Chem. J. Chinese Universities ›› 2018, Vol. 39 ›› Issue (6): 1334.doi: 10.7503/cjcu20170676

• Polymer Chemistry • Previous Articles Next Articles

ZHANG Jianping1, SONG Liyuan1, WANG Hao3, WANG Riguo2, HE Aihua1,*( )

)

Received:2017-10-13

Online:2018-06-10

Published:2018-03-20

Contact:

HE Aihua

E-mail:aihuahe@iccas.ac.cn

Supported by:TrendMD:

ZHANG Jianping, SONG Liyuan, WANG Hao, WANG Riguo, HE Aihua. Structure and Properties of Brominated Butyl Rubber/Nature Rubber(BIIR/NR) Blends Modified with TBIR†[J]. Chem. J. Chinese Universities, 2018, 39(6): 1334.

| w(BIIR)/w(NR)/w(TBIR) | Green strength/MPa | Elongation at break(%) | Hardness(Shore A) |

|---|---|---|---|

| 70/30/0 | 0.17 | 725 | 30 |

| 70/20/10 | 0.19 | 519 | 33 |

| 70/10/20 | 0.33 | 411 | 35 |

| 70/0/30 | 0.91 | 342 | 40 |

Table 1 Properties of BIIR/NR/TBIR compounds

| w(BIIR)/w(NR)/w(TBIR) | Green strength/MPa | Elongation at break(%) | Hardness(Shore A) |

|---|---|---|---|

| 70/30/0 | 0.17 | 725 | 30 |

| 70/20/10 | 0.19 | 519 | 33 |

| 70/10/20 | 0.33 | 411 | 35 |

| 70/0/30 | 0.91 | 342 | 40 |

| w(BIIR)/w(NR)/w(TBIR) | ML/(dN·m) | MH/(dN·m) | MH-ML/(dN·m) | t10/min | t90/min | 104Crosslink density/ (mol·c |

|---|---|---|---|---|---|---|

| 70/30/0 | 1.36 | 6.84 | 5.48 | 6.0 | 25.3 | 2.03 |

| 70/20/10 | 1.55 | 6.32 | 4.77 | 6.2 | 25.0 | 1.87 |

| 70/10/20 | 1.58 | 6.29 | 4.71 | 5.7 | 24.5 | 1.72 |

| 70/0/30 | 1.83 | 6.59 | 4.76 | 4.5 | 23.4 | 1.82 |

Table 2 Cure characteristics of BIIR/NR/TBIR compounds

| w(BIIR)/w(NR)/w(TBIR) | ML/(dN·m) | MH/(dN·m) | MH-ML/(dN·m) | t10/min | t90/min | 104Crosslink density/ (mol·c |

|---|---|---|---|---|---|---|

| 70/30/0 | 1.36 | 6.84 | 5.48 | 6.0 | 25.3 | 2.03 |

| 70/20/10 | 1.55 | 6.32 | 4.77 | 6.2 | 25.0 | 1.87 |

| 70/10/20 | 1.58 | 6.29 | 4.71 | 5.7 | 24.5 | 1.72 |

| 70/0/30 | 1.83 | 6.59 | 4.76 | 4.5 | 23.4 | 1.82 |

| w(BIIR)/w(NR)/w(TBIR) | Tensile strength/MPa | Modulus at 100%/MPa | Modulus at 300%/MPa | Tear strength/ (kN·m-1) | Elongation at break(%) | Rebound(%) |

|---|---|---|---|---|---|---|

| 70/30/0 | 9.0 | 1.3 | 3.6 | 34.5 | 745 | 7 |

| 70/20/10 | 8.3 | 1.2 | 3.2 | 33.4 | 799 | 7 |

| 70/10/20 | 8.1 | 1.1 | 2.9 | 32.7 | 835 | 8 |

| 70/0/30 | 7.1 | 1.3 | 3.4 | 31.1 | 753 | 8 |

Table 3 Mechanical properties of BIIR/NR/TBIR vulcanizats

| w(BIIR)/w(NR)/w(TBIR) | Tensile strength/MPa | Modulus at 100%/MPa | Modulus at 300%/MPa | Tear strength/ (kN·m-1) | Elongation at break(%) | Rebound(%) |

|---|---|---|---|---|---|---|

| 70/30/0 | 9.0 | 1.3 | 3.6 | 34.5 | 745 | 7 |

| 70/20/10 | 8.3 | 1.2 | 3.2 | 33.4 | 799 | 7 |

| 70/10/20 | 8.1 | 1.1 | 2.9 | 32.7 | 835 | 8 |

| 70/0/30 | 7.1 | 1.3 | 3.4 | 31.1 | 753 | 8 |

| w(BIIR)/w(NR)/w(TBIR) | Tensile strength/MPa | Modulus at 100%/MPa | Modulus at 300%/MPa | Elongation at break(%) | Ageing coefficient(%) |

|---|---|---|---|---|---|

| 70/30/0 | 8.2 | 1.6 | 3.9 | 677 | 82.8 |

| 70/20/10 | 7.9 | 1.5 | 3.6 | 778 | 92.7 |

| 70/10/20 | 7.6 | 1.3 | 3.3 | 838 | 94.2 |

| 70/0/30 | 7.3 | 1.5 | 3.8 | 694 | 94.8 |

Table 4 Properties after hot air ageing(100 ℃, 48 h) of BIIR/NR/TBIR vulcanizats

| w(BIIR)/w(NR)/w(TBIR) | Tensile strength/MPa | Modulus at 100%/MPa | Modulus at 300%/MPa | Elongation at break(%) | Ageing coefficient(%) |

|---|---|---|---|---|---|

| 70/30/0 | 8.2 | 1.6 | 3.9 | 677 | 82.8 |

| 70/20/10 | 7.9 | 1.5 | 3.6 | 778 | 92.7 |

| 70/10/20 | 7.6 | 1.3 | 3.3 | 838 | 94.2 |

| 70/0/30 | 7.3 | 1.5 | 3.8 | 694 | 94.8 |

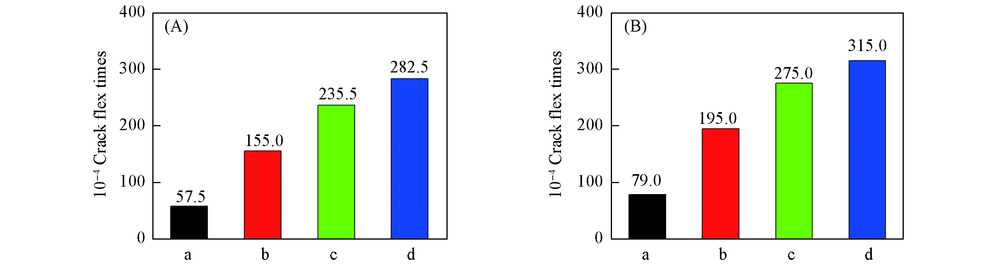

Fig.4 Flex fatigue resistances of BIIR/NR/TBIR vulcanizates (A) The 1st-class; (B) the 6th-class crack flex times. w(BIIR)/w(NR)/w(TBIR): a. 70/30/0; b. 70/20/10; c. 70/10/20; d. 70/0/30.

| w(BIIR)/w(NR)/w(TBIR) | Dispersion(%) | Mean aggregate size/μm |

|---|---|---|

| 70/30/0 | 94.3 | 10.1 |

| 70/20/10 | 96.3 | 10.2 |

| 70/10/20 | 95.5 | 10.0 |

| 70/0/30 | 95.1 | 10.2 |

Table 5 Filler dispersion and mean aggregate size in BIIR/NR/TBIR vulcanizates

| w(BIIR)/w(NR)/w(TBIR) | Dispersion(%) | Mean aggregate size/μm |

|---|---|---|

| 70/30/0 | 94.3 | 10.1 |

| 70/20/10 | 96.3 | 10.2 |

| 70/10/20 | 95.5 | 10.0 |

| 70/0/30 | 95.1 | 10.2 |

| w(BIIR)/w(NR)/w(TBIR) | Dispersion(%) | Mean aggregate size/μm |

|---|---|---|

| 70/30/0 | 93.2 | 11.5 |

| 70/20/10 | 92.8 | 11.3 |

| 70/10/20 | 94.2 | 11.0 |

| 70/0/30 | 93.8 | 10.3 |

Table 6 Filler dispersion and mean aggregate size in BIIR/NR/TBIR vulcanizates after 4×105 times fatigue test

| w(BIIR)/w(NR)/w(TBIR) | Dispersion(%) | Mean aggregate size/μm |

|---|---|---|

| 70/30/0 | 93.2 | 11.5 |

| 70/20/10 | 92.8 | 11.3 |

| 70/10/20 | 94.2 | 11.0 |

| 70/0/30 | 93.8 | 10.3 |

| [1] | Parent J. S., Thom D. J., White G., Whitney R. A., Hopkins W., J. Polym. Sci. Polym. Chem., 2001, 39(12), 2019—2026 |

| [2] | Malmberg S. M., Parent J. S., Pratt D. A., Whitney R. A., Macromolecules, 2010, 43(20), 8456—8461 |

| [3] | Wang J., Pan S., Zhang Y., Gao S., Polym. Test, 2017, 59, 253—261 |

| [4] | Chu C. Y., Vukov R., Macromolecules, 1985, 18(18), 1423—1430 |

| [5] | Faba M. A. J., Parent J. S., Whitney R. A., Ind. Eng. Chem. Res., 2011, 50(2), 680—685 |

| [6] | Moumita K., Shib S. B., Anil K., Polymer, 2016, 82, 121—132 |

| [7] | Li F. Q., Chen F. L., Qin L., Zhou Y. H., China Rubber Ind., 2008, 55(12), 763—767 |

| (李福强, 陈福林, 岑兰, 周彦豪. 橡胶工业, 2008, 55(12), 763—767) | |

| [8] | Xing X. J., Li J. F., Zhang Y. F., Xiao J. B., China Rubber Ind., 2014, 61(3), 157—160 |

| (邢祥菊, 李建芳, 张艳芬, 肖建斌. 橡胶工业, 2014, 61(3), 157—160) | |

| [9] | Lin Y., Zhang A., Wang L., J. Appl. Polym. Sci., 2010, 108(3), 1393—1401 |

| [10] | Peng Z., Zhong J. P., Liao S. Q., Chinese Polym. Bull., 2014, (5), 41—48 |

| (彭政, 钟杰平, 廖双泉. 高分子通报, 2014, (5), 41—48) | |

| [11] | Choi S. S., Kim J. C., Lee S. G., Yong L. J., Macromol. Res., 2008, 16(6), 561—566 |

| [12] | He A. H., Huang B. C., Jiao S. K., Hu Y. L., J. Appl. Polym. Sci., 2003, 89(7), 1800—1807 |

| [13] | He A. H., Yao W., Jia Z. F., Huang B. C., Jiao S. K., Acta Polym. Sin., 2002, (1), 19—24 |

| (贺爱华, 姚薇, 贾志峰, 黄宝琛, 焦书科. 高分子学报, 2002, (1), 19—24) | |

| [14] | Du A. H., Zhao Y. X., Huang B. C., Yao W., J. Macromol. Sci. B, 2008, 47(2), 358—367 |

| [15] | Niu Q. T., Zou C., Liu X. Y., Wang R. G., He A. H., Polymer, 2017, 109, 197—204 |

| [16] | Song J. S., Huang B. C., Yu D. S., J. Appl. Polym. Sci., 2001, 82(1), 81—89 |

| [17] | Jiang X. B., Zhang Q. F., He A. H., Chinese J. Polym. Sci., 2015, 33(6), 815—822 |

| [18] | Zhang Q. F., Jiang X. B., He A. H., Chinese J. Polym. Sci., 2014, 32(8), 1068—1076 |

| [19] | He A. H., Yao W., Huang B. C., Huang Y. Q., Jiao S. K., J. Appl. Polym. Sci., 2004, 92(5), 2941—2948 |

| [20] | Sandstrom P. H., Tire With Sidewall Comprised of Low Viscosity Trans-1,4-polybutadiene, Cis-1,4-polyisoprene Rubber and Cis-1,4-polybutadiene Rubber, US 20080216934 A, 2008-09-11 |

| [21] | Wang H., Cui H. H., Ma Y. S., Zhang J. P., Song L. Y., He A. H., Chinese Polym. Bull., 2016, (10), 61—67 |

| (王浩, 崔虹虹, 马韵升, 张剑平, 宋丽媛, 贺爱华. 高分子通报, 2016, (10), 61—67) | |

| [22] | Wang H., Zou C., He A .H., Acta Polym. Sin., 2015, (12), 1387—1395 |

| (王浩, 邹陈, 贺爱华. 高分子学报, 2015, (12), 1387—1395) | |

| [23] | Technical Committee ISO/TC45/SC2, ISO9026-2007, Raw Rubber or Unvulcanized Compounds-determination of Green Strength, International Standards Organization, Geneva, 2007 |

| [24] | Standardization Administration of the People’s Republic of China, GB/T 16584-1996, Rubber-Measurement of Vulcanization Characteristics With Rotorless Curemeters, Standards Press of China, Beijing, 1996 |

| (中国国家标准化管理委员会. GB/T 16584-1996, 橡胶用无转子硫化仪测定硫化特性, 北京, 中国标准出版社, 1996) | |

| [25] | Standardization Administration of the People’s Republic of China, GB/T 528-2009, Rubber, Vulcanized or Thermoplastic Determination of Tensile Stress-strain Properties, Standards Press of China, Beijing, 2009 |

| (中国国家标准化管理委员会. GB/T 528-2009, 硫化橡胶或热塑性橡胶拉伸应力应变性能的测定, 北京, 中国标准出版社, 2009) | |

| [26] | Standardization Administration of the People’s Republic of China, GB/T 529-2008, Rubber, Vulcanized or Thermoplastic Determination of Tear Strength, Standards Press of China, Beijing, 2008 |

| (中国国家标准化管理委员会. GB/T 529-2008, 硫化橡胶或热塑性橡胶撕裂强度的测定, 北京, 中国标准出版社, 2008) | |

| [27] | Standardization Administration of the People’s Republic of China, GB/T 3512- 2001, Rubber, Vulcanized or Thermoplastic-accelerated Ageing and Heat Resistance Tests-air-oven Method, Standards Press of China, Beijing, 2001 |

| (中国国家标准化管理委员会. 硫化橡胶或热塑性橡胶热空气加速老化和耐热试验. 北京, 中国标准出版社, 2001) | |

| [28] | Standardization Administration of the People’s Republic of China, GB/T 13934-2006, Rubber, Vulcanized or Thermoplastic Determination of Flex Cracking and Crack Growth(De Mattia), Standards Press of China, Beijing, 2006 |

| (中国国家标准化管理委员会. 硫化橡胶或热塑性橡胶屈挠龟裂和裂口增长的测定(德墨西亚型), 北京, 中国标准出版社, 2006) | |

| [29] | ASTM committee D11, ASTM D7723-11, Standard Test Method for Rubber Property——Macro-dispersion of Fill, American Society for Testing and Materials, New York, 2011 |

| [30] | Standardization Administration of the People’s Republic of China, GB/T1038-2000, Plastics-film and Sheeting-determination of Gas Transmissions——Differential-pressure Method, Standards Press of China, Beijing, 2000 |

| (中国国家标准化管理委员会. 塑料薄膜和薄片气体透过性试验方法——压差法, 北京, 中国标准出版社, 2000) | |

| [31] | Medalia A. I., Heckman F. A., Carbon, 1969, 7(5), 567—582 |

| [32] | Liu X., Zhao S. H., Zhang X. Y., Li X. L., Bai Y., Polymer, 2014, 55(8), 1964—1976 |

| [33] | Huneau B., Masquelier I., Marco Y., Saux V. L., Noizet S., Schiel C., Charrier P., Rubber Chem. Technol., 2016, 89(1), 126—141 |

| [1] | LIU Miao, LIU Ruibo, LIU Badi, QIAN Ying. Synthesis, Two-photon Fluorescence Imaging and Photodynamic Therapy of Lysosome-targeted Indole-BODIPY Photosensitizer [J]. Chem. J. Chinese Universities, 2022, 43(10): 20220326. |

| [2] | WANG Wei, ZOU Bingchen, HOU Jie, ZHOU Wanli, LUO Jianping, WANG Kangli, JIANG Kai. In⁃situ Analysis of Interfacial Reaction Process Inside Li-Ga Liquid Metal Battery [J]. Chem. J. Chinese Universities, 2022, 43(10): 20220261. |

| [3] | ZHU Zhaotian, LI Shengkai, SONG Minghui, CAI Xinqi, SONG Zhiling, CHEN Long, CHEN Zhuo. Recent Progress of Versatile Metal Graphitic Nanocapsules in Biomedical Applications [J]. Chem. J. Chinese Universities, 2021, 42(9): 2701. |

| [4] | MENG Fanwei, GAO Qi, YE Qing, LI Chenxi. Potassium Poisoning Mechanism of Cu-SAPO-18 Catalyst for Selective Catalytic Reduction of NOx by Ammonia [J]. Chem. J. Chinese Universities, 2021, 42(9): 2832. |

| [5] | LI Anran, ZHAO Bing, KAN Wei, SONG Tianshu, KONG Xiangdong, BU Fanqiang, SUN Li, YIN Guangming, WANG Liyan. ON-OFF-ON Double Colorimetric and Fluorescent Probes Based on Phenanthro[9,10-d]imidazole Derivatives and Their Living Cells Imaging [J]. Chem. J. Chinese Universities, 2021, 42(8): 2403. |

| [6] | HUANG Chibao, KANG Shuai, PAN Qi, LYU Guoling. Carbazole-derived Dicyanostilbene Two-photon Fluorescence Probe for Lipid Raft [J]. Chem. J. Chinese Universities, 2021, 42(8): 2443. |

| [7] | CHEN Hongda, ZHANG Hua, WANG Zhenxin. Development of Small Animals in vivo Fluorescence-photothermal Dual Mode Imaging System [J]. Chem. J. Chinese Universities, 2021, 42(3): 725. |

| [8] | CHEN Weiju, CHEN Shiya, XUE Caoye, LIU Bo, ZHENG Jing. Fluorescent Probe for Hypoxia-triggered Imaging and Cancer Therapy [J]. Chem. J. Chinese Universities, 2021, 42(11): 3433. |

| [9] | ZHANG Yaqing, LI Linyao, HAO Mengqi, LUO Qin, DENG Siyu, YANG Yun, LIANG Xuewei, FANG Weiwei, SONG Erqun. Research Progress of Bacterial Infection Imaging [J]. Chem. J. Chinese Universities, 2021, 42(11): 3265. |

| [10] | LIU Hong, JIANG Jinghong, DUAN Zhijuan, XU Shijun, HUANG Fujian, XIA Fan. Recent Advance in Light-controlled CRISPR Technology [J]. Chem. J. Chinese Universities, 2021, 42(11): 3321. |

| [11] | KE Mengting, YUAN Jiangpei, ZHANG Heng, FANG Yu. Coordination Porous Polymers for Targeting Subcellular Organelles: Bio-imaging, Diagnosis and Therapy [J]. Chem. J. Chinese Universities, 2021, 42(11): 3295. |

| [12] | WANG Mengmeng, LUAN Tianjiao, YANG Mingyan, LYU Jiajia, GAO Jie, LI Hongyu, WEI Gang, YUAN Zeli. Rhodamine Fluorescent Probe for Tumor Targeted Hypoxia-imaging as Intra-operative Navigators [J]. Chem. J. Chinese Universities, 2021, 42(10): 3071. |

| [13] | GONG Shaohua, ZHANG Xia, LI Na, TANG Bo. Recent Progress of Fluorescent Nanoprobes for Organelle pH Detection [J]. Chem. J. Chinese Universities, 2020, 41(9): 1933. |

| [14] | BAI Cuiting, YUE Renye, LUO Liegao, MA Nan. Quantitative Analysis of MicroRNA Content by Fluorescence Imaging in Cancer Cells Using Dual-color Fluorescence Nanosensor † [J]. Chem. J. Chinese Universities, 2020, 41(6): 1252. |

| [15] | LIANG Yuxin, ZHAO Rong, LIANG Xinyue, FANG Xiaohong. Single-molecule Imaging and Analysis of Signal Transduction Proteins on Cell Membranes † [J]. Chem. J. Chinese Universities, 2020, 41(6): 1127. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||