Chem. J. Chinese Universities ›› 2017, Vol. 38 ›› Issue (2): 294.doi: 10.7503/cjcu20160599

• Polymer Chemistry • Previous Articles Next Articles

LI Pei1, FU Hai1, ZHAO Ou1, LAI Fang1, CHEN Shimei1, MEI Guiyou1, ZHAO Wei2, BAN Daming1,*( )

)

Received:2016-08-24

Online:2017-02-10

Published:2017-01-05

Contact:

BAN Daming

E-mail:bdaming@gznu.edu.cn

Supported by:CLC Number:

TrendMD:

LI Pei, FU Hai, ZHAO Ou, LAI Fang, CHEN Shimei, MEI Guiyou, ZHAO Wei, BAN Daming. Influence of Polyphosphate Flame Retardant Couple with Ammonium Polyphosphate on Epoxy Resin†[J]. Chem. J. Chinese Universities, 2017, 38(2): 294.

| Sample | wE-44(%) | wm-PDA(%) | wPOPP(%) | wAPP(%) | LOI(%) | UL-94 rating | wP(%) |

|---|---|---|---|---|---|---|---|

| EP-0 | 92 | 8 | 0 | 0 | 20.0 | No rating | 0 |

| EP-a1 | 87 | 8 | 5 | 0 | 24.2 | V-0 | 0.67 |

| EP-a2 | 82 | 8 | 10 | 0 | 24.8 | V-0 | 1.35 |

| EP-a3 | 77 | 8 | 15 | 0 | 25.5 | V-0 | 2.02 |

| EP-b1 | 87 | 8 | 1.67 | 3.33 | 27.7 | V-0 | 1.25 |

| EP-b2 | 82 | 8 | 3.33 | 6.67 | 28.9 | V-0 | 1.66 |

| EP-b3 | 77 | 8 | 5 | 10 | 33.8 | V-0 | 3.77 |

Table 1 Composition, LOI and UL94 vertical burning values of the samples

| Sample | wE-44(%) | wm-PDA(%) | wPOPP(%) | wAPP(%) | LOI(%) | UL-94 rating | wP(%) |

|---|---|---|---|---|---|---|---|

| EP-0 | 92 | 8 | 0 | 0 | 20.0 | No rating | 0 |

| EP-a1 | 87 | 8 | 5 | 0 | 24.2 | V-0 | 0.67 |

| EP-a2 | 82 | 8 | 10 | 0 | 24.8 | V-0 | 1.35 |

| EP-a3 | 77 | 8 | 15 | 0 | 25.5 | V-0 | 2.02 |

| EP-b1 | 87 | 8 | 1.67 | 3.33 | 27.7 | V-0 | 1.25 |

| EP-b2 | 82 | 8 | 3.33 | 6.67 | 28.9 | V-0 | 1.66 |

| EP-b3 | 77 | 8 | 5 | 10 | 33.8 | V-0 | 3.77 |

| Sample | T5%/℃ | T10%/℃ | T50%/℃ | Tmax/℃ | Residue(%) |

|---|---|---|---|---|---|

| POPP | 393.23 | 449.88 | 567.42 | 510.94, 557.57 | 35.30 |

| EP-0 | 362.76 | 374.81 | 411.90 | 398.44 | 15.03 |

| EP-b1 | 328.78 | 344.83 | 392.99 | 388.17 | 20.55 |

| EP-b2 | 316.95 | 334.03 | 386.93 | 378.10 | 22.49 |

| EP-b3 | 308.82 | 327.4482 | 387.50 | 367.89 | 23.62 |

Table 2 Thermal gravimetric data of the EP with different content

| Sample | T5%/℃ | T10%/℃ | T50%/℃ | Tmax/℃ | Residue(%) |

|---|---|---|---|---|---|

| POPP | 393.23 | 449.88 | 567.42 | 510.94, 557.57 | 35.30 |

| EP-0 | 362.76 | 374.81 | 411.90 | 398.44 | 15.03 |

| EP-b1 | 328.78 | 344.83 | 392.99 | 388.17 | 20.55 |

| EP-b2 | 316.95 | 334.03 | 386.93 | 378.10 | 22.49 |

| EP-b3 | 308.82 | 327.4482 | 387.50 | 367.89 | 23.62 |

| Sample | Breaking elongation(%) | Tensile strength/MPa | Elasticity modulus/MPa | Stressmax/MPa |

|---|---|---|---|---|

| EP-0 | 6.93 | 84.89 | 927.35 | 1398.73 |

| EP-b1 | 6.45 | 76.12 | 1000.35 | 1141.82 |

| EP-b2 | 6.05 | 64.57 | 879.90 | 968.57 |

| EP-b3 | 4.22 | 40.30 | 1058.99 | 604.49 |

Table 3 Mechanical properties of the EP with different content

| Sample | Breaking elongation(%) | Tensile strength/MPa | Elasticity modulus/MPa | Stressmax/MPa |

|---|---|---|---|---|

| EP-0 | 6.93 | 84.89 | 927.35 | 1398.73 |

| EP-b1 | 6.45 | 76.12 | 1000.35 | 1141.82 |

| EP-b2 | 6.05 | 64.57 | 879.90 | 968.57 |

| EP-b3 | 4.22 | 40.30 | 1058.99 | 604.49 |

| Sample | TTI/s | PkHRR/ (kW·m-2) | THR/ (MJ·m-2) | Mass loss/g |

|---|---|---|---|---|

| EP-0 | 43 | 831.5 | 54.0 | 14.5 |

| EP-b1 | 41 | 545.1 | 50.5 | 22.1 |

| EP-b3 | 40 | 346.8 | 41.6 | 23.0 |

Table 4 Cone calorimeter data of EP-0, EP-b1 and EP-b3

| Sample | TTI/s | PkHRR/ (kW·m-2) | THR/ (MJ·m-2) | Mass loss/g |

|---|---|---|---|---|

| EP-0 | 43 | 831.5 | 54.0 | 14.5 |

| EP-b1 | 41 | 545.1 | 50.5 | 22.1 |

| EP-b3 | 40 | 346.8 | 41.6 | 23.0 |

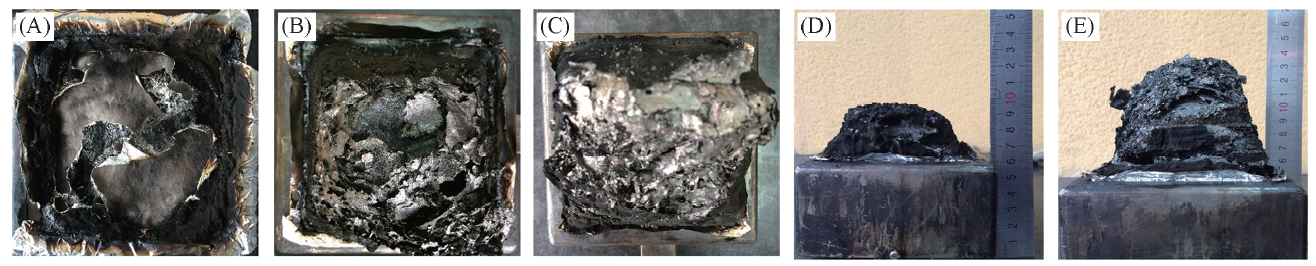

Fig.5 Photos of residues of cured epoxy resin samples after cone calorimeter tests(A) EP-0 in vertical view; (B) EP-b1 in vertical view; (C) EP-b3 in vertical view; (D) EP-b1 in level vision; (E) EP-b3 in level vision.

| [1] | Wang C. S., Song J. Y., J. Appl. Polym. Sci., 1999, 73(3), 353—361 |

| [2] | Lin C. H., Polym., 2004, 45(23), 7911—7926 |

| [3] | Mariappan T., Wilkie C. A., Fire Mater., 2014, 38, 588—598 |

| [4] | Sergei V.L., Edward D. W., Polym. Int., 2004, 53, 1901—1929 |

| [5] | Chen Y. H., Wang Q., Adv. Powder. Technol., 2007, 18(8), 587—600 |

| [6] | Li B., Xu M. J., Polym. Degrad. Stabil., 2006, 91(6), 1380—1386 |

| [7] | Xie F., Wang. Y. Z., Yang B., Liu Y., Macromol Mater. Eng., 2006, 291(3), 247—253 |

| [8] | Wang G. B., Gao. J. R., Jia J. H., Sheng W. J., Wang X., Acta Materiae Compositae Sinica,2010, 27(6), 45—52 |

| (黄国波, 高建荣, 贾建洪, 盛卫坚, 王旭. 复合材料学报, 2010, 27(6), 45—52) | |

| [9] | Halpern Y., Denna M. M., Niswander R. H., Ind. Eng. Chem. Prod. Res. Dev., 1984, 23(2), 233—238 |

| [10] | Shui Y. L., Lan H., Prog. Polym. Sci., 2002, 27(8), 1661—1712 |

| [11] | Nie S. B., Hu Y., Song L., He Q. L., Yang D.D., Chen H., Polym. Advan. Technol., 2008, 19(8), 1077—1083 |

| [12] | Thirumal M., Khastgir D., Singha N. K., Manjunath B. S., Naik Y. P., J. Appl. Polym. Sci., 2008, 110(5), 2586—2594 |

| [13] | Wang Y. X., Jiang H. W., Acta. Polym. Sin., 2009, 4, 325—330 |

| (王宇旋, 姜宏伟. 高分子学报, 2009, 4, 325—330) | |

| [14] | Wu N., Yang R.J., Hao J. W., Liu G. S.,Acta Polym. Sin., 2009, (12), 1205—1210 |

| (吴娜, 杨荣杰, 郝建薇, 刘国胜. 高分子学报, 2009, (12), 1205—1210) | |

| [15] | Heinrich H., Stefan P., Polym. Inter., 2000, 49(10), 1106—1114 |

| [16] | Liu J. C., Xu M. J., Li B., Chem. J. Chinese Universities,2015, 36(6), 1228—1235 |

| (刘建超, 许苗军, 李斌. 高等学校化学学报, 2015, 36(6), 1228—1235) | |

| [17] | Ban D. M., Qi. H. L., Zhao O., Zhang Y. H., Liu Z. M., Wei W. L., The Manufacturing Methods and Applications of 10-(2,5-dihydroxyphenyl)-9,10-dihydro-9-xa-10-phosphaphenanthrene-10-oxide Based Polyphosphate Esters Flame Retardants, CN 102796253A,2012-11-28 |

| (班大明, 秦好丽, 赵欧, 张永航, 刘真美, 韦万丽. ODOPB基聚磷酸酯阻燃剂及其制备方法和用途, CN 102796253A, 2012-11-28) | |

| [18] | Liu Y. J., Ma L., Polym. Mater. Sci. Eng., 2013, 34(12), 2903—2910 |

| [19] | Bao C. L., Guo Y. Q., Song L., Kan Y. C., Qian X. D., Hu Y., J. Mater. Chem., 2011, 21, 13290—13298 |

| [20] | Liao S. H, Liu P. L., Hsiao M. C., Teng C. C., Wang C. A., Ger M. D., Chiang C. L., Ind. Eng. Chem. Res., 2012, 51, 4573—4581 |

| [21] | Annakutty K. S., Kishore K., Eur. Polym. J., 1993, 29(10), 1387—1390 |

| [22] | Zhang D. F., Fan L. Z., Guo R. H., Fan Z. T., Chem. J. Chinese Universities,2014, 35(11), 2466—2471 |

| (张丹凤, 范楼珍, 郭瑞华, 樊择坛. 高等学校化学学报, 2014, 35(11), 2466—2471) | |

| [23] | Gao M., Li G. F., Yang R. J., Chin. J. Process. Eng., 2008, 8(1), 182—186 |

| (高明, 李桂芬, 杨荣杰. 过程工程学报, 2008, 8(1), 182—186) | |

| [24] | Krevelen D., Nijenhuis K.T.,Prop. Polym., 2009, 71—108 |

| [25] | Lai X. J., Zeng X. R., Li H. Q., Liao F., Zhang H. L., Yin C. Y., J. Macromol. Sci. B,2012, 51(1), 35—47 |

| [26] | Wen P. Y., Wang. X. F., Xing W. Y., Feng X. M., Yu B., Shi Y. Q., Tang G., Song L., Hu Y., Richard K. K. Yuen., Ind. Eng. Chem. Res., 2013, 52(48), 17015—17022 |

| [27] | Song Y., Li J. C., Zhang X. J., Changzhou Univ.(Nat. Sci. Ed.)., 2015, 27(4), 20—25 |

| (宋艳, 李锦春, 张鑫. 常州大学学报(自然科学版), 2015, 27(4), 20—25) | |

| [28] | Levchik S. V., Edward. D. W., Polym. Int., 2000, 49(10), 1033—1073 |

| [29] | Wang D. Y., Costa F. R., Vyalikh A., Leuteritz A., Scheler U., Jehnichen D., Wagenknecht U., Hässler L., Heinrich G., Chem. Mater., 2009, 21, 4490—4497 |

| [30] | Ran S. Y., Xu Y. Y., Guo Z. H., Fang Z. P., Chem. J. Chinese Universities,2013, 34(2), 467—473 |

| (冉诗雅, 许远远, 郭正虹, 方征平. 高等学校化学学报, 2013, 34(2), 467—473) | |

| [31] | Wang F., Hao J.W., Li Z. S., Zou H. F.,Acta. Polym. Sin., 2015, (8), 897—905 |

| (王芳, 郝建薇, 李茁实, 邹红飞. 高分子学报, 2015, (8), 897—905) | |

| [32] | Shan X. Y., Tai Q. L., Hu Y., Song L., Yuan G. J., Lu Z. M., Chem. J. Chinese Universities,2013, 34(10), 2431—2436 |

| (单雪影, 台启龙, 胡源, 宋磊, 袁国杰, 卢兆明. 高等学校化学学报, 2013, 34(10), 2431—2436) | |

| [33] | Usta N., J. Appl. Polym. Sci., 2012, 124, 3372—3382 |

| [34] | Wang X. B., Yang. S. S., Plast. Sci. Technol., 2010, 38(5), 47—49 |

| (王学宝, 杨守生. 塑料科技, 2010, 38(5), 47—49) | |

| [35] | Dong Y. Q., Zhang L., Hou T. G., Chen H. L., Gao C. J., Chem. J. Chinese Universites,2007, 28(12), 2422—2426 |

| (董永全, 张林, 侯同刚, 陈欢林, 高从堦. 高等学校化学学报, 2007, 28(12), 2422—2426) | |

| [36] | Sao B., Zhang Z. J., Wang Q. W., Song Y. M., Polym. Mater. Sci. Eng., 2008, 4, 93—96, 100 |

| (邵博, 张志军, 王清文, 宋永明. 高分子材料科学与工程, 2008, 4 93—96, 100) | |

| [37] | Lu L. G., Yin D. M., Wang D. W., Xu X. N., Shu Z., J. China. Plas., 2008, 22(5), 38—43 |

| (卢林刚, 殷全明, 王大为, 徐晓楠, 舒仲俊. 中国塑料, 2008, 22(5), 38—43) | |

| [38] | Wang F., Hao J.W., Li Z. S., Zou H. F.,Acta Polym. Sin., 2016, (7), 860—870 |

| (王芳, 郝建薇, 李茁实, 邹红飞. 高分子学报, 2016, (7), 860—870) | |

| [39] | Le B.M., Camino. G., Bourbigot S., Royal. Soc. Chem.,Cambridge, 1998, 3—32 |

| [40] | Li X., Ou Y. X., J. B. Inst. of Eng. Technol., 2001, 21(3), 388—391 |

| (李昕, 欧育湘. 北京理工大学学报, 2001, 21(3), 388—391) | |

| [41] | Zhou Y., Hao J. W., Liu G. S., Du J. X., Chinese J. Inorg. Chem., 2013, 29(6), 1115—1122 |

| (周友, 郝建薇, 刘国胜, 杜建新. 无机化学学报, 2013, 29(6), 1115—1122) | |

| [42] | Zhao C. X., Li Y. T., Xing Y. L., He D., Yue J., J. Appl. Polym Sci., 2014, 131(9), 40218—40225 |

| [43] | Duquesne S., Bras M. L., Bourbigot S., Delobelr R., Camino G., Eling B., Lindsay C., Roels T., Vezin E J., Appl. Polym. Sci., 2001, 82, 3262—3274 |

| [44] | Fang K.Y., Li. J., Ke C. H., Zhu Q. L., Tao K., Yan Q., Wang Y. Z.,Acta Polym. Sin., 2011, (1), 55—62 |

| (方科益, 李娟, 柯晨皓, 朱琦良, 陶慷, 严庆, 王玉忠. 高分子学报, 2011, (1), 55—62) |

| [1] | WENG Meiqi, SHANG Guiming, WANG Jiatai, LI Shenghua, FAN Zhi, LIN Song, GUO Minjie. Template Simulation of Organophosphorus Nerve Agent Molecularly Imprinted Polymers [J]. Chem. J. Chinese Universities, 2022, 43(8): 20220136. |

| [2] | DONG Luming, SU Yanyue, WANG Chunzheng, QIAO Yafei, CHEN Yajun, MA Haiyun. Synthesis of Micro- to Nano-scale Perovskite Calcium Hydroxytinate and Its Performance as a Flame Retardant in Epoxy Resin [J]. Chem. J. Chinese Universities, 2021, 42(3): 937. |

| [3] | WANG Peng, MAO Dan, WAN Jiawei, QI Qi, DU Jiang, WANG Dan. Effect of Hollow Multi-shelled TiO2 on Mechanical Properties of Epoxy Resin Composites [J]. Chem. J. Chinese Universities, 2021, 42(10): 3218. |

| [4] | SHA Di, YU Xumin, ZHAO Jiang, MA Xiaofei, WANG Hanfu, LIU Fangfang, QIU Xuepeng. Preparation and Mechanical Properties of Carbon Fiber Triaxial Woven Fabric/Epoxy Composites † [J]. Chem. J. Chinese Universities, 2020, 41(4): 838. |

| [5] | LIU Yina, YANG Rongjie, HU Weiguo, LI Dinghua. Analysis of Characteristic Phosphorus in High Polymerization Ammonium Polyphosphate by 31P NMR [J]. Chem. J. Chinese Universities, 2020, 41(12): 2832. |

| [6] | LI Xiangnan, WANG Qiuxian, FAN Yong, YU Mingming, ZHANG Huishuang, YANG Shuting. Deposition Method Synthesis of Nano-phosphorus/Biomass Carbon Composites and Their High- and Low-temperature Electrochemical Performances as Anode Material in Lithium-ion Batteries † [J]. Chem. J. Chinese Universities, 2019, 40(9): 1949. |

| [7] | HAN Tao,CAI Xiaoxia,LI Cong,QIAO Congde,ZHAO Hui. Preparation and Properties Characterization of Biobased Dihydrocoumarin Toughened Epoxy Resin† [J]. Chem. J. Chinese Universities, 2019, 40(5): 1043. |

| [8] | WANG Na,YANG Fei,ZHANG Jing,FANG Qinghong. Inflame-retardant Water-borne Epoxy Resin of APP Microsphere with Carrageenan Cladding† [J]. Chem. J. Chinese Universities, 2019, 40(2): 385. |

| [9] | Minwen JIANG,Chenhui YIN,Sheng LI,Xiaoli LI. Synthesis of DOPO-based Cyclotriphosphazene Macromolecule Flame Retardant and Its Performance in Flame-retarded Epoxy Resin † [J]. Chem. J. Chinese Universities, 2019, 40(12): 2615. |

| [10] | LI Xiangnan,YU Mingming,FAN Yong,WANG Qiuxian,ZHANG Huishuang,YANG Shuting. Study on Electrochemical Performances of N-doped P/C Composite as Anode Material of Lithium Ion Batteries † [J]. Chem. J. Chinese Universities, 2019, 40(11): 2360. |

| [11] | QIAN Yihao, ZHANG Dongjie, CHENG Zhongjun, KANG Hongjun, LIU Yuyan. Preparation of Hydrophilic Epoxy Resin and Its Wettability Regulation† [J]. Chem. J. Chinese Universities, 2018, 39(8): 1823. |

| [12] | WANG Yingnan, DAI Xueyan, XU Tianlu, QU Lijie, ZHANG Chunling. Preparation and Anticorrosion Properties of Silane Grafted Nano-silica/Epoxy Composite Coating† [J]. Chem. J. Chinese Universities, 2018, 39(7): 1564. |

| [13] | LU Lingang,CHENG Zhe,QIU Xinming,WANG Huiya,YANG Shousheng,QIAN Xiaodong,WANG Xuebao. Preparation of Green Star-topology Phosphazene Flame Retardant and Properties of Flame-retardant Epoxy Resin† [J]. Chem. J. Chinese Universities, 2018, 39(12): 2789. |

| [14] | LUO Huayong,RONG Hongwei,ZENG Xueyang,WANG Randeng,CHU Zhaorui. Performance of Phosphorus Sorption on Thermosensitive Zirconium Alginate Hydrogel Beads with Full-interpenetrating Network† [J]. Chem. J. Chinese Universities, 2018, 39(10): 2289. |

| [15] | HUANG Haihong, ZHANG Baoyu, ZHAO Zhipei. Degradation and Characterization of Recycling Carbon Fiber/Epoxy Resin Composites in Supercritical n-Butanol† [J]. Chem. J. Chinese Universities, 2017, 38(9): 1687. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||