高等学校化学学报 ›› 2024, Vol. 45 ›› Issue (12): 20240323.doi: 10.7503/cjcu20240323

收稿日期:2024-07-01

出版日期:2024-12-10

发布日期:2024-10-11

通讯作者:

何文涛

E-mail:wentaohe@aliyun.com

基金资助:

SHI Lingrui, WU Xiaoyu, CAO Hailiang, HE Wentao( )

)

Received:2024-07-01

Online:2024-12-10

Published:2024-10-11

Contact:

HE Wentao

E-mail:wentaohe@aliyun.com

Supported by:摘要:

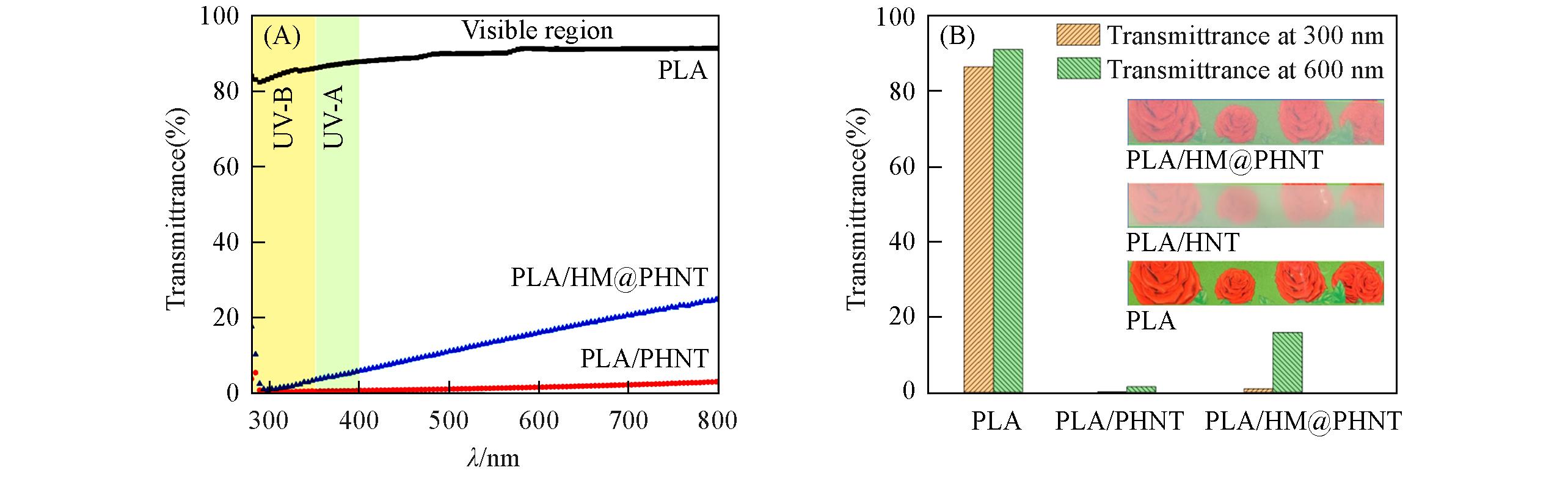

通过苯基磷酸插层和环磷腈网络包覆有机改性埃洛石, 制备了磷氮改性埃洛石纳米管(HM@PHNT), 系统研究了HM@PHNT作为多功能助剂对聚乳酸(PLA)热稳定性、 结晶行为、 阻燃性能、 力学性能及紫外屏蔽性能的影响. 研究结果表明, 添加5%(质量分数)的HM@PHNT, PLA的结晶度从7.7%显著增加到21.2%, 拉伸强度和断裂伸长率均得到一定的改善. 阻燃性能测试结果表明, 5%(质量分数)HM@PHNT的引入使PLA的热释放速率峰值和总热释放量分别由510.1 kW/m2和72.5 MJ/m2降低到472.3 kW/m2和67.5 MJ/m2. 阻燃机理分析表明HM@PHNT降解产生的P-N结构和HNT促进了炭层的形成, 从而降低了材料的热释放. 此外, PLA复合材料的紫外屏蔽性能显著提高, 在300 nm处的透过率由83.2%降低到1.0%.

中图分类号:

TrendMD:

石灵睿, 吴小雨, 曹海良, 何文涛. 磷氮改性埃洛石纳米管的制备及对聚乳酸阻燃、 力学及紫外屏蔽性能的影响. 高等学校化学学报, 2024, 45(12): 20240323.

SHI Lingrui, WU Xiaoyu, CAO Hailiang, HE Wentao. Preparation of Phosphorus and Nitrogen Modified Halloysite Nanotube and Its Effects on the Flame Retardant, Mechanical and Ultroviolet Shielding Properties of Polylactic Acid. Chem. J. Chinese Universities, 2024, 45(12): 20240323.

| Sample | Si(%) | Al(%) | C(%) | O(%) | P(%) | N(%) |

|---|---|---|---|---|---|---|

| HNT | 16.71 | 13.73 | 8.42 | 61.14 | — | — |

| PHNT | 4.03 | 7.01 | 46.68 | 33.80 | 8.48 | — |

| HM@PHNT | 6.45 | 4.87 | 34.05 | 40.69 | 6.86 | 7.08 |

Table 1 Atomic fraction(%) of Si, Al, C, O, P and N from the XPS spectra of HNT, PHNT and HM@PHNT

| Sample | Si(%) | Al(%) | C(%) | O(%) | P(%) | N(%) |

|---|---|---|---|---|---|---|

| HNT | 16.71 | 13.73 | 8.42 | 61.14 | — | — |

| PHNT | 4.03 | 7.01 | 46.68 | 33.80 | 8.48 | — |

| HM@PHNT | 6.45 | 4.87 | 34.05 | 40.69 | 6.86 | 7.08 |

| Sample | Tg/℃ | Tc /℃ | Tm1/℃ | Tm2/℃ | Hcc/(J∙g-1) | Hm/(J∙g-1) | Xc(%) |

|---|---|---|---|---|---|---|---|

| PLA | 62.1 | — | 160.1 | — | 0 | 7.2 | 7.7 |

| PLA/PHNT | 62.8 | 101.8 | 156.3 | 161.2 | 7.8 | 29.5 | 23.2 |

| PLA/HM@PHNT | 63.0 | 97.3 | 153.7 | 160.8 | 15.5 | 35.3 | 21.2 |

Table 2 Results from the DSC curves of PLA and PLA composites

| Sample | Tg/℃ | Tc /℃ | Tm1/℃ | Tm2/℃ | Hcc/(J∙g-1) | Hm/(J∙g-1) | Xc(%) |

|---|---|---|---|---|---|---|---|

| PLA | 62.1 | — | 160.1 | — | 0 | 7.2 | 7.7 |

| PLA/PHNT | 62.8 | 101.8 | 156.3 | 161.2 | 7.8 | 29.5 | 23.2 |

| PLA/HM@PHNT | 63.0 | 97.3 | 153.7 | 160.8 | 15.5 | 35.3 | 21.2 |

| Sample | TTI/s | PHRR/ (kW∙m-2) | THR/ (MJ∙m-2) | EHC/ (MJ∙kg-1) | Mean CO yield/(kg∙kg-1) | Mean CO2 yield/(kg∙kg-1) | Mass fraction of residue(%) |

|---|---|---|---|---|---|---|---|

| PLA | 55 | 510.1 | 72.5 | 21.3 | 0.0719 | 6.0138 | 0.6 |

| PLA/PHNT | 57 | 502.4 | 73.1 | 21.7 | 0.0683 | 5.5019 | 4.9 |

| PLA/HM@PHNT | 51 | 472.3 | 67.5 | 20.0 | 1.6436 | 4.1953 | 8.1 |

Table 3 Results from CCT of PLA, PLA/PHNT and PLA/HM@PHNT

| Sample | TTI/s | PHRR/ (kW∙m-2) | THR/ (MJ∙m-2) | EHC/ (MJ∙kg-1) | Mean CO yield/(kg∙kg-1) | Mean CO2 yield/(kg∙kg-1) | Mass fraction of residue(%) |

|---|---|---|---|---|---|---|---|

| PLA | 55 | 510.1 | 72.5 | 21.3 | 0.0719 | 6.0138 | 0.6 |

| PLA/PHNT | 57 | 502.4 | 73.1 | 21.7 | 0.0683 | 5.5019 | 4.9 |

| PLA/HM@PHNT | 51 | 472.3 | 67.5 | 20.0 | 1.6436 | 4.1953 | 8.1 |

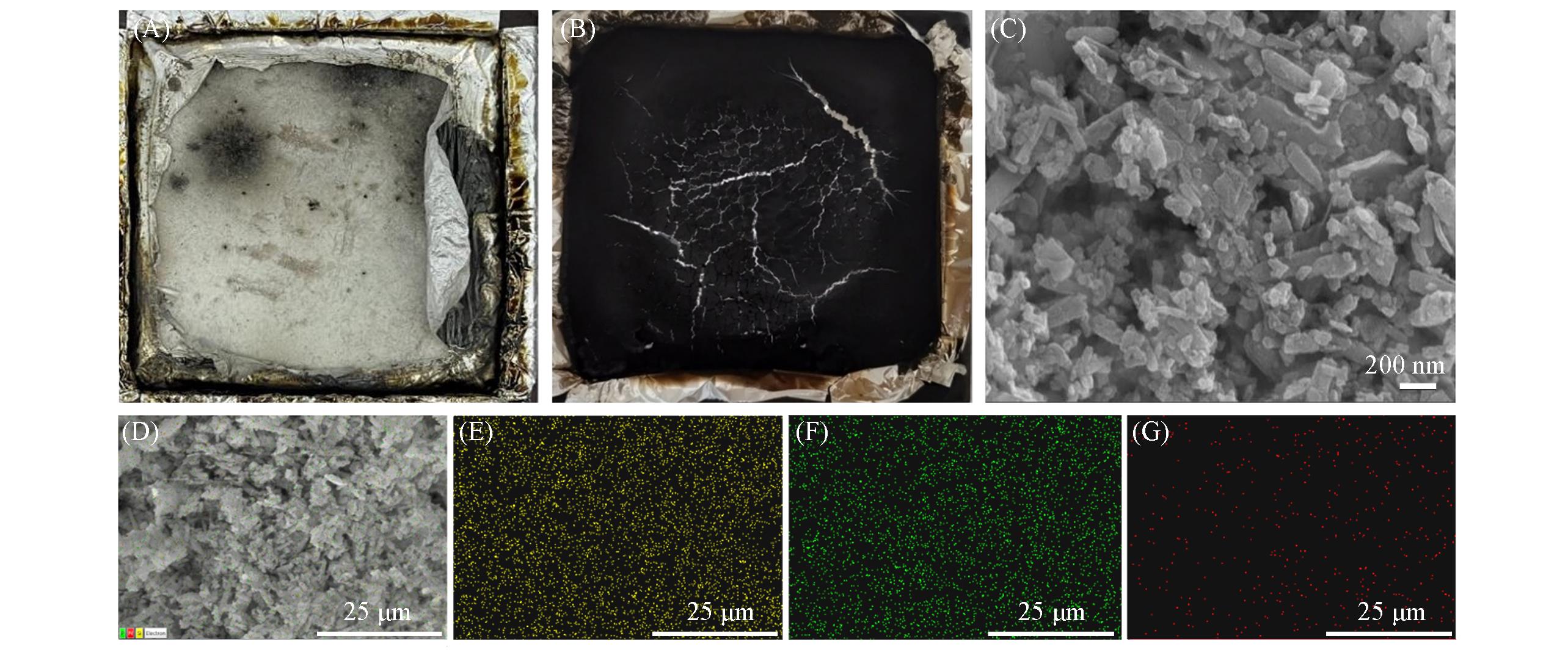

Fig.6 Digital photos(A, B) and external surface FESEM images(C) of the char residues after the CCT of PLA(A) and PLA/HM@PNHNT(B, C) and the EDS mapping(D) and the corresponding Si(E), P(F) and N(G) mapping of the char residues from PLA/HM@PHNT

Fig.10 UV⁃Vis transmittance(A) and bar graphs of the transmittance values at 300 and 600 nm(B) of PLA, PLA/PHNT and PLA/HM@PHNT compositesThe insets show the appearances of PLA, PLA/PHNT and PLA/HM@PHNT.

| Sample | Loading amount,mass fraction(%) | ∆ in TS(%) | ∆ in EAB(%) | ∆ inXc(%) | ∆ in PHRR(%) | ∆ in THR(%) | T300(%) | Ref. |

|---|---|---|---|---|---|---|---|---|

| PLA/pHNTs | 2 | +15.3 | +253.8 | +135.2 | - | - | - | [ |

| PLA/zinc oxide treated HNT | 3 | +6.2 | +21.6 | - | - | - | about 20 | [ |

| PLA/HNT@MAH@DOPO | 5 | - | - | +9.6 | -20.2 | -8.8 | - | [ |

| PLA/DM⁃OH8 | 1.5 | -11.3 | -12.5 | - | -4.5 | -2.9 | - | [ |

| PLA/PNSiHNT | 5 | +77 | +116 | - | -18 | -12 | 4.1 | [ |

| PLA/HM@PHNT | 5 | +25.6 | +87.9 | 175.3 | -7.4 | -6.9 | 1.0 | This work |

Table 4 Performance comparison of various reported PLA/modified HNT composites*

| Sample | Loading amount,mass fraction(%) | ∆ in TS(%) | ∆ in EAB(%) | ∆ inXc(%) | ∆ in PHRR(%) | ∆ in THR(%) | T300(%) | Ref. |

|---|---|---|---|---|---|---|---|---|

| PLA/pHNTs | 2 | +15.3 | +253.8 | +135.2 | - | - | - | [ |

| PLA/zinc oxide treated HNT | 3 | +6.2 | +21.6 | - | - | - | about 20 | [ |

| PLA/HNT@MAH@DOPO | 5 | - | - | +9.6 | -20.2 | -8.8 | - | [ |

| PLA/DM⁃OH8 | 1.5 | -11.3 | -12.5 | - | -4.5 | -2.9 | - | [ |

| PLA/PNSiHNT | 5 | +77 | +116 | - | -18 | -12 | 4.1 | [ |

| PLA/HM@PHNT | 5 | +25.6 | +87.9 | 175.3 | -7.4 | -6.9 | 1.0 | This work |

| 1 | Xue Y., Feng J., Ma Z., Liu L., Zhang Y., Dai J., Xu Z., Bourbigot S., Wang H., Song P., Mater. Today Phys., 2021, 21, 100568 |

| 2 | Feng S., Zhao W., He J., Zhang Y., Chem. Res. Chinese Universities, 2023, 39(5), 750—756 |

| 3 | Xue Y., Zhang T., Tian L., Feng J., Song F., Pan Z., Zhang M., Zhou Y., Song P., Chem. Eng. J., 2023, 472, 144986 |

| 4 | Xiao D., Lv J. X., Wu F. J., Wang Z. B., Harre K., Chen J. H., Gohs U., Wang D. Y., Inter. J. Biol. Macromol., 2022, 215, 646—656 |

| 5 | Zhou Y., Lin Y., Tawiah B., Sun J., Yuen R. K. K., Fei B., ACS Appl. Mater. Inter., 2021, 13, 21876—21887 |

| 6 | Tawiah B., Zhou Y., Yuen R. K. K., Sun J., Fei B., Chem. Eng. J., 2020, 402, 126209 |

| 7 | Jin X., Cui S., Sun S., Gu X., Li H., Liu X., Tang W., Sun J., Bourbigot S., Zhang S., Compos. Part A: Appl. S., 2019, 124, 105485 |

| 8 | Sun J. H, Ni J. P., Lu D., Tang Z. B., Acta Polym. Sin., 2019, 124, 105485 |

| 孙晋皓, 倪金平, 路丹, 汤兆宾. 高分子学报, 2022, 53(3), 227—235 | |

| 9 | Cao X., Huang J., Tang Z., Tong Y., Yuen A. C. Y., Zhao W., Huang Q., Li R. K. Y., Wu W., Inter. J. Biol. Macromol., 2023, 236, 123947 |

| 10 | Dong L., Xue Y., Huang H., Shen D., Gao W., Xu F., Weng Y., Zhang Y., Polym. Degrad. Stab., 2023, 214, 110412 |

| 11 | He W., Song P., Yu B., Fang Z., Wang H., Prog. Mater. Sci., 2020, 114, 100687 |

| 12 | Gao J., He W. T., Wang X. X., Xiang Y. S., Long L. J., Qin S. H., Chem. J. Chinese Universities, 2022, 43(3), 20210670 |

| 高京, 何文涛, 王欣欣, 向宇姝, 龙丽娟, 秦舒浩. 高等学校化学学报, 2022, 43(3), 20210670 | |

| 13 | Yang W., Zhang H., Hu X., Liu Y., Zhang S., Xie C., Polym. Degrad. Stab., 2021, 191, 109664 |

| 14 | Cui X., Wu Q., Sun J., Gu X., Li H., Zhang S., Polym. Degrad. Stab., 2022, 202, 110037 |

| 15 | Lu M., Liu P., Wang F., Ding Y., Zhang S., Yang M., Polym. Int., 2018, 67(4), 356—373 |

| 16 | Yang W., Zhou Q., Pan W., Zhu S., Wei C., Lu H., Yang W., Yuen A. C. Y., Chem. Eng. J., 2023, 469, 143935 |

| 17 | Qiu S., Sun J., Li H., Gu X., Fei B., Zhang S., Polym. Degrad. Stab., 2022, 196, 109831 |

| 18 | He W., Xu H., Song P., Xiang Y., Qin S., Polym. Degrad. Stab., 2022, 196, 109847 |

| 19 | Feng J., Luo W., He W., Ai X., Song P., Polym. Degrad. Stab., 2023, 217, 110509 |

| 20 | Lou Y., Ma H., Su Y., Ma Y., Yang L., Zhang H., Xu J., Appl. Clay Sci., 2023, 23, 106756 |

| 21 | Zhong L., Li T., Zhang J., Wang J., Zhang D., Eur. Polym. J., 2022, 179, 111564 |

| 22 | Hong J., Wu T., Wang X., Lu Z., Zhang J., Zeng B., Yuan C., Dai L., Compos. Part B: Eng., 2022, 230, 109547 |

| 23 | Hong J., Wu T., Wu H., Zeng B., Zeng S., Chen T., Wang X., Lu Z., Yuan C., Balaji K., Petric D. F. S., Dai L., Chem. Eng. J., 2021, 407, 127087—127099 |

| 24 | Marney D. C. O., Yang W., Russell L. J., Shen S. Z., Nguyen T., Yuan Q., Varley R., Li S., Polym. Adv. Technol., 2012, 23, 1564—1571 |

| 25 | Malkappa K., Ray S. S., ACS Omega, 2019, 4, 9615—9628 |

| 26 | Zhang Z., Han Z., Pan Y. T., Li D., Wang D. Y., Yang R., Chem. Eng. J., 2020, 395, 125076 |

| 27 | Liu Q., Chen X., Zhu G., Gu X., Li H., Zhang S., Sun J., Jin X., Fire Safety J., 2022, 128, 103536 |

| 28 | Li Y., Li P., Wu M., Yu X., Naito K., Zhang Q., J. Appl. Polym. Sci., 2021, 138, 49668 |

| 29 | Liu L., Xu Y., Pan Y., Xu M., Di Y., Li B., Chem. Eng. J., 2021, 421, 127761 |

| 30 | Tang G., Tao Y., Deng D., Zhang D. X., Zhang S. H., Liu X. Y., Wu Q., Shen H. F., Sun J. J., Chem. J. Chinese Universities, 2024, 45(4), 20230494 |

| 唐刚, 陶熠, 邓丹, 张冬欣, 张诗华, 刘秀玉, 伍强, 沈海峰, 孙俊杰. 高等学校化学学报, 2024, 45(4), 20230494 | |

| 31 | Zhou Y., Qiu S., Guo W., Chu F., Zhou X., Chen W., Wang J., Zhang K., Cheng L., Hu Y., Chem. Eng. J., 2022, 427, 131634 |

| 32 | Guan J., Sun Z., Chem. Res. Chinese Universities, 2023, 39(5), 741—749 |

| 33 | Gao H., Shi R., Zhu Y., Qian H. Lu Z., Chem. Res. Chinese Universities, 2022, 38(3), 653—670 |

| 34 | Lim K., Chow W. S., Pung S. Y., J. Polym. Environ., 2019, 27, 1746—1759 |

| 35 | Li Z., Expósito D. F., González A. J., Wang D. Y., Eur. Polym. J., 2017, 93, 458—470 |

| 36 | Feng J., Lu Y., Xie H., Xu Z., Huang G., Cao C. F., Zhang Y., Chevali V. S., Song P., Wang H., ACS Sustainable Chem. Eng., 2022, 10, 15223—15232 |

| [1] | 王晨竹, 高明坤, 高艳静, 齐思贤, 于吉红. Beta@ZIF-67复合材料的制备及对聚乳酸塑料的催化降解性能[J]. 高等学校化学学报, 2024, 45(9): 20240221. |

| [2] | 宋欣译, 唐梦珂, 王存民, 朱金佗, 黄胜, 徐欢, 何新建. 立构复合化聚乳酸纳纤膜的制备及高效滤除PM2.5性能[J]. 高等学校化学学报, 2024, 45(2): 20230352. |

| [3] | 张广翔, 杨可, 杨佳怡, 刘阳, 郑松祺, 赵桂艳. 官能化PBAT的制备及对PBAT/TPS/PLA共混物的增容作用[J]. 高等学校化学学报, 2024, 45(12): 20240381. |

| [4] | 王存民, 江亮, 李佳琪, 李欣雨, 张一帆, 袁慧, 张明明, 朱金佗, 徐欢, 雷磊, 侯冲, 郭震, 何新建. 高取向立构复合化聚乳酸超细纳米纤维膜的制备及长效驻极与滤除PM0.3性能[J]. 高等学校化学学报, 2024, 45(10): 20240210. |

| [5] | 黄荣廷, 朱桂英, 李欣雨, 唐道远, 张勇, 王斌, 朱金佗, 何新建, 徐欢. 电活性聚乳酸纳纤膜的形态调控及高效捕集PM0.3性能[J]. 高等学校化学学报, 2024, 45(1): 20230353. |

| [6] | 黄雨晴, 刘妍, 张宏丽, 林森, 孙仕勇, GOLUBEV Evgeny, 吕瑞, KOTOVA Olga, KOTOVA Elena. GOx@Fe3O4-HNTs微囊反应器的构筑及多酶级联催化性能[J]. 高等学校化学学报, 2024, 45(1): 20230403. |

| [7] | 唐梦珂, 江亮, 徐文轩, 张子林, 唐道远, 黄东辉, 杨皓然, 高杰峰, 吉祥, 王延庆, 徐欢. 微波辅助仿生矿化增强石墨烯与聚乳酸的界面相互作用[J]. 高等学校化学学报, 2023, 44(4): 20220601. |

| [8] | 李小川, 唐梦珂, 朱金佗, 何新建, 徐欢. 界面立构复合化电活性聚乳酸纳纤膜的制备及高效过滤性能[J]. 高等学校化学学报, 2023, 44(12): 20230311. |

| [9] | 李真, 郝凯, 贺超良, 田华雨. PLGA-姜黄素纳米颗粒的制备及体外抗炎性能评价[J]. 高等学校化学学报, 2023, 44(10): 20230154. |

| [10] | 高京, 何文涛, 王欣欣, 向宇姝, 龙丽娟, 秦舒浩. DOPO衍生物改性碳纳米管的制备及对聚乳酸阻燃性能的影响[J]. 高等学校化学学报, 2022, 43(3): 20210670. |

| [11] | 徐欢, 柯律, 唐梦珂, 尚涵, 徐文轩, 张子林, 付亚男, 韩广东, 崔金声, 杨皓然, 高杰峰, 张生辉, 何新建. 液相剪切原位剥离蒙脱土纳米片增强高阻氧聚乳酸[J]. 高等学校化学学报, 2022, 43(11): 20220316. |

| [12] | 李欣宇, 李志伟, 张兴元. 硫磺素型聚乳酸/苯磺酸室温磷光体系的构建[J]. 高等学校化学学报, 2021, 42(6): 1987. |

| [13] | 夏艺玮, 王光鑫, 冯玉林, 胡跃鑫, 赵桂艳. 生物基超韧聚乳酸复合材料的制备与性能[J]. 高等学校化学学报, 2020, 41(8): 1881. |

| [14] | 殷平, 闫红强, 程捷, 方征平. 新型生物基苯并噁嗪的合成及性能[J]. 高等学校化学学报, 2019, 40(5): 1071. |

| [15] | 刘垚杉,吴海林,贾智,杜博,刘大勇,周志敏. 丝素改性聚乳酸-羟基乙酸共聚物多孔微球作为牙龈间充质干细胞递送载体的研究[J]. 高等学校化学学报, 2019, 40(11): 2419. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||