Chem. J. Chinese Universities ›› 2020, Vol. 41 ›› Issue (4): 829.doi: 10.7503/cjcu20190549

• Material Chemistry • Previous Articles Next Articles

WANG Xia,LIU Yanji,JIA Yongfeng,JI Lei,HU Quanli,DUAN Limei( ),LIU Jinghai(

),LIU Jinghai( )

)

Received:2019-10-23

Online:2020-04-10

Published:2020-03-02

Contact:

Limei DUAN,Jinghai LIU

E-mail:duanlmxie@126.com;jhliu2008@sinano.ac.cn

Supported by:CLC Number:

TrendMD:

WANG Xia, LIU Yanji, JIA Yongfeng, JI Lei, HU Quanli, DUAN Limei, LIU Jinghai. Preparative Chemistry of N-containing Porous Carbon Nanofibers for Capacity Improvement in Lithium-sulfur Battery †[J]. Chem. J. Chinese Universities, 2020, 41(4): 829.

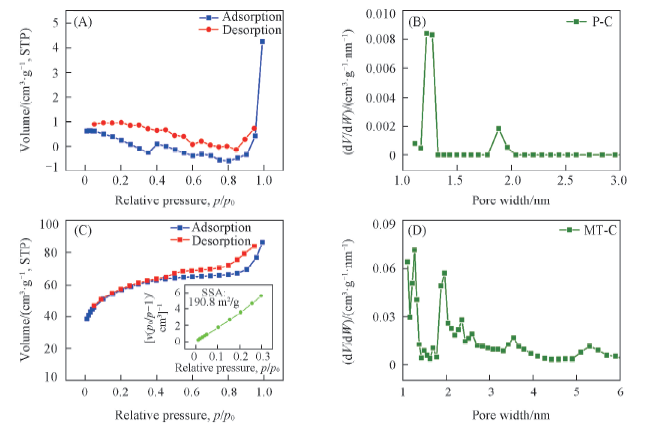

Fig.4 Nitrogen adsorption-desorption isotherms(A, C) and pore size distributions(B, D) for P-C(A, B) and MT-C-0.4(C, D)Insets: BET curves; SSA: specific surface area.

| Sample | Surface area/(m2·g-1) | Total-pore volume/(cm3·g-1) | Micropore volume/(cm3·g-1) | Average pore diameter/nm |

|---|---|---|---|---|

| MT-C-0.3 | 18.8 | 0.01 | 0.006 | 2.43 |

| MT-C-0.4 | 190.8 | 0.13 | 0.066 | 2.82 |

| MT-C-0.6 | 117.6 | 0.16 | 0.022 | 5.55 |

| MT-C-0.8 | 129.3 | 0.29 | 0.021 | 9.22 |

| Sample | Surface area/(m2·g-1) | Total-pore volume/(cm3·g-1) | Micropore volume/(cm3·g-1) | Average pore diameter/nm |

|---|---|---|---|---|

| MT-C-0.3 | 18.8 | 0.01 | 0.006 | 2.43 |

| MT-C-0.4 | 190.8 | 0.13 | 0.066 | 2.82 |

| MT-C-0.6 | 117.6 | 0.16 | 0.022 | 5.55 |

| MT-C-0.8 | 129.3 | 0.29 | 0.021 | 9.22 |

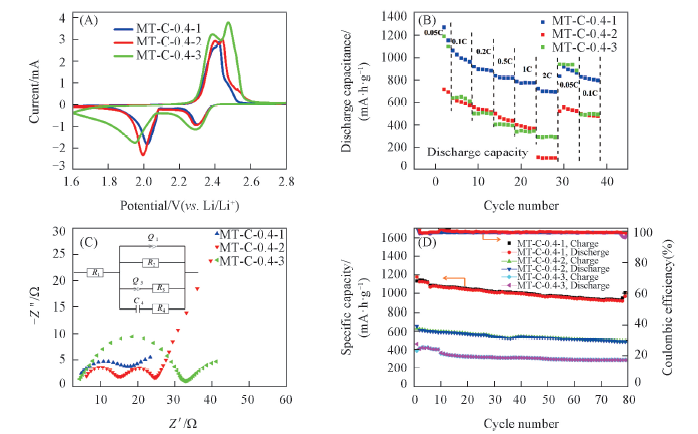

Fig.8 Electrochemical performances of MT-C-0.4/S with different S contents(A) CV curves, scan rate: 0.1 mV/s; (B) rate capabilities; (C) EIS curves. Inset in (C): model circuit; (D) cycling stability.

| [1] | Qie L., Chen W . M., Wang Z. H., Shao Q. G., Li X., Yuan L. X., Hu X. L., Zhang W. X., Huang Y. H., Adv. Mater., 2012, 24, 2047— 2050 |

| [2] | Ge Y. Q., Jiang H., Fu K., Zhang C. H., Zhu J. D., Chen C., Lu Y., Qiu Y. P., Zhang X. W., J. Power Sources, 2014, 272, 860— 865 |

| [3] | Chen Y. M., Li X. Y., Park K., Song J., Hong J. H., Zhou L. M., Mai Y. W., Huang H. T., Goodenough J. B., J. Am. Chem. Soc., 2013, 135, 16280— 16283 |

| [4] | Zhang Z., Jing H. K., Liu S., Li G. R., Gao X. P., J. Mater. Chem. A, 2015, 3, 6827— 6834 |

| [5] | Liu X., Huang J. Q., Zhang Q., Mai L., Adv. Mater., 2017, 29, 1601759 |

| [6] | Pan H., Wei X., Henderson W. A., Shao Y., Chen J., Bhattacharya P., Xiao J., Liu J., Adv. Energy Mater., 2015, 5, 1500113 |

| [7] | Lin L. L., Pei F., Peng J., Fu A., Cui J. Q., Fang X. L., Zheng N. F., Nano Energy., 2018, 54, 50— 58 |

| [8] | Meng X. B., Gao Q. M., Chem. J. Chinese Universities, 2014, 35 8), 1715— 1719 |

| ( 孟宪斌,高秋明.高等学校化学学报, 2014, 35(8), 1715— 1719) | |

| [9] | Pang Q., Liang X., Kwok C. Y., Nazar L. F., Nat. Energy, 2016, 1, 16132 |

| [10] | Rana M., Li M., Huang X., Luo B., Gentle L., Knibbe R., J. Mater. Chem. A, 2019, 7, 6596— 6615 |

| [11] | Wang J., Sun X. G., Chen W., Li X., Huang Y. P., Wei C. C., Hu H., Liang G. D., Chem. J. Chinese Universities, 2018, 39 8), 1782— 1789 |

| ( 王杰,孙晓刚,陈玮,李旭,黄雅盼,魏成成,胡浩,梁国东.高等学校化学学报, 2018, 39(8), 1782— 1789) | |

| [12] | Xiong S. Z., Xie K., Hong X. B., Chem. J. Chinese Universities., 2011, 32 11), 2645— 2649 |

| ( 熊仕昭,谢凯,洪晓斌.高等学校化学学报, 2011, 32(11), 2645— 2649) | |

| [13] | Fan L. L., Li M., Li X. F., Xiao W., Chen Z. W., Lu J ., Joule, 2019, 3, 361— 386 |

| [14] | He G., Mandlmeier B., Schuster J., Nazar L. F., Bein T., Chem. Mater., 2014, 26, 3879— 3886 |

| [15] | Rodríguez E., Camean I., Garcia R., Garcia A. B., Electrochim. Acta, 2011, 56, 5090— 5094 |

| [16] | Zhou X., Tang J., Yang J., Xie J., Huang B., J. Mater. Chem. A, 2013, 1, 5037— 5044 |

| [17] | Sun X., Wang X., Mayes R . T., Dai S., ChemSusChem, 2013, 5, 2079— 2085 |

| [18] | Sun F., Wang J., Chen H., Li W., Qiao W., Long D., Ling L., ACS Appl. Mater. Interfaces, 2013, 5, 5630— 5638 |

| [19] | Yan D., Teng B., Chem. Res. Chinese Universities, 2019, 35( 4), 654— 661 |

| [20] | Yang J., Xie J., Zhou X Y .,Zou Y. L., Tang J. J.,Wang S. C., Chen F., Wang L. Y J. Phys. Chem. C, 2014,118, 1800— 1807 |

| [21] | Zhou L., Lin X. J., Huang T., Yu A. S., Electrochimica Acta, 2014, 116, 210— 216 |

| [22] | Wu Y. Z., Balakrishna R., Reddy M. V., Nair A. S., Chowdari B. V. R., Ramakrishna S., J. Alloys Comp., 2012, 517, 69— 74 |

| [23] | Kim C., Jeong Y.I., Ngoc B. T. N., Yang K. S., Kojima M., Kim Y. A., Endo M., Lee J. W ., Small, 2007, 3, 91— 95 |

| [24] | Sun H.X. , Du H. R., Yu M. K., Huang K. F., Yu N., Geng B. Y ., Nano Res., 2019, 12,1937— 1942 |

| [25] | Wang D. D., Wang J. N., Chemical Engineering Journal, 2017, 314, 714— 726 |

| [26] | Chung S. H., Manthiram A., Adv. Mater., 2014, 26, 7352— 7357 |

| [27] | Zhou G. M., Pei S. F., Li L., Wang D. W., Wang S. G., Huang K., Yin L. C., Li F., Cheng H. M., Adv. Mater., 2014, 26, 625— 631 |

| [28] | Chen W., Lei T. Y., Qian T., Lv W. Q., He W. D., Wu C. Y., Liu X. J., Liu J., Chen B., Yan C. L., Xiong J., Adv. Energy Mater., 2018, 8, 1702889 |

| [29] | Xu R., Lu J., Amine K., Adv. Energy Mater., 2015, 5, 1500408 |

| [30] | Ji X. L., Nazar L. F., J. Mater. Chem., 2010, 20, 9821— 9826 |

| [31] | Barchasz C., Molton F., Duboc C., Leprêtre J. C., Patoux S., Alloin F., Anal. Chem., 2012, 84, 3973— 3980 |

| [32] | Su Y. S., Manthiram A., Nat. Commun., 2012, 3, 1166— 1172 |

| [33] | Song J. X., Gordin M. L., Xu T., Chen S. R., Yu Z. X., Sohn H., Lu J., Ren Y., Duan Y. H., Wang D. H., Angew. Chem. Int. Ed., 2015, 54, 4325— 4329 |

| [34] | Wang Z., Feng M., Sun H., Li G. R., Fu Q., Li H. B., Liu J., Sun L. Q., Mauger A., Julien C. M., Xie H. M., Chen Z. W., Nano Energy, 2019, 59, 390— 398 |

| [35] | Doerfler S., Strubel P., Jaumann T., Troschke E., Hippauf F., Kensy C., Schökel A., Althues H., Giebeler L., Oswald S., Kaskel S., Nano Energy, 2018, 54, 116— 128 |

| [36] | Tang C., Zhang Q., Zhao M. Q., Huang J. Q., Cheng X. B., Tian G. L., Peng H. J., Wei F., Adv. Mater., 2014, 26, 6100— 6105 |

| [37] | Cheon S. E., Ko K. S., Cho J. H., Kim S. U., Chin E. Y., Kim H. T., J. Electrochem. Soc., 2003, 150, A796— A799 |

| [38] | Lian P. C., Zhu X. F., Liang S. Z., Li Z., Yang W. S., Wang H. H., Electrochem. Acta, 2010, 55, 3909— 3914 |

| [39] | Liu C., Liu X. G., Tan J., Wang Q. F., Wen H., Zhang C. H., J. Power Sources, 2017, 342, 157— 164 |

| [40] | Luo W. B., Chou S. L., Wang J. Z., Zhai Y. C., Liu H. K ., Small, 2015, 11, 2817— 2824 |

| [41] | Yin Y. X., Xin S., Guo Y. G., Wan L. J., Angew. Chem. Int. Ed., 2013, 52, 13186— 13200 |

| [42] | Zhang S. S., J. Electrochem. Soc., 2012, 159, A920— A923 |

| [43] | Tan G. Q., Xu R., Xing Z. Y., Yuan Y. F., Lu J., Wen J. G., Liu C., Ma L., Zhan C., Liu Q., Wu T. P., Jian Z. L., Shahbazian-Yassar R., Ren Y., Miller D. J., Curtiss L. A., Ji X. L., Amine K., Nat. Energy, 2017, 2, 17090 |

| [44] | Qiao Q. Q., Zhang H. Z., Li G. R., Ye S. H., Wang C. W., Gao X. P., J. Mater. Chem. A, 2013, 1, 5262— 5268 |

| [45] | Gao X. P., Liu J., Ye S. H., Song D. Y., Zhang Y. S., J. Alloys Compd., 1997, 253 254, 515— 519 |

| [46] | Du C., Gao C. H., Yin G. P., Chen M., Wang L., Energy Environ. Sci., 2011, 4, 1037— 1042 |

| [1] | WU Yu, LI Xuan, YANG Hengpan, HE Chuanxin. Construction of Cobalt Single Atoms via Double-confinement Strategy for High-performance Electrocatalytic Reduction of Carbon Dioxide [J]. Chem. J. Chinese Universities, 2022, 43(9): 20220343. |

| [2] | BAI Yanqun,WANG Cunguo,LI Xue,FAN Wenqi,SONG Penghao,GU Yuanchun,LIU Faqian,LIU Guangye. Preparation and Electrochemical Properties of S@C Composite Material with High Capacity and Ordered Alignment of Channels † [J]. Chem. J. Chinese Universities, 2020, 41(6): 1306. |

| [3] | QIN Chunping, WANG Xianliu, TANG Han, YI Bingcheng, LIU Chang, ZHANG Yanzhong. Osteogenesis-promoting Effects of the Electrospun Nanofibers Containing Decellularized Bone Matrix † [J]. Chem. J. Chinese Universities, 2020, 41(4): 780. |

| [4] | WANG Yongpeng,XU Zibo,LIU Mengzhu,ZHANG Haibo,JIANG Zhenhua. Non-enzymatic Glucose Sensor Based on the Electrospun Porous Foamy Copper Oxides Micro-nanofibers† [J]. Chem. J. Chinese Universities, 2019, 40(6): 1310. |

| [5] | CAI Jiao,YU Qiongwei,HE Xiaomei,XU Jing,DING Qiong,FENG Yuqi. Preparation of SiW11 Incorporated SiO2 Nanofibers(SiW11/SiO2) and Its Application in the Analysis of Polyamines in Arabidopsis† [J]. Chem. J. Chinese Universities, 2019, 40(5): 901. |

| [6] | ZHAO Yuxuan,CHEN Yanjun,PAN Guxin,WANG Chang,PENG Zhenbo,SUN Zongxu,LIANG Yongri,SHI Qisong. Preparation and Performance of Novel Tb-PEG+Eu-PEG/PANI/PAN Luminescent-electrical-phase Change Composite Fibers by Electrospinning† [J]. Chem. J. Chinese Universities, 2019, 40(4): 824. |

| [7] | GAO Ningxiao,XU Yulong,LIU Yong. Preparation of Carbon Dots from Soy Milk Powder and Fluorescent Nanofibers Containing Carbon Dots† [J]. Chem. J. Chinese Universities, 2019, 40(3): 555. |

| [8] | ZHANG Xinmu,CUI Xiangxu,YAOMA Kangyue,LI Tingting,ZHANG Zhiming. Electrospinning Preparation and Photocatalytic Activity of H4SiW12O40/Ethylene Vinyl Alcohol Copolymer Nanofibrous Membrane† [J]. Chem. J. Chinese Universities, 2019, 40(2): 372. |

| [9] | LI Xiangnan,YU Mingming,FAN Yong,WANG Qiuxian,ZHANG Huishuang,YANG Shuting. Study on Electrochemical Performances of N-doped P/C Composite as Anode Material of Lithium Ion Batteries † [J]. Chem. J. Chinese Universities, 2019, 40(11): 2360. |

| [10] | XU Dan,DING Yadan,WANG Xue,CONG Tie,LIU Junping,HONG Xia,PAN Ying. Microdroplet Detection of Protein Based on Superhydrophobic Polystyrene Film† [J]. Chem. J. Chinese Universities, 2018, 39(9): 1913. |

| [11] | NIE Guangdi, ZHU Yun, TIAN Di, WANG Ce. Research Progress in the Electrospun Nanofiber-based Supercapacitor Electrode Materials† [J]. Chem. J. Chinese Universities, 2018, 39(7): 1349. |

| [12] | ZHOU Ying, WANG Xianliu, YI Bingcheng, YU Zhepao, YANG Shangying, SHEN Yanbing, ZHANG Yanzhong. Engineering Shape Memory Enabled Composite Nanofibers for Bone Tissue Engineering† [J]. Chem. J. Chinese Universities, 2018, 39(7): 1554. |

| [13] | HAN Zhiying, LI Youji, LIN Xiao, WANG Ziyu, LI Ziqin, WANG Hao. Preparation and Photoelectrocatalytic Performance of Fe2O3/ZnO Composite Electrode Loading on Conductive Glass† [J]. Chem. J. Chinese Universities, 2018, 39(4): 771. |

| [14] | REN Jing, WANG Shugang, LI Yanchun, YANG Qingbiao, SONG Yan, LI Yaoxian. Preparation of AOPAN@PAN Coaxial Nanofiber Membrane and It’s Adsorption Property† [J]. Chem. J. Chinese Universities, 2018, 39(4): 825. |

| [15] | LU Guanxiu, LIU Qingwen, KONG Xiangyi, CONG Lele, SONG Yan, ZHAO Qing, YANG Qingbiao, LI Yaoxian. Preparation of PVA/GA/β-CD Nanofibers and Its Adsorption of Dyestuff [J]. Chem. J. Chinese Universities, 2017, 38(8): 1465. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||