高等学校化学学报 ›› 2019, Vol. 40 ›› Issue (5): 1005.doi: 10.7503/cjcu20180757

收稿日期:2018-11-09

出版日期:2019-04-18

发布日期:2019-04-18

作者简介:联系人简介: 姚志龙, 男, 博士, 研究员, 主要从事生物质化工利用技术和石油化工技术方面的研究. E-mail:

基金资助:

HUANG Rui, YAO Zhilong*( ), SUN Peiyong, ZHANG Shenghong

), SUN Peiyong, ZHANG Shenghong

Received:2018-11-09

Online:2019-04-18

Published:2019-04-18

Contact:

YAO Zhilong

E-mail:yaozl@bipt.edu.cn

Supported by:摘要:

采用共沉淀法制备了不同CuO和WO3含量的CuO-WO3-ZrO2催化剂. 利用X射线衍射(XRD)、 扫描电子显微镜(SEM)、 X射线荧光光谱(XRF)、 N2气物理吸附、 氢气程序升温还原(H2-TPR)、 X射线光电子能谱(XPS)及程序升温脱附(TPD)等手段对催化剂的结构和表面性质进行了表征. 结果表明, WO3的引入可以调变ZrO2的晶型, 从而使催化剂的比表面积和孔径发生变化, 促进CuO在催化剂表面的分散, 并影响催化剂的酸碱性. 在苯甲醛加氢制备苯甲醇反应中, 以CuO质量分数为18%, WO3质量分数为10%的CuO-WO3-ZrO2为催化剂时苯甲醛单程转化率达到92.03%, 产物苯甲醇的选择性为94.76%.

中图分类号:

TrendMD:

黄锐, 姚志龙, 孙培永, 张胜红. CuO-WO3-ZrO2的结构和性质对苯甲醛加氢反应催化性能的影响. 高等学校化学学报, 2019, 40(5): 1005.

HUANG Rui,YAO Zhilong,SUN Peiyong,ZHANG Shenghong. Effect of Structure and Properties of CuO-WO3-ZrO2 on Hydrogenation Catalytic of Benzaldehyde†. Chem. J. Chinese Universities, 2019, 40(5): 1005.

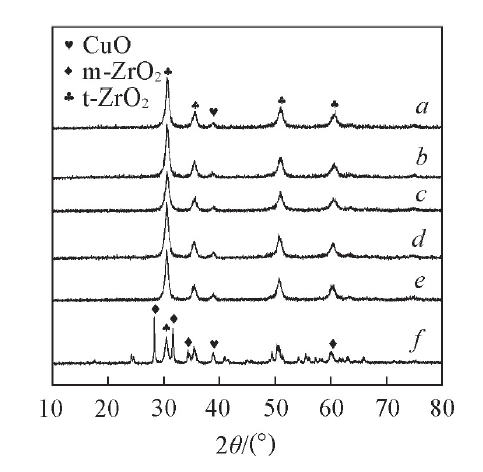

Fig.1 XRD patterns of catalysts with different WO3 contents a. 18CuO-12WO3-ZrO2; b. 18CuO-10WO3-ZrO2; c. 18CuO-8WO3-ZrO2; d. 18CuO-6WO3-ZrO2; e. 18CuO-4WO3-ZrO2; f. 18CuO-0WO3-ZrO2.

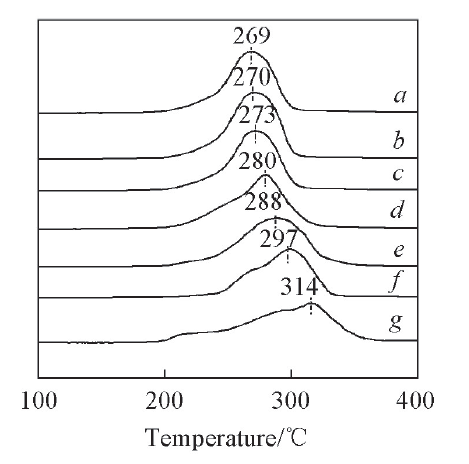

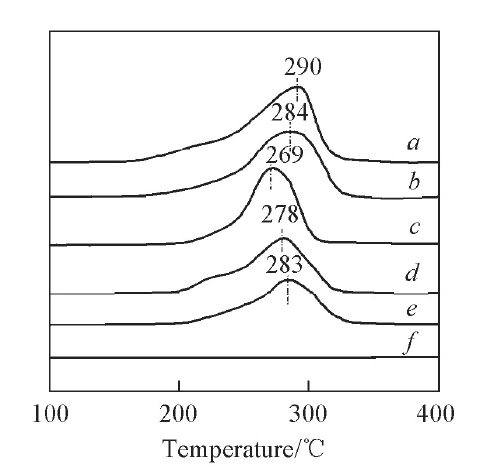

Fig.2 H2-TPR profiles of catalysts with different WO3 contentsa. 18CuO-14WO3-ZrO2; b. 18CuO-12WO3-ZrO2; c. 18CuO-10WO3-ZrO2; d. 18CuO-8WO3-ZrO2; e. 18CuO-6WO3-ZrO2; f. 18CuO-4WO3-ZrO2; g. 18CuO-0WO3-ZrO2.

| Catalyst | Mass fraction of WO3(%) | Surface area/(m2·g-1) | Average pore diameter/nm | Catalyst | Mass fraction of WO3(%) | Surface area/(m2·g-1) | Average pore diameter/nm | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 18CuO-0WO3-ZrO2 | 0.00 | 10.3 | 16.91 | 18CuO-10WO3-ZrO2 | 9.83 | 35.5 | 8.95 | ||||||

| 18CuO-4WO3-ZrO2 | 3.25 | 19.8 | 15.37 | 18CuO-12WO3-ZrO2 | 10.86 | 36.3 | 8.50 | ||||||

| 18CuO-6WO3-ZrO2 | 5.80 | 25.9 | 10.77 | 18CuO-14WO3-ZrO2 | 11.42 | 37.0 | 8.37 | ||||||

| 18CuO-8WO3-ZrO2 | 8.08 | 31.5 | 9.60 | ||||||||||

Table 1 Textural properties of catalysts with different WO3 contents

| Catalyst | Mass fraction of WO3(%) | Surface area/(m2·g-1) | Average pore diameter/nm | Catalyst | Mass fraction of WO3(%) | Surface area/(m2·g-1) | Average pore diameter/nm | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 18CuO-0WO3-ZrO2 | 0.00 | 10.3 | 16.91 | 18CuO-10WO3-ZrO2 | 9.83 | 35.5 | 8.95 | ||||||

| 18CuO-4WO3-ZrO2 | 3.25 | 19.8 | 15.37 | 18CuO-12WO3-ZrO2 | 10.86 | 36.3 | 8.50 | ||||||

| 18CuO-6WO3-ZrO2 | 5.80 | 25.9 | 10.77 | 18CuO-14WO3-ZrO2 | 11.42 | 37.0 | 8.37 | ||||||

| 18CuO-8WO3-ZrO2 | 8.08 | 31.5 | 9.60 | ||||||||||

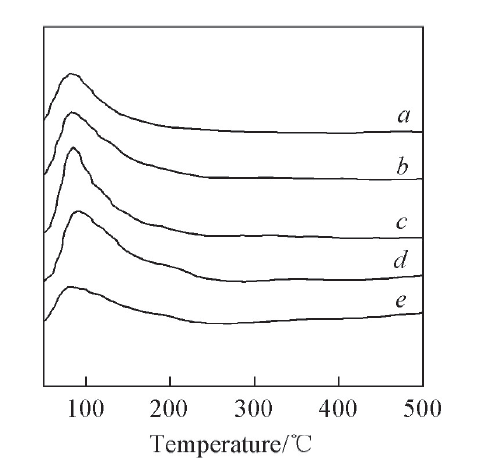

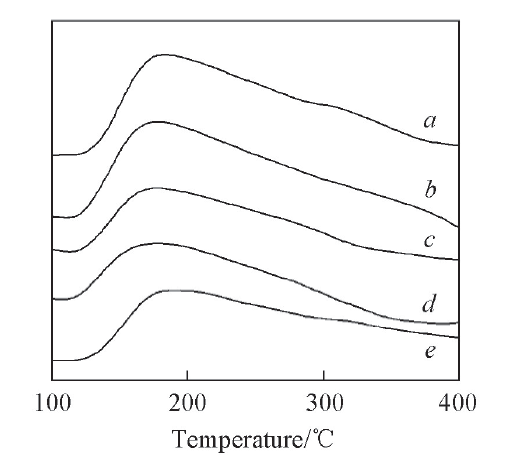

Fig.4 CO2-TPD profiles of catalysts with different WO3 contentsa. 18CuO-14WO3-ZrO2; b. 18CuO-12WO3-ZrO2; c. 18CuO-10WO3-ZrO2; d. 18CuO-8WO3-ZrO2; e. 18CuO-6WO3-ZrO2.

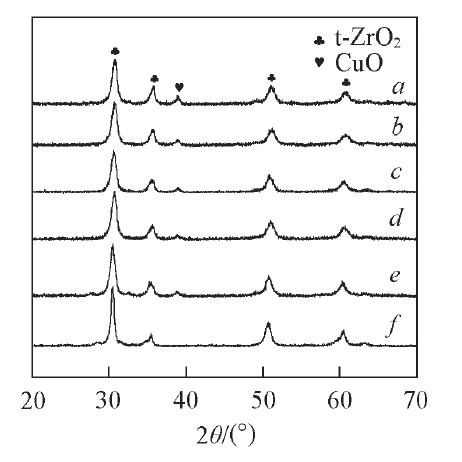

Fig.5 XRD patterns of catalysts with different CuO contents a. 24CuO-10WO3-ZrO2; b. 21CuO-10WO3-ZrO2; c. 18CuO-10WO3-ZrO2; d. 15CuO-10WO3-ZrO2; e. 12CuO-10WO3-ZrO2; f. 0CuO-10WO3-ZrO2.

Fig.6 H2-TPR profiles of catalysts with different CuO contentsa. 24CuO-10WO3-ZrO2; b. 21CuO-10WO3-ZrO2; c. 18CuO-10WO3-ZrO2; d. 15CuO-10WO3-ZrO2; e. 12CuO-10WO3-ZrO2; f. 0CuO-10WO3-ZrO2.

| Catalyst | Surface area/(m2·g-1) | Average pore diameter/nm | Catalyst | Surface area/(m2·g-1) | Average pore diameter/nm |

|---|---|---|---|---|---|

| 12CuO-10WO3-ZrO2 | 36.4 | 9.02 | 21CuO-10WO3-ZrO2 | 33.0 | 9.96 |

| 15CuO-10WO3-ZrO2 | 36.4 | 9.68 | 24CuO-10WO3-ZrO2 | 32.2 | 9.39 |

| 18CuO-10WO3-ZrO2 | 35.5 | 8.95 |

Table 2 Textural properties of catalysts with different CuO contents

| Catalyst | Surface area/(m2·g-1) | Average pore diameter/nm | Catalyst | Surface area/(m2·g-1) | Average pore diameter/nm |

|---|---|---|---|---|---|

| 12CuO-10WO3-ZrO2 | 36.4 | 9.02 | 21CuO-10WO3-ZrO2 | 33.0 | 9.96 |

| 15CuO-10WO3-ZrO2 | 36.4 | 9.68 | 24CuO-10WO3-ZrO2 | 32.2 | 9.39 |

| 18CuO-10WO3-ZrO2 | 35.5 | 8.95 |

Fig.8 NH3-TPD profiles of catalysts with different CuO contentsa. 24CuO-10WO-ZrO23; b. 21CuO-10WO3-ZrO2; c. 18CuO-10WO3-ZrO2; d. 15CuO-10WO3-ZrO2; e. 12CuO-10WO3-ZrO2.

| w(WO3)(%) | Conversion(%) | Selectivity(%) | ||

|---|---|---|---|---|

| Benzyl alcohol | Benzyl benzoate | Diphenylmethane | ||

| 0 | 60.38 | 90.85 | 0.28 | Trace |

| 4 | 79.34 | 89.24 | 0.46 | 1.06 |

| 6 | 84.07 | 90.28 | 1.25 | 1.01 |

| 8 | 88.99 | 90.89 | 1.33 | 0.97 |

| 10 | 94.76 | 92.03 | 1.59 | 0.97 |

| 12 | 94.08 | 92.17 | 0.74 | 0.96 |

Table 3 Performance of catalysts with different WO3 contents*

| w(WO3)(%) | Conversion(%) | Selectivity(%) | ||

|---|---|---|---|---|

| Benzyl alcohol | Benzyl benzoate | Diphenylmethane | ||

| 0 | 60.38 | 90.85 | 0.28 | Trace |

| 4 | 79.34 | 89.24 | 0.46 | 1.06 |

| 6 | 84.07 | 90.28 | 1.25 | 1.01 |

| 8 | 88.99 | 90.89 | 1.33 | 0.97 |

| 10 | 94.76 | 92.03 | 1.59 | 0.97 |

| 12 | 94.08 | 92.17 | 0.74 | 0.96 |

| w(CuO)(%) | Conversion(%) | Selectivity(%) | |||

|---|---|---|---|---|---|

| Benzyl alcohol | Toluene | Diphenylmethane | Benzene | ||

| 0 | 15.56 | 42.38 | 1.45 | Trace | Trace |

| 12 | 47.61 | 92.70 | 1.96 | 0.98 | 0.22 |

| 15 | 81.80 | 90.96 | 2.68 | 0.98 | 0.23 |

| 18 | 94.76 | 92.03 | 4.34 | 0.97 | 0.20 |

| 21 | 74.42 | 90.52 | 2.58 | 0.89 | 0.22 |

| 24 | 66.93 | 96.36 | 2.05 | 0.87 | 0.21 |

Table 4 Performance of catalysts with different CuO contents*

| w(CuO)(%) | Conversion(%) | Selectivity(%) | |||

|---|---|---|---|---|---|

| Benzyl alcohol | Toluene | Diphenylmethane | Benzene | ||

| 0 | 15.56 | 42.38 | 1.45 | Trace | Trace |

| 12 | 47.61 | 92.70 | 1.96 | 0.98 | 0.22 |

| 15 | 81.80 | 90.96 | 2.68 | 0.98 | 0.23 |

| 18 | 94.76 | 92.03 | 4.34 | 0.97 | 0.20 |

| 21 | 74.42 | 90.52 | 2.58 | 0.89 | 0.22 |

| 24 | 66.93 | 96.36 | 2.05 | 0.87 | 0.21 |

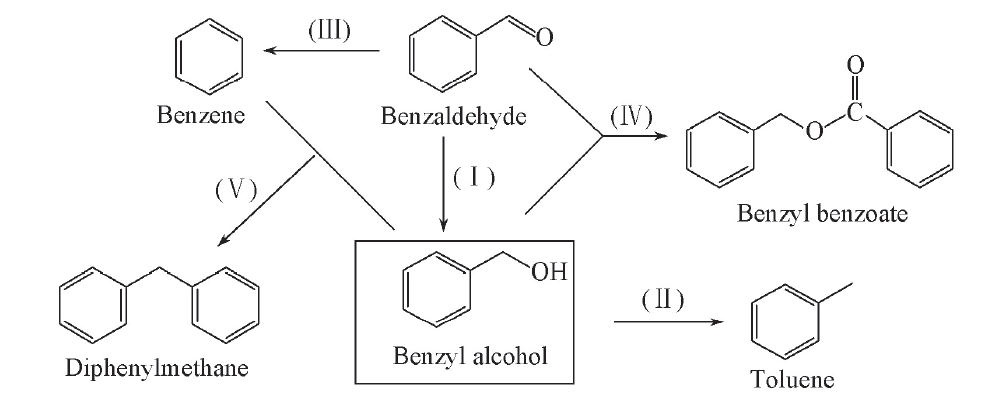

Scheme 2 Possible reaction pathways associated with the hydrogenation of benzaldehyde to the target benzyl alcohol and isolated byproducts(Ⅰ) Hydrogenation of benzaldehyde; (Ⅱ) hydrogenation of benzyl alcohol; (Ⅲ) decarburization of benzaldehyde; (Ⅳ) dehydrogenation and condensation of benzaldehyde and benzyl alcohol; (Ⅴ) alkylation of benzyl alcohol and benzene.

| [1] | Messiha F. S., Comp. Biochem. Physiol. C, 1991, 99(3), 445—449 |

| [2] | Ingamells W., Narasimham K. V., Color. Technol.,2010, 93(8), 306—312 |

| [3] | Distaso J., J. Clean Prod., 1998, 5(1), 170 |

| [4] | Zhang Z., Yuan A., Wang H., Ling Z., Hong X., Zheng C., Korean J. Chem. Eng.,2014, 31(4), 719—723 |

| [5] | Dong D.F.,Photosensitive Mater., 1990, (4), 45—46 |

| (董代富. 感光材料, 1990, (4), 45—46) | |

| [6] | Nair B., Int. J. Toxicol., 2001, 20(Suppl. 3), 23—50 |

| [7] | Xu H.L., Hydrogenation of Methyl Benzoate to Benzaldehyde and Benzyl Alcohol Over MnO/γ-Al2O3 and Cu/SiO2 Catalysts, Fudan University, Shanghai, 2006 |

| (徐华龙. MnO/γ-Al2O3和Cu/SiO2催化剂在苯甲酸甲酯加氢合成苯甲醛和苯甲醇反应过程中的研究, 上海: 复旦大学, 2006) | |

| [8] | Okamoto M., Hirao T., Yamaai T., J. Catal.,2010, 276(2), 423—428 |

| [9] | Merabti R., Bachari K., Halliche D., Rassoul Z., Saadi A., React. Kinet. Mech. Cat.,2010, 101(1), 195—208 |

| [10] | Kong X. J., Chen L. G., Appl. Catal. A-Gen.,2014, 476, 34—38 |

| [11] | Saadi A., Merabti R., Rassoul Z., Bettahar M. M., J. Mol. Catal. A: Chem.,2006, 253(1), 79—85 |

| [12] | Jenck J., Germain J. E., Cheminform,1980, 65(1), 141—149 |

| [13] | Bhanushali J. T., Kainthla I., Keri R. S., Nagaraja B. M., Chemistry Select,2016, 1(13), 3839—3853 |

| [14] | Lanasri K., Saadi A., Bachari K., Halliche D., Cherifi O., Stud. Surf. Sci. Catal.,2008, 174(8), 1279—1282 |

| [15] | Saadi A., Rassoul Z., Bettahar M. M., J. Mol. Catal. A: Chem.,2000, 164(1/2), 205—216 |

| [16] | Saadi A., Bettahar M. M., Rassoul Z., Stud. Surf. Sci. Catal.,2000, 130, 2261—2266 |

| [17] | Zhang H., Fu X., Niu S., Mater. Chem. Phys.,2005, 91(2/3), 361—364 |

| [18] | Lü C.X., The Study of Crystallization Process of ZrO2, Lanzhou University of Technology, Lanzhou, 2010 |

| (吕彩霞. 氧化锆晶化过程的研究, 兰州: 兰州理工大学, 2010) | |

| [19] | Marrero-Jerez J., Chinarro E., Moreno B., Peña-Martínez. J., Núñez. P., Ceram. Int.,2015, 41(9), 10904—10909 |

| [20] | Hanson J. C., Si R., Xu W., Senanayake S. D., Mudiyanselage K., Stacchiola D., Rodriguez J. A., Zhao H., Beyer K. A., Jennings G., Catal. Today,2014, 229(9), 64—71 |

| [21] | Perret N., Cárdenas-Lizana F., Keane M. A., Catal. Commun.,2011, 16(1), 159—164 |

| [22] | Huirache-Acuña R., Pawelec B., Rivera-Muñoz E., Nava R., Espino J., Fierro J. L. G., Appl. Catal. B: Environ.,2009, 92(1), 168—184 |

| [1] | 丁杨, 王万辉, 包明. 多孔骨架固定分子催化剂催化CO2加氢制备甲酸研究进展[J]. 高等学校化学学报, 2022, 43(7): 20220309. |

| [2] | 张昕昕, 许狄, 王艳秋, 洪昕林, 刘国亮, 杨恒权. CO2加氢制低碳醇CuFe基催化剂中的Mn助剂效应[J]. 高等学校化学学报, 2022, 43(7): 20220187. |

| [3] | 周紫璇, 杨海艳, 孙予罕, 高鹏. 二氧化碳加氢制甲醇多相催化剂研究进展[J]. 高等学校化学学报, 2022, 43(7): 20220235. |

| [4] | 黄孝舜, 马海英, 柳淑娟, 王斌, 王红利, 钱波, 崔新江, 石峰. 二氧化碳间接转化制化学品的研究进展[J]. 高等学校化学学报, 2022, 43(7): 20220222. |

| [5] | 周雷雷, 程海洋, 赵凤玉. Pd基多相催化剂上CO2加氢反应的研究进展[J]. 高等学校化学学报, 2022, 43(7): 20220279. |

| [6] | 宋有为, 安江伟, 王征, 王旭慧, 权燕红, 任军, 赵金仙. Ag,Zn,Pd掺杂对铜基催化剂草酸二甲酯选择性加氢反应的影响[J]. 高等学校化学学报, 2022, 43(6): 20210842. |

| [7] | 孟祥钰, 詹琦, 武亚南, 马晓双, 姜靖逸, 孙岳明, 代云茜. 光热效应增强的Au/RGO/Na2Ti3O7光催化加氢性能[J]. 高等学校化学学报, 2022, 43(3): 20210655. |

| [8] | 李学宇, 王朝, 陈雅, 李可可, 李建全, 金顺敬, 陈丽华, 苏宝连. 等离激元共振光转热增强负载纳米金对丁二烯选择性加氢的催化性能[J]. 高等学校化学学报, 2022, 43(10): 20220174. |

| [9] | 闫鹏泉, 王竟荣, 沈亚星, 左志军, 高志华, 黄伟. CuAl2O4尖晶石结构对浆态床一氧化碳加氢性能的影响[J]. 高等学校化学学报, 2021, 42(6): 1846. |

| [10] | 樊晔, 韩慧慧, 方云, 冯瑞沁, 夏咏梅. 简易合成纳米多层级镍中空亚微球及其催化苯酚加氢的研究[J]. 高等学校化学学报, 2021, 42(6): 1801. |

| [11] | 刘瀚林, 尹琳琳, 陈西凤, 李国栋. 氧化铟基纳米催化剂用于二氧化碳选择性加氢的研究进展[J]. 高等学校化学学报, 2021, 42(5): 1430. |

| [12] | 陈祥云, 朱本强, 袁冰, 于凤丽, 解从霞, 于世涛. 磁性碱木素胺稳定的Ru纳米粒子催化α-蒎烯加氢反应[J]. 高等学校化学学报, 2020, 41(8): 1826. |

| [13] | 蔡中顺, 朱子慧, 潘菁, 孙妍妍, 习玲玲, 侯昭胤. Co-Al催化剂在环氧丙醇加氢制备1,3-丙二醇中的应用[J]. 高等学校化学学报, 2020, 41(8): 1818. |

| [14] | 刘思明, 汪建南, 余申, 刘湛, 王朝, 李小云, 陈丽华, 苏宝连. 高比表面积等级孔γ-Al2O3的金属醇酯一步水解法制备及性能[J]. 高等学校化学学报, 2020, 41(6): 1208. |

| [15] | 张维中,温月丽,宋镕鹏,王斌,张倩,黄伟. 催化剂表面Cu0含量对二氧化碳加氢合成C2+醇性能的影响[J]. 高等学校化学学报, 2020, 41(6): 1297. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||