高等学校化学学报 ›› 2026, Vol. 47 ›› Issue (1): 20250319.doi: 10.7503/cjcu20250319

胡锦宏, 蔡铭威, 甘一乐, 张扬, 施海南( ), 闵永刚(

), 闵永刚( )

)

收稿日期:2025-10-31

出版日期:2026-01-10

发布日期:2025-12-10

通讯作者:

施海南,闵永刚

E-mail:4015081@qq.com;ygmin@gdut.edu.cn

基金资助:

HU Jinhong, CAI Mingwei, GAN Yile, ZHANG Yang, SHI Hainan( ), MIN Yonggang(

), MIN Yonggang( )

)

Received:2025-10-31

Online:2026-01-10

Published:2025-12-10

Contact:

SHI Hainan, MIN Yonggang

E-mail:4015081@qq.com;ygmin@gdut.edu.cn

Supported by:摘要:

聚酰亚胺作为高性能聚合物的关键代表, 以其卓越的耐热性、 优异的力学性能及突出的介电特性, 在集成电路、 新能源、 航空航天等国家战略新兴领域中扮演着不可替代的角色. 然而, 面对柔性电子、 高效能源转换及“双碳”战略等前沿领域的快速发展, 传统聚酰亚胺材料在介电、 柔性、 功能集成及热管理等方面仍存在显著瓶颈. 基于此, 本文综合评述了本课题组围绕“芯-屏-器/气-合” 5个关键维度所取得的多功能聚酰亚胺的创新研究成果. 在“芯”层面, 发展了具有超低介电常数与高强度的材料体系, 服务于高端芯片封装; 在“屏”层面, 研制出高透光、 耐折曲的柔性薄膜, 满足柔性显示需求; 在“器/气”层面, 一方面拓展了其在能源器件与航空航天热管理中的应用, 另一方面通过结构设计显著提升了气体分离性能, 服务于“双碳”目标; 在“合”层面, 通过构建多维导热网络, 实现了复合材料热管理能力的突破. 本文不仅展示了聚酰亚胺巨大的功能可塑性, 也为解决相关科技领域的关键材料挑战提供了重要的理论与技术支撑.

中图分类号:

TrendMD:

胡锦宏, 蔡铭威, 甘一乐, 张扬, 施海南, 闵永刚. “芯-屏-器/气-合”——多功能化聚酰亚胺材料的核心技术突破、 性能优化及应用场景探索. 高等学校化学学报, 2026, 47(1): 20250319.

HU Jinhong, CAI Mingwei, GAN Yile, ZHANG Yang, SHI Hainan, MIN Yonggang. “IC-Display-Device/Gas separation-Composite”—Breakthroughs in Core Technologies, Performance Optimization, and Application Exploration of Multifunctional Polyimide Materials. Chem. J. Chinese Universities, 2026, 47(1): 20250319.

| Characteristic | Negative⁃tone photosensitive polyimide | Positive⁃tone photosensitive polyimide |

|---|---|---|

| Core mechanism | Photo⁃induced crosslinking | Photo⁃induced increase in solubility |

| Photosensitive groups | Acrylate groups, epoxy groups, vinyl ether, etc. | Diazonaphthoquinone(DNQ) compounds, etc. |

| Development result | Exposed areas are insoluble and retained | Exposed areas are soluble and removed |

| Features | Mature process, widely applied, good adhesion, | Higher resolution, good pattern precision |

| fast photosensitivity, low cost | ||

| Application scenarios | Advanced packaging, insulating buffer layers | High⁃density integrated circuits, fine pattern transfer |

Table 1 Characteristics of negative/positive photoresist polyimide

| Characteristic | Negative⁃tone photosensitive polyimide | Positive⁃tone photosensitive polyimide |

|---|---|---|

| Core mechanism | Photo⁃induced crosslinking | Photo⁃induced increase in solubility |

| Photosensitive groups | Acrylate groups, epoxy groups, vinyl ether, etc. | Diazonaphthoquinone(DNQ) compounds, etc. |

| Development result | Exposed areas are insoluble and retained | Exposed areas are soluble and removed |

| Features | Mature process, widely applied, good adhesion, | Higher resolution, good pattern precision |

| fast photosensitivity, low cost | ||

| Application scenarios | Advanced packaging, insulating buffer layers | High⁃density integrated circuits, fine pattern transfer |

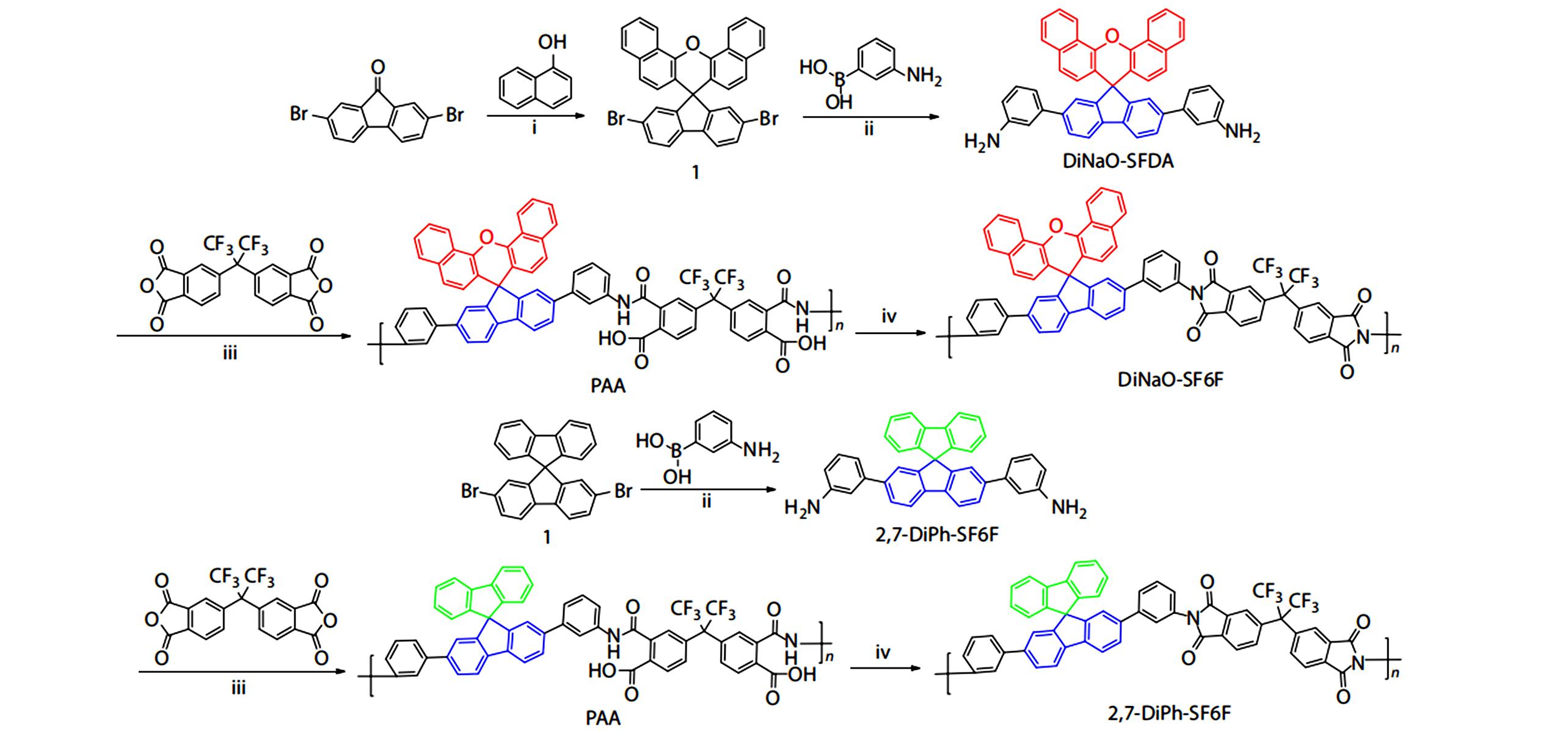

Fig.5 Synthetic route of MPIs[5](i) Methanesulfonic acid, 160 ℃; (ii) Pd(PPh3)4, Na2CO3 aqueous solution(2 mol/L), toluene, 95 ℃; (iii) dimethylacetamide(DMAc), r.t.; (iv) thermal imidization.

| Application field | Application |

|---|---|

| Mechanical | TPI, with excellent mechanical properties and friction resistance, can replace titanium alloys for manufacturing engine |

| industry | inner covers, dense parts, and clutch rings |

| Aerospace | TPI exhibits good flame retardancy, applicable to producing aircraft components and reducing fire⁃related damage risks |

| Electronics & | In harsh environments(high temperature, pressure, humidity), TPI maintains good electrical insulation, used for |

| communications | wafer carriers, electronic insulating films, and connectors |

| Medical | Artificial bones made from TPI resin are lightweight, non⁃toxic, and highly corrosion⁃resistant |

| Power | TPI, featuring good thermal stability and dielectric properties, is applied in wires, cables, and power equipment |

| Coatings | Coating metal surfaces with TPI fine powder creates coatings with excellent insulation, corrosion/heat/water |

| resistance, widely used in chemical anticorrosion, home appliances, electronics, and machinery |

Table 2 TPI application areas and their use scenarios

| Application field | Application |

|---|---|

| Mechanical | TPI, with excellent mechanical properties and friction resistance, can replace titanium alloys for manufacturing engine |

| industry | inner covers, dense parts, and clutch rings |

| Aerospace | TPI exhibits good flame retardancy, applicable to producing aircraft components and reducing fire⁃related damage risks |

| Electronics & | In harsh environments(high temperature, pressure, humidity), TPI maintains good electrical insulation, used for |

| communications | wafer carriers, electronic insulating films, and connectors |

| Medical | Artificial bones made from TPI resin are lightweight, non⁃toxic, and highly corrosion⁃resistant |

| Power | TPI, featuring good thermal stability and dielectric properties, is applied in wires, cables, and power equipment |

| Coatings | Coating metal surfaces with TPI fine powder creates coatings with excellent insulation, corrosion/heat/water |

| resistance, widely used in chemical anticorrosion, home appliances, electronics, and machinery |

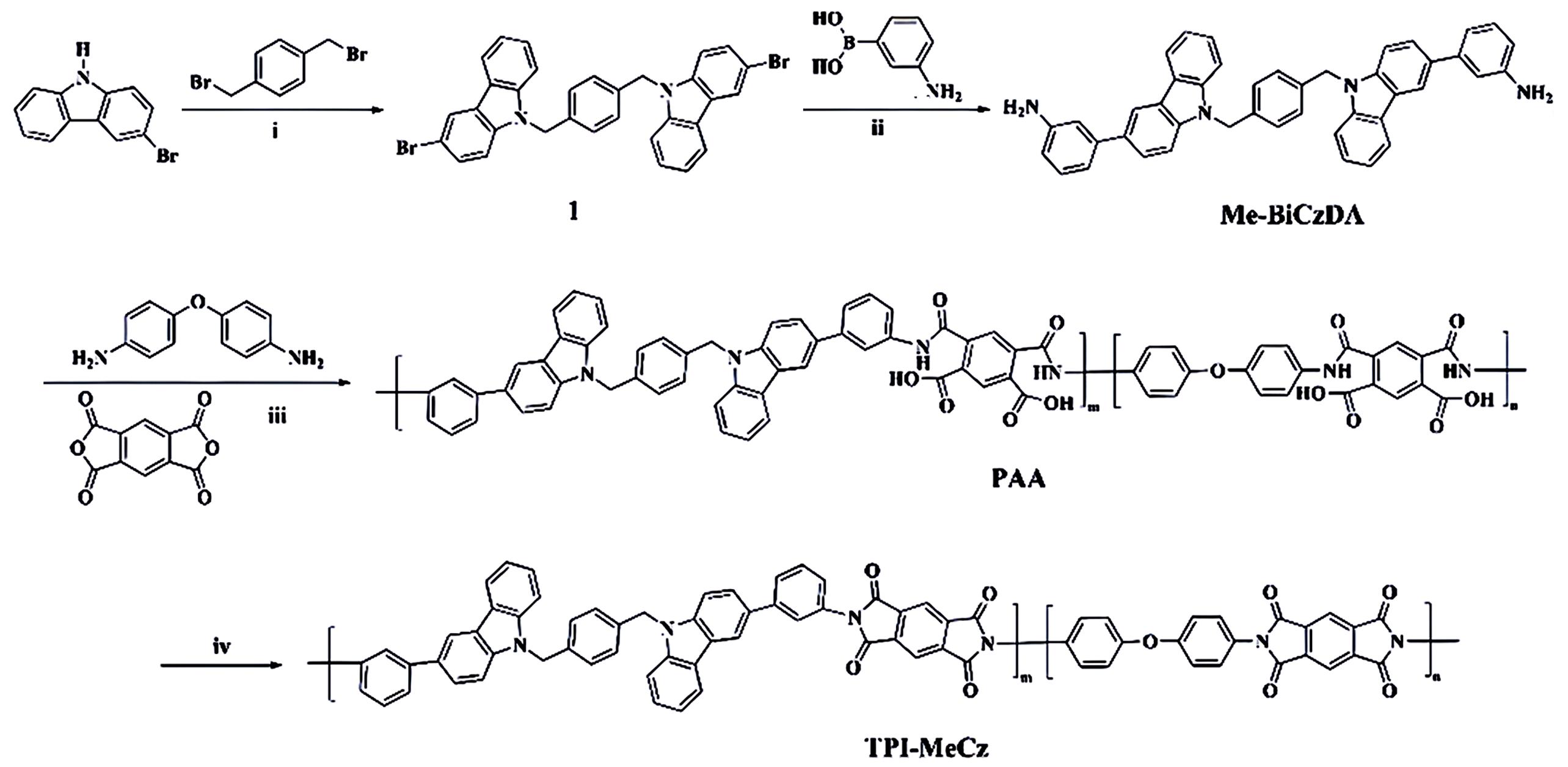

Fig.9 Synthetic route to TPI[53](i) Potassium hydroxide, THF, r.t.; (ii) Pd(PPh3)4, Na2CO3 aqueous solution(2 mol/L), ethanol and toluene, 70 ℃, (iii) DMAc, r.t.; (iv) thermal imidization.

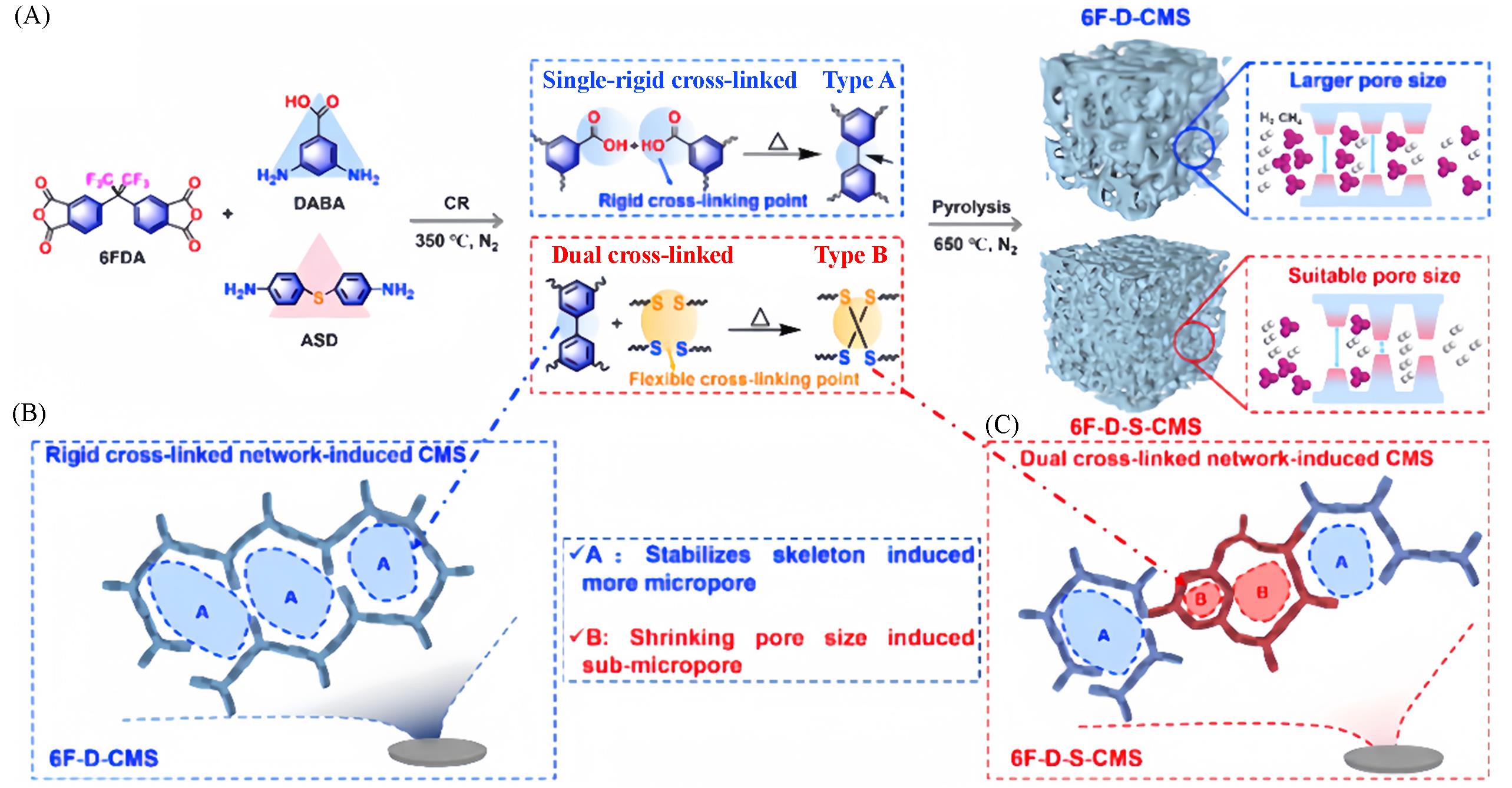

Fig.16 Schematic illustration of CMS membranes derived from two types of cross⁃linked precursors(Types A and B)(A), schematic diagram of the rigid cross⁃linked mechanism(B), illustration of sub⁃nanometer pore structural transformation in the CMSMs during pyrolysis of the dual cross⁃linked precursor(C)[24]

| Membrane | Permeability(Barrer) | Ideal selectivity(αX/Y) | Ref. | ||||

|---|---|---|---|---|---|---|---|

| H₂ | CO₂ | N₂ | CH₄ | H₂/CH₄ | H₂/CO₂ | ||

| 6F⁃D⁃S⁃CMS | 3464 | 904 | 12 | 0.91 | 3807 | 2.7 | [ |

| 6F⁃D⁃S⁃CMS⁃850 | 523 | 3.5 | 0.32 | 0.08 | 6538 | 149 | [ |

| PEK⁃C⁃900 | 2919 | 26.3 | 12.3 | 1.57 | 1859 | 110 | [ |

| 6F⁃DABA⁃75⁃CM576 | 5832 | 3573 | 113 | 69 | 84.3 | 1.6 | [ |

| BAPP⁃PMDA⁃900 | 323 | 192 | 2 | 1 | 323 | 1.7 | [ |

| TR⁃CMS⁃0.5 | 3843 | 901 | 14.6 | 6.3 | 610 | 4.3 | [ |

| Ti⁃MOF | 6444 | 4633 | 118 | 118 | 54.6 | 1.4 | [ |

| CMS/10X⁃7.5 | 1709 | 691 | 16.2 | 3.1 | 551 | 2.5 | [ |

Table 3 Comparison of the performance of the prepared gas separation membranes with some reported CMS membranes(tested at 35 ℃ and 0.2 MPa)

| Membrane | Permeability(Barrer) | Ideal selectivity(αX/Y) | Ref. | ||||

|---|---|---|---|---|---|---|---|

| H₂ | CO₂ | N₂ | CH₄ | H₂/CH₄ | H₂/CO₂ | ||

| 6F⁃D⁃S⁃CMS | 3464 | 904 | 12 | 0.91 | 3807 | 2.7 | [ |

| 6F⁃D⁃S⁃CMS⁃850 | 523 | 3.5 | 0.32 | 0.08 | 6538 | 149 | [ |

| PEK⁃C⁃900 | 2919 | 26.3 | 12.3 | 1.57 | 1859 | 110 | [ |

| 6F⁃DABA⁃75⁃CM576 | 5832 | 3573 | 113 | 69 | 84.3 | 1.6 | [ |

| BAPP⁃PMDA⁃900 | 323 | 192 | 2 | 1 | 323 | 1.7 | [ |

| TR⁃CMS⁃0.5 | 3843 | 901 | 14.6 | 6.3 | 610 | 4.3 | [ |

| Ti⁃MOF | 6444 | 4633 | 118 | 118 | 54.6 | 1.4 | [ |

| CMS/10X⁃7.5 | 1709 | 691 | 16.2 | 3.1 | 551 | 2.5 | [ |

| [1] | Luo J. R., Liu Y. D., Liu H., Chen W. P., Cui T. T., Xiao L., Min Y., Materials, 2022, 15, 8014 |

| [2] | Chen Y., Liu Y., Min Y., Materials, 2022, 15, 2755 |

| [3] | Wu J., Zhang S., Cai M., Li Q., Wang Z., Lu X., Min Y., High Perform. Polym., 2023, 35, 1026 |

| [4] | Chen Y., Liu Y., Min Y., Polymers, 2023, 15, 1256 |

| [5] | Tan W. Y., Jian L. F., Chen W. P., Zhang Y. W., Lu X. C., Huang W. J., Zhang J. S., Wu J. W., Feng J. L., Liu Y. D., Cui T. T., Min Y. G., Chin. J. Polym. Sci., 2023, 41, 288 |

| [6] | Jian L. F., Lu Z. Y., Tan W. Y., Min Y. G., Mod. Plast. Process. Appl., 2024, 36, 17 |

| 简凌锋, 卢治宇, 谭婉怡, 闵永刚. 现代塑料加工应用, 2024, 36, 17 | |

| [7] | Lu X. C., Yu W. T., Weng M. M., Liu Y. D., Zhang J. S., Fang J. Y., Min Y. G., Insul. Mater., 2021, 54, 11 |

| 卢小闯, 余文涛, 翁梦蔓, 刘屹东, 张继升, 方基永, 闵永刚. 绝缘材料, 2021, 54, 11 | |

| [8] | Lu J., Zhang J., Liu H., Chen W., Luo J., Wang Z., Cui T., Min Y., Liu Y., High Perform. Polym., 2023, 35, 936 |

| [9] | Huang X. W., Liao S. Y., Liu Y. D., Rao Q. S., Peng X. K., Min Y. G., Electrochimica Acta, 2021, 389, 138747 |

| [10] | Hu J. Q., Li Y. Z., Liao S. Y., Huang X. W., Chen Y. Z., Peng X. K., Yang Y. B., Min Y. G., ACS Appl. Energy Mater., 2021, 4, 9721 |

| [11] | Song T., Min Y., J. Appl. Polym. Sci., 2024, 141, e55721 |

| [12] | Liu C. S., Hu J. Q., Mao T. T., Liao S. Y., Feng R. M., Liu Y. D., Min Y. G., Chin. J. Polym. Sci., 2024, 42, 521 |

| [13] | Huang J., Su J., Weng M., Xiong L., Wang P., Liu Y., Lin X., Min Y., Sol. Energy Mater. Sol. Cells, 2022, 245, 111872 |

| [14] | Cao Y., Zhao Z., Zeng X., Teng J., Huang J., Min Y., Adv. Compos. Hybrid Mater., 2025, 8, 104 |

| [15] | Yu W., Lin J., Cao Y., Fang J., Wang Z., Huang J., Min Y., RSC Adv., 2024, 14, 16971 |

| [16] | Cao Y., Zeng X., Su J., Yu W., Zhang H., Abdou S. N., Ibrahim M. M., Fallatah A. M., Zhang J., Amangeldi N., Algadi H., Ainur Y., Toktarbay Z., Huang J., Min Y., Guo Z., Carbon, 2025, 242, 120427 |

| [17] | Wang Z., Min Y., Fang J., Yu W., Huang W., Lu X., Wang B., RSC Adv., 2023, 13, 7055 |

| [18] | Yu W., Lin J., Zhao Z., Fang J., Wang Z., Huang J., Min Y., RSC Adv., 2024, 14, 9716 |

| [19] | Huang J., Zeng X., Yu W., Zhang H., Min Y., Diam. Relat. Mater., 2025, 152, 111968 |

| [20] | Ji W., Li K., Min Y. G., Shi W., Li J., Ma X., J. Membr. Sci., 2021, 623, 119091 |

| [21] | Cai M., Chen J., Liu H., Sun L., Wu J., Han Z., Chen Z., Cui T., Zhang S., Ma X., Min Y., Sep. Purif. Technol., 2024, 341, 126945 |

| [22] | Zhang S., Xu Z., Weng Y., Cai M., Wang Y., Zhu W., Min Y., Ma X., J. Membr. Sci., 2023, 672, 121464 |

| [23] | Cai M., Liu H., Chen J., Wu J., Han Z., Chen Z., Zhang S., Min Y., Microporous Mesoporous Mater., 2024, 365, 112889 |

| [24] | Cai M., Liang H., Liang F., Tao M., Sun L., Ma X., Zhang S., Min Y., Angew. Chem. Int. Ed., 2025, 64, e202509756 |

| [25] | Zhang S., Lu X., Cai M., Wang Z., Han Z., Chen Z., Liu R., Li K., Min Y., Polymers, 2022, 14, 5391 |

| [26] | Cai M., Liu H., Chen J., Sun L., Wu J., Chen Z., Han Z., Cui T., Zhang S., Min Y., Ma X., Sep. Purif. Technol., 2024, 335, 126163 |

| [27] | Luo X. L., Wu J. H., Liu J., Wang Z. Q., Min Y. G., Liu Y. D., Funct. Mater., 2023, 54, 7145 |

| 罗旭良, 吴嘉豪, 刘靖, 王子青, 闵永刚, 刘屹东. 功能材料, 2023, 54, 7145 | |

| [28] | Weng M. M., Yu W. T., Lu X. C., Li Q. L., Liu J., Liu Y. D., Min Y. G., Insul. Mater., 2021, 54(4), 1 |

| 翁梦蔓, 余文涛, 卢小闯, 李清玲, 刘佳, 刘屹东, 闵永刚. 绝缘材料, 2021, 54(4), 1 | |

| [29] | Weng M. M., Zhao X. J., Luo X. L., Min Y. G., Polym. Bull., 2023, 36, 1090 |

| 翁梦蔓, 赵晓君, 罗旭良, 闵永刚. 高分子通报, 2023, 36, 1090 | |

| [30] | Luo X., Huang J., Wang X., Weng M., Cao Y., Min Y., Chem. Commun., 2023, 59, 13321 |

| [31] | Weng M., Luo X., Jian L., Liang J., Hu J., Liu Y., Zhang J., Feng X., Min Y., Appl. Surf. Sci., 2022, 578, 152029 |

| [32] | Liaw D. J., Wang K. L., Huang Y. C., Lee K. R., Lai J. Y., Ha C. S., Prog. Polym. Sci., 2012, 37, 907 |

| [33] | Viehbeck A., Goldberg M. J., Kovac C. A., J. Electrochem. Soc., 1990, 137, 1460 |

| [34] | Rothman L. B., J. Electrochem. Soc., 1980, 127, 2216 |

| [35] | Muruganand S., Narayandass S. K., Mangalaraj D., Vijayan T. M., Polym. Int., 2001, 50, 1089 |

| [36] | Chen S. T., MRS Online Proc. Libr. OPL, 1995, 381, 141 |

| [37] | Ohya H., Kudryavsev V. V., Semenova S. I., Polyimide Membranes: Applications, Fabrications and Properties, Routledge, London, 2022 |

| [38] | Dixit B. C., Dixit R. B., Desai D. J., Int. J. Polym. Mater., 2009, 58(4), 229 |

| [39] | Jeon J. Y., Tak T. M., J. Appl. Polym. Sci., 1996, 61, 371 |

| [40] | Dong J., Yin C., Luo W., Zhang Q., J. Mater. Sci., 2013, 48, 7594 |

| [41] | Chen T. A., Jen A. K. Y., Cai Y., Macromolecules, 1996, 29, 535 |

| [42] | Fang B., Pan K., Meng Q., Cao B., Polym. Int., 2012, 61, 111 |

| [43] | Rensch T., Fabig S., Grätz S., Borchardt L., ChemSusChem, 2022, 15, e202101975 |

| [44] | Xu Z., Croft Z. L., Guo D., Cao K., Liu G., J. Polym. Sci., 2021, 59, 943 |

| [45] | Bell V. L., Stump B. L., Gager H., J. Polym. Sci. Polym. Chem. Ed., 1976, 14, 2275 |

| [46] | Sezer Hicyilmaz A., Celik Bedeloglu A., SN Appl. Sci., 2021, 3, 363 |

| [47] | Kreuz J. A., Edman J. R., Adv. Mater., 1998, 10, 1229 |

| [48] | Peng X. K., Huang X. W., Liu R. T., Zhang Y. W., Zhang S. Y., Huang J. T., Min Y. G., Mater. Rev., 2022, 36, 184 |

| 朋小康, 黄兴文, 刘荣涛, 张永文, 张诗洋, 黄锦涛, 闵永刚. 材料导报, 2022, 36, 184 | |

| [49] | Liu H., Liu Y. D., Chen W. P., Cui T. T., Min Y. G., Chem. Bull., 2024, 87, 605 |

| 刘恒, 刘屹东, 陈伟鹏, 崔婷婷, 闵永刚. 化学通报, 2024, 87, 605 | |

| [50] | Meador M. A. B., McMillon E., Sandberg A., Barrios E., Wilmoth N. G., Mueller C. H., Miranda F. A., ACS Appl. Mater. Interfaces, 2014, 6, 6062 |

| [51] | Zhang D., Li L., Wang Y., Zhang C., Teng C., J. Sol⁃Gel Sci. Technol., 2023, 108, 1 |

| [52] | Liu C. S., Chen Y. W., Cao J. R., Liu J., Ma X. H., Liu Y. D., Min Y. G., Insul. Mater., 2021, 54(2), 1 |

| 刘存生, 陈钰玮, 曹景茹, 刘佳, 马小华, 刘屹东, 闵永刚. 绝缘材料, 2021, 54(2), 1 | |

| [53] | Du Q., Chen W., Guo H., Wang Z., Zhao L., Zhu Y., Tan W., Min Y., Liu Y., J. Polym. Sci., 2024, 62, 3066 |

| [54] | Liu Y., Chen W., Liu H., Luo J., Zhao L., Zhang J., Wang H., Wu J. W., Feng J. L., Zhu Y., Tan W. Y., Cui T., Min Y., Polym. Degrad. Stab., 2023, 209, 110264 |

| [55] | Wang Q., Huang F., Cornelius C. J., Fan Y., J. Membr. Sci., 2021, 621, 118785 |

| [56] | Hou M., Qi W., Li L., Xu R., Xue J., Zhang Y., Song C., Wang T., J. Membr. Sci., 2021, 635, 119541 |

| [57] | Chen S., Wahiduzzaman M., Ji T., Liu Y., Li Y., Wang C., Sun Y., He G., Maurin G., Wang S., Liu Y., Angew. Chem., 2025, 137, e202413701 |

| [58] | Liu L., Li Q., Sun L., Riaz A., Li J., Wang Y., Pinnau I., Ma X., J. Membr. Sci., 2025, 717, 123647 |

| [59] | Lei L., Pan F., Lindbråthen A., Zhang X., Hillestad M., Nie Y., Bai L., He X., Guiver M. D., Nat. Commun., 2021, 12, 268 |

| [60] | Hu L., Lee W. I., Roy S., Subramanian A., Kisslinger K., Zhu L., Fan S., Hwang S., Bui V. T., Tran T., Zhang G., Ding Y., Ajayan P. M., Nam C. Y., Lin H., Nat. Commun., 2024, 15, 5688 |

| [61] | Zhang C., Koros W. J., Adv. Mater., 2017, 29, 1701631 |

| [62] | Cai M. W., Wang Z., Lu X. C., Wu J. H., Zhang S. Y., Min Y. G., Chem. Bull., 2023, 86, 153 |

| 蔡铭威, 王知, 卢小闯, 吴嘉豪, 张诗洋, 闵永刚. 化学通报, 2023, 86, 153 | |

| [63] | Zhang S. Y., Ye B., Zhao W. T., Min Y. G., Contemp. Chem. Res., 2022, (19), 17—20 |

| 张诗洋, 叶彬, 赵文通, 闵永刚. 当代化工研究, 2022, (19), 17—20 | |

| [64] | Wang Z., Zhang S. Y., Cai M. W., Lu X. C., Liu Y. D., Min Y. G., Chem. Bull., 2023, 86, 270 |

| 王知, 张诗洋, 蔡铭威, 卢小闯, 刘屹东, 闵永刚. 化学通报, 2023, 86, 270 | |

| [65] | Cai M. W., Wang Z., Lu X. C., Zhuang J. W., Wu J. H., Zhang S. Y., Min Y. G., Chem. Ind. Eng. Prog., 2023, 42, 5232 |

| 蔡铭威, 王知, 卢小闯, 庄俊伟, 吴嘉豪, 张诗洋, 闵永刚. 化工进展, 2023, 42, 5232 | |

| [66] | Zhao X. J., Luo X. L., Weng M. M., Min Y. G., Funct. Mater., 2023, 54, 12018 |

| 赵晓君, 罗旭良, 翁梦蔓, 闵永刚. 功能材料, 2023, 54, 12018 | |

| [67] | Ha H. W., Choudhury A., Kamal T., Kim D. H., Park S. Y., ACS Appl. Mater. Interfaces, 2012, 4, 4623 |

| [68] | Huang J., Lv H., Zhao X., Lee J. M., Min Y., J. Appl. Polym. Sci., 2025, 142, e56879 |

| [1] | 郭卓欢, 汪大洋. 表面羧基构型与润湿性之间的热力学关联[J]. 高等学校化学学报, 2026, 47(1): 239. |

| [2] | 詹森华, 石彤非. 基于分子指纹与量子化学描述符预测聚酰亚胺玻璃化转变温度的机器学习模型[J]. 高等学校化学学报, 2025, 46(4): 20240556. |

| [3] | 万志鑫, 余威, 张敏轩, 徐格, 冒爱琴. 磁控溅射制备MoON薄膜电极及其电化学储能性质[J]. 高等学校化学学报, 2025, 46(12): 20250220. |

| [4] | 张苡宁, 卫来, 石彤非, 徐林. 界面吸附对高分子液体膜去润湿动力学的影响[J]. 高等学校化学学报, 2024, 45(5): 20240046. |

| [5] | 孙冰, 李赛萌, 周康康, 彭忠祥, 叶龙. 有机光伏薄膜的力学性能调控与预测[J]. 高等学校化学学报, 2023, 44(9): 20230168. |

| [6] | 张永倩, 朱小玉, 苗俊辉, 刘俊, 王利祥. 烷基链支化位点对全稠环小分子受体聚集的影响[J]. 高等学校化学学报, 2023, 44(7): 20230068. |

| [7] | 柳春蕾, 杨继凯, 刘昱麟, 李思远, 刘昊睿. 基于WO3/Ag和TiO2/NiO/CdS复合电极的高性能电光双方式调控变色器件[J]. 高等学校化学学报, 2023, 44(10): 20230203. |

| [8] | 仇心声, 吴芹, 史大昕, 张耀远, 陈康成, 黎汉生. 离子型交联磺化聚酰亚胺质子交换膜的制备及高温燃料电池性能[J]. 高等学校化学学报, 2022, 43(8): 20220140. |

| [9] | 龚妍熹, 王建兵, 柴歩瑜, 韩元春, 马云飞, 贾超敏. 钾掺杂g-C3N4薄膜光阳极的制备及光电催化氧化降解水中双氯芬酸钠性能[J]. 高等学校化学学报, 2022, 43(6): 20220005. |

| [10] | 赵君禹, 王春博, 王成杨, 张克, 丛冰, 杨岚, 赵晓刚, 陈春海. 导热膨胀石墨/聚醚酰亚胺复合材料的制备与性能[J]. 高等学校化学学报, 2022, 43(4): 20210800. |

| [11] | 闫文卿, 张则尧, 李彦. 碳纳米管透明导电薄膜的可控制备[J]. 高等学校化学学报, 2022, 43(3): 20210626. |

| [12] | 王瑞洁, 焦小雨, 潘宇, 王训春, 杨洋, 成中军. 透明抗静电多功能超疏水薄膜的制备[J]. 高等学校化学学报, 2022, 43(3): 20210703. |

| [13] | 王寿柏, 吴修明, 束辰, 钟敏, 黄卫, 颜德岳. 含叔丁基聚酰亚胺均质膜的气体分离性能[J]. 高等学校化学学报, 2022, 43(11): 20220357. |

| [14] | 王寿柏, 吴修明, 吴锦明, 汤艳峰, 束辰, 钟敏, 黄卫, 颜德岳. 含叔丁基/异丁基二胺的可溶性透明聚酰亚胺的合成与性能[J]. 高等学校化学学报, 2021, 42(9): 2944. |

| [15] | 朱德帅, 赵剑英, 杨正慧, 郭海泉, 高连勋. 基于多层结构设计的高储能密度氧化石墨烯/聚酰亚胺复合材料[J]. 高等学校化学学报, 2021, 42(8): 2694. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||