高等学校化学学报 ›› 2022, Vol. 43 ›› Issue (3): 20210626.doi: 10.7503/cjcu20210626

闫文卿1,2, 张则尧1,3,4( ), 李彦1,2,3,4(

), 李彦1,2,3,4( )

)

收稿日期:2021-08-31

出版日期:2022-03-10

发布日期:2021-11-18

通讯作者:

张则尧,李彦

E-mail:zeyaozhang@pku.edu.cn;yanli@pku.edu.cn

基金资助:

YAN Wenqing1,2, ZHANG Zeyao1,3,4( ), LI Yan1,2,3,4(

), LI Yan1,2,3,4( )

)

Received:2021-08-31

Online:2022-03-10

Published:2021-11-18

Contact:

ZHANG Zeyao,LI Yan

E-mail:zeyaozhang@pku.edu.cn;yanli@pku.edu.cn

Supported by:摘要:

碳纳米管具有优秀的导电性能、 透光性能和十分突出的柔性, 在柔性透明导电薄膜中有着良好的应用前景. 如何制备同时拥有良好导电性能和透光性能的碳纳米管薄膜是这一领域研究的核心问题. 本综述介绍了碳纳米管薄膜的制备方法, 并重点讨论了基于漂浮催化剂化学气相沉积法的碳纳米管薄膜的可控制备. 在生长过程中限制碳纳米管的团聚、 增加碳纳米管的长度、 降低杂质的含量是提高碳纳米管薄膜性能的主要策略.

中图分类号:

TrendMD:

闫文卿, 张则尧, 李彦. 碳纳米管透明导电薄膜的可控制备. 高等学校化学学报, 2022, 43(3): 20210626.

YAN Wenqing, ZHANG Zeyao, LI Yan. Controlled Preparation of Carbon Nanotube Transparent Conductive Films. Chem. J. Chinese Universities, 2022, 43(3): 20210626.

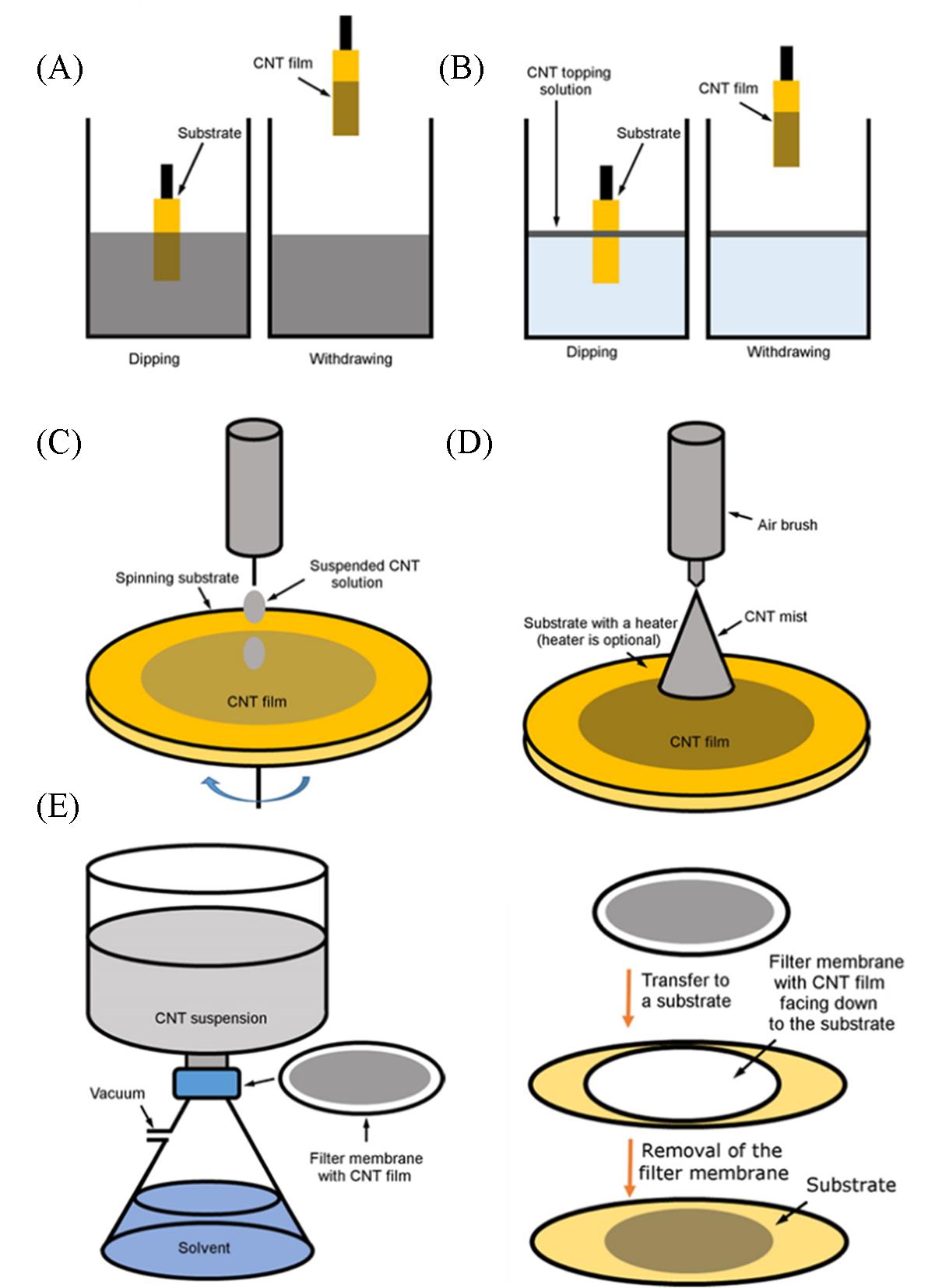

Fig.3 Schematic diagram of preparing carbon nanotube films by solution method[8](A) Dipping method; (B) LB method; (C) spin coating method; (D) spraying method;(E) vacuum filtration method. Copyright 2016, American Chemical Society.

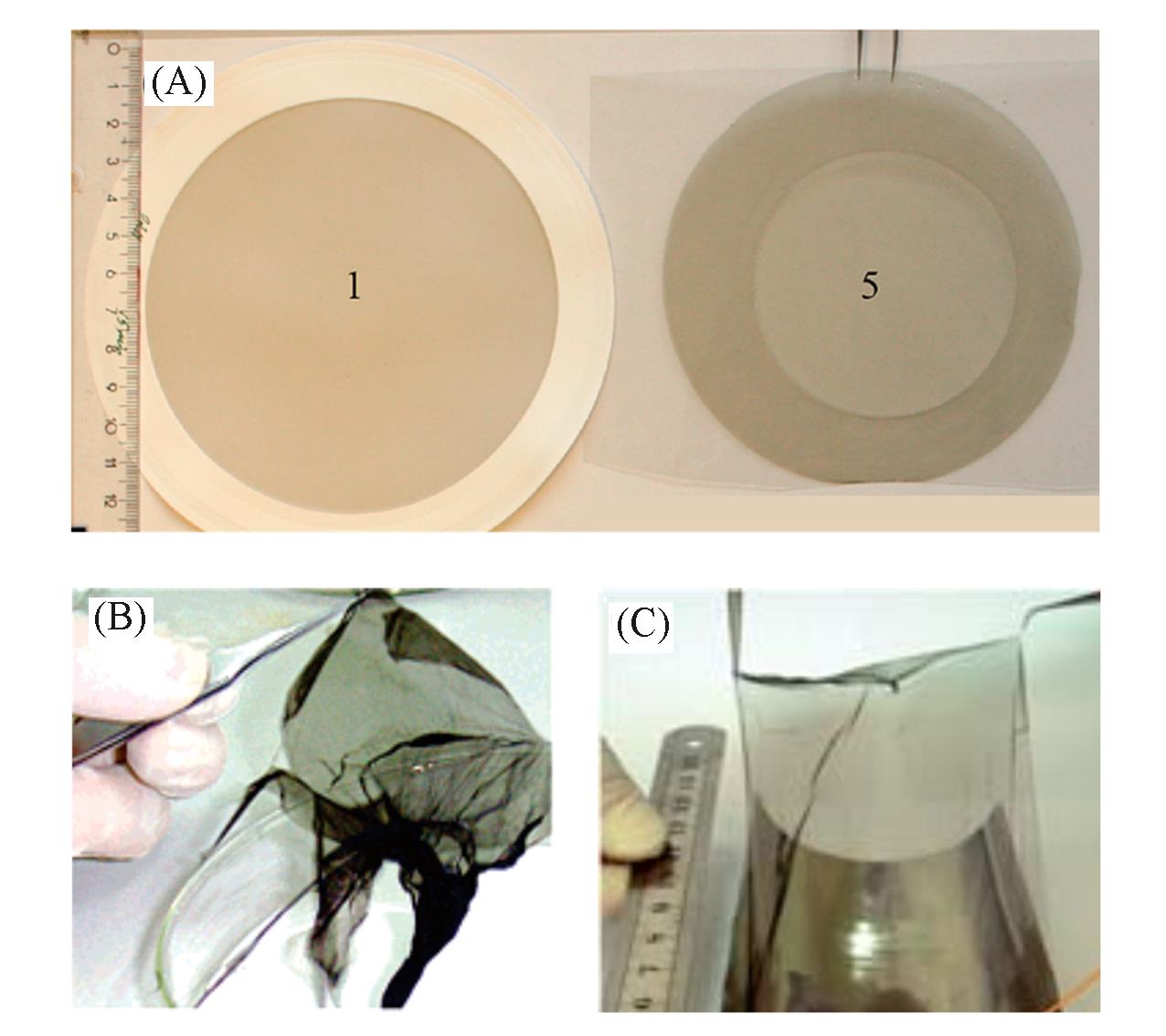

Fig.4 Carbon nanotube films prepared by FCCVD with different carbon sources(A) CO[53]. The left side of (A) is a nitrocellulose filter paper, and the right side is a polyethylene terephthalate film with holes. Copyright 2011, American Chemical Society. (B) Methane[50]. Copyright 2007, American Chemical Society. (C) Xylene[48]. Copyright 2010, the Royal Society of Chemistry.

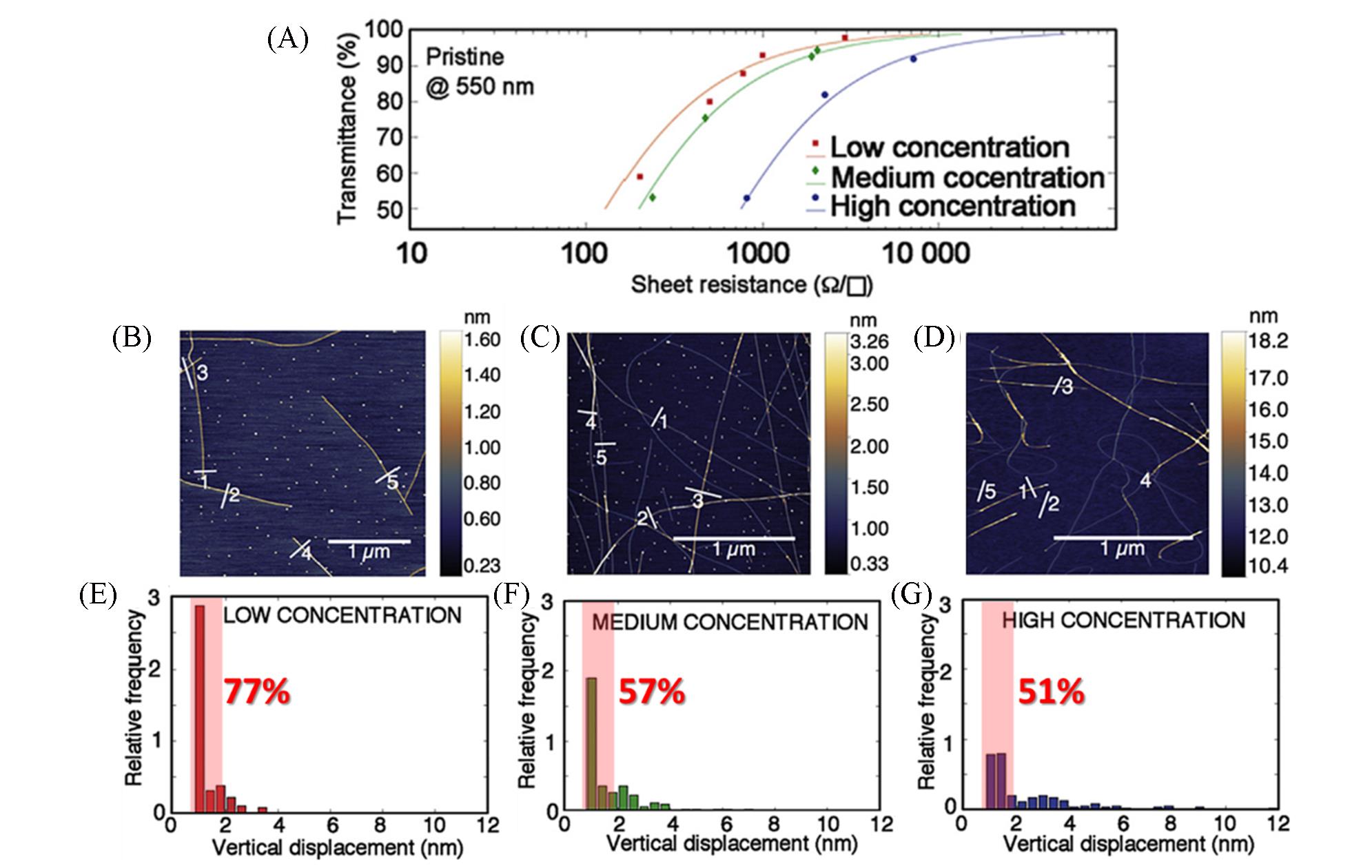

Fig.5 Effect of catalyst concentrations on carbon nanotube films[58](A) Transparent and conductive properties of carbon nanotube films grown with different catalyst concentrations; (B)—(D) AFM height maps of carbon nanotube films deposited with three catalyst concentrations; (E)—(G) corresponding statistical results of the height information of carbon nanotubes or tube bundles. The columns located in the red area represents individual carbon nanotubes, for the height of those nanotubes are below 1.8 nm. Copyright 2016, Elsevier Ltd.

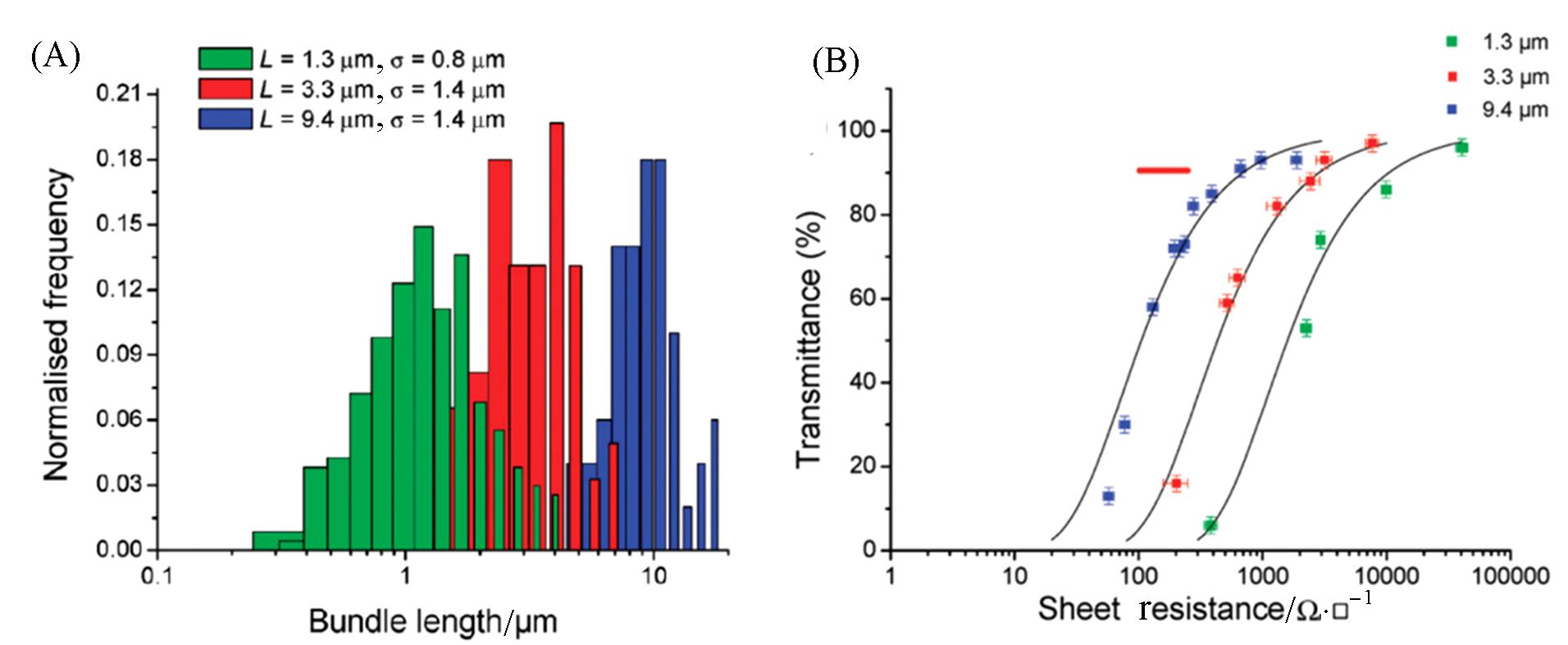

Fig.6 Effect of carbon nanotube bundle length on film properties[59](A) Statistics of the length of tube bundles in carbon nanotube films grown with different conditions; (B) corresponding film properties. Copyright 2010, American Chemical Society.

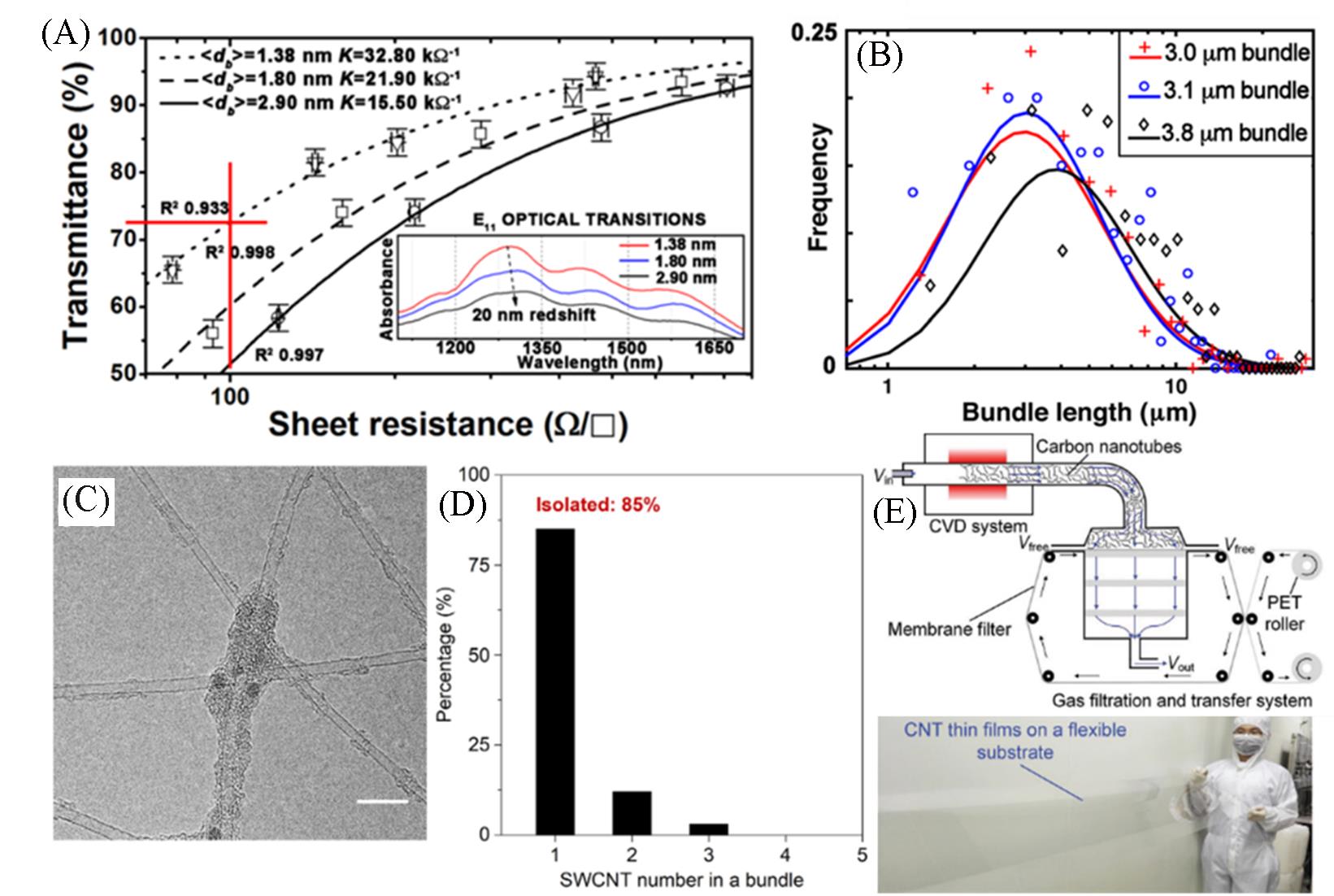

Fig.7 Effect of carbon nanotube aggregation degree on film properties(A) The transparent and conductive properties of the films with different carbon nanotube aggregation conditions; the inset is the absorption spectrum of the S11 region of the corresponding films; (B) corresponding to the length distribution of the carbon nanotube bundles in the three films[61]. Copyright 2015, American Institute of Physics. (C) Typical TEM image of carbon-welded isolated SWCNTs; (D) statistical data of the numbers of isolated and bundled SWCNTs in the network[62]. Copyright 2018, American Association for the Advancement of Science. (E) Continuous fabrication of meter-scale SWCNT films[63]. The upper part of the figure is a schematic showing the apparatus designed for the synthesis, deposition, and transfer of SWCNT films. Below that is a SWCNT thin film transferred on a flexible PET substrate with a length of more than 2 m. Copyright 2018, John Wiley & Sons Inc.

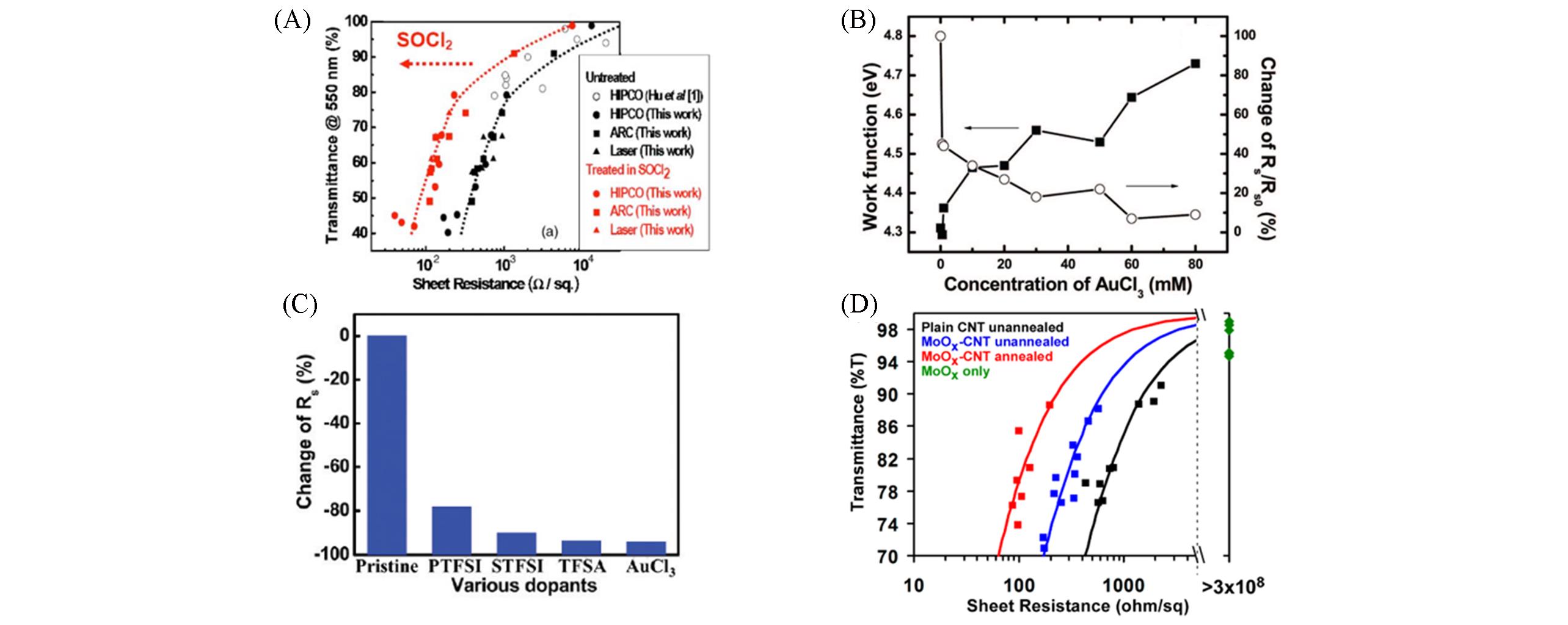

Fig.8 Effect of dopants on the properties of carbon nanotube films(A) The relationship between light transmittance and square resistance of carbon nanotube films before and after SOCl2 doping[68]. Copyright 2007, American Institute of Physics. (B) Effect of AuCl3 solution of different concentrations on the square resistance of carbon nanotube films[69]. Copyright 2008, American Chemical Society. (C) The change of resistance after the films doped with AuCl3 and three organic molecules with TFSI functional groups[76]. Copyright 2010, American Chemical Society. (D) Effect of MoO3 doping on the transparent conductivity of carbon nanotube films[72]. Copyright 2012, American Chemical Society.

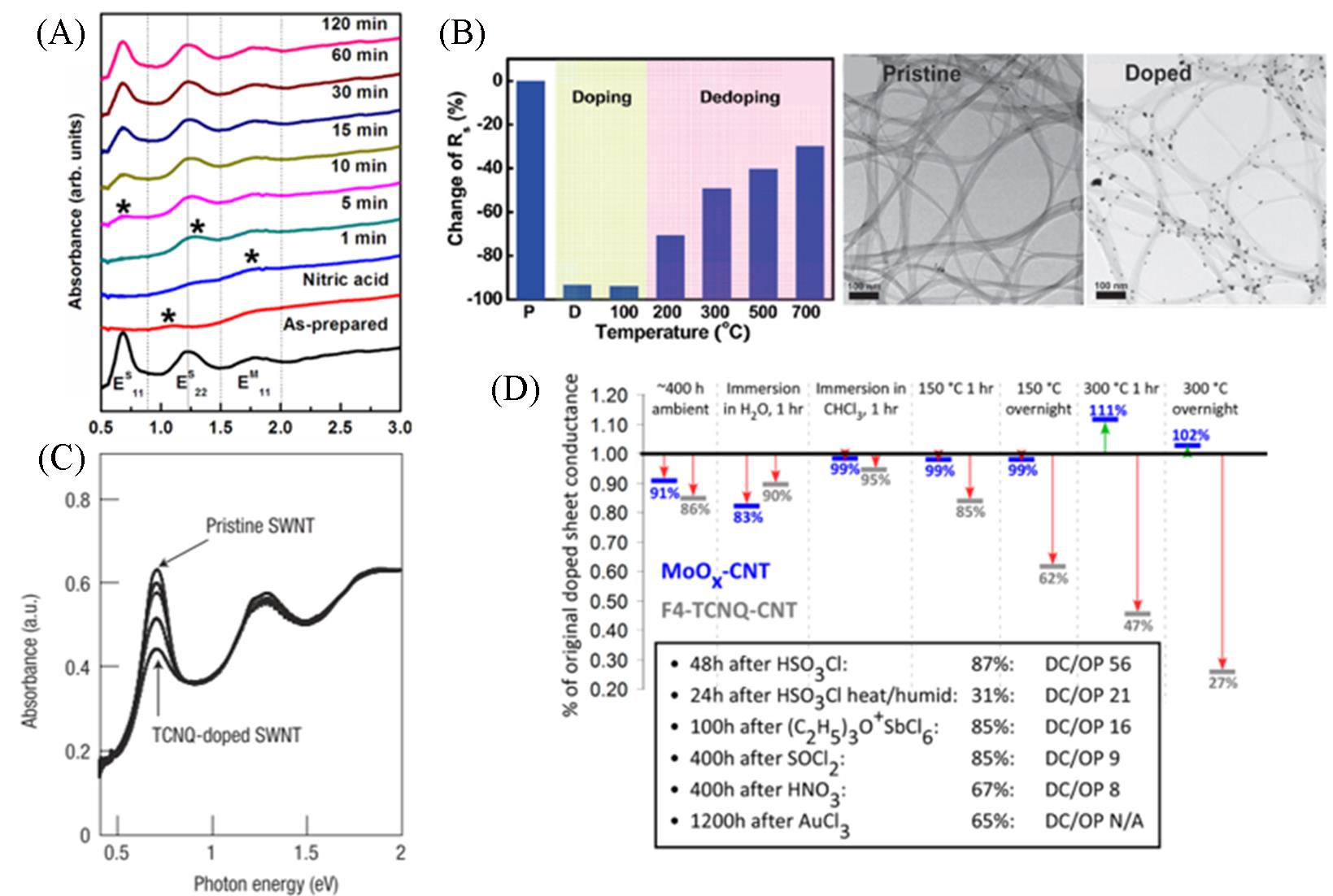

Fig.9 Limitations of existing dopants(A) The ultraviolet-visible-near-infrared absorption spectrum of carbon nanotube films doped by HNO3 with the increase of drying time[66]. Copyright 2009, IOP Publishing. (B) The picture on the left shows the change of the square resistance of AuCl3 doped carbon nanotube films annealed at different temperatures in Ar for 1 h. The two pictures on the right are TEM pictures of carbon nanotube films before and after doping[70]. Copyright 2011, American Chemical Society. (C) The absorption spectrum of the TCNQ doped carbon nanotube films after vacuum heating. The curves from bottom to top are: TCNQ doped carbon nanotube film, 200 ℃ heating, 250 ℃ heating, 300 ℃ heating and original absorption spectrum of carbon nanotube film[74]. Copyright 2003, Springer Nature. (D) Performance changes of carbon nanotube films doped with MoO3 and F4-TCNQ under different conditions. The inset shows the doping results of other dopants[72]. Copyright 2012, American Chemical Society.

| 1 | Hu L., Hecht D. S., Grüner G., Chem. Rev., 2010, 110(10), 5790—5844 |

| 2 | Cao Z., Wei B. B., Energy Environ. Sci., 2013, 6(11), 3183—3201 |

| 3 | Zhang Z., Wei L., Qin X., Li Y., Nano Energy, 2015, 15, 490—522 |

| 4 | Hirotani J., Ohno Y., Top. Curr. Chem., 2019, 377(1), 3 |

| 5 | Jeon I., Xiang R., Shawky A., Matsuo Y., Maruyama S., Adv. Energy Mater., 2019, 9(23), 1801312 |

| 6 | Hecht D. S., Hu L., Irvin G., Adv. Mater., 2011, 23(13), 1482—1513 |

| 7 | Du J., Pei S., Ma L., Cheng H. M., Adv. Mater., 2014, 26(13), 1958—1991 |

| 8 | Yu L., Shearer C., Shapter J., Chem. Rev., 2016, 116(22), 13413—13453 |

| 9 | Zhang Q., Wei N., Laiho P., Kauppinen E. I., Top. Curr. Chem., 2017, 375(6), 90 |

| 10 | Jiang S., Hou P. X., Liu C., Cheng H. M., J. Mater. Sci. Technol., 2019, 35(11), 2447—2462 |

| 11 | Güneş F., Shin H. J., Biswas C., Han G. H., Kim E. S., Chae S. J., Choi J. Y., Lee Y. H., ACS Nano, 2010, 4(8), 4595 |

| 12 | Cairns D. R., Witte R. P., Sparacin D. K., Sachsman S. M., Paine D. C., Crawford G. P., Newton R., Appl. Phys. Lett., 2000, 76(11), 1425—1427 |

| 13 | Green M. A., Prog. Photovolt: Res. Appl., 2009, 17(5), 347—359 |

| 14 | Jeon I., Yoon J., Ahn N., Atwa M., Delacou C., Anisimov A., Kauppinen E. I., Choi M., Maruyama S., Matsuo Y., J. Phys. Chem. Lett., 2017, 8(21), 5395—5401 |

| 15 | Cheng H. M., Li F., Su G., Pan H. Y., He L. L., Sun X., Dresselhaus M. S., Appl. Phys. Lett., 1998, 72(25), 3282—3284 |

| 16 | Nasibulin A. G., Kaskela A., Mustonen K., Anisimov A. S., Ruiz V., Kivisto S., Rackauskas S., Timmermans M. Y., Pudas M., Aitchison B., Kauppinen M., Brown D. P., Okhotnikov O. G., Kauppinen E. I., ACS Nano, 2011, 5(4), 3214—3221 |

| 17 | Moisala A., Nasibulin A. G., Brown D. P., Jiang H., Khriachtchev L., Kauppinen E. I., Chem. Eng. Sci., 2006, 61(13), 4393—4402 |

| 18 | Li Z., Kandel H. R., Dervishi E., Saini V., Biris A. S., Biris A. R., Lupu D., Appl. Phys. Lett., 2007, 91(5), 053115 |

| 19 | Bahr J. L., Mickelson E. T., Bronikowski M. J., Smalley R. E., Tour J. M., Chem. Commun., 2001, (2), 193—194 |

| 20 | Song Y. I., Yang C. M., Kim D. Y., Kanoh H., Kaneko K., J. Colloid Interface Sci., 2008, 318(2), 365—371 |

| 21 | Park C., Ounaies Z., Watson K. A., Crooks R. E., Smith J., Lowther S. E., Connell J. W., Siochi E. J., Harrison J. S., Clair T. L. S., Chem. Phys. Lett., 2002, 364(3), 303—308 |

| 22 | Mistry K. S., Larsen B. A., Blackburn J. L., ACS Nano, 2013, 7(3), 2231—2239 |

| 23 | Hecht D. S., Ramirez R. J. A., Briman M., Artukovic E., Chichak K. S., Stoddart J. F., Grüner G., Nano Lett., 2006, 6(9), 2031—2036 |

| 24 | Tardani F., Sennato S., J. Phys. Chem. C, 2014, 118(17), 9268—9274 |

| 25 | Wang H., Li S., Si Y., Sun Z., Li S., Lin Y., J. Mater. Chem. B, 2014, 2(28), 4442—4448 |

| 26 | Wang H., Li S., Si Y., Zhang N., Sun Z., Wu H., Lin Y., Nanoscale, 2014, 6(14), 8107—8116 |

| 27 | Khripin C. Y., Tu X., Heddleston J. M., Silvera⁃Batista C., Hight Walker A. R., Fagan J., Zheng M., Anal. Chem., 2013, 85(3), 1382—1388 |

| 28 | Wang J., Sun J., Gao L., Wang Y., Zhang J., Kajiura H., Li Y., Noda K., J. Phys. Chem. C, 2009, 113(41), 17685—17690 |

| 29 | Li X., Li Q., Chen G. X., Mater. Lett., 2014, 134, 38—41 |

| 30 | Jamnani B. D., Hosseini S., Rahmanian S., Rashid S. A., Mustapha S. A. B., Balavandy S. K., J. Nanomater., 2015, 2015, 149736 |

| 31 | Kim Y., Minami N., Zhu W., Kazaoui S., Azumi R., Matsumoto M., Jpn. J. Appl. Phys., 2003, 42(2), 7629—7634 |

| 32 | Pichumani M., Bagheri P., Poduska K. M., Gonzalez⁃Vinas W., Yethiraj A., Soft Matter, 2013, 9(12), 3220—3229 |

| 33 | Toolan D. T. W., Hodgkinson R., Howse J. R., J. Polym. Sci., Part B: Polym. Phys., 2014, 52(1), 17—25 |

| 34 | Tuukkanen S., Välimäki M., Lehtimäki S., Vuorinen T., Lupo D., Sci. Rep., 2016, 6(1), 22967 |

| 35 | King B., Panchapakesan B., Nanotech., 2014, 25(17), 175201 |

| 36 | White C. T., Todorov T. N., Nature, 1998, 393(6682), 240—242 |

| 37 | Purewal M. S., Hong B. H., Ravi A., Chandra B., Hone J., Kim P., Phys. Rev. Lett., 2007, 98(18), 186808 |

| 38 | Fuhrer M., Nygård J., Shih L., Forero M., Yoon Y. G., Choi H. J., Ihm J., Louie S. G., Zettl A., McEuen P. L., Science, 2000, 288(5465), 494—497 |

| 39 | Znidarsic A., Kaskela A., Laiho P., Gaberscek M., Ohno Y., Nasibulin A. G., Kauppinen E. I., Hassanien A., J. Phys. Chem. C, 2013, 117(25), 13324—13330 |

| 40 | Han J. H., Strano M. S., Mater. Res. Bull., 2014, 58, 1—5 |

| 41 | Anoshkin I. V., Nasibulin A. G., Tian Y., Liu B., Jiang H., Kauppinen E. I., Carbon, 2014, 78, 130—136 |

| 42 | Cheng H. M., Li F., Sun X., Brown S. D. M., Pimenta M. A., Marucci A., Dresselhaus G., Dresselhaus M. S., Chem. Phys. Lett., 1998, 289(5), 602—610 |

| 43 | Reynaud O., Nasibulin A. G., Anisimov A. S., Anoshkin I. V., Jiang H., Kauppinen E. I., Chem. Eng. J., 2014, 255, 134—140 |

| 44 | Wei J., Jiang B., Wu D., Wei B., J. Phys. Chem. B, 2004, 108(26), 8844—8847 |

| 45 | Wei J., Zhu H., Li Y., Chen B., Jia Y., Wang K., Wang Z., Liu W., Luo J., Zheng M., Wu D., Zhu Y., Wei B., Adv. Mater., 2006, 18(13), 1695—1700 |

| 46 | Wei J., Jia Y., Shu Q., Gu Z., Wang K., Zhuang D., Zhang G., Wang Z., Luo J., Cao A., Wu D., Nano Lett., 2007, 7(8), 2317—2321 |

| 47 | Jia Y., Wei J., Wang K., Cao A., Shu Q., Gui X., Zhu Y., Zhuang D., Zhang G., Ma B., Adv. Mater., 2008, 20(23), 4594—4598 |

| 48 | Li Z., Jia Y., Wei J., Wang K., Shu Q., Gui X., Zhu H., Cao A., Wu D., J. Mater. Chem., 2010, 20(34), 7236—7240 |

| 49 | Wei N., Laiho P., Khan A. T., Hussain A., Lyuleeva A., Ahmed S., Zhang Q., Liao Y., Tian Y., Ding E. X., Ohno Y., Kauppinen E. I., Adv. Funct. Mater., 2019, 30(5), 1907150 |

| 50 | Zhang Z., Liang X., Wang S., Yao K., Hu Y., Zhu Y., Chen Q., Zhou W., Li Y., Yao Y., Zhang J., Peng L. M., Nano Lett., 2007, 7(12), 3603—3607 |

| 51 | Hou P. X., Yu B., Su Y., Shi C., Zhang L. L., Liu C., Li S., Du J. H., Cheng H. M., J. Mater. Chem. A, 2014, 2(4), 1159—1164 |

| 52 | Hussain A., Liao Y., Zhang Q., Ding E. X., Laiho P., Ahmad S., Wei N., Tian Y., Jiang H., Kauppinen E. I., Nanoscale, 2018, 10(20), 9752—9759 |

| 53 | Tian Y., Timmermans M. Y., Partanen M., Nasibulin A. G., Jiang H., Zhu Z., Kauppinen E. I., Carbon, 2011, 49(14), 4636—4643 |

| 54 | Maruyama S., Kojima R., Miyauchi Y., Chiashi S., Kohno M., Chem. Phys. Lett., 2002, 360(3), 229—234 |

| 55 | Murakami Y., Miyauchi Y., Chiashi S., Maruyama S., Chem. Phys. Lett., 2003, 374(1), 53—58 |

| 56 | Ding E., Jiang H., Zhang Q., Tian Y., Laiho P., Hussain A., Liao Y., Wei N., Kauppinen E., Nanoscale, 2017, 9(44), 17601—17609 |

| 57 | Ding E. X., Zhang Q., Wei N., Khan A. T., Kauppinen E. I., R. Soc. Open Sci., 2018, 5(6), 180392 |

| 58 | Kaskela A., Laiho P., Fukaya N., Mustonen K., Susi T., Jiang H., Houbenov N., Ohno Y., Kauppinen E. I., Carbon, 2016, 103, 228—234 |

| 59 | Kaskela A., Nasibulin A. G., Timmermans M. Y., Aitchison B., Papadimitratos A., Tian Y., Zhu Z., Jiang H., Brown D. P., Zakhidov A., Kauppinen E. I., Nano Lett., 2010, 10(11), 4349—4355 |

| 60 | Reynaud O., Nasibulin A. G., Anisimov A. S., Anoshkin I. V., Jiang H., Kauppinen E. I., Chem. Eng. J., 2014, 255, 134—140 |

| 61 | Mustonen K., Laiho P., Kaskela A., Susi T., Nasibulin A. G., Kauppinen E. I., Appl. Phys. Lett., 2015, 107(14), 143113 |

| 62 | Jiang S., Hou P. X., Chen M. L., Wang B. W., Sun D. M., Tang D. M., Jin Q., Guo Q. X., Zhang D. D., Du J. H., Tai K. P., Tan J., Kauppinen E. I., Liu C., Cheng H. M., Sci. Adv., 2018, 4(5), 9264 |

| 63 | Wang B. W., Jiang S., Zhu Q. B., Sun Y., Luan J., Hou P. X., Qiu S., Li Q. W., Liu C., Sun D. M., Cheng H. M., Adv. Mater., 2018, 30(32), 1802057 |

| 64 | Nasibulin A. G., Brown D. P., Queipo P., Gonzalez D., Jiang H., Kauppinen E. I., Chem. Phys. Lett., 2006, 417(1), 179—184 |

| 65 | Tenent R. C., Barnes T. M., Bergeson J. D., Ferguson A. J., To B., Gedvilas L. M., Heben M. J., Blackburn J. L., Adv. Mater., 2009, 21(31), 3210—3216 |

| 66 | Shin D. W., Lee J. H., Kim Y. H., Yu S. M., Park S. Y., Yoo J. B., Nanotech., 2009, 20(47), 475703 |

| 67 | Dettlaff⁃Weglikowska U., Skákalová V., Graupner R., Jhang S. H., Kim B. H., Lee H. J., Ley L., Park Y. W., Berber S., Tománek D., Roth S., J. Am. Chem. Soc., 2005, 127(14), 5125—5131 |

| 68 | Parekh B. B., Fanchini G., Eda G., Chhowalla M., Appl. Phys. Lett., 2007, 90(12), 121913 |

| 69 | Kim K. K., Bae J. J., Park H. K., Kim S. M., Geng H. Z., Park K. A., Shin H. J., Yoon S. M., Benayad A., Choi J. Y., Lee Y. H., J. Am. Chem. Soc., 2008, 130(38), 12757—12761 |

| 70 | Kim S. M., Kim K. K., Jo Y. W., Park M. H., Chae S. J., Duong D. L., Yang C. W., Kong J., Lee Y. H., ACS Nano, 2011, 5(2), 1236—1242 |

| 71 | Yoon S. M., Kim U. J., Benayad A., Lee I. H., Son H., Shin H. J., Choi W. M., Lee Y. H., Jin Y. W., Lee E. H., Lee S. Y., Choi J. Y., Kim J. M., ACS Nano, 2011, 5(2), 1353—1359 |

| 72 | Hellstrom S. L., Vosgueritchian M., Stoltenberg R. M., Irfan I., Hammock M., Wang Y. B., Jia C., Guo X., Gao Y., Bao Z., Nano Lett., 2012, 12(7), 3574—3580 |

| 73 | Jeon I., Cui K., Chiba T., Anisimov A., Nasibulin A. G., Kauppinen E. I., Maruyama S., Matsuo Y., J. Am. Chem. Soc., 2015, 137(25), 7982—7985 |

| 74 | Takenobu T., Takano T., Shiraishi M., Murakami Y., Ata M., Kataura H., Achiba Y., Iwasa Y., Nat. Mater., 2003, 2(10), 683—688 |

| 75 | Chandra B., Afzali A., Khare N., El⁃Ashry M. M., Tulevski G. S., Chem. Mater., 2010, 22(18), 5179—5183 |

| 76 | Kim S. M., Jo Y. W., Kim K. K., Duong D. L., Shin H.⁃J., Han J. H., Choi J. Y., Kong J., Lee Y. H., ACS Nano, 2010, 4(11), 6998—7004 |

| 77 | Puchades I., Lawlor C. C., Schauerman C. M., Bucossi A. R., Rossi J. E., Cox N. D., Landi B. J., J. Mater. Chem. C, 2015, 3(39), 10256—10266 |

| [1] | 骆鑫妍, 贾若男, 向勇, 张晓琨. 可拉伸聚合物基复合固体电解质研究进展[J]. 高等学校化学学报, 2022, 43(8): 20220149. |

| [2] | 赵润瑶, 纪桂鹏, 刘志敏. 吡咯氮配位单原子铜催化剂的电催化二氧化碳还原性能[J]. 高等学校化学学报, 2022, 43(7): 20220272. |

| [3] | 高京, 何文涛, 王欣欣, 向宇姝, 龙丽娟, 秦舒浩. DOPO衍生物改性碳纳米管的制备及对聚乳酸阻燃性能的影响[J]. 高等学校化学学报, 2022, 43(3): 20210670. |

| [4] | 丁钦, 张梓轩, 徐培程, 李晓宇, 段莉梅, 王寅, 刘景海. Cu, Ni, Co掺杂对Fe碳纳米管的结构及电催化性能的影响[J]. 高等学校化学学报, 2022, 43(11): 20220421. |

| [5] | 矫龙, 代学民, 牟建新, 杜志军, 王汉夫, 董志鑫, 邱雪鹏. 柔性OLED用高耐热聚酰亚胺薄膜的制备与性能[J]. 高等学校化学学报, 2022, 43(11): 20220390. |

| [6] | 刘杰, 李金晟, 柏景森, 金钊, 葛君杰, 刘长鹏, 邢巍. 降低直接甲醇燃料电池浓差极化的含磺化碳管阻水夹层的构建[J]. 高等学校化学学报, 2022, 43(11): 20220420. |

| [7] | 侯从聪, 王惠颖, 李婷婷, 张志明, 常春蕊, 安立宝. N-CNTs/NiCo-LDH复合材料的制备及电化学性能[J]. 高等学校化学学报, 2022, 43(10): 20220351. |

| [8] | 许晓坚, 李博, 林猛枭, 詹硕. 多孔碳基复合膜的真空冷冻干燥制备及高效太阳能水蒸发性能[J]. 高等学校化学学报, 2022, 43(10): 20220361. |

| [9] | 莫宗文, 张学文, 周浩龙, 周东东, 张杰鹏. 一种多孔配位聚合物的氢键协同客体响应[J]. 高等学校化学学报, 2022, 43(1): 20210576. |

| [10] | 初明月, 李峰博, 高宁, 杨昕, 于婷婷, 马慧媛, 杨桂欣, 庞海军. 轮型多金属氧酸盐复合物膜的制备及在检测亚硝酸盐中的应用[J]. 高等学校化学学报, 2022, 43(1): 20210579. |

| [11] | 赵凌云, 黄汉雄, 罗杜宇, 苏逢春. 复合材料柔软性对倒金字塔微结构阵列传感器性能的影响[J]. 高等学校化学学报, 2021, 42(9): 2953. |

| [12] | 薛谨, 曹小卫, 刘依帆, 王敏. 纸质空心金纳米笼SERS传感器的制备及对非小细胞肺癌患者痰液中miRNAs的快速高灵敏检测[J]. 高等学校化学学报, 2021, 42(8): 2393. |

| [13] | 吴同华, 岳喜贵, 梅笑寒, 梁留博, 彭鑫, 马友美, 张淑玲. 三明治结构多壁碳纳米管/聚醚醚酮电磁屏蔽复合材料的制备[J]. 高等学校化学学报, 2021, 42(8): 2627. |

| [14] | 谢璠, 陈珊珊, 卓龙海, 陆赵情, 高坤, 代啓阳. 聚对二甲苯纳米纤维阵列的CVD液晶模板法制备及降解性能[J]. 高等学校化学学报, 2021, 42(8): 2643. |

| [15] | 梁平平, 刘帅, 李红艺, 丁亚丹, 温晓琨, 刘俊平, 洪霞. PVDF⁃CNT自漂浮多孔微珠的制备及在高效太阳能驱动界面水蒸发中的应用[J]. 高等学校化学学报, 2021, 42(8): 2689. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||