Chem. J. Chinese Universities ›› 2014, Vol. 35 ›› Issue (2): 389.doi: 10.7503/cjcu20130913

• Polymer Chemistry • Previous Articles Next Articles

LI Tingting1, LIU Ce2, ZHANG Zhiming1,*( ), AN Libao3, YANG Cuihuan1

), AN Libao3, YANG Cuihuan1

Received:2013-09-16

Online:2014-02-10

Published:2014-01-03

Contact:

ZHANG Zhiming

E-mail:zhangzhiming1942@163.com

Supported by:CLC Number:

TrendMD:

LI Tingting, LIU Ce, ZHANG Zhiming, AN Libao, YANG Cuihuan. Preparation and Performance of POMs/PS/PVA Electrospinning Fiber Membranes†[J]. Chem. J. Chinese Universities, 2014, 35(2): 389.

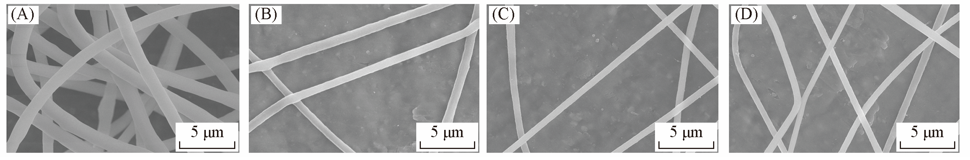

Fig.4 SEM images of the composite fibers with different contents of POMs in the spinning solutionContent of POMs/(mg·mL-1): (A) 5; (B) 10; (C) 15; (D) 20.

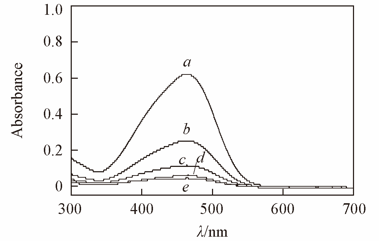

Fig.5 UV-Vis spectra of reaction of methyl orange catalysed by the POMs/PS/PVA composite fiber membranes at different timeTime of reaction/min: a. 5; b. 10; c. 15; d. 20; e. 25.

| No. | pH | Mass of POMs in the water/mg | Mass loss of POMs(%) |

|---|---|---|---|

| 1 | 7.18 | 0 | 0 |

| 2 | 7.19 | 0 | 0 |

| 3 | 7.18 | 0 | 0 |

| 4 | 5.35 | 0.27 | 0.14 |

| 5 | 5.09 | 0.49 | 0.25 |

Table 1 Mass loss of POMs measured at an interval of 25 min(total 5 intervals) after the composite fiber membrane immersed in water*

| No. | pH | Mass of POMs in the water/mg | Mass loss of POMs(%) |

|---|---|---|---|

| 1 | 7.18 | 0 | 0 |

| 2 | 7.19 | 0 | 0 |

| 3 | 7.18 | 0 | 0 |

| 4 | 5.35 | 0.27 | 0.14 |

| 5 | 5.09 | 0.49 | 0.25 |

| Mass ratio of PS/PVA | Cold pressing(room temperature) | Hot pressing(50 ℃) | ||

|---|---|---|---|---|

| Tensile strength / MPa | Tensile fracture strain(%) | Tensile strength/MPa | Tensile fracture strain(%) | |

| 1∶2 | 0.43 | 58.15 | 8.16 | 220.77 |

| 1∶1 | 0.44 | 45.14 | 9.56 | 123.56 |

| 3∶2 | 0.47 | 30.63 | 10.34 | 113.46 |

| 2∶1 | 0.68 | 15.22 | 11.68 | 68.85 |

Table 2 Tensile strength and elongation of the composite fiber membrane with different mass ratio of PS and PVA

| Mass ratio of PS/PVA | Cold pressing(room temperature) | Hot pressing(50 ℃) | ||

|---|---|---|---|---|

| Tensile strength / MPa | Tensile fracture strain(%) | Tensile strength/MPa | Tensile fracture strain(%) | |

| 1∶2 | 0.43 | 58.15 | 8.16 | 220.77 |

| 1∶1 | 0.44 | 45.14 | 9.56 | 123.56 |

| 3∶2 | 0.47 | 30.63 | 10.34 | 113.46 |

| 2∶1 | 0.68 | 15.22 | 11.68 | 68.85 |

| Mass fraction of POMs(%) | Cold pressing(room temperature) | Hot pressing(50 ℃) | ||

|---|---|---|---|---|

| Tensile strength/MPa | Tensile fracture strain(%) | Tensile strength/MPa | Tensile fracture strain(%) | |

| 4.76 | 0.42 | 72.80 | 9.99 | 188.88 |

| 9.09 | 0.68 | 68.15 | 15.22 | 183.73 |

| 13.04 | 0.60 | 65.65 | 13.43 | 165.66 |

| 16.67 | 0.44 | 40.48 | 10.74 | 134.03 |

Table 3 Tensile strength and elongation of composite fiber membranes with different contents of POMs

| Mass fraction of POMs(%) | Cold pressing(room temperature) | Hot pressing(50 ℃) | ||

|---|---|---|---|---|

| Tensile strength/MPa | Tensile fracture strain(%) | Tensile strength/MPa | Tensile fracture strain(%) | |

| 4.76 | 0.42 | 72.80 | 9.99 | 188.88 |

| 9.09 | 0.68 | 68.15 | 15.22 | 183.73 |

| 13.04 | 0.60 | 65.65 | 13.43 | 165.66 |

| 16.67 | 0.44 | 40.48 | 10.74 | 134.03 |

| [1] | Bae E., Lee J. W., Hwang B. H., Yeo J., Yoon J., Cha H. J., Choi W., Chemosphere, 2008, 72(2), 174—181 |

| [2] | Neal C., Neal M., Wickham H., Sci. Total Environ., 2000, 251/252(1), 511—522 |

| [3] | Feng C. G., Shang H. R., Chem. Res. Chinese Universities, 2012, 28(3), 366—370 |

| [4] | Teli S. B., Gokavi G. S., Sairam M., Aminabhavi T. M., Colloids and Surfaces A, 2007, 301(1—3), 55—62 |

| [5] | Mizuno N., Watanabe T., Mori H., Misono M., J. Catal., 1990, 123(1), 157—163 |

| [6] | Izumi Y., Hasebe R., Urabe K., J. Catal., 1983, 84(2), 402—409 |

| [7] | El-Wahab M. M. M. A., Said A. A., J. Mol. Catal. A: Chem., 2005, 240(1/2), 109—118 |

| [8] | Alcañiz-Monge J., Trautwein G., Marco-Lozar J. P., Appl. Catal. A: Gen., 2013, 468(1), 432—441 |

| [9] | Mallik S., Dash S. S., Parida K. M., Mohapatra B. K., J. Colloid Interf. Sci., 2006, 300(1), 237—243 |

| [10] | Feng W., Zhang T. R., Liu Y., Lu R., Zhao Y. Y., Li T. J., Yao J. N., J. Solid State Chem., 2002, 169(1), 1—4 |

| [11] | Huang Z. M., Zhang Y. Z., Kotaki M., Ramakrishna S., Compos. Sci. Technol., 2003, 63(15), 2223—2253 |

| [12] | Li D., Xia Y. N. , Adv. Mater., 2004, 16(14), 1151—1170 |

| [13] | Greiner A., Wendorff J. H., Angew. Chem. Int. Ed. Engl., 2007, 46(30), 5670—5703 |

| [14] | Nie G. D., Li S. K., Lu X. F., Wang C., Chem. J. Chinese Universities, 2013, 34(1), 15—29 |

| (乜广弟, 力尚昆, 卢晓峰, 王策.高等学校化学学报,2013, 34(1), 15—29) | |

| [15] | Zhang T. Z., Ge L. Q., Wang X., Gu Z. Z., Polymer, 2008, 49(12), 2898—2902 |

| [16] | Sui C. H., Li C., Guo X. H., Cheng T. X., Gao Y. K., Zhou G. D., Gong J., Du J. S., Appl. Surf. Sci., 2012, 258(18), 7105—7111 |

| [17] | Megelski S., Stephens J. S., Chase D. B., Rabolt J. F., Macromolecules, 2002, 35(22), 8456—8466 |

| [18] | Kang M. S., Jung R., Kim H. S., Jin H. J., Colloids and Surfaces A, 2008, 313/314(1), 411—414 |

| [19] | Krissanasaeranee M., Supaphol P., Wongkasemjit S., Mater. Chem. Phys., 2010, 119(1/2), 175—181 |

| [20] | Lu Y., Jiang H. L., Tu K. H., Wang L. Q., Acta Biomater., 2009, 5(5), 1562—1574 |

| [21] | Ignatova M., Manolova N., Lachkova V., Varbanov S., Rashkov I., Macromol. Rapid Comm., 2008, 29(23), 1871—1876 |

| [22] | Deng G. H., Yu L. X., Hao J. H., Chen C. X., Li L., Polym. Mater. Sci. Eng., 2001, 17(6), 122—125 |

| (邓国宏, 余立新, 郝继华, 陈翠仙, 李琳.高分子材料科学与工程,2001, 17(6), 122—125) | |

| [23] | Wang E.B., Introduction of Polyacid Chemistry, Chemical Industry Press, Beijing, 1998, 171—175 |

| (王恩波. 多酸化学导论, 北京: 化学工业出版社, 1998, 171—175) | |

| [24] | Baumgarten P. K., J. Colloid Interf. Sci., 1971, 36(1), 71—79 |

| [25] | Jin X., Hsieh Y. L., Polymer, 2005, 46(1), 5149—5160 |

| [1] | WU Yu, LI Xuan, YANG Hengpan, HE Chuanxin. Construction of Cobalt Single Atoms via Double-confinement Strategy for High-performance Electrocatalytic Reduction of Carbon Dioxide [J]. Chem. J. Chinese Universities, 2022, 43(9): 20220343. |

| [2] | LI Wei, LUO Piao, HUANG Lianzhan, CUI Zhiming. Lithium Polystyrene Sulfonate Based Interfacial Protective Layer for Lithium Metal Anodes [J]. Chem. J. Chinese Universities, 2022, 43(8): 20220166. |

| [3] | YANG Zhaohua, CHENG Hongjing, YANG Yi, LIU Hui, DU Feipeng, ZHANG Yunfei. Preparation of Silver-loaded Polyvinyl Alcohol Sponge and Its Interfacial Photothermal Driven Water Evaporation Performance [J]. Chem. J. Chinese Universities, 2022, 43(10): 20220181. |

| [4] | NI Qingsheng, DU Miao, SHAN Guorong, SONG Yihu, WU Ziliang, ZHENG Qiang. Regulation of Rheological Behavior of Polyvinyl Alcohol Aqueous Solution by One-dimensional Particles [J]. Chem. J. Chinese Universities, 2021, 42(12): 3738. |

| [5] | GONG Yuning, WANG Qi, WANG Honglei, GUAN Shuang. Preparation and Properties of Polyvinye Alconol/Polyvinylpyrrolidone/Iodine Composite Hydrogels [J]. Chem. J. Chinese Universities, 2020, 41(9): 2078. |

| [6] | SUN Mengying,Lü Jingchun,XU Hong,ZHANG Linping,ZHONG Yi,CHEN Zhize,SUI Xiaofeng,MAO Zhiping. Synthesis and Electrochromic Performance of Phosphazene-viologen Polymer † [J]. Chem. J. Chinese Universities, 2020, 41(6): 1399. |

| [7] | QIN Chunping, WANG Xianliu, TANG Han, YI Bingcheng, LIU Chang, ZHANG Yanzhong. Osteogenesis-promoting Effects of the Electrospun Nanofibers Containing Decellularized Bone Matrix † [J]. Chem. J. Chinese Universities, 2020, 41(4): 780. |

| [8] | WANG Xia, LIU Yanji, JIA Yongfeng, JI Lei, HU Quanli, DUAN Limei, LIU Jinghai. Preparative Chemistry of N-containing Porous Carbon Nanofibers for Capacity Improvement in Lithium-sulfur Battery † [J]. Chem. J. Chinese Universities, 2020, 41(4): 829. |

| [9] | YAN Ming,ZHOU Weidong,ZHANG Hong,SHI Junfeng,ZHAO Yunhe,YE Yongming,GUO Jing,YU Yue. PVA Microcrystalline Cross-linking and SA/PAA Double Network Synergistic Modification of SA Fiber † [J]. Chem. J. Chinese Universities, 2020, 41(2): 349. |

| [10] | WANG Lin, ZHANG Yanhui, Arzugul Muslim, LAN Haidie. Morphology and Size Regulation of Polyaniline Induced by PS-b-P2VP as Template and Its Electrochemical Characters [J]. Chem. J. Chinese Universities, 2019, 40(8): 1748. |

| [11] | FENG Wei,WANG Bowei,JIANG Yang,LI Longyun. Design, Preparation and Surface-enhanced Raman Scattering(SERS) Spectrum of Single Ag Nanodot† [J]. Chem. J. Chinese Universities, 2019, 40(7): 1345. |

| [12] | WANG Yongpeng,XU Zibo,LIU Mengzhu,ZHANG Haibo,JIANG Zhenhua. Non-enzymatic Glucose Sensor Based on the Electrospun Porous Foamy Copper Oxides Micro-nanofibers† [J]. Chem. J. Chinese Universities, 2019, 40(6): 1310. |

| [13] | CAI Jiao,YU Qiongwei,HE Xiaomei,XU Jing,DING Qiong,FENG Yuqi. Preparation of SiW11 Incorporated SiO2 Nanofibers(SiW11/SiO2) and Its Application in the Analysis of Polyamines in Arabidopsis† [J]. Chem. J. Chinese Universities, 2019, 40(5): 901. |

| [14] | ZHAO Yuxuan,CHEN Yanjun,PAN Guxin,WANG Chang,PENG Zhenbo,SUN Zongxu,LIANG Yongri,SHI Qisong. Preparation and Performance of Novel Tb-PEG+Eu-PEG/PANI/PAN Luminescent-electrical-phase Change Composite Fibers by Electrospinning† [J]. Chem. J. Chinese Universities, 2019, 40(4): 824. |

| [15] | GAO Ningxiao,XU Yulong,LIU Yong. Preparation of Carbon Dots from Soy Milk Powder and Fluorescent Nanofibers Containing Carbon Dots† [J]. Chem. J. Chinese Universities, 2019, 40(3): 555. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||