Chem. J. Chinese Universities ›› 2018, Vol. 39 ›› Issue (4): 771.doi: 10.7503/cjcu20170388

• Physical Chemistry • Previous Articles Next Articles

HAN Zhiying, LI Youji*( ), LIN Xiao, WANG Ziyu, LI Ziqin, WANG Hao

), LIN Xiao, WANG Ziyu, LI Ziqin, WANG Hao

Received:2017-06-19

Online:2018-04-10

Published:2018-03-21

Contact:

LI Youji

E-mail:bcclyj@163.com

Supported by:TrendMD:

HAN Zhiying, LI Youji, LIN Xiao, WANG Ziyu, LI Ziqin, WANG Hao. Preparation and Photoelectrocatalytic Performance of Fe2O3/ZnO Composite Electrode Loading on Conductive Glass†[J]. Chem. J. Chinese Universities, 2018, 39(4): 771.

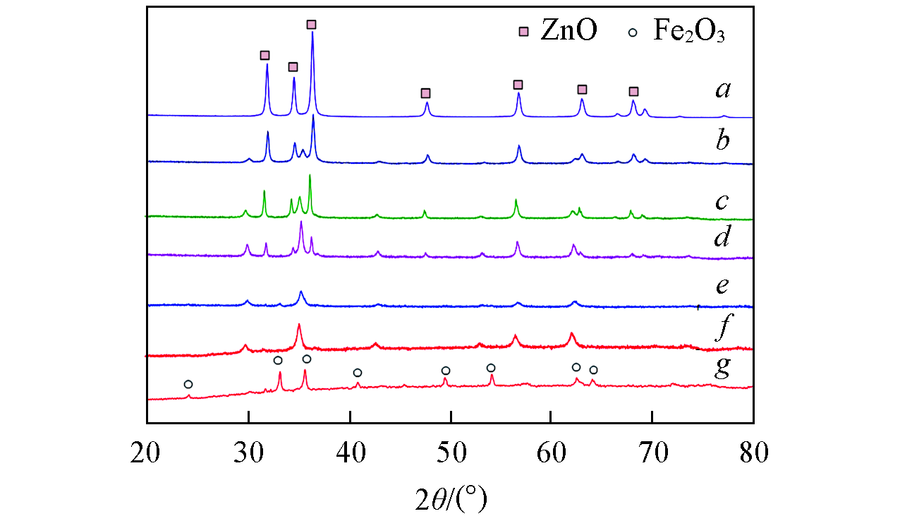

Fig.4 XRD patterns of pure ZnO/FTO, Fe2O3/FTO and Fe2O3/ZnO/FTO with different molar ratiosn(Fe)/n(Zn): a. 0:1; b. 1:4; c. 1:2; d. 1:1;e. 2:1; f. 4:1; g. 1:0.

| n(Fe)/n(Zn) | ZnO/nm | Fe2O3 /nm | n(Fe)/n(Zn) | ZnO/nm | Fe2O3 /nm |

|---|---|---|---|---|---|

| 0:1 | 27.2 | - | 2:1 | 28.0 | 29.5 |

| 1:4 | 28.2 | 25.1 | 4:1 | 28.5 | 23.9 |

| 1:2 | 33.6 | 28.9 | 1:0 | - | 29.1 |

| 1:1 | 34.5 | 33.0 |

Table 1 Grain size parameters of different samples

| n(Fe)/n(Zn) | ZnO/nm | Fe2O3 /nm | n(Fe)/n(Zn) | ZnO/nm | Fe2O3 /nm |

|---|---|---|---|---|---|

| 0:1 | 27.2 | - | 2:1 | 28.0 | 29.5 |

| 1:4 | 28.2 | 25.1 | 4:1 | 28.5 | 23.9 |

| 1:2 | 33.6 | 28.9 | 1:0 | - | 29.1 |

| 1:1 | 34.5 | 33.0 |

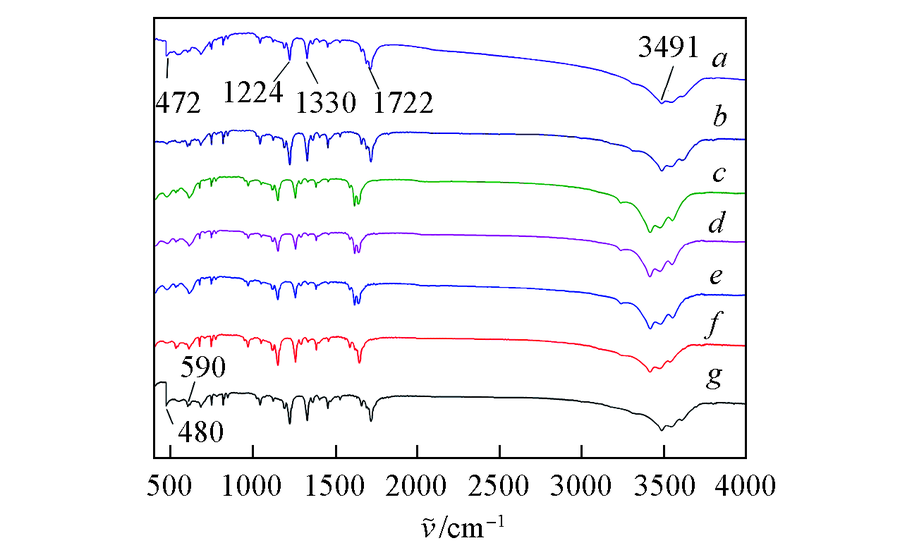

Fig.7 FTIR spectra of pure ZnO/FTO, Fe2O3/FTO and Fe2O3/ZnO/FTO with different molar ratiosn(Fe)/n(Zn): a. 0:1; b. 1:4; c. 1:2; d. 1:1;e. 2:1; f. 4:1; g. 1:0.

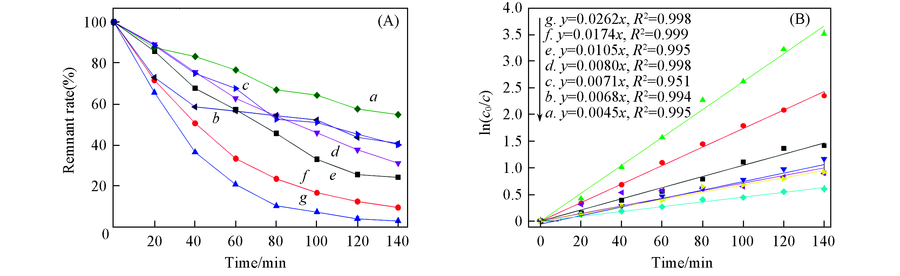

Fig.9 Effects of degradation time on MB degradation remnant rate(A) and ln(c0/c) of different catalysts(B)n(Fe)/n(Zn): a. 0:1; b. 1:0; c. 4:1; d. 1:4; e. 2:1; f. 1:2; g. 1:1.

| [1] | Tian X. L., Guo Q. G., Han C., Global Environ. Change, 2016, 39, 244-257 |

| [2] | Zhang S. H., Li Y. Q., Zhang T. X., Peng Y., J. Environ. Manage., 2015, 156, 31-40 |

| [3] | Sui Y. j., Su C. Y., Yang X. D., Hu J. L., Lin X. J., J. Mol. Catal. A: Chem., 2015, 410(2), 226-234 |

| [4] | Prawit N., Saksit C., Ratana M., Won C. O., J. Environ. Chem. Eng., 2016, 4(2), 2170-2177 |

| [5] | Helali N., Bessekhouad Y., Bouguelia A., Trari M., Sol. Energy, 2009, 84(7), 1187-1192 |

| [6] | Yu C. L., Yang K., Shu Q., Yu J. C., Cao F. F., Li X., Chinese J. Catal., 2011, 32(4), 555-565 |

| (余长林, 杨凯, 舒庆, YU Jimmy C., 操芳芳, 李鑫. 催化学报, 2011, 32(4), 555-565) | |

| [7] | Fatima T. J., Woo G. J., App. Catal. A: General, 2015, 491, 52-57 |

| [8] | Li Z. S., Ye L. T., Lei F. L., Wang Y. L., Xu S. H., Lin S., Electrochim. Acta, 2016, 188, 450-460 |

| [9] | Asma T., Wiem B., Brigitte S., Ahmed A., Habib E., Mokhtar F., Rabah B., Appl. Surf. Sci., 2017, 396, 1528-1538 |

| [10] | Zhu C. Q., Lu B. G., Su Q., Xie E. Q., Lan W., Nanoscale,2012, 4(10), 3060-3064 |

| [11] | Liang J., He X., Dong H. L., Liu H. R., Zhang H., Xu B. S., Chem. J. Chinese Universities, 2014, 35(3), 455-460 |

| (梁建, 何霞, 董海亮, 刘海瑞, 张华, 许并社. 高等学校化学学报, 2014, 35(3), 455-460) | |

| [12] | Seongpil A., Bhavana N. J., Min W. L., Na Y. K., Sam S. Y., Appl. Surf. Sci., 2014, 294, 24-28 |

| [13] | Huang R. B., Li S., Hu J. S., Qin G. W., J. Mater. Metal., 2012, 11(04), 303-307 |

| (黄若宾, 李松, 胡建设, 秦高梧. 材料与冶金学报, 2012, 11(04), 303-307) | |

| [14] | Xia S. J., Meng Y., Zhou X. B., Xue J. L., Pan G. X., Ni Z. M., Appl. Catal. B: Environ., 2016, 187, 122-133 |

| [15] | Hadis D., Alireza N. E., J. Colloid Interface Sci., 2017, 490, 314-327 |

| [16] | Zhang Z. Y., Shao C. L., Li X. H., Wang C. H., Zhang M. Y., Liu Y. C., ACS Appl. Mat. Interfaces, 2010, 2, 2915-2923 |

| [17] | Xu P., Li Y. J., Liu C., Deng R. C., Chem. J. Chinese Universities, 2014, 35(9), 1954-1961 |

| (徐鹏, 李佑稷, 刘晨, 李铭, 邓瑞成. 高等学校化学学报, 2014, 35(9), 1954-1961) | |

| [18] | Wang X. J., Xiao Y., Xu P., Zhang X. Q., Zhang Z. P., Chinese J. Inorg. Chem., 2014, 30(08), 1821-1826 |

| (王新娟, 肖洋, 徐斐, 张曦乔, 张资平. 无机化学学报, 2014, 30(08), 1821-1826) | |

| [19] | Song C., Dong X. T., Wang J. X. Liu G. X., Acta Chimica Sinica, 2011, 69(20), 2471-2478 |

| (宋超, 董相廷, 王进贤, 刘桂霞. 化学学报, 2011, 69(20), 2471-2478) | |

| [20] | Huang H., Liu J. Y., Liu X. X., Xiao J. F., Zhong S., She X. C., Fu Z. H., Yin D. L., Fuel,2016, 182, 373-381 |

| [21] | Zhang Z. Y., Shao C. L., Li X. H., Zhang L., Xue H. M., Wang C. H., Liu Y. C., J. Phys. Chem. C, 2010, 114(17), 7920-7925 |

| [22] | Zatsepin D. A., Boukhvalov D. W., Gavrilov N. V., Kurmaev E. Z., Zhidkov I. S., Appl. Surf. Sci., 2016, 387, 1093-1099 |

| [23] | Yu C. L., Yang K., Yu J. M., Peng P., Cao F. F., Li X., Zhou X. C., Acta Phys. Chim. Sin., 2011, 27(2), 505-512 |

| (余长林, 杨凯, 余济美, 彭鹏, 操芳芳, 李鑫, 周晓春. 物理化学学报, 2011, 27(2), 505-512) |

| [1] | WU Yu, LI Xuan, YANG Hengpan, HE Chuanxin. Construction of Cobalt Single Atoms via Double-confinement Strategy for High-performance Electrocatalytic Reduction of Carbon Dioxide [J]. Chem. J. Chinese Universities, 2022, 43(9): 20220343. |

| [2] | YANG Ruiqi, YU Xin, LIU Hong. Scientific Study of Photocatalytic Material Based on Sn3O4 [J]. Chem. J. Chinese Universities, 2021, 42(5): 1340. |

| [3] | WANG Xia, LIU Yanji, JIA Yongfeng, JI Lei, HU Quanli, DUAN Limei, LIU Jinghai. Preparative Chemistry of N-containing Porous Carbon Nanofibers for Capacity Improvement in Lithium-sulfur Battery † [J]. Chem. J. Chinese Universities, 2020, 41(4): 829. |

| [4] | QIN Chunping, WANG Xianliu, TANG Han, YI Bingcheng, LIU Chang, ZHANG Yanzhong. Osteogenesis-promoting Effects of the Electrospun Nanofibers Containing Decellularized Bone Matrix † [J]. Chem. J. Chinese Universities, 2020, 41(4): 780. |

| [5] | LIU Fen, ZHOU Min, WANG Suxia, WANG Rong, YANG Ning, MA Yongjun. Study on Photoelectrocatalytic Decolorization Mechanism of Methylene Blue Under the Visible-light Irradiation by Measuring Chemical Oxygen Demand Index† [J]. Chem. J. Chinese Universities, 2019, 40(9): 1988. |

| [6] | WANG Yongpeng,XU Zibo,LIU Mengzhu,ZHANG Haibo,JIANG Zhenhua. Non-enzymatic Glucose Sensor Based on the Electrospun Porous Foamy Copper Oxides Micro-nanofibers† [J]. Chem. J. Chinese Universities, 2019, 40(6): 1310. |

| [7] | CAI Jiao,YU Qiongwei,HE Xiaomei,XU Jing,DING Qiong,FENG Yuqi. Preparation of SiW11 Incorporated SiO2 Nanofibers(SiW11/SiO2) and Its Application in the Analysis of Polyamines in Arabidopsis† [J]. Chem. J. Chinese Universities, 2019, 40(5): 901. |

| [8] | ZHAO Yuxuan,CHEN Yanjun,PAN Guxin,WANG Chang,PENG Zhenbo,SUN Zongxu,LIANG Yongri,SHI Qisong. Preparation and Performance of Novel Tb-PEG+Eu-PEG/PANI/PAN Luminescent-electrical-phase Change Composite Fibers by Electrospinning† [J]. Chem. J. Chinese Universities, 2019, 40(4): 824. |

| [9] | GAO Ningxiao,XU Yulong,LIU Yong. Preparation of Carbon Dots from Soy Milk Powder and Fluorescent Nanofibers Containing Carbon Dots† [J]. Chem. J. Chinese Universities, 2019, 40(3): 555. |

| [10] | ZHANG Xinmu,CUI Xiangxu,YAOMA Kangyue,LI Tingting,ZHANG Zhiming. Electrospinning Preparation and Photocatalytic Activity of H4SiW12O40/Ethylene Vinyl Alcohol Copolymer Nanofibrous Membrane† [J]. Chem. J. Chinese Universities, 2019, 40(2): 372. |

| [11] | XU Dan,DING Yadan,WANG Xue,CONG Tie,LIU Junping,HONG Xia,PAN Ying. Microdroplet Detection of Protein Based on Superhydrophobic Polystyrene Film† [J]. Chem. J. Chinese Universities, 2018, 39(9): 1913. |

| [12] | NIE Guangdi, ZHU Yun, TIAN Di, WANG Ce. Research Progress in the Electrospun Nanofiber-based Supercapacitor Electrode Materials† [J]. Chem. J. Chinese Universities, 2018, 39(7): 1349. |

| [13] | ZHOU Ying, WANG Xianliu, YI Bingcheng, YU Zhepao, YANG Shangying, SHEN Yanbing, ZHANG Yanzhong. Engineering Shape Memory Enabled Composite Nanofibers for Bone Tissue Engineering† [J]. Chem. J. Chinese Universities, 2018, 39(7): 1554. |

| [14] | REN Jing, WANG Shugang, LI Yanchun, YANG Qingbiao, SONG Yan, LI Yaoxian. Preparation of AOPAN@PAN Coaxial Nanofiber Membrane and It’s Adsorption Property† [J]. Chem. J. Chinese Universities, 2018, 39(4): 825. |

| [15] | LU Guanxiu, LIU Qingwen, KONG Xiangyi, CONG Lele, SONG Yan, ZHAO Qing, YANG Qingbiao, LI Yaoxian. Preparation of PVA/GA/β-CD Nanofibers and Its Adsorption of Dyestuff [J]. Chem. J. Chinese Universities, 2017, 38(8): 1465. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||