高等学校化学学报 ›› 2017, Vol. 38 ›› Issue (9): 1687.doi: 10.7503/cjcu20170037

收稿日期:2017-01-16

出版日期:2017-09-10

发布日期:2017-08-25

作者简介:联系人简介: 黄海鸿, 男, 博士, 教授, 博士生导师, 主要从事绿色制造、 再制造与回收再资源化等研究. E-mail:基金资助:

HUANG Haihong*( ), ZHANG Baoyu, ZHAO Zhipei

), ZHANG Baoyu, ZHAO Zhipei

Received:2017-01-16

Online:2017-09-10

Published:2017-08-25

Contact:

HUANG Haihong

E-mail:huanghaihong@hfut.edu.cn

Supported by:摘要:

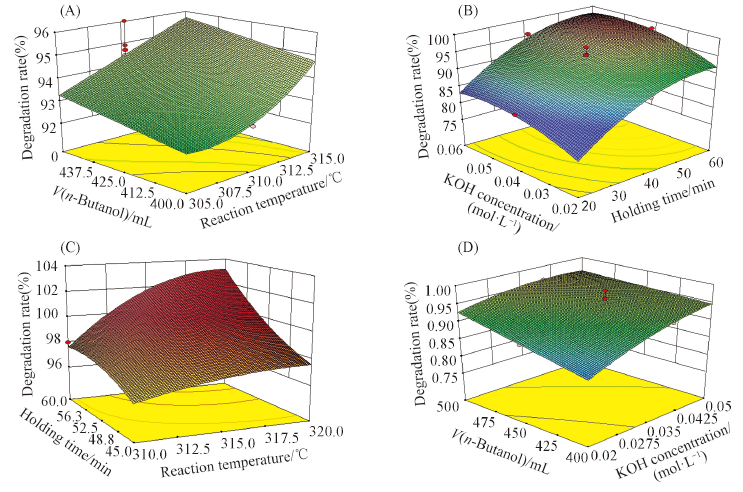

采用响应面分析方法设计超临界正丁醇降解废弃的碳纤维/环氧树脂(CF/EP)复合材料降解实验, 用以回收碳纤维. 通过Design-Expert V8.0建立环氧树脂降解率和工艺参数之间的数学模型, 获得了最优工艺参数; 通过图形优化研究了工艺参数对环氧树脂基体降解率的影响规律; 通过场发射电子扫描显微镜、 原子力显微镜、 X射线光电子能谱仪、 显微共焦激光拉曼光谱仪及单丝拉伸等分析最优工艺参数下回收的碳纤维的表面形貌、 表面化学、 石墨化程度及力学性能. 结果表明, 建立的数学模型拟合误差范围为±5.5%, 实现了回收工艺参数的预估; 单因素对环氧树脂基体降解率的影响程度为: 反应温度>保温时间>添加剂浓度>正丁醇含量; 最优工艺参数为: 反应温度330 ℃, 保温时间60 min, 添加剂浓度0.0538 mol/L, 投料比0.024 g/mL. 回收的碳纤维表面无残留树脂, 没有发生明显的石墨化, 且表面平均粗糙度与原碳纤维相近; 与原始碳纤维相比, 回收的碳纤维的拉伸强度约为原碳纤维的93.58%, 杨氏模量约为原碳纤维的94.87%.

中图分类号:

TrendMD:

黄海鸿, 张保玉, 赵志培. 超临界正丁醇对回收碳纤维复合材料的降解及表征. 高等学校化学学报, 2017, 38(9): 1687.

HUANG Haihong, ZHANG Baoyu, ZHAO Zhipei. Degradation and Characterization of Recycling Carbon Fiber/Epoxy Resin Composites in Supercritical n-Butanol†. Chem. J. Chinese Universities, 2017, 38(9): 1687.

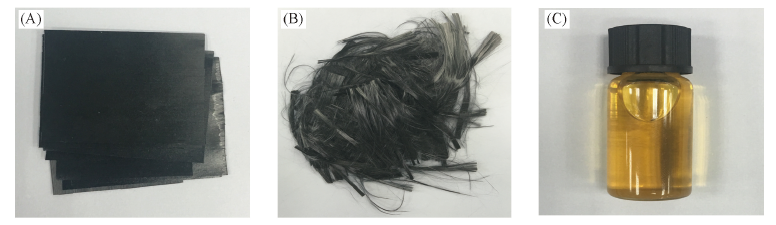

Fig.1 CF/EP before degradation and products after degradation(A) CF/EP before degradation; (B) solid residue of CF/EP after degradation; (C) liquid residue of CF/EP after degradation.

| Code | Process parameter | Level | ||||

|---|---|---|---|---|---|---|

| -2 | -1 | 0 | 1 | 2 | ||

| A | Reaction temperature/℃ | 290 | 300 | 310 | 320 | 330 |

| B | Holding time/min | 20 | 30 | 40 | 50 | 60 |

| C | cKOH/(mol·L-1) | 0.02 | 0.03 | 0.04 | 0.05 | 0.06 |

| D | V(n-Butanol)/mL | 400 | 425 | 450 | 475 | 500 |

Table 1 Process parameters and levels

| Code | Process parameter | Level | ||||

|---|---|---|---|---|---|---|

| -2 | -1 | 0 | 1 | 2 | ||

| A | Reaction temperature/℃ | 290 | 300 | 310 | 320 | 330 |

| B | Holding time/min | 20 | 30 | 40 | 50 | 60 |

| C | cKOH/(mol·L-1) | 0.02 | 0.03 | 0.04 | 0.05 | 0.06 |

| D | V(n-Butanol)/mL | 400 | 425 | 450 | 475 | 500 |

| Source | Sum of squares | Degree of freedom | F-value | P-value>F-value | Significance |

|---|---|---|---|---|---|

| Relation | 0.066 | 12 | 19.53 | <0.0001 | Significant |

| A | 4.773×10-3 | 1 | 16.87 | 0.0007 | Significant |

| B | 0.011 | 1 | 38.60 | <0.0001 | Significant |

| C | 5.367×10-3 | 1 | 18.97 | 0.0004 | Significant |

| D | 6.055×10-4 | 1 | 2.14 | 0.1608 | Significant |

| AC | 1.830×10-3 | 1 | 6.47 | 0.0204 | Significant |

| CD | 4.442×10-4 | 1 | 1.57 | 0.2263 | Not significant |

| B2 | 3.353×10-3 | 1 | 11.85 | 0.0029 | Significant |

| C2 | 1.273×10-3 | 1 | 4.50 | 0.0480 | Significant |

| BCD | 1.051×10-3 | 1 | 3.72 | 0.0698 | Not significant |

| A2B | 4.726×10-3 | 1 | 16.70 | 0.0007 | Significant |

| A2D | 1.287×10-3 | 1 | 4.55 | 0.0470 | Significant |

| AB2 | 2.735×10-3 | 1 | 9.66 | 0.0061 | Significant |

| Residual | 5.093×10-3 | 18 | |||

| Lack of fit | 4.109×10-3 | 12 | 2.09 | 0.1884 | Not significant |

| Pure error | 9.843 | 6 |

Table 2 Analysis of variance for established mathematical model

| Source | Sum of squares | Degree of freedom | F-value | P-value>F-value | Significance |

|---|---|---|---|---|---|

| Relation | 0.066 | 12 | 19.53 | <0.0001 | Significant |

| A | 4.773×10-3 | 1 | 16.87 | 0.0007 | Significant |

| B | 0.011 | 1 | 38.60 | <0.0001 | Significant |

| C | 5.367×10-3 | 1 | 18.97 | 0.0004 | Significant |

| D | 6.055×10-4 | 1 | 2.14 | 0.1608 | Significant |

| AC | 1.830×10-3 | 1 | 6.47 | 0.0204 | Significant |

| CD | 4.442×10-4 | 1 | 1.57 | 0.2263 | Not significant |

| B2 | 3.353×10-3 | 1 | 11.85 | 0.0029 | Significant |

| C2 | 1.273×10-3 | 1 | 4.50 | 0.0480 | Significant |

| BCD | 1.051×10-3 | 1 | 3.72 | 0.0698 | Not significant |

| A2B | 4.726×10-3 | 1 | 16.70 | 0.0007 | Significant |

| A2D | 1.287×10-3 | 1 | 4.55 | 0.0470 | Significant |

| AB2 | 2.735×10-3 | 1 | 9.66 | 0.0061 | Significant |

| Residual | 5.093×10-3 | 18 | |||

| Lack of fit | 4.109×10-3 | 12 | 2.09 | 0.1884 | Not significant |

| Pure error | 9.843 | 6 |

| No. | Reactor temperature/℃ | Holding time/min | Additive concentration/ (mol·L-1) | V(n-Butanol)/ mL | Actual degradation rate(%) | Theoretical degradation rate(%) | Error (%) |

|---|---|---|---|---|---|---|---|

| 1 | 330 | 40 | 0.04 | 443 | 98.82 | 99.20 | -0.38 |

| 2 | 300 | 50 | 0.04 | 450 | 91.19 | 88.90 | 2.58 |

| 3 | 320 | 20 | 0.04 | 500 | 92.98 | 98.34 | -5.45 |

| 4 | 330 | 60 | 0.03 | 430 | 99.59 | 101.50 | -1.91 |

| 5 | 310 | 50 | 0.05 | 430 | 97.23 | 96.98 | 0.25 |

| 6 | 300 | 60 | 0.04 | 500 | 80.12 | 77.94 | -2.18 |

Table 3 Experiments of process parameters to verify the mathematical model

| No. | Reactor temperature/℃ | Holding time/min | Additive concentration/ (mol·L-1) | V(n-Butanol)/ mL | Actual degradation rate(%) | Theoretical degradation rate(%) | Error (%) |

|---|---|---|---|---|---|---|---|

| 1 | 330 | 40 | 0.04 | 443 | 98.82 | 99.20 | -0.38 |

| 2 | 300 | 50 | 0.04 | 450 | 91.19 | 88.90 | 2.58 |

| 3 | 320 | 20 | 0.04 | 500 | 92.98 | 98.34 | -5.45 |

| 4 | 330 | 60 | 0.03 | 430 | 99.59 | 101.50 | -1.91 |

| 5 | 310 | 50 | 0.05 | 430 | 97.23 | 96.98 | 0.25 |

| 6 | 300 | 60 | 0.04 | 500 | 80.12 | 77.94 | -2.18 |

Fig.2 Effect of different process parameters on degradation rate(A) t=40 min, c=0.04 mol/L; (B) temperature=310 ℃, L= 450 mL; (C) c=0.04 mol/L, L= 450 mL;(D) t=40 min, temperature=310 ℃.

| No. | Reaction temperature/℃ | Holding time/ min | c(Additive)/ (mol·L-1) | V(n-Butanol)/ mL | Actual degradation rate(%) | Theoretical degradation rate(%) |

|---|---|---|---|---|---|---|

| 1 | 330 | 60 | 0.0538 | 413 | 100.69 | 100.00 |

| 2 | 330 | 60 | 0.0538 | 413 | 98.17 | |

| 3 | 330 | 60 | 0.0538 | 413 | 99.50 | |

| 4 | 330 | 60 | 0.0538 | 413 | 98.71 | |

| 5 | 330 | 60 | 0.0538 | 413 | 100.40 | |

| 6 | 330 | 60 | 0.0538 | 413 | 99.87 |

Table 4 Experiments under the optimal process parameters

| No. | Reaction temperature/℃ | Holding time/ min | c(Additive)/ (mol·L-1) | V(n-Butanol)/ mL | Actual degradation rate(%) | Theoretical degradation rate(%) |

|---|---|---|---|---|---|---|

| 1 | 330 | 60 | 0.0538 | 413 | 100.69 | 100.00 |

| 2 | 330 | 60 | 0.0538 | 413 | 98.17 | |

| 3 | 330 | 60 | 0.0538 | 413 | 99.50 | |

| 4 | 330 | 60 | 0.0538 | 413 | 98.71 | |

| 5 | 330 | 60 | 0.0538 | 413 | 100.40 | |

| 6 | 330 | 60 | 0.0538 | 413 | 99.87 |

| Species | C(%) | O(%) | N(%) | Si(%) | K(%) | O/C |

|---|---|---|---|---|---|---|

| Original carbon fiber | 77.96 | 20.29 | 1.09 | 0.66 | 0 | 0.260 |

| Recycled carbon fiber | 78.46 | 16.70 | 1.86 | 1.71 | 1.27 | 0.213 |

Table 5 Elemental composition of carbon fibers from XPS spectra

| Species | C(%) | O(%) | N(%) | Si(%) | K(%) | O/C |

|---|---|---|---|---|---|---|

| Original carbon fiber | 77.96 | 20.29 | 1.09 | 0.66 | 0 | 0.260 |

| Recycled carbon fiber | 78.46 | 16.70 | 1.86 | 1.71 | 1.27 | 0.213 |

| Species | Comporition(%) | ||||

|---|---|---|---|---|---|

| C—C | C—OH | C | COOH | C | |

| Original carbon fiber | 67.93 | 29.13 | 1.45 | 0.48 | 0.99 |

| Recycled carbon fiber | 33.76 | 44.74 | 18.74 | 1.23 | 1.53 |

Table 6 Oxygen functional groups of carbon fibers from XPS spectra

| Species | Comporition(%) | ||||

|---|---|---|---|---|---|

| C—C | C—OH | C | COOH | C | |

| Original carbon fiber | 67.93 | 29.13 | 1.45 | 0.48 | 0.99 |

| Recycled carbon fiber | 33.76 | 44.74 | 18.74 | 1.23 | 1.53 |

| [1] | Zhang X. H., Meng Y., Zhang W., Fiber Compos., 2004, 21(1), 50—53 |

| (张晓虎, 孟宇, 张炜.纤维复合材料,2004, 21(1), 50—53) | |

| [2] | Su X. P., Hi-Tech. Fiber Appl., 2004, 29(5), 34—36 |

| (苏小萍.高科技纤维与应用,2004, 29(5), 34—36) | |

| [3] | Zhao J. X., Hi-Tech. Fiber Appl., 2003, 28(3), 1—4 |

| (赵稼祥.高科技纤维与应用,2003, 28(3), 1—4) | |

| [4] | Li W., Guo Q. F., Chin. J. Opt. Lett., 2011, 4(3), 201—212 |

| (李威, 郭权锋.中国光学,2011, 4(3), 201—212) | |

| [5] | Piñero-Hernanz R., Dodds C., Hyde J., García-Serna J., Composites Part A, 2008, 39(3), 454—461 |

| [6] | Bai Y. P., Wang Z., Feng L. Q., Mater. Des., 2010, 31(2), 999—1002 |

| [7] | Okajima I., Yamada K., Sugeta T., Kagaku Kogaku Ronbun, 2002, 28(5), 553—558 |

| [8] | Liu Y. Y., Meng L. L., Huang Y. D., J. Appl. Polym. Sci., 2004, 91(5), 1912—1916 |

| [9] | Jiang G., Pickering S. J., Lester E., Compos. Sci. Technol., 2009, 69(2), 192—198 |

| [10] | Hyde J. R., Lester E., Kingman S., Composites Part A, 2006, 37(11), 2171—2175 |

| [11] | Piñero-Hernanz R., García-Serna J., Dodds C., J. Supercrit. Fluids, 2008, 46(1), 83—92 |

| [12] | Okajima I., Watanabe K., Haramiishi S., J. Supercrit. Fluids, 2017, 119, 44—51 |

| [13] | Liu Y. Y., Shan G. H., Meng L. H., Mater. Sci.Eng., A,2009, 520(1/2), 179—183 |

| [14] | Yan H., Lv C. X., Jing D. Q., New Carbon Mater., 2016, 31(1), 46—54 |

| (严华, 吕春祥, 经德齐.新型炭材料,2016, 31(1), 46—54) | |

| [15] | Huang H. H., Zhao Z. P., Cheng H. B., Yin Y. Z., Jing D. Q., Acta. Mater. Compos. Sin., 2016, 33(8), 1621—1629 |

| (黄海鸿, 赵志培, 成焕波, 殷晏珍, 经德齐.复合材料学报,2016, 33(8), 1621—1629) | |

| [16] | Huang H.H., Yin Y. Z., Cheng H. B., Zhao Z. P., Zhang B. Y.,J. Polym. Environ., 2016, 1—11 |

| [17] | GB/T31290-2014, Carbon Fibre. Determination of the Tensile Properties of Single-filament Specimens, Standards Press of China, Beijing, 2014 |

| (GB/T31290-2014, 碳纤维-单丝拉伸性能的测定, 北京: 中国标准出版社, 2014) | |

| [18] | GB/T3855-2005, Test Method for Resin Content of Carbon Fiber Reinforced Plastics, Standards Press of China,Beijing, 2008 |

| (GB/T3855-2005, 碳纤维增强塑料树脂含量实验方法, 北京: 中国标准出版社, 2008) | |

| [19] | Bezerra M. A., Santelli R. E., Oliveira E. P., Talanta,2008, 76(5), 965—977 |

| [20] | Montgomery D.C., Disign and Analysis of Experiments, Translated by Fu Y. S., Zhang J., Wang Z. Y., The People s Posts and Telecommunications Press, Beijing, 2009, 366—379 |

| (傅钰生, 张健, 王振羽[译]. 实验设计与分析 , 北京: 人民邮电出版社, 2009, 366—379) | |

| [21] | Qu L. L., Li Y. Q., Zheng B., Chem. J. Chinese Universities, 2009, 30(6), 1121—1127 |

| (渠凌丽, 黎源倩, 郑波.高等学校化学学报,2009, 30(6), 1121—1127) | |

| [22] | Xu X.H., He M. Z., Experimental design and Design-Expert, SPSS application, Science Press, Beijing, 2010, 109—124 |

| (徐向宏, 何明珠.试验设计与Design-Expert、 SPSS应用, 北京: 科学出版社, 2010, 109—124) |

| [1] | 唐刚, 孙俊杰, 张冬欣, 伍强, 张贺新, 沈海峰, 陶熠, 刘秀玉. 磷杂菲改性腰果酚多元醇的合成及阻燃聚氨酯硬泡性能[J]. 高等学校化学学报, 2022, 43(4): 20210847. |

| [2] | 谢璠, 陈珊珊, 卓龙海, 陆赵情, 高坤, 代啓阳. 聚对二甲苯纳米纤维阵列的CVD液晶模板法制备及降解性能[J]. 高等学校化学学报, 2021, 42(8): 2643. |

| [3] | 彭小明, 吴健群, 戴红玲, 杨展宏, 许莉, 许高平, 胡锋平. Ni-N-C单原子催化剂活化过硫酸盐降解苯酚[J]. 高等学校化学学报, 2021, 42(8): 2581. |

| [4] | 常书晴, 辛旭, 黄雅琦, 张信聪, 傅仰河, 朱伟东, 张富民, 李晓娜. Zr基金属有机框架材料的冷热驱动热释电催化性能[J]. 高等学校化学学报, 2021, 42(8): 2558. |

| [5] | 李冬平, 李彬, 李长恒, 于薛刚, 单妍, 陈克正. Ni5P4/g-C3N4复合光催化剂的制备及光催化性能[J]. 高等学校化学学报, 2021, 42(4): 1292. |

| [6] | 姚明彩, 杨强, 孟健, 刘孝娟. 纤锌矿型β-CuGa1-xZnxO2的Zn2+取代Ga3+不等价掺杂对其结构及光催化性质的影响[J]. 高等学校化学学报, 2021, 42(12): 3561. |

| [7] | 李琛, 李悦生. 吡啶基有机碱催化O-羧基酐的活性开环聚合[J]. 高等学校化学学报, 2021, 42(10): 3203. |

| [8] | 李肖乾, 张华, 路海健, 刘畅, 刘庆龙, 马夏禹, 方媛萍, 梁大鹏. 内部萃取电喷雾电离质谱对二氧化钛纳米线阵列光催化降解罗丹明B反应机理的研究[J]. 高等学校化学学报, 2020, 41(9): 2003. |

| [9] | 李丽, 李鹏飞, 王博. 共价有机框架材料在光催化领域中的应用[J]. 高等学校化学学报, 2020, 41(9): 1917. |

| [10] | 高霞,潘会宾,乔成芳,陈凤英,周元,杨文华. 基于多级孔金属有机骨架构筑HRP固定化酶反应器及其染料降解应用[J]. 高等学校化学学报, 2020, 41(7): 1591. |

| [11] | 王蕊,徐梅,谢家文,叶盛英,宋贤良. 水热反应条件对多孔球状Bi2WO6光催化剂结构及性能的影响[J]. 高等学校化学学报, 2020, 41(6): 1320. |

| [12] | 刘东旭, 陈雪冰, 杨霞, 张静, 陈常东. 光生电荷梯度连续传递链的构筑及对光催化性能的增强作用[J]. 高等学校化学学报, 2020, 41(4): 742. |

| [13] | 刘丛远, 刘佳, 杜佩瑶, 张振, 卢小泉. 亲水性FePt纳米颗粒协同催化有机污染物的降解[J]. 高等学校化学学报, 2020, 41(4): 697. |

| [14] | 刘义刚,赵鹏,韩玉贵,宋鑫,韩志鹏,谢良波,李壮,贾晓庆,李轶. W元素掺杂CeO2非均相电芬顿催化剂高效处理含油污水[J]. 高等学校化学学报, 2020, 41(3): 498. |

| [15] | 华涛, 李胜男, 李凤祥, 王浩楠. 生物电化学系统降解多环芳烃萘及微生物群落研究[J]. 高等学校化学学报, 2019, 40(9): 1964. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||