Chem. J. Chinese Universities ›› 2020, Vol. 41 ›› Issue (2): 349.doi: 10.7503/cjcu20190473

• Polymer Chemistry • Previous Articles Next Articles

YAN Ming,ZHOU Weidong,ZHANG Hong( ),SHI Junfeng,ZHAO Yunhe,YE Yongming,GUO Jing,YU Yue

),SHI Junfeng,ZHAO Yunhe,YE Yongming,GUO Jing,YU Yue

Received:2019-09-02

Online:2020-02-10

Published:2019-12-31

Contact:

Hong ZHANG

E-mail:zhang_hong1234@sina.com

Supported by:CLC Number:

TrendMD:

YAN Ming,ZHOU Weidong,ZHANG Hong,SHI Junfeng,ZHAO Yunhe,YE Yongming,GUO Jing,YU Yue. PVA Microcrystalline Cross-linking and SA/PAA Double Network Synergistic Modification of SA Fiber †[J]. Chem. J. Chinese Universities, 2020, 41(2): 349.

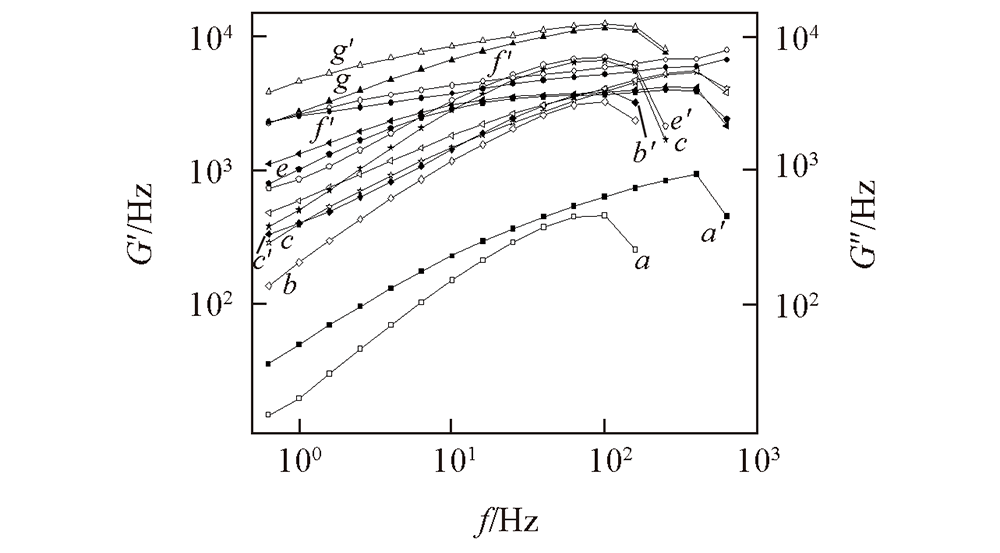

Fig.1 Characterization of rheological properties of SA/PAA/PVA blend solution a—g. Loss modulus; a'—g' storage modulus. a, a'. Regenerated SA; b, b'. SA/PAA/PVA, not frozen; c, c'. SA/PAA/PVA, already frozen; d, d'. SA/PAA/PVA, 0.25%MBA; e, e'. SA/PAA/PVA, 0.5%MBA; f, f'. SA/PAA/PVA, 0.75%MBA; g, g'. SA/PAA/PVA, 1%MBA.

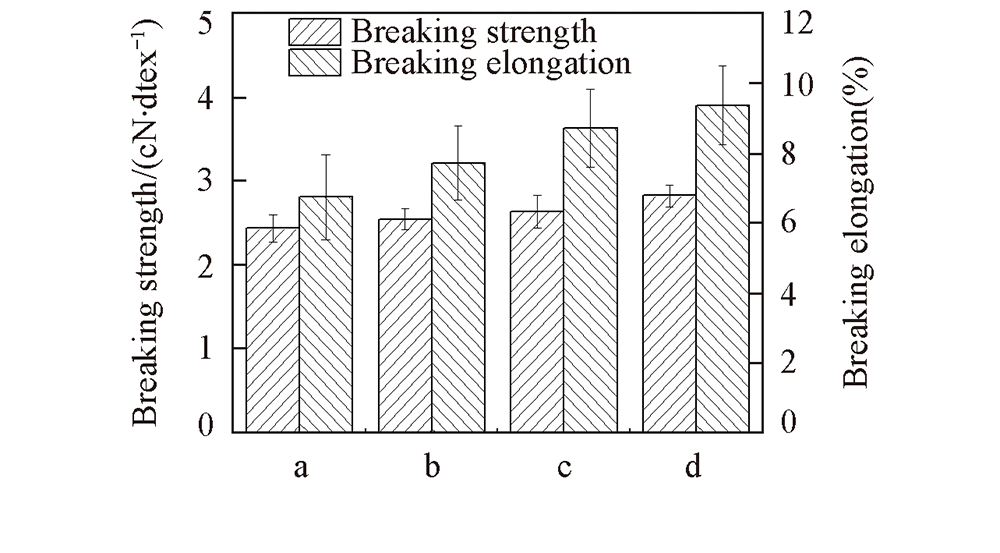

Fig.3 Mechanical properties of regenerated SA fiber and SA/PAA/PVA composite fibers treated under different conditions a. Regenerated SA; b. not frozen, SA/PAA/PVA; c. 0.25% MB and already frozen, SA/PAA/PVA; d. 0.5% MBA and already frozen, SA/PAA/PVA.

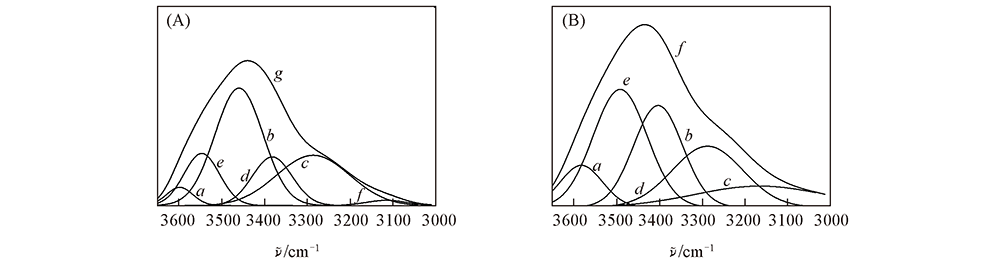

Fig.5 Fitted IR curves of regenerated SA fiber(A) and SA/PAA/PVA composite fiber(B) (A) a—f. Fitted curves 1—6; g. originaL curve. (B) a—e. Fitted curves 1—5; f. original curve.

| Sapmle | Type of hydrogen bond | Structural formula | Peak area | Relative Strength(%) | |

|---|---|---|---|---|---|

| Regenerated SA fiber | Free hydroxyl | —OH | 3599 | 1.55 | 3.5 |

| Intramolecular hydrogen bond | OH…OH | 3442 | 18.33 | 54.2 | |

| Four association | 3097 | 5.99 | |||

| Intermolecular hydrogen bond | OH…O(in ether) | 3266 | 12.10 | 42.3 | |

| OH…π | 3543 | 6.25 | |||

| OH…N | 3126 | 0.68 | |||

| SA/PAA/PVAComposite fiber | Free hydroxyl | —OH | 3582 | 5.21 | 8.9 |

| Intramolecular hydrogen bond | OH…OH | 3403 | 14.85 | 37.1 | |

| Four association | 3165 | 6.95 | |||

| Intermolecular hydrogen bond | OH…O(in ether) | 3287 | 12.80 | 54.0 | |

| OH…π | 3492 | 18.90 |

| Sapmle | Type of hydrogen bond | Structural formula | Peak area | Relative Strength(%) | |

|---|---|---|---|---|---|

| Regenerated SA fiber | Free hydroxyl | —OH | 3599 | 1.55 | 3.5 |

| Intramolecular hydrogen bond | OH…OH | 3442 | 18.33 | 54.2 | |

| Four association | 3097 | 5.99 | |||

| Intermolecular hydrogen bond | OH…O(in ether) | 3266 | 12.10 | 42.3 | |

| OH…π | 3543 | 6.25 | |||

| OH…N | 3126 | 0.68 | |||

| SA/PAA/PVAComposite fiber | Free hydroxyl | —OH | 3582 | 5.21 | 8.9 |

| Intramolecular hydrogen bond | OH…OH | 3403 | 14.85 | 37.1 | |

| Four association | 3165 | 6.95 | |||

| Intermolecular hydrogen bond | OH…O(in ether) | 3287 | 12.80 | 54.0 | |

| OH…π | 3492 | 18.90 |

| [1] |

Sarikaya E., Çallioglu H., Demirel H., Composites Part B: Engineering, 2019,167, 461— 466

doi: 10.1016/j.compositesb.2019.03.020 URL |

| [2] |

Sow L. C., Yu Toh N. Z., Wong C. W., Yang H., Food Hydrocolloids, 2019,94, 459— 467

doi: 10.1016/j.foodhyd.2019.03.041 URL |

| [3] |

Bai Y. Y., Lei Y. H., Shen X. J., Luo J., Yao C. L., Sun R. C., Carbohydrate Polymers, 2017,174, 610— 616

doi: 10.1016/j.carbpol.2017.06.091 URL |

| [4] |

Varaprasad K., Raghavendra G. M., Jayaramudu T., Seo J., Carbohydrate Polymers, 2016,135, 349— 355

doi: 10.1016/j.carbpol.2015.08.078 URL |

| [5] |

Wu N. J., Niu F. K., Lang W. C., Xia M. F., Carbohydrate Polymers, 2019,221, 221— 230

doi: 10.1016/j.carbpol.2019.06.007 URL |

| [6] |

Li X. L., Chen M. J., Chen H. B., Composites Part B: Engineering, 2019,164, 18— 25

doi: 10.1016/j.compositesb.2018.11.055 URL |

| [7] | Qin H. H., Fang X. X., Zhao X., Song F. J., You J. X., Industrial Textiles, 2018,36(4), 1— 6 |

| ( 秦洪花, 房学祥, 赵霞, 宋福杰, 尤金秀 . 产业用纺织品, 2018,36(4), 1— 6) | |

| [8] |

Zhang K., Zhu P., Sui S. Y., Dong C. H., Zhang X. Y., Wuhan University Journal of Natural Sciences, 2017,22(3), 197— 200

doi: 10.1007/s11859-017-1235-4 URL |

| [9] | Helmiyati, Aprilliza M ., IOP Conference Series Materials Science and Engineering, 2017,188(1), 1— 5 |

| [10] | You W. T., Dan W. H., Dan N. H., Liang Y. X., Liu B. W., Wen H. T., China Leather, 2017,4(8), 19— 24 |

| ( 尤伟婷, 但卫华, 但年华, 梁永贤, 刘博文, 温会涛 . 中国皮革, 2017,4(8), 19— 24) | |

| [11] | Ran Q., Liu X. P., Zhang C., Xiang X. L., Yunnan Chemical Technology, 2019,46(3), 127— 129 |

| ( 冉青, 刘信平, 张驰, 向戌连 . 云南化工, 2019,46(3), 127— 129) | |

| [12] |

Summa M., Russo D., Penna I., Margaroli N., Bayer I. S., Bandiera T., Athanassiou A., Bertorelli R., European Journal of Pharmaceutics and Biopharmaceutics, 2018,122, 17— 24

doi: 10.1016/j.ejpb.2017.10.004 URL |

| [13] |

Yuan N. N., Li S. J., Li G. Q., Journal of Drug Delivery Science and Technology, 2018,46, 348— 353

doi: 10.1016/j.jddst.2018.05.026 URL |

| [14] |

Yang M. L., Wang L., Xia Y. Z., International Journal of Biological Macromolecules, 2019,124, 1238— 1245

doi: 10.1016/j.ijbiomac.2018.12.012 URL |

| [15] |

Lacoste C., Hage R. E., Bergeret A., Corn S., Lacroix P., Carbohydrate Polymers, 2018,184, 1— 8

doi: 10.1016/j.carbpol.2017.12.019 URL |

| [16] |

Zou X. Q., Zhang H., Chen T., Li H. T., Meng C. H., Xia Y., Guo J., Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2019,567, 184— 192

doi: 10.1016/j.colsurfa.2018.12.019 URL |

| [17] |

Megan S., Chris R., Julien B., Johan F. E., Journal of Applied Polymer Science, 2018,135(7), 45857— 45866

doi: 10.1002/app.45857 URL |

| [18] |

Li X. F., Wang H., Li D. P., Long S. J., Zhang G. W., Wu Z. L., ACS Applied Materials & Interfaces, 2018,10(37), 31198— 31207

doi: 10.1021/acsami.8b13038 URL |

| [19] | Rao Z. L., Liu S. M., Wu R. Y., Wang G. L., Sun Z. X., Bai L. J., Wang W. X., Chen H., Yang H. W., Wei D. L., Niu Y. Z., International Journal of Biological Macromolecules, DOI: 10.1016/j.ijbiomac, 2019,129 916— 926 |

| [20] |

Gong J. P., Katsuyama Y., Kurokawa T., Osada Y., Advanced Materials, 2003,15(14), 1155— 1158

doi: 10.1002/adma.200304907 URL |

| [21] | Sun T. W., Yang R. H., Ma C. W., Liang Z., Acta Universitatis Medicinalis Anhui, 2018,53(7), 1139— 1142 |

| ( 孙天文, 杨润怀, 马长望, 梁振 . 安徽医科大学学报, 2018,53(7), 1139— 1142) | |

| [22] |

Bahrami Z., Akbari A., Eftekhari-Sis B ., International Journal of Biological Macromolecules, 2019,129, 187— 197

doi: 10.1016/j.ijbiomac.2019.02.046 URL |

| [23] | Yang M. L., Shi Y. L., Yu Z. H., Liu J. W., Bai Y. X., Shi J. S., Food Science and Technology, 2019,44(4), 274— 280 |

| ( 杨曼丽, 石云龙, 于志浩, 刘佳伟, 白映雪, 师进生 . 食品科技, 2019,44(4), 274— 280) | |

| [24] | Zhu G. F., Zhang H., Li H. T., Chen T., Yu Y., Guo J., Acta Materiae Compositae Sinica, 2017,34(11), 2571— 2579 |

| ( 祝国富, 张鸿, 李会涛, 陈涛, 于跃, 郭静 . 复合材料学报, 2017,34(11), 2571— 2579) | |

| [25] | Zhang Y ., Study on Rheological Properties of Carbon Nanotubes/Sodium Alginate Solution and Preparation of Composite Fibers, Qingdao University, Qingdao, 2013 |

| ( 张杨 . 碳纳米管/海藻酸钠溶液流变性能的研究及复合纤维的制备, 青岛: 青岛大学, 2013) | |

| [26] | Tuo C., Morden Salt Science & Technology, 2017,44(3), 1— 2) |

| ( 庹超 . 现代盐化工, 2017,44(3), 1— 2) | |

| [27] |

Lei Z. Y., Wang Q. K., Sun S. T., Zhu W. C., Wu P. Y., Advanced Materials, 2017,29, 1700321— 1700326

doi: 10.1002/adma.v29.22 URL |

| [28] | Jiang Y. P., Yang T., Fei G. X., Xia H. S., Polymer Materials Science & Engineering, 2018,34(7), 150— 155 |

| ( 蒋瑶珮, 杨涛, 费国霞, 夏和生 . 高分子材料科学与工程, 2018,34(7), 150— 155) | |

| [29] | Guo Y., Wang X. H., Xie H. Y., Journal of Xinjiang Agricultural University, 2017,40(3), 198— 203 |

| ( 郭渊, 王晓焕, 谢海燕 . 新疆农业大学学报, 2017,40(3), 198— 203) | |

| [30] | Gao D. G., Zang Y. H., Lv B., Ma J. Z., Fine Chemicals, 2018,35(2), 298— 302 |

| ( 高党鸽, 张亚红, 吕斌, 马建中 . 精细化工, 2018,35(2), 298— 302) | |

| [31] | Wang Z., Wang Y., Liu G., Dong W. F., Plastic, 2017,46(6), 17— 19 |

| ( 王竹, 汪洋, 刘耘, 东为富 . 塑料, 2017,46(6), 17— 19) | |

| [32] | Wang Z. L., Xing S. L., Yin C. P., Yang J. S., Engineering Plastics Application, 2018,46(8), 131— 137 |

| ( 王子龙, 邢素丽, 尹昌平, 杨金水 . 工程塑料应用, 2018,46(8), 131— 137) |

| [1] | YANG Zhaohua, CHENG Hongjing, YANG Yi, LIU Hui, DU Feipeng, ZHANG Yunfei. Preparation of Silver-loaded Polyvinyl Alcohol Sponge and Its Interfacial Photothermal Driven Water Evaporation Performance [J]. Chem. J. Chinese Universities, 2022, 43(10): 20220181. |

| [2] | NI Qingsheng, DU Miao, SHAN Guorong, SONG Yihu, WU Ziliang, ZHENG Qiang. Regulation of Rheological Behavior of Polyvinyl Alcohol Aqueous Solution by One-dimensional Particles [J]. Chem. J. Chinese Universities, 2021, 42(12): 3738. |

| [3] | WANG Mingxia, LIU Zhihui, ZHU Zhen, LI Lingfeng, WANG Bowei. Preparation and Properties of Nano Lithium Magnesium Silicate-chitosan-sodium Alginate Composite Scaffold Materials [J]. Chem. J. Chinese Universities, 2021, 42(10): 3240. |

| [4] | WANG Bowei, MA Rui, WU Fan, LIU Zhihui, LI Lingfeng, ZHANG Xiao, LIU Dingkun, YANG Nan, LI Meihui, YANG Defeng, SUN Qi. Preparation and Characterization of Graphene Oxide-sodium Alginate-chitosan Composite Scaffold [J]. Chem. J. Chinese Universities, 2020, 41(9): 2099. |

| [5] | GONG Yuning, WANG Qi, WANG Honglei, GUAN Shuang. Preparation and Properties of Polyvinye Alconol/Polyvinylpyrrolidone/Iodine Composite Hydrogels [J]. Chem. J. Chinese Universities, 2020, 41(9): 2078. |

| [6] | SUN Mengying,Lü Jingchun,XU Hong,ZHANG Linping,ZHONG Yi,CHEN Zhize,SUI Xiaofeng,MAO Zhiping. Synthesis and Electrochromic Performance of Phosphazene-viologen Polymer † [J]. Chem. J. Chinese Universities, 2020, 41(6): 1399. |

| [7] | Yujie LI,Yong LIU,Qizhi ZHAO,Chunman ZHENG. Study on Improving Storage Life of Lithium Ion Batteries Based on Construction of Polymer Functional Protective Film on the Surface of Graphite Anode † [J]. Chem. J. Chinese Universities, 2019, 40(12): 2542. |

| [8] | WANG Qiuxian,LI Kai,YANG Beining,YUE Hongyun,YANG Shuting. Sodium Alginate Directed Synthesis of ZnFe2O4 with Micro-nano Structure and Its Performance in Lithium Ion Batteries† [J]. Chem. J. Chinese Universities, 2018, 39(9): 2039. |

| [9] | LIU Zhihui,QIU Tianyuan,DU Liuyi,YANG Junxing,LIU Kang,WANG Bowei. Preparation and Characterization of Chitosan Alginate Plastic Scaffolds† [J]. Chem. J. Chinese Universities, 2018, 39(5): 1105. |

| [10] | LONG Shijun,CHEN Mingmin,ZHAO Youjiao,WANG Xiaotao,LI Xuefeng,LIAO Yonggui. Regulation of Gemini Surfactant on Photochromic Behavior of PVA Dispersed Spiropyran Organogel Thin Film† [J]. Chem. J. Chinese Universities, 2018, 39(5): 1078. |

| [11] | WU Jing, GUO Jing, ZHANG Sen, GONG Yumei, ZHANG Hong. Correlativity of Characterization for Sodium Alginate/Antarctic Krill Protein by Salt Concentration† [J]. Chem. J. Chinese Universities, 2017, 38(9): 1701. |

| [12] | SHI Zhanping, SHI Mai, ZHANG Wenhui, SHEN Shigang, YUE Zhilian, YANG Hui, DING Liang, PAN Xuefeng. Preparation, Characterization and Toxicological Analysis of Alginate-phospholipid Vesicle Composite Hydrogels† [J]. Chem. J. Chinese Universities, 2017, 38(7): 1270. |

| [13] | YANG Meiyue, WANG Wei, TIAN Zhiqing, LI Yingying, YUAN Zhi. Preparation of Glycyrrhetinic Acid-modified Sodium Alginate Microgel Spheres for 3D Cell Culture† [J]. Chem. J. Chinese Universities, 2017, 38(2): 326. |

| [14] | LI Zhigang, ZHANG Yixuan, ZHANG Qingsong, MA Youwei, HU Tao, BAI Haihui, LIU Pengfei, WANG Ke, ZHANG Xiaoyong. Adsorption Kinetics/Thermodynamic Behavior and Adsorption/Desorption Mechanism of Crystal Violet by Semi-interpenetrating Sodium Alginate/Polyacrylamide Hydrogel† [J]. Chem. J. Chinese Universities, 2017, 38(11): 2118. |

| [15] | YANG Ziwei, ZHOU Shunli, WANG Rui, WANG Feng, JIANG Yan, ZHANG Xiuqin. Preparation and Characterization of Self-cleaning Cotton Fabric† [J]. Chem. J. Chinese Universities, 2017, 38(10): 1880. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||