高等学校化学学报 ›› 2020, Vol. 41 ›› Issue (12): 2851.doi: 10.7503/cjcu20200277

• 高分子化学 • 上一篇

马亚萍, 张宁, 郑伟平, 肖玮佳, 刘晨光( ), 贺爱华(

), 贺爱华( ), 邵华锋

), 邵华锋

收稿日期:2020-05-21

出版日期:2020-12-10

发布日期:2020-12-09

通讯作者:

贺爱华

E-mail:liuchenguang@qust.edu.cn;aihuahe@iccas.ac.cn

作者简介:刘晨光, 女, 博士, 副教授, 主要从事定向聚合制备橡塑新材料的基础与应用研究. E-mail: 基金资助:

MA Yaping, ZHANG Ning, ZHENG Weiping, XIAO Weijia, LIU Chenguang( ), HE Aihua(

), HE Aihua( ), SHAO Huafeng

), SHAO Huafeng

Received:2020-05-21

Online:2020-12-10

Published:2020-12-09

Contact:

HE Aihua

E-mail:liuchenguang@qust.edu.cn;aihuahe@iccas.ac.cn

摘要:

高分子材料的组成、 组分分布及链结构与宏观性能紧密相关. 因此, 分析多组分釜内合金材料的链结构特点与性能之间的关系至关重要. 采用升温淋洗分级的方法对两种采用序贯两段聚合原位合成的等规聚丙烯/聚丁烯-1(iPP/iPB)釜内合金在-30 ℃~140 ℃温度范围进行分级, 采用核磁共振波谱仪、 傅里叶变换红外光谱仪、 差示扫描量热仪和凝胶渗透色谱仪等表征了级分的链结构及序列分布、 热行为、 分子量(Mw)及分子量分布(Mw/Mn)等. 结果表明iPP/iPB合金主要由5种级分组成, 高等规聚丁烯(iPB)为主要组分, 同时含有少量的丁烯-丙烯嵌段共聚物(PB-b-PP)和等规聚丙烯(iPP)等. 随淋洗温度升高, PB-b-PP级分中PP嵌段长度逐渐增加, PB嵌段长度逐渐减小; 在相同的淋洗温度, 合金B的嵌段共聚物级分中PP嵌段较长且结晶较完善; 合金B中iPB组分及嵌段共聚物组分含量较高, 使得合金B具有较高的拉伸强度、 弯曲强度、 优异的抗冲击性能、 较高的维卡软化温度及较快的晶型转变速率.

中图分类号:

TrendMD:

马亚萍, 张宁, 郑伟平, 肖玮佳, 刘晨光, 贺爱华, 邵华锋. 等规聚丙烯/聚丁烯-1釜内合金的结构与性能. 高等学校化学学报, 2020, 41(12): 2851.

MA Yaping, ZHANG Ning, ZHENG Weiping, XIAO Weijia, LIU Chenguang, HE Aihua, SHAO Huafeng. Structures and Properties of Isotactic Polypropylene/Polybutene-1 In-reactor Alloys. Chem. J. Chinese Universities, 2020, 41(12): 2851.

| Sample | MFRa(g/10 min) | 10-4Mwb | Mw/Mnb | Isotacticityc(%) | mmmm of PBd(%) | PPe(%) |

|---|---|---|---|---|---|---|

| iPB | 0.47 | 67.9 | 5.3 | 97.5 | 95.6 | — |

| AlloyA | 0.40 | 94.2 | 7.4 | 95.4 | 92.3 | 6.3 |

| AlloyB | 0.70 | 89.2 | 7.5 | 96.4 | 95.4 | 20.8 |

Table 1 Physical parameters of samples

| Sample | MFRa(g/10 min) | 10-4Mwb | Mw/Mnb | Isotacticityc(%) | mmmm of PBd(%) | PPe(%) |

|---|---|---|---|---|---|---|

| iPB | 0.47 | 67.9 | 5.3 | 97.5 | 95.6 | — |

| AlloyA | 0.40 | 94.2 | 7.4 | 95.4 | 92.3 | 6.3 |

| AlloyB | 0.70 | 89.2 | 7.5 | 96.4 | 95.4 | 20.8 |

| Component | Fractionation temperature/℃ | Mass fraction(%) | Dyad sequence distribution(%) | [B](%) | [P](%) | mmmm(%) | 10-4Mw | Mw/Mn | Tm/℃ | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [BB] | [PB] | [PP] | PB | PP | PB | PP | |||||||

| aPB | -30 | 8.2 | 100 | 0 | 0 | 100 | 0 | 55.9 | |||||

| -20―20 | 3.4 | 100 | 0 | 0 | 100 | 0 | |||||||

| mPB | 30 | 8.5 | 100 | 0 | 0 | 100 | 0 | 92.0 | 74.1 | 12.1 | 111.0 | ||

| 40 | 1.0 | 100 | 0 | 0 | 100 | 0 | 109.0 | ||||||

| iPB | 50 | 31.4 | 100 | 0 | 0 | 100 | 0 | 88.4 | 69.8 | 6.6 | 116.8 | ||

| 60 | 39.6 | 100 | 0 | 0 | 100 | 0 | 82.3 | 7.1 | 118.9 | ||||

| 70 | 2.0 | 100 | 0 | 0 | 100 | 0 | 92.3 | 77.1 | 5.3 | 114.7 | |||

| PB?b?PP | 80 | 0.8 | 86.3 | 6.9 | 106.3 | 137.8 | |||||||

| copolymer | 90 | 0.5 | 78.9 | 6.8 | 14.3 | 82.3 | 17.7 | 96.7 | 113.6 | 152.0 | |||

| 100 | 1.4 | 51.7 | 3.3 | 45.1 | 53.3 | 46.7 | 88.8 | 90.1 | 50.6 | 29.7 | 110.9 | 157.0 | |

| 110 | 1.2 | 32.4 | 15.8 | ||||||||||

| 120 | 0.9 | 114.4 | 160.2 | ||||||||||

| 130 | 0.8 | ||||||||||||

| iPP | 140 | 0.3 | |||||||||||

Table 2 Characterization of the main fractions of Alloy A

| Component | Fractionation temperature/℃ | Mass fraction(%) | Dyad sequence distribution(%) | [B](%) | [P](%) | mmmm(%) | 10-4Mw | Mw/Mn | Tm/℃ | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [BB] | [PB] | [PP] | PB | PP | PB | PP | |||||||

| aPB | -30 | 8.2 | 100 | 0 | 0 | 100 | 0 | 55.9 | |||||

| -20―20 | 3.4 | 100 | 0 | 0 | 100 | 0 | |||||||

| mPB | 30 | 8.5 | 100 | 0 | 0 | 100 | 0 | 92.0 | 74.1 | 12.1 | 111.0 | ||

| 40 | 1.0 | 100 | 0 | 0 | 100 | 0 | 109.0 | ||||||

| iPB | 50 | 31.4 | 100 | 0 | 0 | 100 | 0 | 88.4 | 69.8 | 6.6 | 116.8 | ||

| 60 | 39.6 | 100 | 0 | 0 | 100 | 0 | 82.3 | 7.1 | 118.9 | ||||

| 70 | 2.0 | 100 | 0 | 0 | 100 | 0 | 92.3 | 77.1 | 5.3 | 114.7 | |||

| PB?b?PP | 80 | 0.8 | 86.3 | 6.9 | 106.3 | 137.8 | |||||||

| copolymer | 90 | 0.5 | 78.9 | 6.8 | 14.3 | 82.3 | 17.7 | 96.7 | 113.6 | 152.0 | |||

| 100 | 1.4 | 51.7 | 3.3 | 45.1 | 53.3 | 46.7 | 88.8 | 90.1 | 50.6 | 29.7 | 110.9 | 157.0 | |

| 110 | 1.2 | 32.4 | 15.8 | ||||||||||

| 120 | 0.9 | 114.4 | 160.2 | ||||||||||

| 130 | 0.8 | ||||||||||||

| iPP | 140 | 0.3 | |||||||||||

| Component | Fractionation temperature/℃ | Mass fraction(%) | Dyad sequence distribution(%) | [B](%) | [P](%) | mmmm(%) | 10-4Mw | Mw/Mn | Tm/℃ | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [BB] | [PB] | [PP] | PB | PP | PB | PP | |||||||

| aPB | -30 | 1.2 | 100 | 0 | 0 | 100 | 0 | 41.4 | |||||

| -20—20 | 0.3 | ||||||||||||

| mPB | 30 | 0.2 | 100 | 0 | 0 | 100 | 0 | ||||||

| 40 | 0.8 | 100 | 0 | 0 | 100 | 0 | 90.2 | 97.7/106.1 | |||||

| iPB | 50 | 46.5 | 100 | 0 | 0 | 90.5 | 84.7 | 5.8 | 116.5 | ||||

| 60 | 37.2 | 91.1 | 106.4 | 4.3 | 116.1 | ||||||||

| 70 | 2.3 | 100 | 0 | 0 | 100 | 0 | 98.4 | 113.1 | 4.4 | 118.1 | |||

| PB?b?PP | 80—90 | 0.4 | 52.1 | 9.1 | 38.8 | 56.6 | 43.4 | 69.3 | 22.1 | 116.9 | 144.7/152.9 | ||

| copolymer | 100 | 1.6 | 34.3 | 6.0 | 59.7 | 37.2 | 62.8 | 87.7 | 92.1 | 58.9 | 28.3 | 116.6 | 158.3 |

| 110 | 1.3 | 11.5 | 3.9 | 84.6 | 13.5 | 86.5 | 88.4 | 95.0 | 43.8 | 15.6 | 117.3 | 162.6 | |

| 120 | 5.0 | 4.4 | 6.9 | 88.7 | 7.9 | 92.1 | 91.6 | 39.1 | 5.7 | 116.3 | 165.2 | ||

| 130 | 0.4 | 8.8 | 0 | 91.2 | 8.8 | 91.2 | 87.7 | 113.1 | 164.8 | ||||

| iPP | 140 | 2.8 | 0 | 0 | 100 | 0 | 100 | 92.0 | 37.7 | 5.6 | 164.6 | ||

Table 3 Characterization of the main fractions of Alloy B

| Component | Fractionation temperature/℃ | Mass fraction(%) | Dyad sequence distribution(%) | [B](%) | [P](%) | mmmm(%) | 10-4Mw | Mw/Mn | Tm/℃ | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [BB] | [PB] | [PP] | PB | PP | PB | PP | |||||||

| aPB | -30 | 1.2 | 100 | 0 | 0 | 100 | 0 | 41.4 | |||||

| -20—20 | 0.3 | ||||||||||||

| mPB | 30 | 0.2 | 100 | 0 | 0 | 100 | 0 | ||||||

| 40 | 0.8 | 100 | 0 | 0 | 100 | 0 | 90.2 | 97.7/106.1 | |||||

| iPB | 50 | 46.5 | 100 | 0 | 0 | 90.5 | 84.7 | 5.8 | 116.5 | ||||

| 60 | 37.2 | 91.1 | 106.4 | 4.3 | 116.1 | ||||||||

| 70 | 2.3 | 100 | 0 | 0 | 100 | 0 | 98.4 | 113.1 | 4.4 | 118.1 | |||

| PB?b?PP | 80—90 | 0.4 | 52.1 | 9.1 | 38.8 | 56.6 | 43.4 | 69.3 | 22.1 | 116.9 | 144.7/152.9 | ||

| copolymer | 100 | 1.6 | 34.3 | 6.0 | 59.7 | 37.2 | 62.8 | 87.7 | 92.1 | 58.9 | 28.3 | 116.6 | 158.3 |

| 110 | 1.3 | 11.5 | 3.9 | 84.6 | 13.5 | 86.5 | 88.4 | 95.0 | 43.8 | 15.6 | 117.3 | 162.6 | |

| 120 | 5.0 | 4.4 | 6.9 | 88.7 | 7.9 | 92.1 | 91.6 | 39.1 | 5.7 | 116.3 | 165.2 | ||

| 130 | 0.4 | 8.8 | 0 | 91.2 | 8.8 | 91.2 | 87.7 | 113.1 | 164.8 | ||||

| iPP | 140 | 2.8 | 0 | 0 | 100 | 0 | 100 | 92.0 | 37.7 | 5.6 | 164.6 | ||

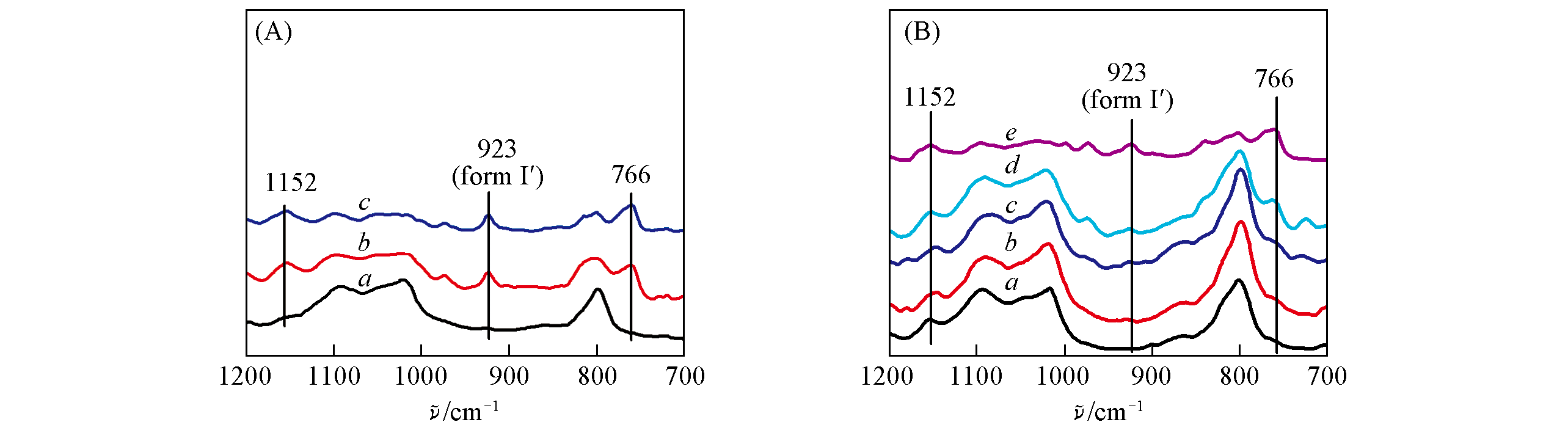

Fig.3 FTIR spectra of fractions of alloys A(A) and B(B)Fractions: (A) a. A0 ℃, b. A10 ℃, c. A20 ℃; (B) a. B-20 ℃, b. B-10 ℃, c. B0 ℃, d. B10 ℃, e. B20 ℃.

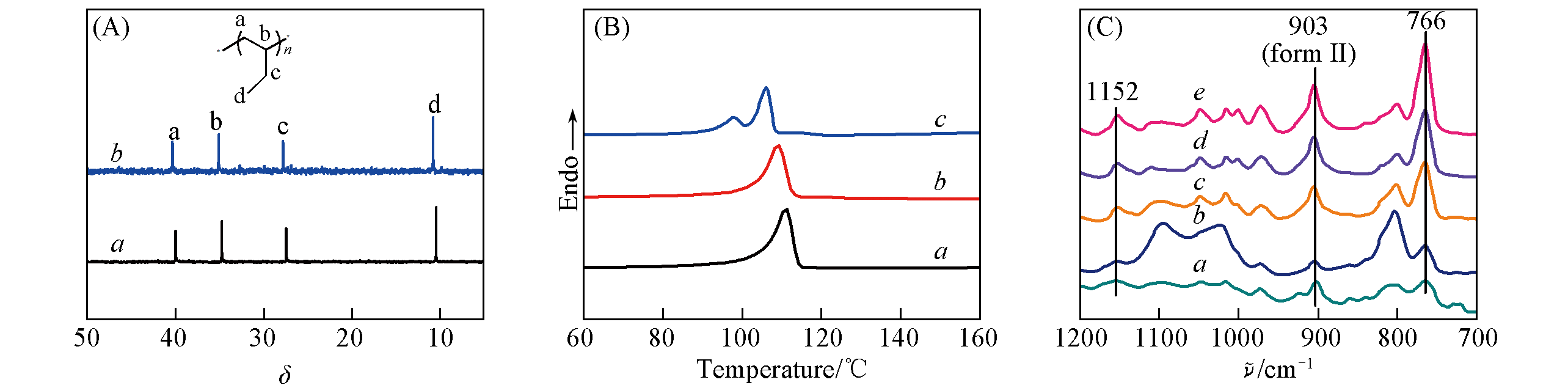

Fig.4 13C NMR spectra(A), DSC heating curves(B) and FTIR spectra(C) of fractions at temperatures ranging from 30 ℃ to 70 ℃Fractions: (A) a. A30 ℃, b. B40 ℃; (B) a. A30 ℃, b. A40 ℃, c. B40 ℃; (C) a. B30 ℃, b. B40 ℃, c. B50 ℃, d. B60 ℃, e. B70 ℃.

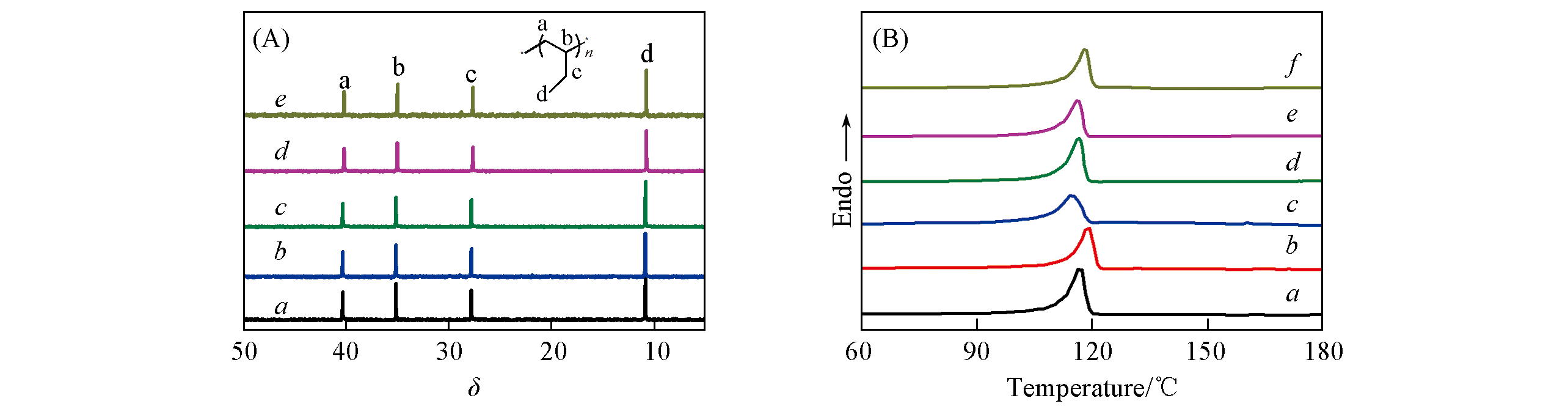

Fig.5 13C NMR spectra(A) and DSC heating curves(B) of fractions at temperatures ranging from 50 ℃ to 70 ℃Fractions: (A) a. A50 ℃, b. A70 ℃; c. B50 ℃, d. B60 ℃, e. B70 ℃; (B) a. A50 ℃, b. A60 ℃, c. A70 ℃, d. B50 ℃, e. B60 ℃, f. B70 ℃.

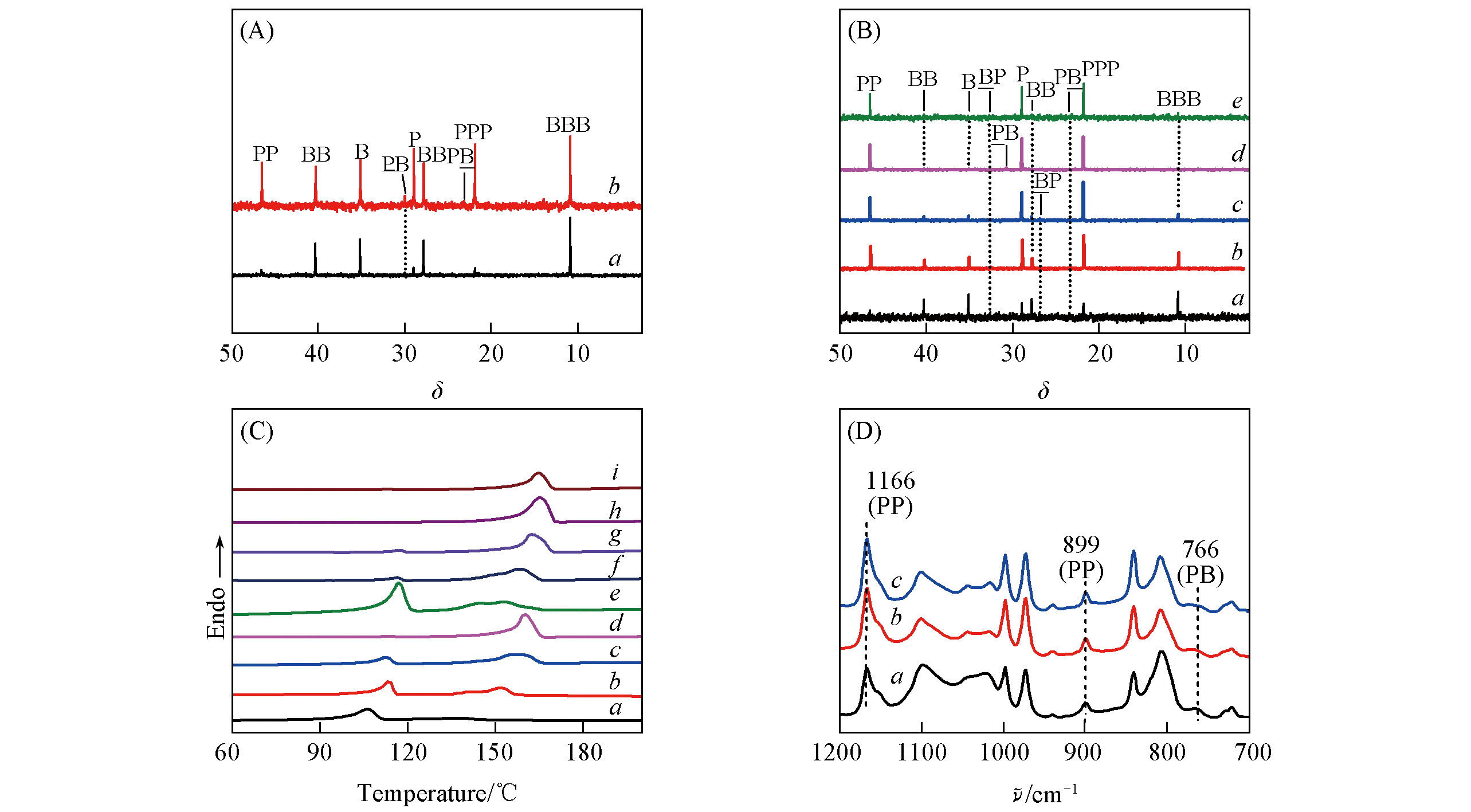

Fig.6 13C NMR spectra of alloys A(A) and B(B), DSC heating curves(C) and FTIR spectra(D) of fractions at temperatures ranging from 80 ℃ to 130 ℃Fractions: (A) a. A90 ℃, b. A100 ℃; (B) a. B80—90 ℃, mixture of B80 ℃ and B90 ℃, b. B100 ℃, c. B110 ℃, d. B120 ℃, e. B130 ℃; (C) a. A80 ℃, b. A90 ℃, c. A100 ℃, d. A120 ℃, e. B80—90℃, f. B100 ℃, g. B110 ℃, h. B120 ℃, i. B130 ℃; (D) a. A110 ℃, b. A120 ℃; c. A130 ℃.

| Sample | Tensile strength/MPa | Elongation at break(%) | Flexural strength/MPa | Flexural modulus/MPa | Impact strength/(kJ?m-2) | Vicat softening temperature/℃ |

|---|---|---|---|---|---|---|

| iPB | 31.4±1.9 | 276.5±15.4 | 8.6±0.3 | 182.3±12.3 | 23.6±2.9 | 84.9 |

| Alloy A | 33.9±1.4 | 279.3±8.3 | 11.4±0.7 | 243.6±27.4 | 22.8±1.2 | 92.7 |

| Alloy B | 37.0±2.7 | 299.1±24.1 | 14.3±0.8 | 293.7±23.9 | 24.0±3.1 | 91.0 |

Table 4 Mechanical properties of iPB and iPP/iPB alloys

| Sample | Tensile strength/MPa | Elongation at break(%) | Flexural strength/MPa | Flexural modulus/MPa | Impact strength/(kJ?m-2) | Vicat softening temperature/℃ |

|---|---|---|---|---|---|---|

| iPB | 31.4±1.9 | 276.5±15.4 | 8.6±0.3 | 182.3±12.3 | 23.6±2.9 | 84.9 |

| Alloy A | 33.9±1.4 | 279.3±8.3 | 11.4±0.7 | 243.6±27.4 | 22.8±1.2 | 92.7 |

| Alloy B | 37.0±2.7 | 299.1±24.1 | 14.3±0.8 | 293.7±23.9 | 24.0±3.1 | 91.0 |

| 1 | Luciani L., Seppala J., Lofgren B., Prog. Polym. Sci.,1988, 13(1), 37—62 |

| 2 | Zhang Y. F., Sun Z. B., Shao H. F., Polym. Mater. Sci. Eng., 2018, 34(10), 105—109(张跃发, 孙照博, 邵华锋. 高分子材料科学与工程, 2018, 34(10), 105—109) |

| 3 | Ma Y. P., Shao H. F., He A. H., Polym. Mater. Sci. Eng., 2016, 32(8), 86—92(马亚萍, 邵华锋, 贺爱华. 高分子材料科学与工程, 2016, 32(8), 86—92) |

| 4 | Shao H. F., Wang S. L., He A. H., Polym. Bull., 2016, 73(11), 3209—3220 |

| 5 | Shao H. F., Ma Y. P., Nie H. R., He A. H., Chinese J. Polym. Sci., 2016, 34(9), 1141—1149 |

| 6 | Ma Y. P., Zheng W. P., Liu C. G., Shao H. F., Nie H. R., He A. H., Chinese J. Polym. Sci., 2020, 38(2), 164—173 |

| 7 | He A. H., Xu C. S., Shao H. F., Yao W., Huang B. C., Polym. Degrad. Stabil., 2010, 95(9), 1443—1448 |

| 8 | Shao H. F., Li L. G., Wang Z. D., He A. H., Huang B. C., Mater. Lett., 2012, 73(15), 24—27 |

| 9 | Lu D. P., Guan R., Polym. Int., 2000, 49(11), 1389—1394 |

| 10 | Xanthos M., Science, 2012, 337(6095), 700—702 |

| 11 | Danesi S., Porter R. S., Polymer, 1978, 19(4), 448—457 |

| 12 | Li Y. M., Wei G. X., Sue H. J., Polym. Eng. Sci., 2000, 40(9), 1979—1988 |

| 13 | Chen Y. H., Yang S., Yang H. Q., Zhang M., Zhang Q. Y., Li Z. M., Ind. Eng. Chem. Res., 2016, 55(32), 8733—8742 |

| 14 | George S., Varughese K. T., Thomas S., Polymer, 2000, 41(14), 5485—5503 |

| 15 | Ren Q., Fan J. S., Zhang Q. L., Yi J. J., Feng J. C., Mater. Design., 2016, 107(5), 295—301 |

| 16 | Shi S. H., Zhang X., Liu Y. S., Nie M., Wang Q., Compos. Sci. Technol., 2016, 135, 76—82 |

| 17 | Xiao W. J., Liu C. G., China Plastics, 2017, 31(9), 56—61(肖玮佳, 刘晨光. 中国塑料, 2017, 31(9), 56—61) |

| 18 | Wang C. X., Shao H. F., He A. H., Plastics, 2015, 44(1), 40—42(王彩霞, 邵华锋, 贺爱华. 塑料, 2015, 44(1), 40—42) |

| 19 | Shao H. F., Wang S. L., Dong X., He A. H., J. Macromol. Sci. Phys., 2018, 57(9), 608—623 |

| 20 | Shao H. F., Wang S. L., Dong X., He A. H., Chinese J. Polym. Sci., 2016, 34(2), 174—184 |

| 21 | Doufnoune R., Baouz T., Bouchareb S., J. Adhes. Sci. Technol., 2019, 33(16), 1729—1757 |

| 22 | Siegmann A., J. Appl. Polym. Sci., 1982, 27(3), 1053—1056 |

| 23 | Shieh Y. T., Lee M. S., Chen S. A., J. Polym. Sci. Pol. Phys., 2002, 40(7), 638—648 |

| 24 | Lee M. S., Chen S. A., J. Polym. Res., 1996, 3(4), 235—258 |

| 25 | Ji Y. X., Su F. M., Cui K. P., Huang N. D., Qi Z. M., Li L. B., Macromolecules, 2016, 49(5), 1761—1769 |

| 26 | Cham P. M., Lee T. H., Marand H., Macromolecules, 1994, 27(15), 4263—4273 |

| 27 | Xu Y., Liu C. G., Nie H. R., He A. H., Chinese J. Polym. Sci., 2018, 36(7), 859—865 |

| 28 | Xu Y., Ma Y. P., Liu C. G., Men Y. F., He A. H., Polymer, 2019, 182, 121817 |

| 29 | Lee M. S., Chen S. A., J. Polym. Sci., Part C: Polym. Lett., 1987, 25(1), 37—43 |

| 30 | Wasiak A., Wenig W., Colloid Polym. Sci., 1984, 262(6), 435—444 |

| 31 | Siegmann A., Appl. Polym. Sci., 1979, 24(12), 2333—2345 |

| 32 | Lotz B., Mathieu C., Thierry A., Lovinger A. J., De Rosa C., Ruiz de Ballesteros O., Auriemma F., Macromolecules, 1998, 31(26), 9253—9257 |

| 33 | Shieh Y. T., Lee M. S., Chen S. A., Polymer, 2001, 42(9), 4439—4448 |

| 34 | Subramanian M. N., Polymer Blends and Composites: Chemistry and Technology, John Wiley & Sons, Inc. Press, New York, 2017, 5, 114—119 |

| 35 | Manson J. A., Sperling L. H., Polymer Blends and Composites: Diblock and Triblock Copolymers, Plennun Press, New York, 1976, 4, 124—129 |

| 36 | Char K., Brown H. R., Deline V. R., Macromolecules, 1993, 26(16), 4164—4171 |

| 37 | Sikka M., Pellegrini N. N., Schmitt E. A., Winey K. I., Macromolecules, 1997, 30(3), 445—455 |

| 38 | Shao H. F., Li L. G., Wang Z. D., He A. H., Huang B. C., Mater. Lett., 2012,73(15), 24—27 |

| 39 | Nie H. R., Xiao W. J., Ma Y. P., Liu C. G., He A. H., Ind. Eng. Chem. Res., 2019, 58(16), 6919—6924 |

| 40 | Jiang B. Y., Shao H. F., Nie H. R., He A. H., J. Polym. Sci., Part A: Polym. Chem., 2015,6(17), 3315—3323 |

| 41 | He A. H., Zheng W. P., Shi Y. W., Liu C. G., Yao W., Huang B. C., Polym. Int., 2012,61(10), 1575—1581 |

| 42 | He A. H., Shi Y. W., Liu C. G., Yao W., Huang B. C., Chinese J. Polym. Sci., 2012, 30(5), 632—641 |

| 43 | Shao H. F., Ren S. T., Wang R. G., He A. H., Polymer, 2020, 186, 122015 |

| 44 | Zheng W. P., Du D. L., He A. H., Ma Y. P., Shao H. F., Liu C. G., Hsiao B. S., Mater. Today Commun., 2020, 23, 100868 |

| 45 | Xue Y. H., Liu W., Li P., Men Y. F., Bo S. Q., Ji X. L., Ind. Eng. Chem. Res., 2019, 58(36), 16869—16876 |

| 46 | Shirayama K., Okada T., Kita S. I., J. Polym. Sci., Part A: Polym. Chem., 1965, 3(3), 907—916 |

| 47 | Fan Y. D., Zhang C. Y., Xue Y. H., Zhang X. Q., Ji X. L., Bo S. Q., Polymer, 2011, 52(2), 557—563 |

| 48 | Xue Y. H., Yang H. R., Bo S. Q., Ji X. L., Acta Poly. Sin., 2014, 12, 1576—1584(薛彦虎, 杨贺然, 薄淑琴, 姬相玲. 高分子学报, 2014, 12, 1576—1584) |

| 49 | Ma Y. P., Zhang N., Zheng W. P., He A. H., Liu C. G., Chinese J. Polym. Sci., 2020, doi: 10.1007/s10118⁃020⁃2468⁃9 |

| 50 | Asakura T., Demura M., Nishiyama Y., Macromolecules, 1991, 24(9), 2334—2340 |

| 51 | Randall J. A., Macromolecules, 1978, 11(3), 592—597 |

| 52 | Abiru T., Mizuno A., Weigand F., J. Appl. Polym. Sci., 1998, 68(9), 1493—1501 |

| 53 | GB/T 1040⁃2006, Plastics⁃Determination of Tensile Properties, Standards Press of China, Beijing, 2006(中国国家标准化管理委员会, GB/T 1040⁃2006, 塑料拉伸性能的测定, 北京: 中国标准出版社, 2006) |

| 54 | GB/T 9341⁃2008, Plastics⁃Determination of Flexural Properties, Standards Press of China, Beijing, 2008(中国国家标准化管理委员会, GB/T 9341⁃008, 塑料弯曲性能的测定, 北京: 中国标准出版社, 2008) |

| 55 | GB/T 1843⁃2008, Plastics⁃Determination of Izod Impact Strength, Standards Press of China, Beijing, 2008(中国国家标准化管理委员会, GB/T 1843⁃2008, 悬臂梁冲击强度的测定, 北京: 中国标准出版社, 2008) |

| 56 | Lee K. H., Givens S. R., Snively C. M., Givens S., Chase D. B., Rabolt J. F., Macromolecules, 2007, 40(7), 2590—2595 |

| [1] | 江博文, 陈敬轩, 成永华, 桑微, 寇宗魁. 单原子材料在电化学生物传感中的研究进展[J]. 高等学校化学学报, 2022, 43(9): 20220334. |

| [2] | 汪思聪, 庞贝贝, 刘潇康, 丁韬, 姚涛. XAFS技术在单原子电催化中的应用[J]. 高等学校化学学报, 2022, 43(9): 20220487. |

| [3] | 高健, 冯奕钰, 方文宇, 王慧, 葛婧, 封伟. 基于低温热释放的烷基接枝相变偶氮苯材料[J]. 高等学校化学学报, 2022, 43(8): 20220146. |

| [4] | 仵宇帅, 尚颖旭, 蒋乔, 丁宝全. 可控自组装DNA折纸结构作为药物载体的研究进展[J]. 高等学校化学学报, 2022, 43(8): 20220179. |

| [5] | 李琳, 齐丰莲, 邱丽莉, 孟子晖. 基于六边形磁纳米片构建动态非晶态光学结构图案[J]. 高等学校化学学报, 2022, 43(8): 20220123. |

| [6] | 贾洋刚, 邵霞, 程婕, 王朋朋, 冒爱琴. 赝电容控制型钙钛矿高熵氧化物La(Co0.2Cr0.2Fe0.2Mn0.2Ni0.2)O3负极材料的制备及储锂性能[J]. 高等学校化学学报, 2022, 43(8): 20220157. |

| [7] | 仇心声, 吴芹, 史大昕, 张耀远, 陈康成, 黎汉生. 离子型交联磺化聚酰亚胺质子交换膜的制备及高温燃料电池性能[J]. 高等学校化学学报, 2022, 43(8): 20220140. |

| [8] | 赵润瑶, 纪桂鹏, 刘志敏. 吡咯氮配位单原子铜催化剂的电催化二氧化碳还原性能[J]. 高等学校化学学报, 2022, 43(7): 20220272. |

| [9] | 杨丹, 刘旭, 戴翼虎, 祝艳, 杨艳辉. 金团簇电催化二氧化碳还原反应的研究进展[J]. 高等学校化学学报, 2022, 43(7): 20220198. |

| [10] | 刘情情, 王普, 王永帅, 赵曼, 董焕丽. 新型萘/苝酰亚胺取代丁二炔衍生物的合成及拓扑聚合[J]. 高等学校化学学报, 2022, 43(6): 20220091. |

| [11] | 施耐克, 张娅, SANSON Andrea, 王蕾, 陈骏. Zn(NCN)单轴的负热膨胀性及机理研究[J]. 高等学校化学学报, 2022, 43(6): 20220124. |

| [12] | 朱凯, 利婕, 武潇逸, 胡薇薇, 吴冬梅, 虞诚潇, 葛志伟, 叶兴乾, 陈士国. 基于多孔石墨化碳柱-四极杆-飞行时间质谱解析甜菜果胶精细结构[J]. 高等学校化学学报, 2022, 43(6): 20220023. |

| [13] | 陈玮琴, 吕佳敏, 余申, 刘湛, 李小云, 陈丽华, 苏宝连. 有机杂化介孔Beta分子筛的合成及在苯甲醇烷基化反应中的应用[J]. 高等学校化学学报, 2022, 43(6): 20220086. |

| [14] | 谷雨, 奚宝娟, 李江潇, 熊胜林. 单原子催化剂在氧还原反应中的分子级调控[J]. 高等学校化学学报, 2022, 43(5): 20220036. |

| [15] | 徐斯然, 阴恒铂, 薛冬萍, 夏会聪, 赵舒琰, 闫文付, 木士春, 张佳楠. 应用于氧还原反应的非贵金属原子分散级金属-氮-碳催化剂的设计[J]. 高等学校化学学报, 2022, 43(5): 20220028. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||