高等学校化学学报 ›› 2022, Vol. 43 ›› Issue (2): 20210546.doi: 10.7503/cjcu20210546

李晓辉1,3, 魏爱佳1,2,3( ), 穆金萍1,2,3, 何蕊1,3, 张利辉1,3, 王军3, 刘振法1,3(

), 穆金萍1,2,3, 何蕊1,3, 张利辉1,3, 王军3, 刘振法1,3( )

)

收稿日期:2021-08-02

出版日期:2022-02-10

发布日期:2021-12-04

通讯作者:

刘振法

E-mail:weiaijia2012@126.com;lzf63@sohu.com

作者简介:魏爱佳, 女, 硕士, 助理研究员, 主要从事新能源材料与器件研究. E-mail: 基金资助:

LI Xiaohui1,3, WEI Aijia1,2,3( ), MU Jinping1,2,3, HE Rui1,3, ZHANG Lihui1,3, WANG Jun3, LIU Zhenfa1,3(

), MU Jinping1,2,3, HE Rui1,3, ZHANG Lihui1,3, WANG Jun3, LIU Zhenfa1,3( )

)

Received:2021-08-02

Online:2022-02-10

Published:2021-12-04

Contact:

LIU Zhenfa

E-mail:weiaijia2012@126.com;lzf63@sohu.com

Supported by:摘要:

尖晶石型镍锰酸锂(LiNi0.5Mn1.5O4)因制备成本低、 放电平台高及循环寿命长等优点, 越来越多地应用于大型储能设备、 能量转换设备、 动力汽车等领域. 然而LiNi0.5Mn1.5O4在高电压(5 V)充电状态下电解液易分解, 从而导致比容量降低以及循环性能衰退. 针对以上问题, 采用水热法制备磷酸钐(SmPO4)表面包覆改性LiNi0.5Mn1.5O4正极材料, 研究了SmPO4包覆量对LiNi0.5Mn1.5O4材料电化学性能的影响. 结果表明, 当SmPO4包覆量为0.5%(质量分数)时, 改性材料(LNMO@SP-0.5)的电化学性能最优, 在0.2C和5C倍率下的放电比容量分别为129.2和90.9 mA?h/g, 而未包覆的材料Pristine LNMO的放电比容量分别仅有114.2和77.7 mA?h/g. 在常温1C倍率下循环200次后, LNMO@SP-0.5的容量保持率为93.4%, 而Pristine LNMO的容量保持率仅为86.6%. 这归因于SmPO4包覆能够有效缓解LiNi0.5Mn1.5O4材料与电解液之间的副反应, 降低电极的极化程度和电荷转移电阻, 增加了Li+的扩散系数.

中图分类号:

TrendMD:

李晓辉, 魏爱佳, 穆金萍, 何蕊, 张利辉, 王军, 刘振法. 磷酸钐包覆对高电压镍锰酸锂正极材料电化学性能的影响. 高等学校化学学报, 2022, 43(2): 20210546.

LI Xiaohui, WEI Aijia, MU Jinping, HE Rui, ZHANG Lihui, WANG Jun, LIU Zhenfa. Effects of SmPO4 Coatingon Electrochemical Performance of High-voltage LiNi0.5Mn1.5O4 Cathode Materials. Chem. J. Chinese Universities, 2022, 43(2): 20210546.

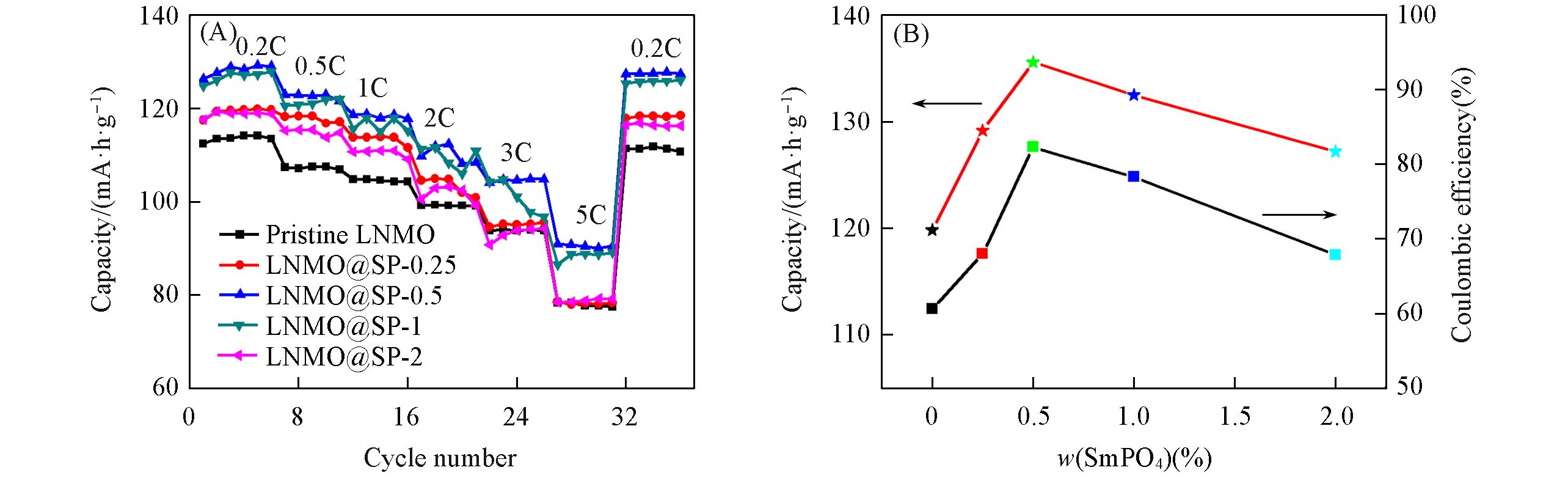

Fig.7 Rate capability curves(A) and initial discharge capacities and coulombic efficiencies(B) of Pristine LNMO, LNMO@SP?0.25, LNMO@SP?0.5, LNMO@SP?1 and LNMO@SP?2 samples

| Sample | Discharge capacity/(mA·h·g-1) | |||||

|---|---|---|---|---|---|---|

| 0.2C | 0.5C | 1C | 2C | 3C | 5C | |

| Pristine LNMO | 114.2 | 107.5 | 104.6 | 99.2 | 93.8 | 77.7 |

| LNMO@SP?0.25 | 119.7 | 118.3 | 113.8 | 104.8 | 95.2 | 78.2 |

| LNMO@SP?0.5 | 129.2 | 122.9 | 118.8 | 112.3 | 104.9 | 90.9 |

| LNMO@SP?1 | 127.9 | 122.0 | 118.0 | 111.6 | 101.0 | 88.8 |

| LNMO@SP?2 | 119.3 | 115.4 | 110.9 | 103.2 | 94.2 | 79.2 |

Table 1 Discharge capacity of Pristine LNMO, LNMO@SP-0.25, LNMO@SP-0.5, LNMO@SP-1 and LNMO@SP-2 samples at different rates

| Sample | Discharge capacity/(mA·h·g-1) | |||||

|---|---|---|---|---|---|---|

| 0.2C | 0.5C | 1C | 2C | 3C | 5C | |

| Pristine LNMO | 114.2 | 107.5 | 104.6 | 99.2 | 93.8 | 77.7 |

| LNMO@SP?0.25 | 119.7 | 118.3 | 113.8 | 104.8 | 95.2 | 78.2 |

| LNMO@SP?0.5 | 129.2 | 122.9 | 118.8 | 112.3 | 104.9 | 90.9 |

| LNMO@SP?1 | 127.9 | 122.0 | 118.0 | 111.6 | 101.0 | 88.8 |

| LNMO@SP?2 | 119.3 | 115.4 | 110.9 | 103.2 | 94.2 | 79.2 |

| Sample | Discharge capacity/(mA·h·g-1) | Capacity retention(%) | |

|---|---|---|---|

| 1st cycle | 200th cycle | ||

| Pristine LNMO | 96.4 | 83.5 | 86.6 |

| LNMO@SP?0.25 | 105.9 | 95.1 | 89.8 |

| LNMO@SP?0.5 | 113.2 | 105.7 | 93.4 |

| LNMO@SP?1 | 109.9 | 99.0 | 90.1 |

| LNMO@SP?2 | 106.0 | 94.5 | 89.2 |

Table 2 Discharge capacity and capacity retention of Pristine LNMO, LNMO@SP-0.25, LNMO@SP-0.5, LNMO@SP-1 and LNMO@SP-2 samples at 1C

| Sample | Discharge capacity/(mA·h·g-1) | Capacity retention(%) | |

|---|---|---|---|

| 1st cycle | 200th cycle | ||

| Pristine LNMO | 96.4 | 83.5 | 86.6 |

| LNMO@SP?0.25 | 105.9 | 95.1 | 89.8 |

| LNMO@SP?0.5 | 113.2 | 105.7 | 93.4 |

| LNMO@SP?1 | 109.9 | 99.0 | 90.1 |

| LNMO@SP?2 | 106.0 | 94.5 | 89.2 |

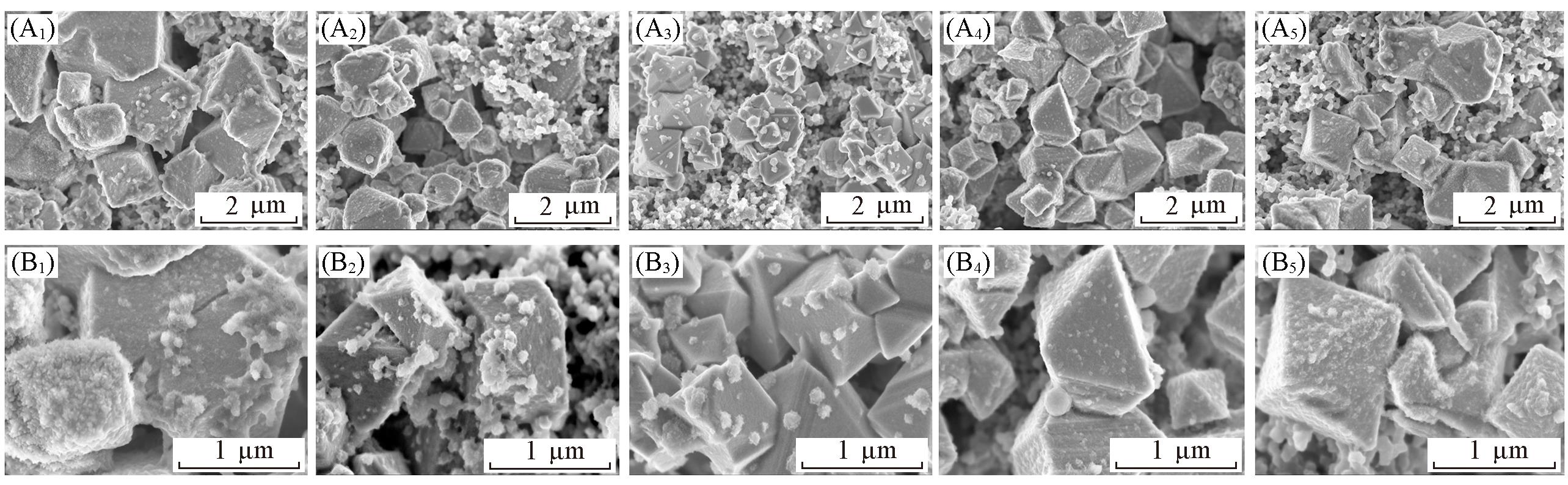

Fig.10 SEM images of Pristine LNMO(A1, B1), LNMO@SP?0.25(A2, B2), LNMO@SP?0.5(A3, B3), LNMO@SP?1(A4, B4) and LNMO@SP?2(A5, B5) electrodes before(A1—A5) and after(B1—B5) 200 cycles at 1C

| Sample | Φpa/V | Φpc/V | ?V/V |

|---|---|---|---|

| Pristine LNMO | 4.821 | 4.582 | 0.239 |

| LNMO@SP?0.25 | 4.830 | 4.611 | 0.219 |

| LNMO@SP?0.5 | 4.834 | 4.622 | 0.212 |

| LNMO@SP?1 | 4.828 | 4.611 | 0.217 |

| LNMO@SP?2 | 4.832 | 4.608 | 0.224 |

Table 3 Potential difference between anode and cathode peaks of Pristine LNMO, LNMO@SP-0.25, LNMO@SP-0.5, LNMO@SP-1 and LNMO@SP-2 samples*

| Sample | Φpa/V | Φpc/V | ?V/V |

|---|---|---|---|

| Pristine LNMO | 4.821 | 4.582 | 0.239 |

| LNMO@SP?0.25 | 4.830 | 4.611 | 0.219 |

| LNMO@SP?0.5 | 4.834 | 4.622 | 0.212 |

| LNMO@SP?1 | 4.828 | 4.611 | 0.217 |

| LNMO@SP?2 | 4.832 | 4.608 | 0.224 |

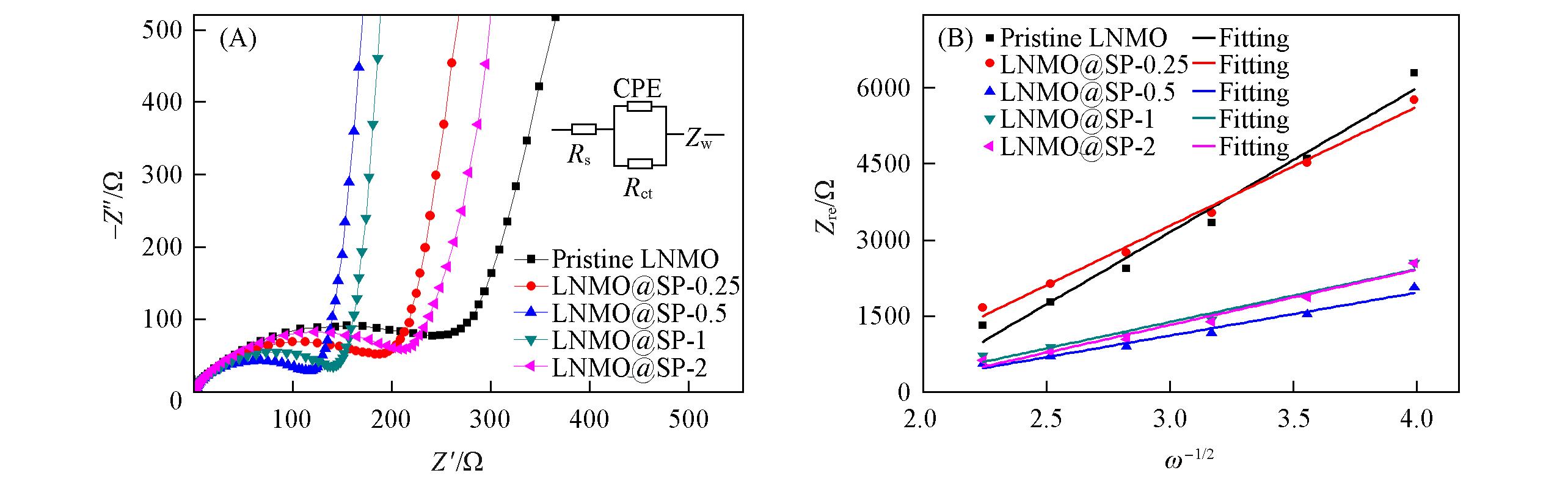

Fig.12 EIS spectra(A) and graph(B) of Zre plotted against ω-1/2 at low?frequency region of Pristine LNMO, LNMO@SP?0.25, LNMO@SP?0.5, LNMO@SP?1 and LNMO@SP?2 samplesInset of (A): equivalent circuit diagram. Rs: The solution resistance of the cell; CPE: constant phase element, representing the double layer capacitance of the interface; Zw: Warburg impedance.

| Sample | Rs/Ω | Rct/Ω |

|---|---|---|

| Pristine LNMO | 1.141 | 240.6 |

| LNMO@SP?0.25 | 1.084 | 188.4 |

| LNMO@SP?0.5 | 1.005 | 118.2 |

| LNMO@SP?1 | 1.070 | 141.3 |

| LNMO@SP?2 | 1.075 | 211.7 |

Table 4 Alternating current(AC) impedance parameters of Pristine LNMO, LNMO@SP-0.25, LNMO@SP-0.5, LNMO@SP-1 and LNMO@SP-2 samples

| Sample | Rs/Ω | Rct/Ω |

|---|---|---|

| Pristine LNMO | 1.141 | 240.6 |

| LNMO@SP?0.25 | 1.084 | 188.4 |

| LNMO@SP?0.5 | 1.005 | 118.2 |

| LNMO@SP?1 | 1.070 | 141.3 |

| LNMO@SP?2 | 1.075 | 211.7 |

| 21 | Wang J., Lin W., Wu B., Zhao J., Electrochim. Acta, 2014, 145, 245—253 |

| 22 | Luo Y., Lu T. L., Zhang Y. X., Yan L. Q., Mao S. S., Xie J. Y., J. Alloys Compd., 2017, 703, 289—297 |

| 23 | Shiu J. J., Pang W. K., Wu S. H., J. Power Sources, 2013, 224, 35—42 |

| 24 | Sun H. Y., Kong X., Wang B. S., Luo T. B., Liu G. Y., Ceram. Int., 2018, 44, 4603—4610 |

| 25 | Qiao Q. Q., Zhang H. Z., Li G. R., Ye S. H., Wang C. W., Gao X. P., J. Mater. Chem., 2013, A1, 5262—5268 |

| 26 | Wu C., Fang X., Guo X., Mao Y., Ma J., Zhao C., Wang Z., Chen L., J. Power Sources, 2013, 231, 44—49 |

| 27 | Li Y., Zhang Q., Xu T., Wang D. D., Pan D., Zhao H. L., Bai Y., Ceram. Int., 2018, 44(4), 4058—4066 |

| 28 | Kim J. H., Myung S. T., Yoon C. S., Kang S. G., Sun Y. K., Chem. Mater., 2004, 16, 906—914 |

| 29 | Deng Y., He L., Ren J., Zheng Q. J., Xu C. G., Lin D. M., Mater. Res. Bull., 2018, 100, 333—344 |

| 30 | Deng Y. F., Zhao S. X., Xu Y. H., Nan C. W., J. Power Sources, 2015, 296, 261—267 |

| 31 | Kunduraci M., Amatucci G. G., J. Electrochem. Soc., 2006, 153, 1345—1352 |

| 32 | Park J. S., Roh K. C., Lee J. W., Song K., Kim Y. I., Kang Y. M., J. Power Sources, 2013, 230, 138—142 |

| 33 | Gu Y. J., Li Y., Chen Y. B., Liu H. Q., Electrochim. Acta, 2016, 213, 368—374 |

| 34 | He L., Xu J. M., Han T., Han H., Wang Y. J., Yang J., Wang J. R., Zhu W. K., Zhang C. J., Zhang Y. H., Ceram. Int., 2017, 43(6), 5267―5273 |

| 35 | Liu W. J., Shi Q., Qu Q. T., Gao T., Zhu G. B., Shao J., Zheng H. H., J. Mater. Chem., 2017, A5(1), 145—154 |

| 36 | Mou J., Deng Y., Song Z., Zheng Q., Lam K. H., Lin D., Dalton T., 2018, 47(20), 7020—7028 |

| 37 | Huang B., Li X. H., Wang Z. X., Guo H. J., Xiong X. H., Wang J. H., J. Alloy. Compd., 2014, 583, 313—319 |

| 38 | Gao X. W., Deng Y. F., Wexler D., J. Mater. Chem. A, 2015, 3, 404—411 |

| 39 | Jia G. L., Jiao C. M., Xue W. J., Zheng S. H., Wang J., Solid State Ionics, 2016, 292, 15—21 |

| 40 | Zhang Q., Chen J. J., Wang X. Y., Yang C., Zheng M. S., Dong Q. F., Phys. Chem. Chem. Phys., 2015, 17, 10353—10357 |

| 41 | Yang L., Ravdel B., Lucht Brett L., Electrochem. Solid St., 2010, 13, A95—A97 |

| 42 | Liu M. H., Huang H. T., Lin C. M., Chen J. M., Liao S. C., Electrochim. Acta, 2014, 120, 133—139 |

| 1 | Diouf B., Pode R., Renew. Energ., 2015, 76, 375—380 |

| 2 | Ren G., Ma G., Cong N., Renew. Sust. Energ. Rev., 2015, 41, 225—236 |

| 3 | Lu J., Lee K. S., Mater. Technol., 2016, 31(11), 628—641 |

| 4 | Jafta Charl J., Mathe Mkhulu K., Manyala N., ACS Appl. Mater. Inter., 2013, 5, 7592—7598 |

| 5 | Bai G. Y., Wang Y., Materials Reports, 2015, 29(6), 15—18(白钢印, 王英. 材料导报, 2015, 29(6), 15—18) |

| 6 | Kim J. W., Kim D. H., Oh D. Y., Lee H., Kim J. H., Lee J. H., Jung Y. S., J. Power Sources, 2015, 274, 1254—1262 |

| 7 | Wang G., Wen W. C., Chen S. H., Yu R. Z., Wang X. Y., Yang X. K., Electrochim. Acta, 2016, 212, 791—799 |

| 8 | Yi T. F., Han X., Chen B., Zhu Y. R., Xie Y., J. Alloy. Compd., 2017, 703, 103—113 |

| 9 | Tron A., Mun J., J. Solid State Chem., 2021, 302(15), 122411 |

| 10 | Wu Q., Yin Y. F., Sun S. W., Zhang X. P., Wan N., Bai Y., Electrochim. Acta, 2015, 158, 73—80 |

| 11 | Yu C. Y., Dong L., Zhang Y. X., Du K., Gao M. M., Zhao H. L., Bai Y., Solid State Ionics, 2020, 357, 115464 |

| 12 | Liu D., Bai Y., Zhao S., Zhang W., J. Power Sources, 2012, 219, 333—338 |

| 13 | Xu T. H., Li Y. P., Wang D. D., Wu M. Y., Pan D., Zhao H. L., Bai Y., ACS Sustainable Chem. Eng., 2018, 6, 5818—5825 |

| 14 | Liu Y. L., Lu Z. P., Deng C. F., Ding J. J., Xu Y., Lu X. J., Yang G., J. Mater. Chem., 2017, A5, 996—1004 |

| 15 | Hwang T., Lee J. K., Mun J., Choi W., J. Power Sources, 2016, 322, 40—48 |

| 16 | Zheng X., Liu W., Qu Q., Shi Q., Zheng H., Huang Y., Appl. Surf. Sci., 2018, 455, 349—356 |

| 17 | Cho J. H., Park J. H., Lee M. H., Song H. K., Lee S. Y., Energy Environ. Sci., 2012, 5, 7124—7131 |

| 18 | Mou J. R., Deng Y. L., He L. H., Zheng Q. J., Jiang N., Lin D. M., Electrochim. Acta, 2018, 260, 101—111 |

| 19 | Deng H., Nie P., Luo H., Zhang Y., Wang J., Zhang X., J. Mater. Chem., 2014, A2(43), 18256—18262 |

| 20 | Deng Y., Mou J., Wu H., Jiang N., Zheng Q., Lam K. H., Xu C. G., Lin D. M., Electrochim. Acta, 2017, 235, 19—31 |

| [1] | 张诗昱, 何润合, 李永兵, 魏士俊, 张兴祥. 辐照交联制备低分子量聚丙烯腈纤维锂硫电池正极材料及其储硫机理[J]. 高等学校化学学报, 2022, 43(3): 20210632. |

| [2] | 鲍俊全, 郑仕兵, 苑旭明, 史金强, 孙田将, 梁静. 有机盐PTO(KPD)2作为高性能锂离子电池正极材料的研究[J]. 高等学校化学学报, 2021, 42(9): 2911. |

| [3] | 王弈艨, 刘凯, 王保国. 高镍三元正极材料的表面包覆策略[J]. 高等学校化学学报, 2021, 42(5): 1514. |

| [4] | 张会双, 高延晓, 王秋娴, 李向南, 刘文凤, 杨书廷. CTAB辅助水热合成高镍三元材料LiNi0.6Co0.2Mn0.2O2及其高低温性能研究[J]. 高等学校化学学报, 2021, 42(3): 819. |

| [5] | 陆地,郑春满,陈宇方,李宇杰,张红梅. 以酚醛树脂为碳源原位合成富锂层状相/尖晶石/碳核壳结构正极材料及其电化学性能[J]. 高等学校化学学报, 2020, 41(7): 1684. |

| [6] | 荣华, 王春刚, 周明. 用作锂离子电池负极的FeS2微球的制备及性能[J]. 高等学校化学学报, 2020, 41(3): 447. |

| [7] | 李新, 陈良, 马晓涛, 张鼎, 徐守冬, 周娴娴, 段东红, 刘世斌. V2O3空心球的制备及在锂硫电池中的应用[J]. 高等学校化学学报, 2019, 40(9): 1972. |

| [8] | 黄贺, 李春光, 施展, 冯守华. 酪氨酸微波水热法制备碳点及其在Fe3+检测和荧光标记方面的应用[J]. 高等学校化学学报, 2019, 40(8): 1579. |

| [9] | 杨金戈, 李宇杰, 陆地, 陈宇方, 孙巍巍, 郑春满. 微纳结构富锂锰基层状正极材料的形貌调控与储锂性能[J]. 高等学校化学学报, 2019, 40(7): 1495. |

| [10] | 姚枫楠, 李瑀, 封伟. 碳包覆氟化亚铁纳米复合材料的制备及电化学性能[J]. 高等学校化学学报, 2019, 40(7): 1418. |

| [11] | 马东玮, 田润赛, 刘振江, 冯源源, 丁泓宇, 冯季军. Na掺杂Li2-xNaxMnSiO4/C正极材料的微波辅助合成与电化学性能[J]. 高等学校化学学报, 2019, 40(6): 1280. |

| [12] | 董向阳, 牛晓青, 魏济时, 熊焕明. 一步水热法制备铜掺杂纳米碳点及其在白光器件中的应用[J]. 高等学校化学学报, 2019, 40(6): 1288. |

| [13] | 陈红, 杜勇慧, 张鑫, 刘文闫, 周晓明. 聚(3-己基噻吩)包覆富锂层状正极材料Li1.18Ni0.15Co0.15Mn0.52O2的制备与电化学性能[J]. 高等学校化学学报, 2019, 40(4): 777. |

| [14] | 贾宏亮, 赵建伟, 秦丽溶, 赵敏. 基于镍丝负载氧化镍纳米片的尿酸生物传感器[J]. 高等学校化学学报, 2019, 40(2): 240. |

| [15] | 刘建,杜海会,孙田将,年庆舜,李海霞,陶占良. 钙钒青铜/碳纳米管复合材料的制备及电化学性能[J]. 高等学校化学学报, 2019, 40(12): 2526. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||