Chem. J. Chinese Universities ›› 2016, Vol. 37 ›› Issue (11): 2117.doi: 10.7503/cjcu20160217

• Polymer Chemistry • Previous Articles

ZHANG Fan1,2, WANG Bin1,2, WANG Jiaona1,2, LI Xiuyan1, LI Congju1,2,*( )

)

Received:2016-04-08

Online:2016-11-10

Published:2016-09-19

Contact:

LI Congju

E-mail:congjuli2014@126.com

Supported by:CLC Number:

TrendMD:

ZHANG Fan, WANG Bin, WANG Jiaona, LI Xiuyan, LI Congju. Preparation of Hierarchically Structured AOPAN@Mg(OH)2 Composite Nanofibrous Membrane and Cr(Ⅵ)-removal Capacity†[J]. Chem. J. Chinese Universities, 2016, 37(11): 2117.

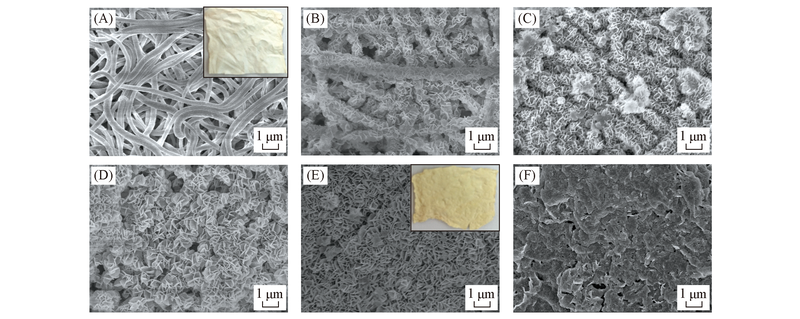

Fig.1 SEM images of AOPAN nanofibrous membranes with different hydrothermal timeTime/h: (A) 0; (B) 1; (C) 3; (D) 5; (E) 7; (F) 9 h. Inset of (A): photo of the AOPAN nanofibrous membrane; inset of (E): photo of AOPAN@Mg(OH)2 composite nanofibrous membrane.

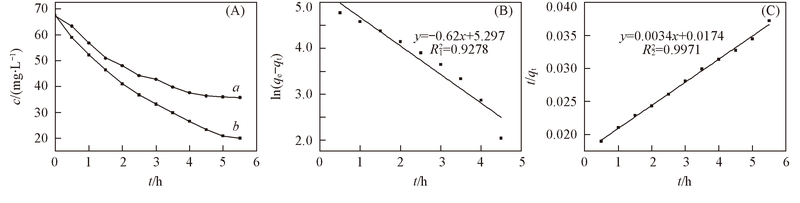

Fig.6 Change of the total Cr(Ⅵ) in AOPAN nanofiber(a) and AOPAN@Mg(OH)2 nanofiber(b) solution with time at pH=2(A), pseudo-frist-order plot(B) and pseudo-second-order plot(C) for adsorption of Cr(Ⅵ) onto the AOPAN@Mg(OH)2 composite nanofibrous membrane

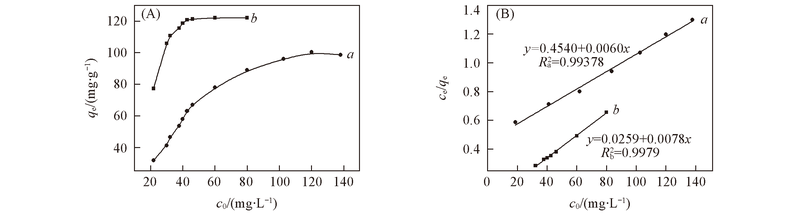

Fig.7 Relationship between concentration of Cr(Ⅵ) and adsorption capacity at pH=2(A) and equilibrium adsorption isotherm of Cr(Ⅵ) fitted with Langmuir adsorption model(B)a. AOPAN; b. AOPAN@Mg(OH)2.

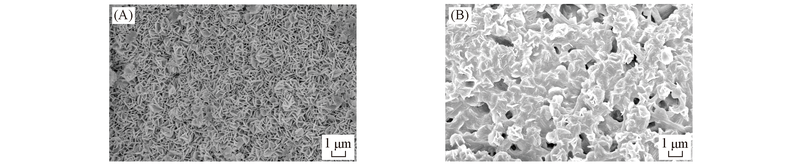

Fig.9 SEM images of AOPAN@Mg(OH)2 composite nanofibrous membrane(A) and the AOPAN@Mg(OH)2 composite nanofibrous membrane(B) washed by 0.1 mol/L NaOH solutions

| [1] | Rozell D., J. , Reaven S., J. , Risk. Anal., 2012, 32( 8), 1382- 1393 |

| [2] | Lu Y., L. , Song, S. , Wang R., S. , Liu Z., Y. , Meng, J. , Sweetman A., J. , Wang T., Y. , Environ. Int., 2015, 77, 5- 15 |

| [3] | Miao, X. , Tang Y., H. , Wong C. W., Y. , Zhang H., Y. , Environ. Pollu., 2015, 196, 473- 477 |

| [4] | Zhang X., Y. , Zhuang D., F. , Ma, X. , Jiang, D. , J. Geogr. Sci., 2014, 24( 1), 46- 58 |

| [5] | Saeed, K. , Haider, S. , Oh T., J. , Park S., Y. , J. Mem. Sci., 2008, 322( 2), 400- 405 |

| [6] | Zhou, S. , Liu, F. , Zhang, Q. , Chen B., Y. , Lin C., J. , Chang C., T. , J. Nanosci. Nanotechno., 2015, 15( 8), 5823- 5832 |

| [7] | Li, Y. , Qiu, T. , Xu, X. , Eur. Polym. J., 2013, 49( 6), 1487- 1494 |

| [8] | 张谦, 夏柯, 刘丽, 刘文畅. 高等学校化学学报, 2013, 34( 11), 2667- 2673 |

| Zhang, Q. , Xia, K. , Liu, L. , Liu Y., C. , Chem. J. Chinese Universities, 2013, 34( 11), 2667- 2673 ( | |

| [9] | Salaberria A., M. , Diaz R., H. , Labidi, J. , Femandes S., C. , Food. Hydrocolloid., 2015, 46, 93- 102 |

| [10] | Aliabadi, M. , Irani, M. , Ismaeili, J. , Piri, H. , Parnian M., J. , Chem. Eng. J., 2013, 220, 237- 243 |

| [11] | 闫春秋, 刘斌, 鲁冠秀, 李耀先, 杨清彪, 宋岩. 高等学校化学学报, 2015, 37( 1), 189- 194 |

| Yan C., Q. , Liu, B. , Lu G., X. , Li Y., X. , Yang Q., B. , Song, Y. , Chem. J. Chinese Universities, 2015, 37( 1), 189- 194 ( | |

| [12] | Avila, M. , Burks, T. , Akhtar, F. , Gothelid, M. , Lanså, ker P. C. , Toprak M., S. , Chem. Eng. J., 2014, 245, 201- 209 |

| [13] | Chaú, que E. F. C. , Dlamini L., N. , Adelodun A., A. , Greyling C., J. , Ngila J., C. , Appl. Surf. Sci., 2016, 369, 19- 28 |

| [14] | Lennerová, D. , Kovanda, F. , Brož, ek J. , Appl. Clay. Sci., 2015, 114, 265- 272 |

| [15] | Lin, Y. , Cai, W. , He, H. , Wang, X. , Wang, G. , RSC Adv., 2012, 2( 5), 1769- 1773 |

| [16] | Jia B., B. , Wang J., N. , Wu, J. , Li C., J. , Chem. Eng. J., 2014, 254, 98- 105 |

| [17] | Li C., J. , Li Y., J. , Wang J., N. , Cheng, J. , Chem. Eng. J., 2013, 220, 294- 301 |

| [18] | Wang J., N , , Jia B., B. , Li C., J. , Nano., 2015, 10( 02), 1550029 |

| [19] | Xu G., R. , Wang J., N. , Li C., J. , Chem. Eng. J., 2012, 198, 310- 317 |

| [20] | 王娇娜, 贺欢, 李秀艳, 李从举. 高分子学报, 2015, (7), 778- 785 |

| Wang J., N. , He H., Li X. Y., Li C. J., Acta Polym Sinica , 2015, (7), 778- 785 ( | |

| [21] | Salman, M. , Athar, M. , Farooq, U. , Rev. Environ. Sci. Bio., 2015, 14( 2), 211- 228 |

| [22] | Sun, B. , Li, X. , Zhao, R. , Yin, M. , J. Taiwan. Inst. Chem. E., 2016, 62, 219- 227 |

| [23] | Alavi M., A. , Morsali, A. , Ultrason. Sonochem., 2010, 17( 2), 441- 446 |

| [24] | Qiu, L. , Xie, R. , Ding, P. , Qu B., J. , Compos. Struct., 2003, 62( 3), 391- 395 |

| [1] | WU Yu, LI Xuan, YANG Hengpan, HE Chuanxin. Construction of Cobalt Single Atoms via Double-confinement Strategy for High-performance Electrocatalytic Reduction of Carbon Dioxide [J]. Chem. J. Chinese Universities, 2022, 43(9): 20220343. |

| [2] | CHEN Weiqin, LYU Jiamin, YU Shen, LIU Zhan, LI Xiaoyun, CHEN Lihua, SU Baolian. Preparation of Organic Hybrid Mesoporous Beta Zeolite for Alkylation of Mesitylene with Benzyl Alcohol [J]. Chem. J. Chinese Universities, 2022, 43(6): 20220086. |

| [3] | ZHANG Shiyu, HE Runhe, LI Yongbing, WEI Shijun, ZHANG Xingxiang. Fabrication of Lithium-sulfur Battery Cathode with Radiation Crosslinked Low Molecular Weight of Polyacrylonitrile and the Mechanism of Sulfur Storage [J]. Chem. J. Chinese Universities, 2022, 43(3): 20210632. |

| [4] | FAN Juanjuan, HAN Yuanyuan, CUI Jie. Monte Carlo Simulation of the Transformation Control of ABC Triblock Copolymer Micelles from Multicompartment Structure to Multicore Structure [J]. Chem. J. Chinese Universities, 2021, 42(3): 857. |

| [5] | CUI Jinping, CHEN Wenxian, YU Feifan, CAO Shiyu, LYU Weiyang, YAO Yuyuan. Adsorption Reduction of Hexavalent Chromium and co-Catalytic Degradation of Organic Pollutants by Carbon Doped Hexagonal Boron Nitride Supported MoS2 [J]. Chem. J. Chinese Universities, 2021, 42(10): 3125. |

| [6] | WANG Xia, LIU Yanji, JIA Yongfeng, JI Lei, HU Quanli, DUAN Limei, LIU Jinghai. Preparative Chemistry of N-containing Porous Carbon Nanofibers for Capacity Improvement in Lithium-sulfur Battery † [J]. Chem. J. Chinese Universities, 2020, 41(4): 829. |

| [7] | QIN Chunping, WANG Xianliu, TANG Han, YI Bingcheng, LIU Chang, ZHANG Yanzhong. Osteogenesis-promoting Effects of the Electrospun Nanofibers Containing Decellularized Bone Matrix † [J]. Chem. J. Chinese Universities, 2020, 41(4): 780. |

| [8] | WANG Yuyao, ZHANG Qiang, YU Jihong. Synthesis of Hierarchical NaX Zeolite and Its CO2 Adsorption Performance † [J]. Chem. J. Chinese Universities, 2020, 41(4): 616. |

| [9] | WANG Yongpeng,XU Zibo,LIU Mengzhu,ZHANG Haibo,JIANG Zhenhua. Non-enzymatic Glucose Sensor Based on the Electrospun Porous Foamy Copper Oxides Micro-nanofibers† [J]. Chem. J. Chinese Universities, 2019, 40(6): 1310. |

| [10] | CAI Jiao,YU Qiongwei,HE Xiaomei,XU Jing,DING Qiong,FENG Yuqi. Preparation of SiW11 Incorporated SiO2 Nanofibers(SiW11/SiO2) and Its Application in the Analysis of Polyamines in Arabidopsis† [J]. Chem. J. Chinese Universities, 2019, 40(5): 901. |

| [11] | ZHAO Yuxuan,CHEN Yanjun,PAN Guxin,WANG Chang,PENG Zhenbo,SUN Zongxu,LIANG Yongri,SHI Qisong. Preparation and Performance of Novel Tb-PEG+Eu-PEG/PANI/PAN Luminescent-electrical-phase Change Composite Fibers by Electrospinning† [J]. Chem. J. Chinese Universities, 2019, 40(4): 824. |

| [12] | GAO Ningxiao,XU Yulong,LIU Yong. Preparation of Carbon Dots from Soy Milk Powder and Fluorescent Nanofibers Containing Carbon Dots† [J]. Chem. J. Chinese Universities, 2019, 40(3): 555. |

| [13] | JI Yuchun,MAO Wenhui,LIAO Hejie,WANG Jilin,LONG Fei,GU Yunle. Boron Nitride Nanotube-nanosheet Hierarchical Structures andIts Optical/adsorption Properties† [J]. Chem. J. Chinese Universities, 2019, 40(2): 216. |

| [14] | ZHANG Xinmu,CUI Xiangxu,YAOMA Kangyue,LI Tingting,ZHANG Zhiming. Electrospinning Preparation and Photocatalytic Activity of H4SiW12O40/Ethylene Vinyl Alcohol Copolymer Nanofibrous Membrane† [J]. Chem. J. Chinese Universities, 2019, 40(2): 372. |

| [15] | XU Dan,DING Yadan,WANG Xue,CONG Tie,LIU Junping,HONG Xia,PAN Ying. Microdroplet Detection of Protein Based on Superhydrophobic Polystyrene Film† [J]. Chem. J. Chinese Universities, 2018, 39(9): 1913. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||