Chem. J. Chinese Universities ›› 2018, Vol. 39 ›› Issue (8): 1823.doi: 10.7503/cjcu20180174

• Polymer Chemistry • Previous Articles Next Articles

QIAN Yihao1, ZHANG Dongjie1, CHENG Zhongjun2,*( ), KANG Hongjun1, LIU Yuyan1,*(

), KANG Hongjun1, LIU Yuyan1,*( )

)

Received:2018-03-06

Online:2018-08-10

Published:2018-08-10

Contact:

CHENG Zhongjun,LIU Yuyan

E-mail:chengzhongjun@iccas.ac.cn;liuyy@hit.edu.cn

Supported by:CLC Number:

TrendMD:

QIAN Yihao, ZHANG Dongjie, CHENG Zhongjun, KANG Hongjun, LIU Yuyan. Preparation of Hydrophilic Epoxy Resin and Its Wettability Regulation†[J]. Chem. J. Chinese Universities, 2018, 39(8): 1823.

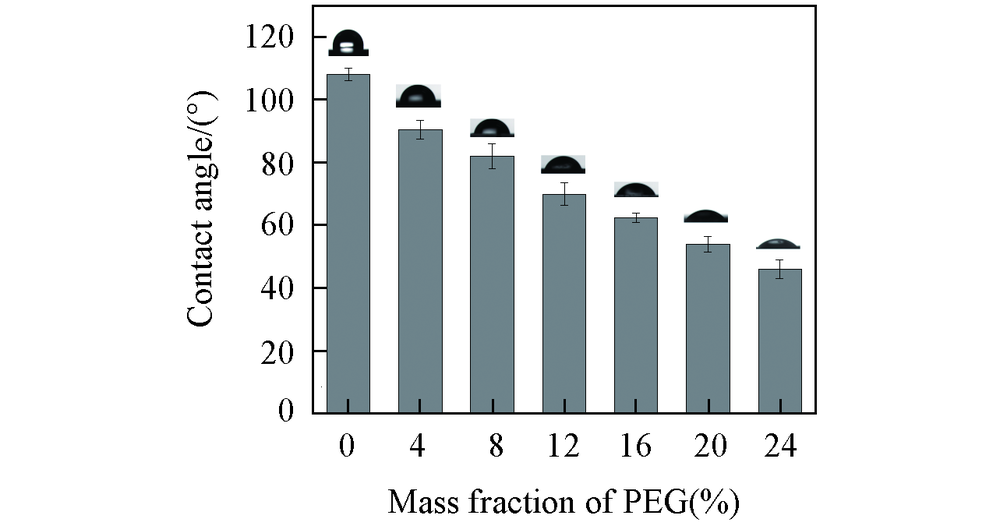

Fig.1 Statistic of the water contact angles of TDE-85 epoxy resin modified by diffe-rent amount of PEGInsets are shapes of a water droplet on the related surface.

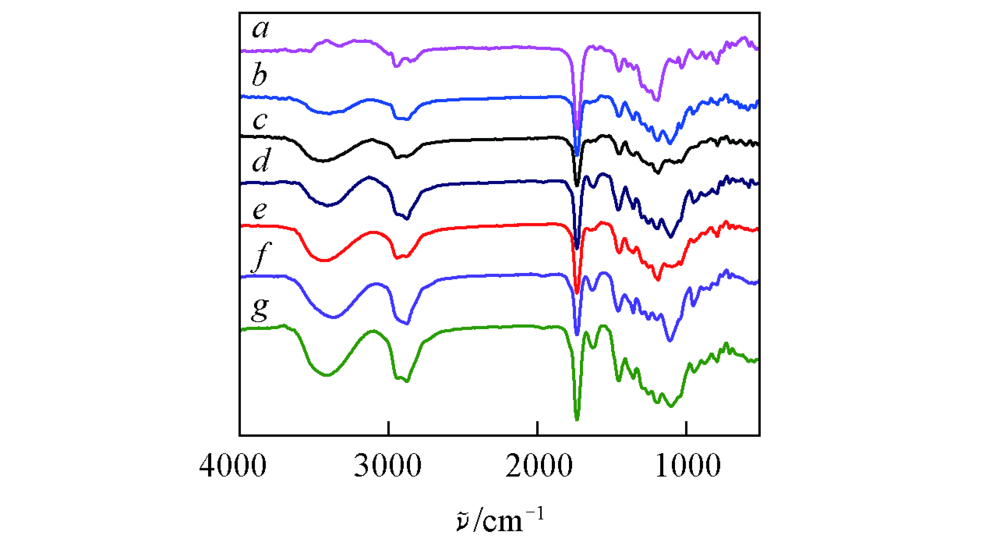

Fig.2 Infrared spectra of TDE-85 epoxy resins modified by different amount of PEGMass fraction of PEG(%): a. 0; b. 4; c. 8; d. 12; e. 16; f. 20; g. 24.

| Mass fraction of PEG(%) | Shape fixed rate(%) | Shape recovery rate(%) |

|---|---|---|

| 4 | 100 | 99.76 |

| 8 | 99.10 | 99.70 |

| 12 | 98.20 | 99.65 |

| 16 | 97.30 | 99.71 |

| 20 | 96.10 | 99.97 |

| 24 | 93.20 | 98.90 |

Table 1 Shape fixed rate and shape recovery rate of TDE-85/MXDA/PEG curing system

| Mass fraction of PEG(%) | Shape fixed rate(%) | Shape recovery rate(%) |

|---|---|---|

| 4 | 100 | 99.76 |

| 8 | 99.10 | 99.70 |

| 12 | 98.20 | 99.65 |

| 16 | 97.30 | 99.71 |

| 20 | 96.10 | 99.97 |

| 24 | 93.20 | 98.90 |

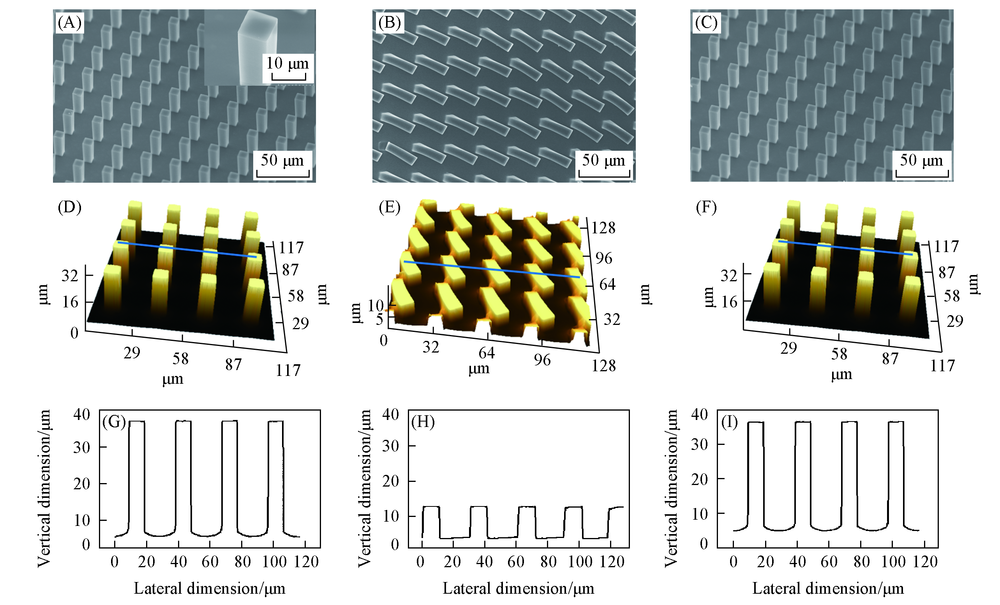

Fig.5 Surface microstructure variation of TDE-85 epoxy curing system with 20% PEG(A)―(C) are SEM images of the surface microstructure at original state, crushed state after pressing and restored state after heating, respectively. Inset in (A) is the magnified image of one pillar corresponding to (A). (D)―(F) are 3D confocal microscopy images of the surface microstructure at original state, crushed state after pressing and restored state after heating, respectively. (G)―(I) are the profile pictures corresponding to (D), (E) and (F), respectively.

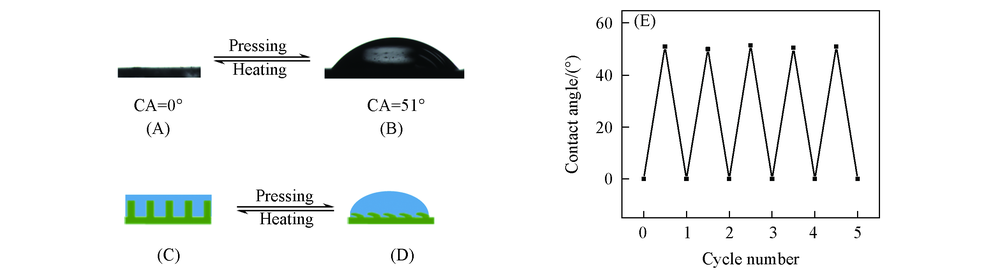

Fig.7 Shapes of a water droplet on the surface with different pillar structures(A) Upright pillars; (B) collapsed pillars; (C) and(D) schematic illustration of different water/solid contact models for surface with different pillar structures; (E) change of water contact angle after cyclic pressing and heating the surface.

| [1] | Cho S.K., Moon H. J., Kim C. J., J. Microelectromech. Syst., 2003, 12(1), 70—80 |

| [2] | Srinivasan V., Pamula V.K., Fair R. B., Lab Chip, 2004, 4(4), 310—315 |

| [3] | Hayes R.A., Feestra B. J., Nature, 2003, 425(6956), 383—385 |

| [4] | Huang X., Sun Y., Soh S., Adv. Mater., 2015, 27(27), 4062—4068 |

| [5] | Yu X., Wang Z.Q., Jiang Y. G., Shi F., Zhang X, Adv. Mater., 2005, 17(10), 1289—1293 |

| [6] | Tian D., Chen Q., Nie F.Q., Xu J., Song Y., Jiang L, Adv. Mater., 2009, 21(37), 3744—3749 |

| [7] | Tian D., Zhang X., Tian Y., Wu Y., Wang X., Zhai J., Jiang L., J. Mater. Chem., 2012, 22(37), 19652—19657 |

| [8] | Janout V., Myers S.B., Register R. A., Regen S. L., J. Am. Chem. Soc., 2007, 129(17), 5756—5759 |

| [9] | Fu Q., Rama R.G. V., Basame S. B., Keller D. J., Artyushkova K., Fulghum J. E., Lopez G. P., J. Am. Chem. Soc., 2004, 126(29), 8904—8905 |

| [10] | Zhang L., Zhang Z., Wang P., NPG Asia Mater., 2012, 4, e8 |

| [11] | Lahann J., Mitragotri S., Tran T.N., Kaido H., Sundaram J., Choi I. S., Hoffer S., Somorjai G. A., Langer R., Science, 2003, 299(5605), 371—374 |

| [12] | Nakata K., Nishimoto S., Kubo A., Tryk D., Ochiai T., Murakami T., Fujishima A., Chem. Asian J., 2009, 4(6), 984—988 |

| [13] | Xia F., Ge H., Hou Y., Sun T.L., Chen L., Zhang G. Z., Jiang L, Adv. Mater., 2007, 19(18), 2520—2524 |

| [14] | Lee S., Yim C., Kim W., Jeon S., ACS Appl. Mater. Inter., 2015, 7(35), 19853—19856 |

| [15] | Wong W.S. Y., Gutruf P., Sriram S., Bhaskaran M., Wang Z., Tricoli A, Adv. Funct. Mater., 2016, 26(3), 399—407 |

| [16] | Wu Z.L., Buguin A., Yang H., Taulemesse J. M., Le Moigne N., Bergeret A., Wang X., Keller P, Adv. Funct. Mater., 2013, 23(24), 3070—3076 |

| [17] | García-Huete N., Cuevas J., Laza J., Vilas J., León L., Polymers, 2015, 7(9), 1674—1688 |

| [18] | Yang S., Chen C., Adv. Mater., 2014, 26(8), 1283—1288 |

| [19] | Sarwate P., Chakraborty A., Garg V., Luo C., J. Micromech. Microeng., 2014, 24(11), 115006 |

| [20] | Lv T., Cheng Z.J., Zhang E. S., Kang H. J., Liu Y. Y., Jiang L., Small, 2017, 13(4), 1503402 |

| [21] | Lü T., Cheng Z.J., Lai H., Zhang E. S., Liu Y. Y., Chem. J. Chinese Universities, 2016, 37(7), 1351—1356 |

| (吕通, 成中军, 来华, 张恩爽, 刘宇艳. 高等学校化学学报, 2016, 37(7), 1351—1356) | |

| [22] | Lü T., Cheng Z.J., Lai H., Zhang E. S., Liu Y. Y., Chem. J. Chinese Universities, 2016, 37(8), 1559—1564 |

| (吕通, 成中军, 来华, 张恩爽, 刘宇艳. 高等学校化学学报, 2016, 37(8), 1559—1564) |

| [1] | YU Pengdong, GUAN Xinghua, WANG Dongdong, XIN Zhirong, SHI Qiang, YIN Jinghua. Preparation and Properties of Novel Optical and Thermal Dual Response Shape Memory Polymers [J]. Chem. J. Chinese Universities, 2022, 43(6): 20220085. |

| [2] | YANG Zhaohua, CHENG Hongjing, YANG Yi, LIU Hui, DU Feipeng, ZHANG Yunfei. Preparation of Silver-loaded Polyvinyl Alcohol Sponge and Its Interfacial Photothermal Driven Water Evaporation Performance [J]. Chem. J. Chinese Universities, 2022, 43(10): 20220181. |

| [3] | HAN Yandong, HAN Mingyong, YANG Wensheng. Sol-gel Construction of Mesoporous Silica Nanomicrostructures [J]. Chem. J. Chinese Universities, 2021, 42(4): 965. |

| [4] | LIU Pengchang, LAI Hua, CHENG Zhongjun, LIU Yuyan. Fabrication of Superwetting Porous Shape Memory Sponge and Its Application in Oil-water Separation [J]. Chem. J. Chinese Universities, 2021, 42(3): 894. |

| [5] | DONG Luming, SU Yanyue, WANG Chunzheng, QIAO Yafei, CHEN Yajun, MA Haiyun. Synthesis of Micro- to Nano-scale Perovskite Calcium Hydroxytinate and Its Performance as a Flame Retardant in Epoxy Resin [J]. Chem. J. Chinese Universities, 2021, 42(3): 937. |

| [6] | WANG Peng, MAO Dan, WAN Jiawei, QI Qi, DU Jiang, WANG Dan. Effect of Hollow Multi-shelled TiO2 on Mechanical Properties of Epoxy Resin Composites [J]. Chem. J. Chinese Universities, 2021, 42(10): 3218. |

| [7] | ZHANG Jiayi, DING Zhenyao, WANG Dandan, CHEN Liping, FENG Xinjian. Fabrication of Triphase Enzyme Electrode Based on Porous Gold Substrate for High-performance Electrochemical Biosensor [J]. Chem. J. Chinese Universities, 2021, 42(10): 3167. |

| [8] | JIANG Huayi,LIU Mei,QI Hongyuan,LIANG Aiguo,WANG Yulong,SUN Nana,WU Zhe. Fractal Characteristics of the Microstructures of Three Hydrophobic Surfaces with Steel Substrate and Their Effects on Wettability † [J]. Chem. J. Chinese Universities, 2020, 41(6): 1313. |

| [9] | SHA Di, YU Xumin, ZHAO Jiang, MA Xiaofei, WANG Hanfu, LIU Fangfang, QIU Xuepeng. Preparation and Mechanical Properties of Carbon Fiber Triaxial Woven Fabric/Epoxy Composites † [J]. Chem. J. Chinese Universities, 2020, 41(4): 838. |

| [10] | ZHANG Li,QIAN Mingchao,LIU Xueke,Gao Shuaitao,YU Jiang,XIE Haishen,WANG Hongbin,SUN Fengjiang,SU Xianghong. Dynamic Study of Oxidative Desulfurization by Iron-based Ionic Liquids/NHD † [J]. Chem. J. Chinese Universities, 2020, 41(2): 317. |

| [11] | GUO Zhaopei,LIN Lin,CHEN Jie,TIAN Huayu,CHEN Xuesi. Polyglutamic Acid Grafted Polyethylene Glycol@Calcium Carbonate Based Shielding System for Improving Polyethyleneimine Gene Transfection Efficiency † [J]. Chem. J. Chinese Universities, 2020, 41(2): 235. |

| [12] | WANG Wu, LAI Hua, CHENG Zhongjun, LIU Yuyan. Reversible Regulation of Droplet Directional/anti-directional Rolling on Superhydrophobic Shape Memory Microarray Surface [J]. Chem. J. Chinese Universities, 2020, 41(11): 2538. |

| [13] | LI Lin, XU Xinru, LI Yingqi, ZHANG Caifeng. Preparation of Targeting Nanodiamond-metaminopterone Drug System and Its Interaction with MCF-7 Cells † [J]. Chem. J. Chinese Universities, 2019, 40(9): 1998. |

| [14] | HAN Tao,CAI Xiaoxia,LI Cong,QIAO Congde,ZHAO Hui. Preparation and Properties Characterization of Biobased Dihydrocoumarin Toughened Epoxy Resin† [J]. Chem. J. Chinese Universities, 2019, 40(5): 1043. |

| [15] | ZHAO Yuxuan,CHEN Yanjun,PAN Guxin,WANG Chang,PENG Zhenbo,SUN Zongxu,LIANG Yongri,SHI Qisong. Preparation and Performance of Novel Tb-PEG+Eu-PEG/PANI/PAN Luminescent-electrical-phase Change Composite Fibers by Electrospinning† [J]. Chem. J. Chinese Universities, 2019, 40(4): 824. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||