俊鹏, 陈立香, 赵峰. 半导体-微生物界面电子传递及其在环境领域的应用[J]. 高等学校化学学报, 2022, 43(6): 20220089. |

| [12] | 冯丽, 邵兰兴, 李思骏, 全文选, 庄金亮. 超薄Sm-MOF纳米片的合成及可见光催化降解芥子气模拟剂性能[J]. 高等学校化学学报, 2022, 43(4): 20210867. |

| [13] | 刘家琪, 李天保. BiVO4/CuBi2O4薄膜光电极的制备及光电性能[J]. 高等学校化学学报, 2022, 43(4): 20220017. |

| [14] | 张志男, 程海明, 滕士勇, 张颖. RbPb2Cl5的合成及光学性质[J]. 高等学校化学学报, 2022, 43(11): 20220418. |

| [15] | 邢珮琪, 陆通, 李光华, 王力彦. 两个镉(II)金属有机骨架的可控合成与结构相关性[J]. 高等学校化学学报, 2022, 43(10): 20220218. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||