高等学校化学学报 ›› 2019, Vol. 40 ›› Issue (7): 1365.doi: 10.7503/cjcu20180831

盛炳琛1, 李从1, 刘颖雅1, 王安杰1, 王瑶1( ), 张箭2, 刘伟旭1

), 张箭2, 刘伟旭1

收稿日期:2018-12-12

出版日期:2019-07-10

发布日期:2019-07-12

作者简介:王 瑶, 女, 博士, 教授, 主要从事反应过程强化技术、 微通道反应器及高性能催化剂等方面的研究. E-mail: 基金资助:

SHENG Bingchen1, LI Cong1, LIU Yingya1, WANG Anjie1, WANG Yao1,*( ), ZHANG Jian2, LIU Weixu1

), ZHANG Jian2, LIU Weixu1

Received:2018-12-12

Online:2019-07-10

Published:2019-07-12

Contact:

WANG Yao

E-mail:wangyao@dlut.edu.cn

Supported by:摘要:

采用内交叉指型微反应器连续合成UiO-66材料. 连续微通道法强化了物料之间的混合, 极大提高了生产效率, 晶体产物呈六面体形, 粒径在100 nm以下. 考察了温度、 总进料流量和停留时间等条件对合成过程及产物的影响. 结果表明, 升高温度有助于晶粒的生长; 随着总进料流量增大, 晶体粒径减小; 晶体的形成需要一定的停留时间, 超过该停留时间, 晶体粒径不再增大. 通过优化实验条件, 可以实现系列纳米级UiO-66-X材料(X=NH2, NO2, Br)的连续合成.

中图分类号:

TrendMD:

盛炳琛, 李从, 刘颖雅, 王安杰, 王瑶, 张箭, 刘伟旭. 微通道连续合成UiO-66系列改性MOF材料. 高等学校化学学报, 2019, 40(7): 1365.

SHENG Bingchen, LI Cong, LIU Yingya, WANG Anjie, WANG Yao, ZHANG Jian, LIU Weixu. Microfluidic Synthesis of UiO-66 Metal-organic Frameworks Modified with Different Functional Groups†. Chem. J. Chinese Universities, 2019, 40(7): 1365.

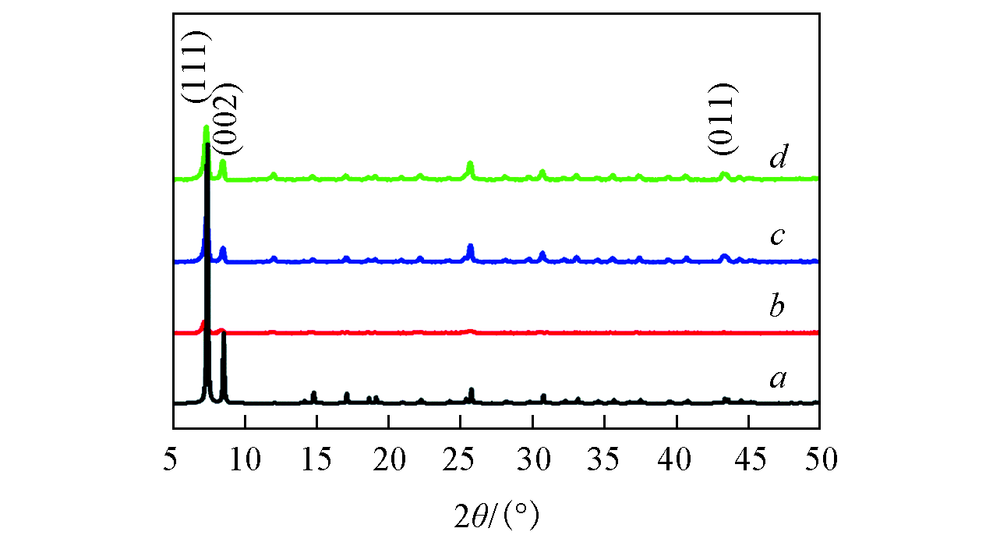

Fig.2 XRD patterns of UiO-66 synthesized under different temperaturesFlowrate: 0.9 mL/min; residence time: 20 min. a. Simulated XRD pattern from single crystal X-ray diffraction; b. 120 ℃; c. 130 ℃; d. 140 ℃.

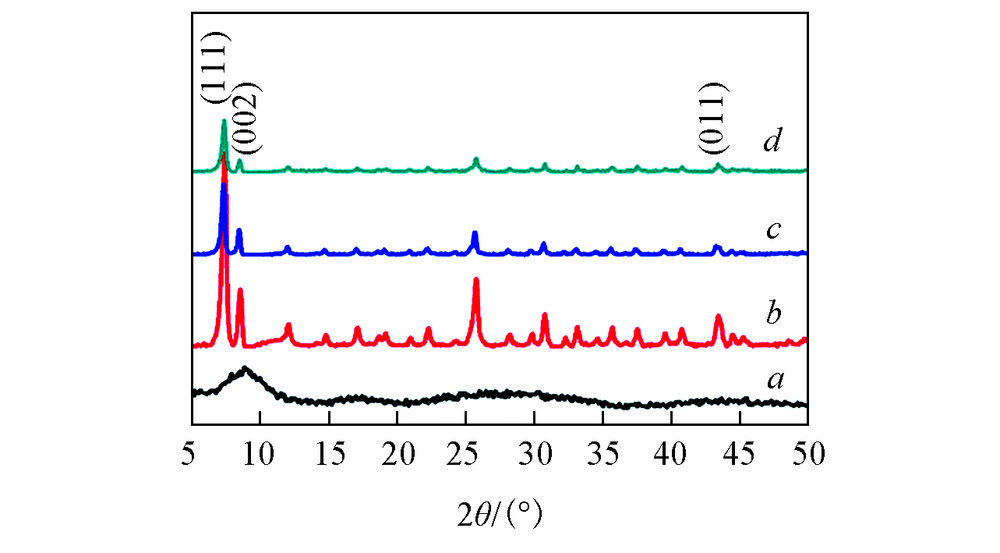

Fig.4 XRD patterns of UiO-66 synthesized under different flowrateResidence time: 20 min; reaction temperature: 130 ℃. Flowrate/(mL·min-1): a. 0.3; b. 0.6; c. 0.9; d. 1.2.

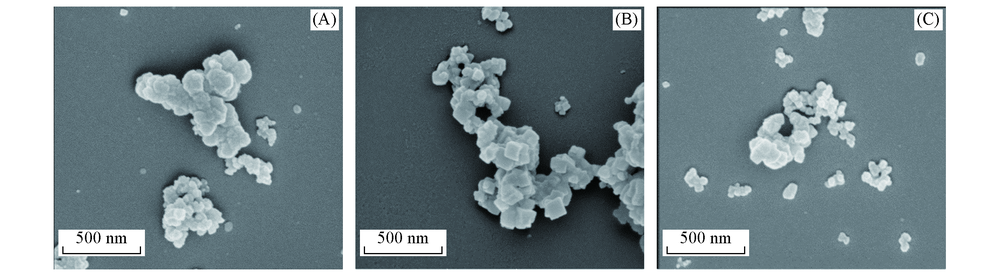

Fig.5 SEM images of UiO-66 synthesized under different flowrateResidence time: 20 min; reaction temperature: 130 ℃. Flowrate/(mL·min-1): (A) 0.6; (B) 0.9; (C) 1.2.

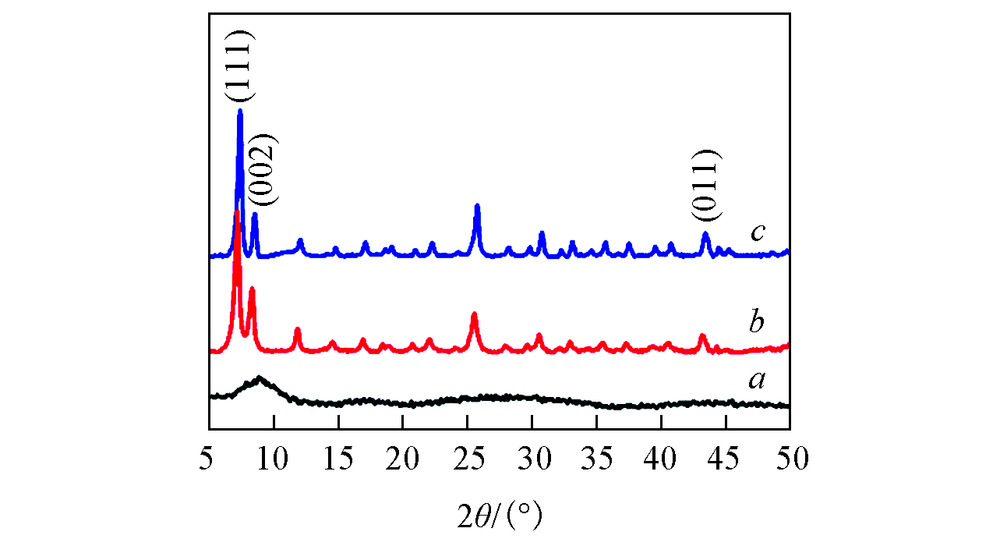

Fig.6 XRD patterns of UiO-66 synthesized under different residence timeFlowrate: 0.6 mL/min; reaction temperature: 130 ℃. Residence time/min: a. 10; b. 20; c. 40.

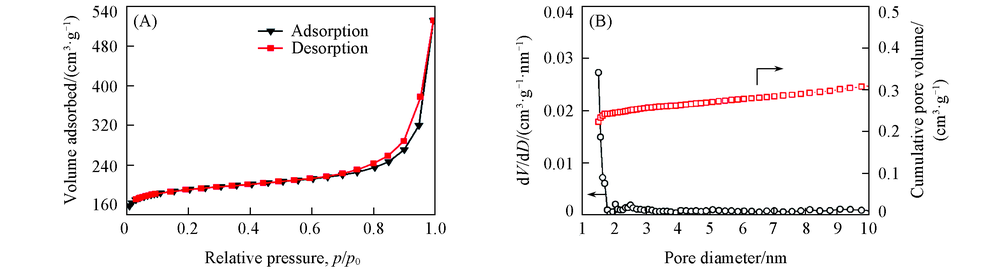

Fig.9 N2 adsorption-desorption isotherm of UiO-66 synthesized by microfluidic method(A) and the corresponding pore-size distribution plots and cumulative pore size distribution(B)

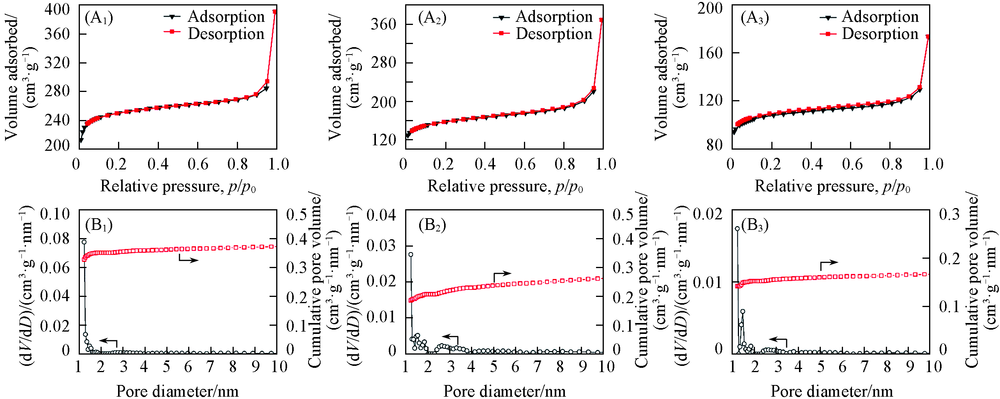

Fig.13 N2 adsorption-desorption isotherms(A1—A3), pore-size distribution plots and cumulative pore size distributions(B1—B3) of UiO-66-X synthesized by microfluidic method(A1, B1) UiO-66-NH2; (A2, B2) UiO-66-NO2; (A3, B3) UiO-66-Br.

| [1] | Han Y. T., Liu M., Li K. Y., Zuo Y., Zhang G. L., Zhang Z. C., Guo X. W., Chin. J. Appl. Chem., 2016, 33(4), 367—378 |

| (韩易潼, 刘民, 李克艳, 左轶, 张国亮, 张宗超, 郭新闻. 应用化学, 2016, 33(4), 367—378) | |

| [2] | Cavka J.H., Jakobsen S., Olsbye U., Guillou N., Lamberti C., Bordiga S., Lillerud K. P.,J. Am. Chem. Soc., 2008, 130(42), 13850—13851 |

| [3] | Wang L. P., Wang G. Y., J. Mol. Catal.(China), 2015, 29(3), 275—288 |

| (王丽苹, 王公应. 分子催化, 2015, 29(3), 275—288) | |

| [4] | Luan Y., Qi Y., Jin Z. K., Peng X.,Gao H. Y., Wang G., RSC Adv., 2015, 5(25), 19273—19278 |

| [5] | Eddaoudi M., Kim J., Rosi N., Vodak D., Wachter J., O’Keeffe M., Yaghi O. M., Science, 2002, 295(5554), 469—472 |

| [6] | Kitagawa S., Kitaura R., Noro S., Angew. Chem. Int. Ed., 2004, 43(18), 2334—2375 |

| [7] | Konstas K., Taylor J. W., Thronton A. W.,Doherty C. M., Lim W. X., Bastow T. J.,Kennedy D. F., Wood C. D., Cox B. J., Hill J. M., Hill A. J., Hill M. R., Angew. Chem. Int. Ed., 2012, 51(27), 6639—6642 |

| [8] | Sumida K., Rogow D. L., Mason J. A.,McDonald T. M., Bloch E. D., Herm Z. R.,Bae T. H., Long J. R., Chem. Rev., 2012, 112(2), 724—781 |

| [9] | Horcajada P., Chalati T., Serre C.,Gillet B., Sebrie C., Baati T., Eubank J. F., Heurtaux D., Clayette P., Kreuz C.,Chang J. S., Hwang Y. K., Marsaud V., Bories P. N., Cynober L., Gil S., Ferey G., Couvreur P., Gref R., Nat. Mater., 2010, 9(2), 172—178 |

| [10] | Liu D. M., Lu K. D.,Poon C., Lin W. B., Inorg. Chem., 2014, 53(4), 1916—1924 |

| [11] | Wang F. X., Wang C. C., Wang P., Xing B. Z., Chin. J. Inorg. Chem., 2017, 33(5), 713—737 |

| (王茀学, 王崇臣, 王鹏, 邢碧枞. 无机化学学报, 2017, 33(5), 713—737) | |

| [12] | Bai Y., Dou Y. B., Xie L. H.,Rutledge W.,Li J. R., Zhou H. C., Chem. Soc. Rev., 2016, 45, 2327—2367 |

| [13] | Yan X. D., Wang K., Xu X. C., Wang S. H.,Ning Q.,Xiao W. M., Zhang N., Chen Z. J., Chen C., Inorg. Chem., 2018, 57, 8033—8036 |

| [14] | Zhang M. W., Chen Y. P., Bosch M., Gentle T.,Wang K. C., Feng D. W., Wang Z. Y. U., Zhou H. C., Angew. Chem. Int. Ed., 2014, 53, 815—818 |

| [15] | Kandiah M., Nilsen M. H., Usseglio S., Jakobsen S., Olsbye U.,Tilset M., Larabi C., Quadrelli E. A., Bonino F., Lillerud K. P., Chem. Mater., 2010, 22(24), 6632—6640 |

| [16] | Ferey G., Chem. Soc. Rev., 2008, 37, 191—214 |

| [17] | Xiao J.D., Qiu L. G., Ke F., Yuan Y. P., Xu G. S., Wang Y. M., Jiang X., J. Mater. Chem. A, 2013, 1, 8745—8752 |

| [18] | Taddei M., Dau P. V., Cohen S. M.,Ranocchiari M., Dalton Trans., 2015, 44, 14019—14026 |

| [19] | MAE K., Chem. Eng. Sci., 2007, 62(18—20), 4842—4851 |

| [20] | Chen G.W., Zhao Y. C., Le J., Dong Z. Y., Cao H. S., Yuan Q., CIESC J., 2013, 64(1), 63—75 |

| (陈光文, 赵玉潮, 乐军, 董正亚, 曹海山, 袁权. 化工学报, 2013, 64(1), 63—75) | |

| [21] | Luo G.S., Wang K., Wang P. J., CIESC J., 2014, 65(7), 2563—2573 |

| (骆广生, 王凯, 王佩坚. 化工学报, 2014, 65(7), 2563—2573) | |

| [22] | Cao Y., Yang H., Inorg. Chem. Ind., 2011, 43(5), 7—10 |

| (曹寅, 杨晖. 无机盐工业, 2011, 43(5), 7—10) | |

| [23] | Jovanovic J., Rebrov E. V., Nuhuis T. A., Kreutzer M. T., Hessel V.,Schouten J. C., Ind. Eng. Chem. Res., 2011, 51(2), 1015—1026 |

| [24] | He W., Fang Z., Chen K. T., Wang Z. D., Guo K., Chin. J. Appl. Chem., 2013, 30(12), 1375—1385 |

| (何伟, 方正, 陈克涛, 万志东, 郭凯. 应用化学, 2013, 30(12), 1375—1385) | |

| [25] | Rubio-Martinez M., Batten M. P., Polyzos A. Carey K., Mardel J. I., Lim K. S.,Hill M. R., Sci. Rep., 2014, 4, 5443 |

| [26] | Wang Y., Li L.J., Dai P. C., Yan L. T., Cao L., Gu X., Zhao X. B., J. Mater. Chem. A, 2017, 5(42), 22372—22379 |

| [27] | Liu H. F. Wang F. C., Wu T., Gong X., Yu Z. H., J. East China university Sci. Technol., 1999, 3, 227—232 |

| (刘海峰, 王辅臣, 吴韬, 龚欣, 于遵宏. 华东理工大学学报, 1999, 3, 227—232) | |

| [28] | Li M., Wang Y., Zhang N., Ren Z.L., Ma X. H., Li X. F., J. Dalian University Technol., 2016, 56(5), 441—446 |

| (李明, 王瑶, 张娜, 任郑玲, 马学虎, 李雪菲. 大连理工大学学报, 2016, 56(3), 441—446) | |

| [29] | Han Y. T., Liu M., Li K. Y., Zuo Y.,Xu S. T., Zhang G. L., Song C. S., Zhang Z. C., Guo X. W., Cryst. Eng. Comm., 2015, 17(33), 6434—6440 |

| [30] | Vanlenzano L., Civalleri B., Chavan S., Bodiga S., Nilsen M. H., Jakobsen S.,Lillerud K. P., Lamberti C., Chem. Mater., 2011, 23(7), 1700—1718 |

| [31] | Brar T., France P., Smirniotis P. G., Ind. Eng. Chem. Res., 2001, 40, 1133—1139 |

| [32] | Ju J.X., Zeng C. F., Zhang L. X., Xu N. P., Chem. Eng. J., 2006, 116, 115—121 |

| [33] | Ren Z.L., Lu C. Y., Wang A. J., Wang Y., CIESC J., 2017, 68(6), 2611—2617 |

| (任郑玲, 卢晨阳, 王安杰, 王瑶. 化工学报, 2017, 68(6), 2611—2617) | |

| [34] | Kim M.B., Kim K. M., Kim T. H., Yoon T. U., Kim E. J., Kim J. H., Bae Y. S., Chem. Eng. J., 2018, 339, 223—229 |

| [1] | 姜宏斌, 代文臣, 张娆, 徐晓晨, 陈捷, 杨光, 杨凤林. Co3O4/UiO-66@α-Al2O3陶瓷膜对VOCs废气的分离催化性能[J]. 高等学校化学学报, 2022, 43(6): 20220025. |

| [2] | 张小玉, 薛冬萍, 杜宇, 蒋粟, 魏一帆, 闫文付, 夏会聪, 张佳楠. MOF衍生碳基电催化剂限域催化O2还原和CO2还原反应[J]. 高等学校化学学报, 2022, 43(3): 20210689. |

| [3] | 李华, 杨科, 黄俊峰, 陈凤娟. UiO-66-NH2/wood的设计构筑及高效去除水中微量重金属离子性能[J]. 高等学校化学学报, 2022, 43(3): 20210701. |

| [4] | 章丽玲, 刘浏, 郑明秋, 方文凯, 刘达, 唐宏武. 基于上转换发光共振能量转移的CRISPR/Cas12a生物传感系统用于HPV16 DNA双信号检测[J]. 高等学校化学学报, 2022, 43(11): 20220412. |

| [5] | 王婕, 霍海燕, 王洋, 张仲, 刘术侠. 铜箔上原位合成NENU-n系列多酸基MOFs的通用策略[J]. 高等学校化学学报, 2022, 43(1): 20210557. |

| [6] | 柳雪广, 杨晓珊, 马菁菁, 刘伟生. 铕基金属有机框架材料从混合染料中选择性分离亚甲基蓝[J]. 高等学校化学学报, 2022, 43(1): 20210715. |

| [7] | 莫宗文, 张学文, 周浩龙, 周东东, 张杰鹏. 一种多孔配位聚合物的氢键协同客体响应[J]. 高等学校化学学报, 2022, 43(1): 20210576. |

| [8] | 李美燕, 陈紫娟, 汪淑华, 陈超. Zr-MOF空心纳米球固载离子液体对CO2环加成反应的催化性能[J]. 高等学校化学学报, 2021, 42(8): 2474. |

| [9] | 常书晴, 辛旭, 黄雅琦, 张信聪, 傅仰河, 朱伟东, 张富民, 李晓娜. Zr基金属有机框架材料的冷热驱动热释电催化性能[J]. 高等学校化学学报, 2021, 42(8): 2558. |

| [10] | 丁中振, 李天, 李长明, 赵宇飞, 宋宇飞. 水滑石基催化剂催化合成碳纳米材料的研究进展[J]. 高等学校化学学报, 2021, 42(6): 1622. |

| [11] | 王常耀, 王帅, 段林林, 朱晓航, 张兴淼, 李伟. 原位限域生长策略制备有序介孔碳负载的超小MoO3纳米颗粒[J]. 高等学校化学学报, 2021, 42(5): 1589. |

| [12] | 杨瑞琪, 于欣, 刘宏. 四氧化三锡基光催化纳米材料的研究进展[J]. 高等学校化学学报, 2021, 42(5): 1340. |

| [13] | 葛浩英, 杜健军, 龙飒然, 孙文, 樊江莉, 彭孝军. 功能化金纳米材料在肿瘤诊疗中的研究与应用[J]. 高等学校化学学报, 2021, 42(4): 1202. |

| [14] | 王隆杰, 范鸿川, 秦渝, 曹秋娥, 郑立炎. 金属有机框架材料在分离分析领域的研究进展[J]. 高等学校化学学报, 2021, 42(4): 1167. |

| [15] | 佘沛鸿, 徐文洲, 关卜源. 大孔道介孔氧化硅/碳基纳米材料的设计合成与应用[J]. 高等学校化学学报, 2021, 42(3): 671. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||