Chem. J. Chinese Universities ›› 2018, Vol. 39 ›› Issue (9): 2089.doi: 10.7503/cjcu20180006

• Polymer Chemistry • Previous Articles Next Articles

HAN Jiahui, HUANG Hanxiong*( ), HUANG Yuxiao

), HUANG Yuxiao

Received:2018-01-03

Online:2018-07-30

Published:2018-07-30

Contact:

HUANG Hanxiong

E-mail:mmhuang@scut.edu.cn

Supported by:TrendMD:

HAN Jiahui,HUANG Hanxiong,HUANG Yuxiao. Improving Crystallization Behavior and Melt Strength of Poly(lactic acid) via Adding Talc and PLA-g-MAH†[J]. Chem. J. Chinese Universities, 2018, 39(9): 2089.

| Sample | w(PLA)(%) | w(Talc)(%) | w(PLA-g-MAH)(%) |

|---|---|---|---|

| PLA | 100 | 0 | 0 |

| PLA/T5 | 95 | 5 | 0 |

| PLA/T10 | 90 | 10 | 0 |

| PLA/T20 | 80 | 20 | 0 |

| PLA/T20/M5 | 75 | 20 | 5 |

| PLA/T20/M10 | 70 | 20 | 10 |

Table 1 Mass fraction of samples

| Sample | w(PLA)(%) | w(Talc)(%) | w(PLA-g-MAH)(%) |

|---|---|---|---|

| PLA | 100 | 0 | 0 |

| PLA/T5 | 95 | 5 | 0 |

| PLA/T10 | 90 | 10 | 0 |

| PLA/T20 | 80 | 20 | 0 |

| PLA/T20/M5 | 75 | 20 | 5 |

| PLA/T20/M10 | 70 | 20 | 10 |

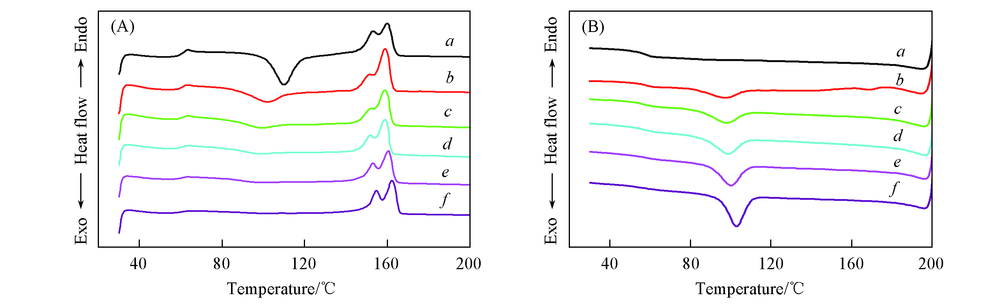

Fig.4 DSC curves of PLA and PLA/talc composite samples (A) Second heating scans; (B) cooling scans. a. PLA; b. PLA/T5; c. PLA/T10; d. PLA/T20; e. PLA/T20/M5; f. PLA/T20/M10.

| Sample | Tg/℃ | Tcc/℃ | Xcc(%) | Tm1/℃ | Tm2/℃ | Xc(%) |

|---|---|---|---|---|---|---|

| PLA | 59.6 | 109.8 | 27.9 | 152.9 | 159.7 | — |

| PLA/T5 | 60.0 | 101.7 | 15.0 | 151.5 | 158.7 | 15.2 |

| PLA/T10 | 59.8 | 99.1 | 7.6 | 152.2 | 158.7 | 19.8 |

| PLA/T20 | 59.8 | 96.6 | 4.5 | 151.7 | 158.7 | 25.1 |

| PLA/T20/M5 | 59.6 | 96.5 | 2.8 | 152.9 | 160.3 | 27.2 |

| PLA/T20/M10 | 59.8 | — | — | 154.4 | 162.1 | 31.6 |

Table 2 Thermal analysis data for PLA and PLA/talc composite samples

| Sample | Tg/℃ | Tcc/℃ | Xcc(%) | Tm1/℃ | Tm2/℃ | Xc(%) |

|---|---|---|---|---|---|---|

| PLA | 59.6 | 109.8 | 27.9 | 152.9 | 159.7 | — |

| PLA/T5 | 60.0 | 101.7 | 15.0 | 151.5 | 158.7 | 15.2 |

| PLA/T10 | 59.8 | 99.1 | 7.6 | 152.2 | 158.7 | 19.8 |

| PLA/T20 | 59.8 | 96.6 | 4.5 | 151.7 | 158.7 | 25.1 |

| PLA/T20/M5 | 59.6 | 96.5 | 2.8 | 152.9 | 160.3 | 27.2 |

| PLA/T20/M10 | 59.8 | — | — | 154.4 | 162.1 | 31.6 |

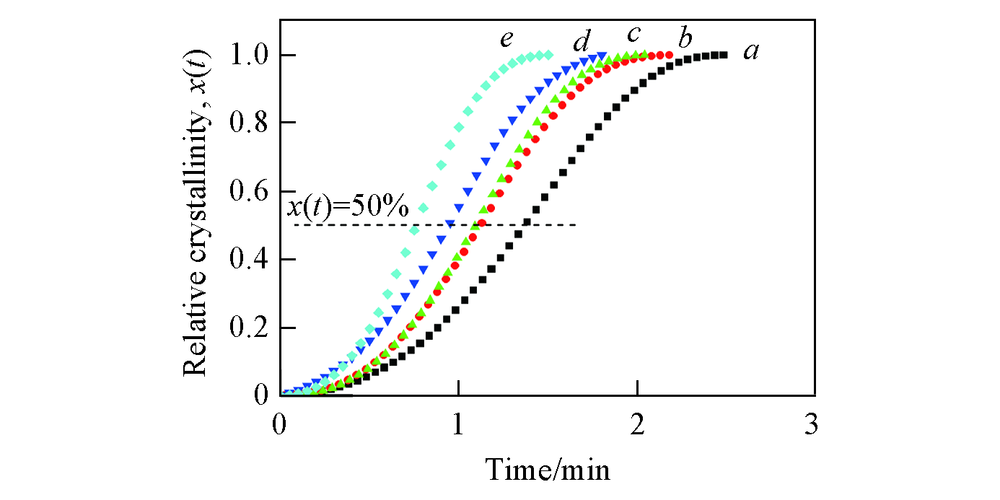

Fig.5 Relative crystallinity versus crystallization time curves for PLA/talc composite samples a. PLA/T5; b. PLA/T10; c. PLA/T20; d. PLA/T20/M5; e. PLA/T20/M10.

| Sample | t1/2/min | n | K/mi | Kc/mi |

|---|---|---|---|---|

| PLA/T5 | 1.38 | 2.60 | 0.3217 | 0.8928 |

| PLA/T10 | 1.13 | 2.64 | 0.5284 | 0.9382 |

| PLA/T20 | 1.09 | 2.76 | 0.5672 | 0.9449 |

| PLA/T20/M5 | 0.92 | 2.37 | 0.8831 | 0.9876 |

| PLA/T20/M10 | 0.76 | 2.67 | 1.4421 | 1.0373 |

Table 3 Crystallization half-time(t1/2) and Jeziorny-modified-Avrami crystallization kinetic parameters for PLA/talc composite samples

| Sample | t1/2/min | n | K/mi | Kc/mi |

|---|---|---|---|---|

| PLA/T5 | 1.38 | 2.60 | 0.3217 | 0.8928 |

| PLA/T10 | 1.13 | 2.64 | 0.5284 | 0.9382 |

| PLA/T20 | 1.09 | 2.76 | 0.5672 | 0.9449 |

| PLA/T20/M5 | 0.92 | 2.37 | 0.8831 | 0.9876 |

| PLA/T20/M10 | 0.76 | 2.67 | 1.4421 | 1.0373 |

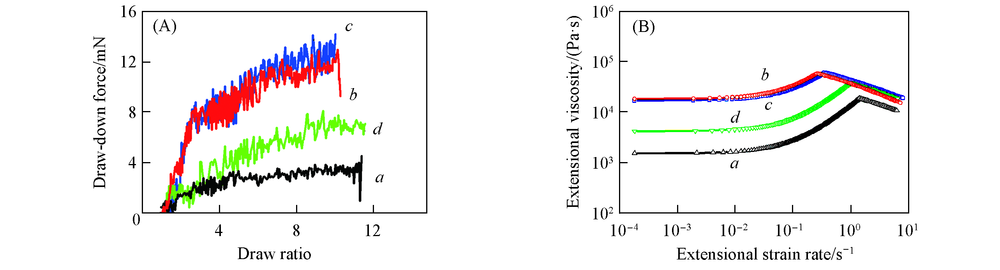

Fig.7 Draw-down force versus draw ratio(A) and extensional viscosity versus extensional strain rate curves(B) for PLA and PLA/talc composite samples a. PLA; b. PLA/T20; c. PLA/T20/M5; d. PLA/T20/M10.

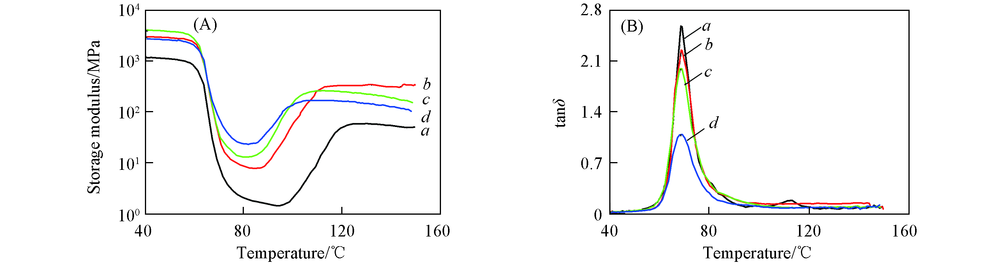

Fig.8 Storage modulus(A) and tanδ versus temperature curves(B) for PLA and PLA/talc composite samples a. PLA; b. PLA/T20; c. PLA/T20/M5; d. PLA/T20/M10.

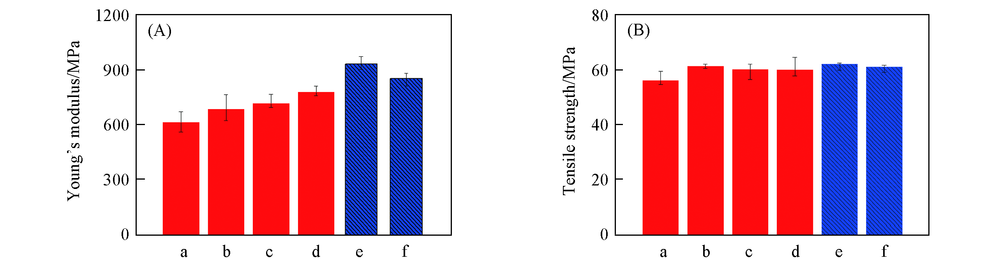

Fig.9 Young’s moduli(A) and tensile strengths(B) of PLA and PLA/talc composite samples a. PLA; b. PLA/T5; c. PLA/T10; d. PLA/T20; e. PLA/T20/M5; f. PLA/T20/M10.

| [1] | Drumright R. E., Gruber P. R., Henton D. E., Adv. Mater., 2000, 12(23), 1841—1846 |

| [2] | Li G. L., Huang J. J., Zhuang H. H., Yuan Z. S., Shao C. G., Ying J., Wang Y. M., Cao W., Liu C. T., Shen C. Y., Chem. J. Chinese Universities, 2017, 38(9), 1663—1669 |

| (李桂丽, 黄静静, 张欢欢, 袁朝圣, 邵春光, 应进, 王亚明, 曹伟, 刘春太, 申长雨. 高等学校化学学报, 2017, 38(9), 1663—1669) | |

| [3] | Li Y. J., Shimizu. H., Macromol. Biosci., 2007, 7(7), 921—928 |

| [4] | Han J. J., Huang H. X., J. Appl. Polym. Sci., 2011, 120(6), 3217—3223 |

| [5] | Zhao F., Huang H. X., Zhang S. D., J. Appl. Polym. Sci., 2015, 132(48), doi/10.1002/app.42511 |

| [6] | Xiong Z. J., Zhang X. Q., Liu G. M., Zhao Y., Wang R., Wang D. J., Chem. J. Chinese Universities, 2013, 34(5), 1288—1294 |

| (熊祖江, 张秀芹, 刘国明, 赵莹, 王锐, 王笃金. 高等学校化学学报, 2013, 34(5), 1288—1294) | |

| [7] | Wang Y. Y., Song Y. M., Du J., Xi Z. H., Wang Q. W., Materials, 2017, 10(9), doi/org/10.3390/ma10090999 |

| [8] | Zhou M., Zhou P., Xiong P., Qian X., Zheng H.H., Macromol. Res., 2015, 23(3), 231—236 |

| [9] | Lai X. L., Yang W., Wang Z., Shi D. W., Liu Z. Y., Yang M. B., J. Appl. Polym. Sci., 2018, 135, doi/10.1002/app.45675 |

| [10] | Nofar M., Mater. Design., 2016, 101, 24—34 |

| [11] | Jain S., Misra M., Mohanty A K., Ghosh A. K., J. Polym. Environ., 2012, 20(4), 1027—1037 |

| [12] | Shakoor A., Thomas N.L., Polym. Eng. Sci., 2014, 54(1), 64—70 |

| [13] | Kaynak C., Erdogan A.R., Polym. Adv. Technol., 2015, 27(6), 812—822 |

| [14] | Zhang S. D., Huang H. X., Jiang G., Polym. Renew. Resour., 2013, 4(4), 153—168 |

| [15] | Zhu R., Liu H. Z., Zhang J. W., Ind. Eng. Chem. Res., 2012, 51(22), 7786—7792 |

| [16] | Kaynak C., Meyva Y., Polym. Adv. Technol., 2015, 25(12), 1622—1632 |

| [17] | Ouchiar S., Stoclet G., Cabaret C., Georges E., Smith A., Martias C., Addad A., Gloaguen V., Appl. Clay. Sci., 2015, 116/117, 231—240 |

| [18] | Jiang G., Huang H. X., Chen Z. K., Polym. Plast. Technol., 2011, 50(10), 1035—1039 |

| [19] | Fowlks A. C., Narayan R., J. Appl. Polym. Sci., 2010, 118(5), 2810—2820 |

| [20] | Barletta M., Pizzi E., Puopolo M., Vesco S., Daneshvar-Fatah F., J. Appl. Polym. Sci., 2017, 134(32), doi/10.1002/app.45179 |

| [21] | Hua C., Chen F., Wang H., Liu Z., Yang W., Yang M., Acta Polym. Sin., 2016, (8), 1136—1144 |

| (华笋, 陈风, 王捍卿, 刘正英, 杨伟, 杨鸣波. 高分子学报, 2016, (8), 1136—1144) | |

| [22] | Yu T., Jiang N., Li Y.,Compos. Part A: Appl. S., 2014, 64(21), 139—146 |

| [23] | Li M., Hu D., Wang Y. M., Shen C. Y., Polym. Eng. Sci., 2010, 50(12), 2298—2305 |

| [24] | Mo Z.S., Acta Polym. Sin., 2008, (7), 656—661 |

| (莫志深. 高分子学报, 2008, (7), 656—661) | |

| [25] | Kawai T., Rahman N., Matsuba G., Nishida K., Kanaya T., Nakano M., Okamoto H., Kawada J., Usuki A., Honma N., Nakajima K., Matsuda M., Macromolecules, 2007, 40, 9463—9469 |

| [26] | Xu L. Q., Huang H. X., Ind. Eng. Chem. Res., 2014, 53(6), 2277—2286 |

| [27] | Shao W. G., Wang Q., Li K. S., Polym. Eng. Sci., 2005, 45(4), 451—457 |

| [28] | Wagner M. H., Bernnat A., Schulze V., J. Rheol., 1997, 42(4), 917—928 |

| [29] | Botta L., Scaffaro R., Mantia F. P. L., Dintcheva N. T., J. Polym. Sci. Polym. Phys., 2010, 48, 344—355 |

| [30] | Bangarusampath D. S., Ruckdaschel H., Altstadt V., Sandler J. K. W., Garray D., Shaffer M. S. P., Polymer, 2009, 50, 5803—5811 |

| [31] | Wang Q. J., Huang H. X., Polym. Test., 2013, 32, 1400—1407 |

| [32] | Singh V. P., Vimal K. K., Kapur G. S., Sharma S., Choudhary V., J. Polym. Res., 2016, 23(43), 1—17 |

| [33] | Lee S. H., Cho E., Youn R. J., J. Appl. Polym. Sci., 2006, 103, 3506—3515 |

| [1] | LIU Shuwei, JIN Hao, YIN Wanzhong, ZHANG Hao. Gemcitabine/polypyrrole Composite Nanoparticles for Chemo-photothermal Combination Ovarian Cancer Therapy [J]. Chem. J. Chinese Universities, 2022, 43(8): 20220345. |

| [2] | ZHAO Sheng, HUO Zhipeng, ZHONG Guoqiang, ZHANG Hong, HU Liqun. Preparation of Modified Gadolinium/Boron/Polyethylene Nanocomposite and Its Radiation Shielding Performance for Neutron and Gamma-ray [J]. Chem. J. Chinese Universities, 2022, 43(6): 20220039. |

| [3] | YU Pengdong, GUAN Xinghua, WANG Dongdong, XIN Zhirong, SHI Qiang, YIN Jinghua. Preparation and Properties of Novel Optical and Thermal Dual Response Shape Memory Polymers [J]. Chem. J. Chinese Universities, 2022, 43(6): 20220085. |

| [4] | ZHAO Junyu, WANG Chunbo, WANG Chengyang, ZHANG Ke, CONG Bing, YANG Lan, ZHAO Xiaogang, CHEN Chunhai. Preparation and Performance of Thermally Conductive Expanded Graphite/Polyetherimide Composites [J]. Chem. J. Chinese Universities, 2022, 43(4): 20210800. |

| [5] | GAO Jing, HE Wentao, WANG Xinxin, XIANG Yushu, LONG Lijuan, QIN Shuhao. Preparation of DOPO Derivative Modified Carbon Nanotubes and Their Effect on Flame Retardancy of Polylactic Acid [J]. Chem. J. Chinese Universities, 2022, 43(3): 20210670. |

| [6] | CHU Yao, WANG Shuo, ZHANG Zinuo, WANG Yibo, CAI Yibing. Preparation and Properties of Cu Particles Loaded Foam-based Phase Change Composites [J]. Chem. J. Chinese Universities, 2022, 43(2): 20210619. |

| [7] | ZHOU Ning, TANG Xiaohua, CAO Hong, ZHA Fei, LI Chun, XIE Chunyan, XU Mingping, SUN Yige. Preparation, Characterization and Degradation to BPA of Pomegranate-like Gel Microsphere Entrapmented Laccase [J]. Chem. J. Chinese Universities, 2022, 43(2): 20210705. |

| [8] | ZHAO Mengyang, HUANG Ziyang. Preparation and in vitro Bioactivity of HA/CuO/SrCO3 Gradiently Composite Coating [J]. Chem. J. Chinese Universities, 2022, 43(2): 20210644. |

| [9] | XU Huan, KE Lyu, TANG Mengke, SHANG Han, XU Wenxuan, ZHANG Zilin, FU Yanan, HAN Guangdong, CUI Jinsheng, YANG Haoran, GAO Jiefeng, ZHANG Shenghui, HE Xinjian. In⁃situ Liquid Exfoliation of Montmorillonite Nanosheets in Poly(lactic acid) to Resist Oxygen Permeation [J]. Chem. J. Chinese Universities, 2022, 43(11): 20220316. |

| [10] | LI Shurong, WANG Lin, CHEN Yuzhen, JIANG Hailong. Research Progress of Metal⁃organic Frameworks on Liquid Phase Catalytic Chemical Hydrogen Production [J]. Chem. J. Chinese Universities, 2022, 43(1): 20210575. |

| [11] | ZHANG Chi, SUN Fuxing, ZHU Guangshan. Synthesis, N2 Adsorption and Mixed-matrix Membrane Performance of Bimetal Isostructural CAU-21 [J]. Chem. J. Chinese Universities, 2022, 43(1): 20210578. |

| [12] | LI Zhanfeng, LIU Benxue, LIU Xiaochan, WANG Xinqiang, ZHANG Jing, YU Shimo, ZHAO Xinfu, ZHANG Xin’en, YI Xibin. Mechanism of the Removal of Acetylacetone Ligands in Zirconia Wet Gel and Fabrication of Zirconia Aerogel Composites [J]. Chem. J. Chinese Universities, 2021, 42(9): 2904. |

| [13] | XU Xiaolong, FANG Lining, LIU Changyu, LIU Minchao, JIA Jianbo. Preparation of Z-type g-C3N4/Pt/TiO2 Nanotube Array Composite Electrode and Its Performance of Photoelectric Oxidation of Methanol [J]. Chem. J. Chinese Universities, 2021, 42(9): 2926. |

| [14] | ZHAO Lingyun, HUANG Hanxiong, LUO Duyu, SU Fengchun. Effect of Flexibility of Composites on Performances of Sensors with Micro-structured Inverted Pyramid Arrays [J]. Chem. J. Chinese Universities, 2021, 42(9): 2953. |

| [15] | GAO Xiaole, WANG Jiaxin, LI Zhifang, LI Yanchun, YANG Donghua. Synthesis of NiOx-ZSM-5 Composite Materials and Its Electrocatalytic Hydrogen Evolution Performance in Microbial Electrolysis Cell [J]. Chem. J. Chinese Universities, 2021, 42(9): 2886. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||