高等学校化学学报 ›› 2020, Vol. 41 ›› Issue (2): 300.doi: 10.7503/cjcu20190480

关芳兰1,李昕1,*( ),张群1,龚1,林紫钰1,陈耀1,王乐军2

),张群1,龚1,林紫钰1,陈耀1,王乐军2

收稿日期:2019-09-06

出版日期:2020-02-10

发布日期:2019-11-04

通讯作者:

李昕

E-mail:clylx@mail.bift.edu.cn

基金资助:

GUAN Fanglan1,LI Xin1,*( ),ZHANG Qun1,GONG Yan1,LIN Ziyu1,CHEN Yao1,WANG Lejun2

),ZHANG Qun1,GONG Yan1,LIN Ziyu1,CHEN Yao1,WANG Lejun2

Received:2019-09-06

Online:2020-02-10

Published:2019-11-04

Contact:

Xin LI

E-mail:clylx@mail.bift.edu.cn

Supported by:摘要:

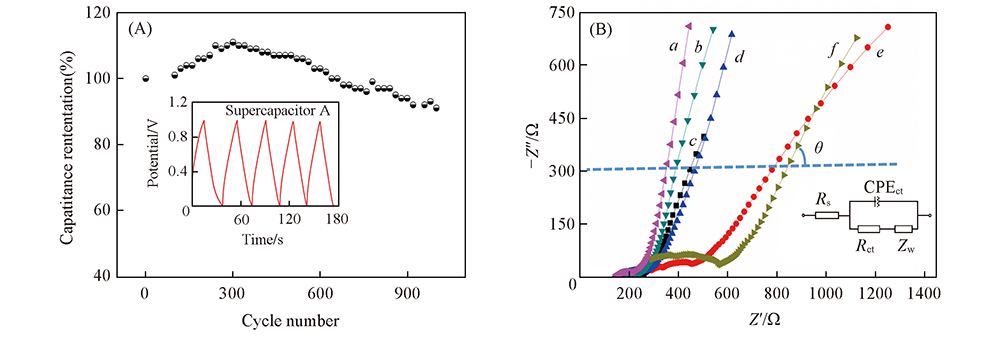

将采用改性Hummers法制备的氧化石墨烯与多壁碳纳米管(MWCNT)复合, 通过激光直写的方法制备了以棉织物(Cotton fabric, CF)为基底的石墨烯复合碳纳米管的同心圆形织物柔性平面超级电容器(RGO/MWCNT/CF). 通过扫描电子显微镜、 X 射线衍射和拉曼光谱技术对RGO/MWCNT/CF进行了表征, 并对超级电容器的电导率和电化学性能进行了测试. 结果表明, 电极材料经激光还原后导电率达到了7.19×10 4 S/m, 表现出良好的导电性能. 以RGO/MWCNT/CF为工作电极、 PVA/LiCl凝胶为电解质组装的超级电容器具有良好的电化学性能, 在电位窗口为0~1 V、 电流密度为40.8 mA/cm 2时比电容达到24 mF/cm 2, 功率密度为61 mW·h/kg, 能量密度为1.22 mW·h/kg, 且循环1000次仍能保持92%的比电容.

中图分类号:

TrendMD:

关芳兰,李昕,张群,龚,林紫钰,陈耀,王乐军. 激光直写微型RGO/MWCNT/CF平面柔性超级电容器的制备及性能. 高等学校化学学报, 2020, 41(2): 300.

GUAN Fanglan,LI Xin,ZHANG Qun,GONG Yan,LIN Ziyu,CHEN Yao,WANG Lejun. Fabrication and Capacitance Performance of Laser-machined RGO/MWCNT/CF In-plane Flexible Micro-supercapacitor †. Chem. J. Chinese Universities, 2020, 41(2): 300.

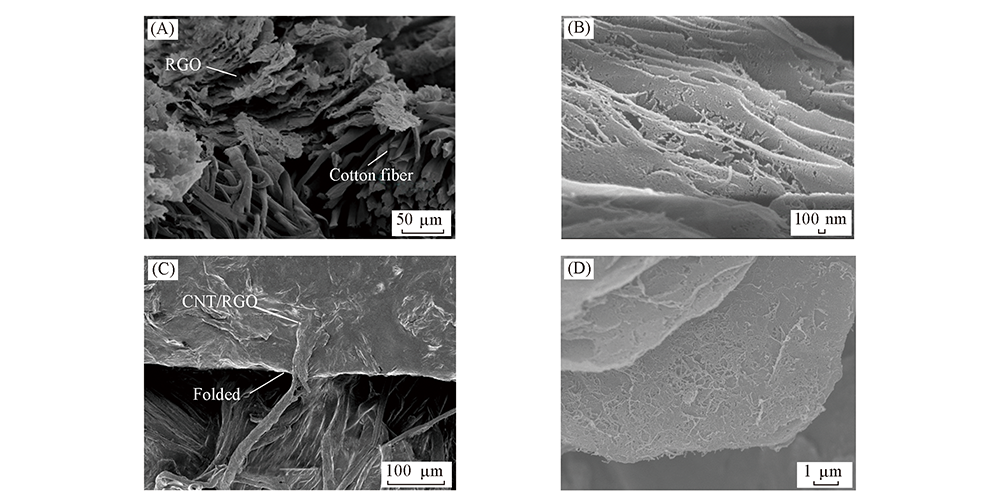

Fig.2 SEM images of RGO/21%MWCNT/CF (A) Interface between RGO/MWCNT and cotton Fabric; (B) RGO/MWCNT layered structure reduced by 5 W laser; (C) cross-sectional image of the folded RGO/21%MWCNT/CF electrode; (D) network structure formed by RGO/21%MWCNT/CF electrode.

Fig.6 Cycling performance of supercapacitor A(A) and EIS spectra(B) of RGO/MWCNT/CF at a scan rate of 100 mA/cm2 a. Supercapacitor A; b. supercapacitor B; c. supercapacitor C; d. supercapacitor D; e. supercapacitor E; f. supercapacitor F. Inset of (A): GCD curves of supercapacitor A. Inset of (B): the equivalent circuit.

| Electrode material | Current collector | Base | Test condition | Capacitance/(mF·cm-2) | Ref. |

|---|---|---|---|---|---|

| RGO/MWCNT | Foamed Ni | Cotton | 100 mV/s | 24 | This work |

| Nylon-graphene | Au-coated vinyl film | Nonwoven | 10 mV/s | 10.37 | [31] |

| GO | None | PET film | 16.8 mA/cm3 | 2.32 | [32] |

| GO | Patterned polyvinyl tap | None | 40 mV/s | 0.51 | [33] |

| MXene | Au | Paper | 20 mV/s | 25 | [34] |

Table 1 Specific capacitance comparison among different planar flexible supercapacitor

| Electrode material | Current collector | Base | Test condition | Capacitance/(mF·cm-2) | Ref. |

|---|---|---|---|---|---|

| RGO/MWCNT | Foamed Ni | Cotton | 100 mV/s | 24 | This work |

| Nylon-graphene | Au-coated vinyl film | Nonwoven | 10 mV/s | 10.37 | [31] |

| GO | None | PET film | 16.8 mA/cm3 | 2.32 | [32] |

| GO | Patterned polyvinyl tap | None | 40 mV/s | 0.51 | [33] |

| MXene | Au | Paper | 20 mV/s | 25 | [34] |

| [1] |

Hu H., Zhang K., Li S., Ji S., Ye C ., Journal of Materials Chemistry A, 2014,2(48), 20916— 20922

doi: 10.1039/c4ta05345a URL |

| [2] | Wang S., Zheng S., Wu Z., Sun C ., Scientia Sinica, 2016,46(8), 732— 744 |

| [3] | Conway B. E., Springer Science & Business Media,New York, 1999, 20— 23 |

| [4] |

Zhang L. L., Zhao X. S., Chemical Society Reviews, 2009,38(9), 2520— 2531

doi: 10.1039/b813846j URL |

| [5] |

Xiao Z. Y., Mei Y. J., Yuan S., Mei H., Xu B., Bao Y. X., Fan L. L., Kang W. P., Dai F. N., Wang R. M., Wang L., Sun D. F., Hu S. Q., Zhou H. C., ACS Nano, 2019,13(6) 7024— 7030

doi: 10.1021/acsnano.9b02106 URL |

| [6] | Li Y. Y., Zhang Q., Zhang Y. H., Wang L., Chem. J. Chinese Universities, 2017,38(11), 2031— 2037 |

| ( 李莹莹, 张琦, 张宜恒, 王磊 . 高等学校化学学报, 2017,38(11), 2031— 2037) | |

| [7] | Meng J. Y., Li X., Gong Y., Wang R., Zheng Y. P., Zhang D. Q., Acta Polymerica Sinica, 2018,3, 389— 394 |

| ( 孟佳意, 李昕, 龚龑, 王锐, 郑一平, 张德泉 . 高分子学报, 2018,3, 389— 394) | |

| [8] |

Stankovich S., Dikin D. A., Dommett G. H. B., Kohlhaas K. M., Zimney E. J., Stach E. A., Piner R. D., Nguyen S. T., Ruoff R. S., Nature, 2006,442, 282— 286

doi: 10.1038/nature04969 URL |

| [9] |

Boehm H. P., Angew. Chem. Int. Ed., 2010,49, 9332— 9335

doi: 10.1002/anie.201004096 URL |

| [10] |

Zhang Y. B., Small J. P., Pontius W. V., Kim P., Appl. Phys. Lett., 2005,86, 073104

doi: 10.1063/1.1862334 URL |

| [11] | Tang Y., Liu H., Lu L. S., Xie Y. X., Yuan W., Wan Z. P., Li Z. T., Ding X. R., Journal of Mechanical Engineering, 2019,55(4), 206— 223 |

| ( 汤勇, 刘辉龙, 陆龙生, 谢颖熙, 袁伟, 万珍平, 李宗涛, 丁鑫锐 . 机械工程学报, 2019,55(4), 206— 223) | |

| [12] |

Mensing J. P., Poochai C., Kerdpocha S., Sriprachuabwong H., Wisitsoraat A., Tuantranont D., Adv. Nat. Sci. , Nanosci. Nanotechnol., 2017,8, 033001— 033008

doi: 10.1088/2043-6254/aa7214 URL |

| [13] | Vivekchand S. R. C., Chandra S. R., Subrahmanyam K. S., Govindaraj A., Cnrrao J., Chem. Sci., 2008, 120, 1, 9— 13 |

| [14] |

Shin H. J., Kim K. K., Benayad A., Yoon S. M., Park H. K., Jung I. S., Adv. Func. Mater., 2009,19, 1987— 1992

doi: 10.1002/adfm.v19:12 URL |

| [15] | Gao W., Neelam S., Song L., Zheng L., Mohana A. L., Ci L. J., Robert V., Zhang Q., Wei B. Q., Pulickel M. A., Nature Nanotech-nology, 2011,6(8), 496— 500 |

| [16] |

Maher F., Kasy El., Veronica S., Sergey D., Richard B ., Kaner, Science, 2012,335(6074), 1326— 1330

doi: 10.1126/science.1216744 URL |

| [17] | Li R. Z., Peng R., Kihm K. D., Bai S., Bridges D., Tumuluri U., Wu Z., Zhang T., Compagnini G., Feng Z. L., Hu A. M., Energy & Environmental Science, 2016,9(4), 1458— 1467 |

| [18] | Jiang Y. Q., Zhou Q., Lin L., IEEE MEMS, 2009, 587— 590 |

| [19] | Hummers W. S, Offeman R. E., J.Am. Chem. Soc. , 1958,208, 1334— 1339 |

| [20] |

Zhou Y., Bao Q., Varghese B., Tang L. A. L., Tan C.K., Sow C. H., Adv. Mater., 22(1), 67— 71

doi: 10.1002/adma.v22:1 URL |

| [21] |

Wang L., Feng X., Ren L. T., Piao Q. H., Zhong J. Q., Wang Y. B., Li H. W., Chen Y., Wang F. B., J. Am. Chem. Soc., 2015,137, 4920— 4927

doi: 10.1021/jacs.5b01613 URL |

| [22] |

Chang J., Adhikari S., Lee T. H., Li B., Yao F., Pham D. T., Le V. T., Lee Y. H., Adv. Energy Mater., 2015,5, 1500003— 1500008

doi: 10.1002/aenm.201500003 URL |

| [23] |

Hu L. B., Pasta M., La Mantia F., Cui L. F., Jeong S., Deshazer H. D., Choi J. W., Han S. M., Cui Y., Nano Lett., 2010,10, 708— 715

doi: 10.1021/nl903949m URL |

| [24] |

Bao L. H., Li X. D., Adv. Mater., 2012,24, 3246— 3251

doi: 10.1002/adma.v24.24 URL |

| [25] |

Meng Y. N., Zhao Y., Hu C. G., Cheng H. H., Hu Y., Zhang Z. P., Shi G. Q., Qu L. T., Adv. Mater., 2013,25, 2326— 2332

doi: 10.1002/adma.201300132 URL |

| [26] |

Yang P. H., Ding Y., Lin Z. Y., Chen Z. W., Li Y. Z., Qiang P. F., Ebrahimi M., Mai W. J., Wong C. P., Wang Z. L., Nano Lett., 2014,14, 731— 737

doi: 10.1021/nl404008e URL |

| [27] |

Xu J., Wang Q. F., X. W. Wan., Xiang Q. Y., Hang B., Chen D., Shen G. Z., ACS Nano, 2013,7, 5453— 5460

doi: 10.1021/nn401450s URL |

| [28] |

Liu W. W., Yan X. B., Lang J. W., Peng C., Xue Q. J., J. Mater. Chem. , 2012,22, 17245— 17249

doi: 10.1039/c2jm32659k URL |

| [29] |

Shen L. F., Chen Q., Li H. S., Zhang X. G., Adv. Funct. Mater., 2014,24, 2630— 2635

doi: 10.1002/adfm.v24.18 URL |

| [30] |

Wang W., Liu W. Y., Zeng Y. X., Han Y., Yu M. H., Lu X. H., Tong Y. X., Adv. Mater., 2015,27, 3572— 3576

doi: 10.1002/adma.v27.23 URL |

| [31] |

Pan Q., Shim E., Pourdeyhimi B., Gao W ., ACS Applied Materials & Interfaces, 2017,9(9), 8308— 8316

doi: 10.1021/acsami.7b00471 URL |

| [32] |

Kady E. L, Strong M. F., Dubin V., Kaner S., Science, 2012,335(6074), 1326— 1330

doi: 10.1126/science.1216744 URL |

| [33] |

Gao W., Singh N., Song L., Liu Z., Reddy A., Ci L. J., Robert V. I., Zhang Q., Wei B. Q., Ajayan P. M., Nature Nanotechnology, 2011,6(8), 496— 500

doi: 10.1038/nnano.2011.110 URL |

| [34] |

Kurra N., Ahmed B., Gogotsi Y ., Advanced Energy Materials, 2016,6(24), 1601372— 1601378

doi: 10.1002/aenm.201601372 URL |

| [1] | 王雪丽, 宋相伟, 解颜宁, 杜妮阳, 王振新. 部分还原氧化石墨烯的制备、 表征及对人宫颈癌HeLa细胞的体外杀伤作用[J]. 高等学校化学学报, 2022, 43(2): 20210595. |

| [2] | 刘杰, 李金晟, 柏景森, 金钊, 葛君杰, 刘长鹏, 邢巍. 降低直接甲醇燃料电池浓差极化的含磺化碳管阻水夹层的构建[J]. 高等学校化学学报, 2022, 43(11): 20220420. |

| [3] | 苗伟俊, 吴锋, 王勇, 王宗宝. 高剪切速率对PCL/RGO附生结晶行为影响的原位研究[J]. 高等学校化学学报, 2021, 42(3): 910. |

| [4] | 黄东雪, 章颖, 曾婷, 张媛媛, 万其进, 杨年俊. 基于过渡金属硫化物/还原氧化石墨烯复合物的高性能超级电容器[J]. 高等学校化学学报, 2021, 42(2): 643. |

| [5] | 陈砚田, 郄晗彤, 张胤杰, 周彩吉, 谭笑, 林爱军. 还原氧化石墨烯负载零价铁的合成及对TNT废水处理[J]. 高等学校化学学报, 2020, 41(8): 1836. |

| [6] | 孙蒙蒙, 常春蕊, 张志明, 安立宝. 掺钯碳纳米管的制备及电接触性能[J]. 高等学校化学学报, 2019, 40(1): 11. |

| [7] | 李龙, 胡红利, 丁书江. 鳞状CoMn2O4/石墨烯复合材料的制备及在超级电容器中的应用[J]. 高等学校化学学报, 2018, 39(9): 2010. |

| [8] | 王杰, 孙晓刚, 陈玮, 李旭, 黄雅盼, 魏成成, 胡浩, 梁国东. 羟基化多壁碳纳米管三明治隔膜对锂硫电池电化学性能的改善[J]. 高等学校化学学报, 2018, 39(8): 1782. |

| [9] | 陈晓菲, 柳朝阳, 雷杨, 范宝安, 郭芬. Ni@MWCNTs催化阳极的制备及在直接尿素(尿液)燃料电池中的应用[J]. 高等学校化学学报, 2018, 39(3): 537. |

| [10] | 孙兵, 蒋尚, 王润伟, 倪玲, 裘式纶, 张宗弢. 高性能钛酸锂/还原氧化石墨烯复合负极材料的合成与应用[J]. 高等学校化学学报, 2018, 39(12): 2767. |

| [11] | 卢林刚, 程哲, 丘新铭, 王会娅, 杨守生, 钱小东, 王学宝. 星型绿色磷腈阻燃剂的制备及阻燃环氧树脂性能[J]. 高等学校化学学报, 2018, 39(12): 2789. |

| [12] | 邱丽娟, 张颖, 刘帅卓, 张骞, 周莹. 超疏水、 高强度石墨烯油水分离材料的制备及应用[J]. 高等学校化学学报, 2018, 39(12): 2758. |

| [13] | 苗瑞, 吴冬雪, 王秋颖, 赵幻希, 李雪, 修洋, 刘淑莹. 基于多壁碳纳米管的人参皂苷快速分离[J]. 高等学校化学学报, 2018, 39(10): 2178. |

| [14] | 王雪丽, 王振新. 基于部分还原氧化石墨烯纳米复合材料的肿瘤靶向光动力-光热联合治疗剂的制备[J]. 高等学校化学学报, 2018, 39(10): 2185. |

| [15] | 林里, 陈峥, 商赢双, 王兆阳, 高雁伟, 姜振华, 张海博. 聚醚醚酮/含萘聚芳醚酮改性碳纳米管复合材料的制备及性能[J]. 高等学校化学学报, 2018, 39(10): 2343. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||