Chem. J. Chinese Universities ›› 2020, Vol. 41 ›› Issue (4): 838.doi: 10.7503/cjcu20190513

• Material Chemistry • Previous Articles Next Articles

SHA Di1,3,YU Xumin2,*( ),ZHAO Jiang2,MA Xiaofei2,WANG Hanfu1,LIU Fangfang1,QIU Xuepeng1,*(

),ZHAO Jiang2,MA Xiaofei2,WANG Hanfu1,LIU Fangfang1,QIU Xuepeng1,*( )

)

Received:2019-10-09

Online:2020-04-10

Published:2020-02-21

Contact:

Xumin YU,Xuepeng QIU

E-mail:1149886452@qq.com;xp_q@ciac.ac.cn

Supported by:CLC Number:

TrendMD:

SHA Di, YU Xumin, ZHAO Jiang, MA Xiaofei, WANG Hanfu, LIU Fangfang, QIU Xuepeng. Preparation and Mechanical Properties of Carbon Fiber Triaxial Woven Fabric/Epoxy Composites †[J]. Chem. J. Chinese Universities, 2020, 41(4): 838.

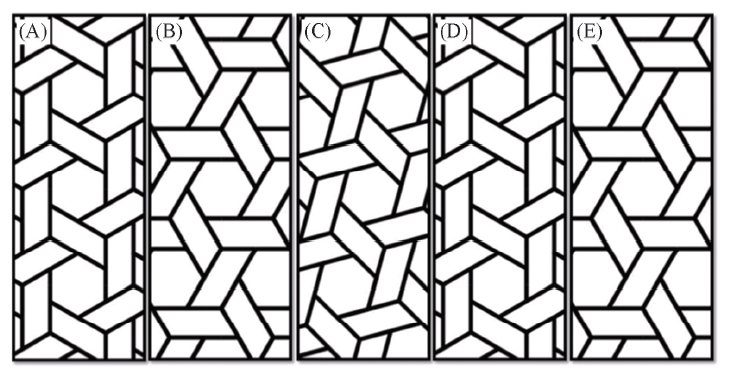

Fig.3 Illustration of carbon fiber triaxial woven fabric/epoxy resin composites with different cutting anglesCutting angle/(°): (A) 0; (B) 30; (C) 45; (D) 60; (E) 90.

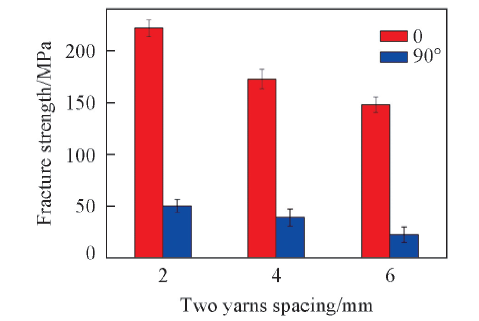

Fig.7 Fracture strength of carbon fiber triaxial woven fabric/epoxy resin composites with different two yarns spacings along cutting angles of 0° and 90°

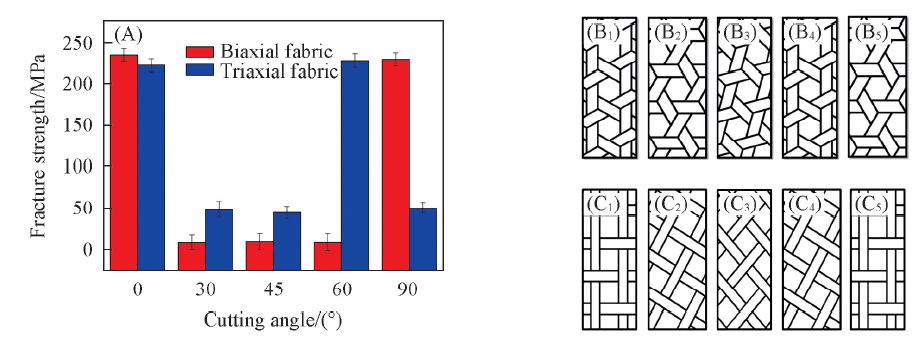

Fig.11 Fracture strength(A)and illustration of carbon fiber triaxial(B) and biaxial(C) woven fabric/epoxy resin composites along different cutting angles Cutting angle/(°): (B1, C1) 0; (B2, C2) 30; (B3, C3) 45; (B4, C4) 60; (B5, C5) 90.

| [1] | Santiago P. J., Baier H., Ceas Space Journal, 2013, 5( 3/4), 89— 115 |

| [2] | Higuchi Y. K., Ogi Y., Watanabe K ., Transactions of the Japan Society for Aeronautical & Space Sciences, 2009, 7( 7), 7— 11 |

| [3] | Leri D., Acta Astronautica, 2010, 66, 1081— 1086 |

| [4] | Sun J., Shi M. W., Qian K., Journal of Textile Research, 2014, 35, 154— 162 |

| ( 孙洁, 施楣梧, 钱坤 . 纺织学报, 2014, 35, 154— 162) | |

| [5] | Leri D., Horst B., Jose A. E., Herve L., Aerospace Science and Technology, 2006, 10, 618— 627 |

| [6] | Horst B., Leri D., Stephan E., Ceas Space Journal, 2013, 5( 3/4), 117— 124 |

| [7] | Feng G. Y., Cao H. J., Wang X. Y., Qian K., Sun J., Aerospace Materials & Technology, 2016, 3, 18— 21 |

| ( 冯古雨, 曹海建, 王新月, 钱坤, 孙洁 . 宇航工艺材料, 2016, 3, 18— 21) | |

| [8] | Yao L., Li W., Wang N., Journal of Materials Science, 2007, 42( 16), 6494— 6500 |

| [9] | Dow N. F., Tranfield G., Textile Research Journal, 1970, 40( 11), 986— 998 |

| [10] | Kueh A. B ., International Journal of Mechanical Sciences, 2013, 66, 45— 54 |

| [11] | Soykasap O., Karakaya S ., Journal of Reinforced Plastics & Composites, 2013, 32( 32), 450— 462 |

| [12] | Nakatani I., Tsurudak K., Yamayoto T., Acta Astronautica, 1995, 35, 337— 344 |

| [13] | Yang Q., China Textile Leader, 1987, 24, 6— 7 |

| ( 杨青. 纺织导报, 1987, 24, 6— 7) | |

| [14] | GB/T 1040 B/T 1040.2-2006, Plastics-Determination of Tensile Properties , Part 2: Test Conditions for Moulded and Extruded Plastics, Standards Press of China, Beijing, 2006 |

| ( 中国国家标准化管理委员会, GB/T 1040 GB/T 1040.2-2006,塑料拉伸性能的测定, 第2部分: 模塑和挤塑塑料的试验条件, 北京, 中国标准出版社, 2006) | |

| [15] | GB/T 3923. 1-2013, Textiles-Tensile Properties of Fabrics,Part 1: Determination of Maximum Force and Elongation at Maximum Force Using the Strip Methed, Standards Press of China ,Beijing, 2013 |

| ( 中国国家标准化管理委员会, GB/T 3923.1-2013, 纺织品织物拉伸性能, 第1部分: 断裂强力和断裂伸长率的测定(条样法), 北京, 中国标准出版社, 2013) | |

| [16] | GB/T 19976-2005, Textiles-Determination of Bursting Strength(Steel Ball Method), Standards Press of China, Beijing, 2005 |

| ( 中国国家标准化管理委员会, GB/T 19976-2005,纺织品顶破强力的测定(钢球法), 北京, 中国标准出版社, 2005) | |

| [17] | Yuan J. L., Technical Textiles, 1988, 10, 31— 34 |

| ( 袁佳玲. 产业用纺织品, 1988, 10, 31— 34) |

| [1] | LUO Xinyan, JIA Ruonan, XIANG Yong, ZHANG Xiaokun. Progress on the Stretchable Composite Solid Polymer Electrolytes [J]. Chem. J. Chinese Universities, 2022, 43(8): 20220149. |

| [2] | LIU Shuwei, JIN Hao, YIN Wanzhong, ZHANG Hao. Gemcitabine/polypyrrole Composite Nanoparticles for Chemo-photothermal Combination Ovarian Cancer Therapy [J]. Chem. J. Chinese Universities, 2022, 43(8): 20220345. |

| [3] | ZHAO Sheng, HUO Zhipeng, ZHONG Guoqiang, ZHANG Hong, HU Liqun. Preparation of Modified Gadolinium/Boron/Polyethylene Nanocomposite and Its Radiation Shielding Performance for Neutron and Gamma-ray [J]. Chem. J. Chinese Universities, 2022, 43(6): 20220039. |

| [4] | YU Pengdong, GUAN Xinghua, WANG Dongdong, XIN Zhirong, SHI Qiang, YIN Jinghua. Preparation and Properties of Novel Optical and Thermal Dual Response Shape Memory Polymers [J]. Chem. J. Chinese Universities, 2022, 43(6): 20220085. |

| [5] | ZHAO Junyu, WANG Chunbo, WANG Chengyang, ZHANG Ke, CONG Bing, YANG Lan, ZHAO Xiaogang, CHEN Chunhai. Preparation and Performance of Thermally Conductive Expanded Graphite/Polyetherimide Composites [J]. Chem. J. Chinese Universities, 2022, 43(4): 20210800. |

| [6] | CHU Yao, WANG Shuo, ZHANG Zinuo, WANG Yibo, CAI Yibing. Preparation and Properties of Cu Particles Loaded Foam-based Phase Change Composites [J]. Chem. J. Chinese Universities, 2022, 43(2): 20210619. |

| [7] | ZHANG Zhibo, SHANG Han, XU Wenxuan, HAN Guangdong, CUI Jinsheng, YANG Haoran, LI Ruixin, ZHANG Shenghui, XU Huan. Self-Assembly of Graphene Oxide at Poly(3-hydroxybutyrate) Microparticles Toward High-performance Intercalated Nanocomposites [J]. Chem. J. Chinese Universities, 2022, 43(2): 20210566. |

| [8] | ZHOU Ning, TANG Xiaohua, CAO Hong, ZHA Fei, LI Chun, XIE Chunyan, XU Mingping, SUN Yige. Preparation, Characterization and Degradation to BPA of Pomegranate-like Gel Microsphere Entrapmented Laccase [J]. Chem. J. Chinese Universities, 2022, 43(2): 20210705. |

| [9] | ZHAO Mengyang, HUANG Ziyang. Preparation and in vitro Bioactivity of HA/CuO/SrCO3 Gradiently Composite Coating [J]. Chem. J. Chinese Universities, 2022, 43(2): 20210644. |

| [10] | XU Huan, KE Lyu, TANG Mengke, SHANG Han, XU Wenxuan, ZHANG Zilin, FU Yanan, HAN Guangdong, CUI Jinsheng, YANG Haoran, GAO Jiefeng, ZHANG Shenghui, HE Xinjian. In⁃situ Liquid Exfoliation of Montmorillonite Nanosheets in Poly(lactic acid) to Resist Oxygen Permeation [J]. Chem. J. Chinese Universities, 2022, 43(11): 20220316. |

| [11] | LI Shurong, WANG Lin, CHEN Yuzhen, JIANG Hailong. Research Progress of Metal⁃organic Frameworks on Liquid Phase Catalytic Chemical Hydrogen Production [J]. Chem. J. Chinese Universities, 2022, 43(1): 20210575. |

| [12] | ZHANG Chi, SUN Fuxing, ZHU Guangshan. Synthesis, N2 Adsorption and Mixed-matrix Membrane Performance of Bimetal Isostructural CAU-21 [J]. Chem. J. Chinese Universities, 2022, 43(1): 20210578. |

| [13] | GAO Xiaole, WANG Jiaxin, LI Zhifang, LI Yanchun, YANG Donghua. Synthesis of NiOx-ZSM-5 Composite Materials and Its Electrocatalytic Hydrogen Evolution Performance in Microbial Electrolysis Cell [J]. Chem. J. Chinese Universities, 2021, 42(9): 2886. |

| [14] | LI Zhanfeng, LIU Benxue, LIU Xiaochan, WANG Xinqiang, ZHANG Jing, YU Shimo, ZHAO Xinfu, ZHANG Xin’en, YI Xibin. Mechanism of the Removal of Acetylacetone Ligands in Zirconia Wet Gel and Fabrication of Zirconia Aerogel Composites [J]. Chem. J. Chinese Universities, 2021, 42(9): 2904. |

| [15] | XU Xiaolong, FANG Lining, LIU Changyu, LIU Minchao, JIA Jianbo. Preparation of Z-type g-C3N4/Pt/TiO2 Nanotube Array Composite Electrode and Its Performance of Photoelectric Oxidation of Methanol [J]. Chem. J. Chinese Universities, 2021, 42(9): 2926. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||