高等学校化学学报 ›› 2015, Vol. 36 ›› Issue (7): 1378.doi: 10.7503/cjcu20150012

宋宇琨1,2, 吕洪1,2( ), 郝传璞1,2, 米灿根1,3

), 郝传璞1,2, 米灿根1,3

收稿日期:2015-01-07

出版日期:2015-07-10

发布日期:2015-06-17

作者简介:联系人简介: 吕 洪, 男, 博士, 副教授, 主要从事先进制氢技术及能源材料研究. E-mail:基金资助:

SONG Yukun1,2, LÜ Hong1,2,*( ), HAO Chuanpu1,2, MI Cangen1,3

), HAO Chuanpu1,2, MI Cangen1,3

Received:2015-01-07

Online:2015-07-10

Published:2015-06-17

Contact:

LÜ Hong

E-mail:lvhong@tongji.edu.cn

Supported by:摘要:

采用亚当斯熔融法(Adams fusion method)在钛网上包覆IrO2催化剂, 并将其用作固体聚合物电解质(SPE)电解器的阳极集电极, 发现其可以显著降低电解过电位. 通过X射线多晶衍射(XRD)和透射电子显微镜(TEM)分析发现, 包裹在钛网上的IrO2催化剂晶粒为2.0~3.0 nm, 结晶度良好; 交流阻抗谱(EIS)和循环伏安(CV)分析结果表明, 改性的钛网集电极层可增加三相反应活性点, 使三相反应通道由催化层延伸到集电极层, 活性催化剂表面积增大, 从而大幅度降低了活化阻抗, 电解性能获得提升. 通过对不同IrO2催化剂负载量改性的钛网进行研究发现, 随着钛网负载IrO2量的增加, 在相同电流密度下, 极化曲线的过电位先减小后增加, 当IrO2负载量为1.38%(质量分数)时, 电解池的过电位最低, 在1 A/cm2电流密度下, 过电位为2.028 V.

中图分类号:

TrendMD:

宋宇琨, 吕洪, 郝传璞, 米灿根. IrO2改性钛网对固体聚合物电解质电解器集电极层电化学性能的影响. 高等学校化学学报, 2015, 36(7): 1378.

SONG Yukun, LÜ Hong, HAO Chuanpu, MI Cangen. Effect of IrO2 Modification of Ti Mesh on Electrochemical Performance of Collector Layer for Solid Polymer Electrolyte Electrolyzer†. Chem. J. Chinese Universities, 2015, 36(7): 1378.

| Ti mesh | Mass before modification/mg | Mass after modification/mg | IrO2 loading/mg | IrO2 loading ratio(%) |

|---|---|---|---|---|

| 50 mesh Adams | 80.53 | 81.92 | 1.39 | 1.70 |

| 100 mesh Adams-1 | 45.98 | 46.19 | 0.21 | 0.45 |

| 100 mesh Adams-2 | 48.71 | 49.39 | 0.68 | 1.38 |

| 100 mesh Adams-3 | 47.34 | 48.63 | 1.29 | 2.65 |

Table 1 Modified Ti mesh specimens

| Ti mesh | Mass before modification/mg | Mass after modification/mg | IrO2 loading/mg | IrO2 loading ratio(%) |

|---|---|---|---|---|

| 50 mesh Adams | 80.53 | 81.92 | 1.39 | 1.70 |

| 100 mesh Adams-1 | 45.98 | 46.19 | 0.21 | 0.45 |

| 100 mesh Adams-2 | 48.71 | 49.39 | 0.68 | 1.38 |

| 100 mesh Adams-3 | 47.34 | 48.63 | 1.29 | 2.65 |

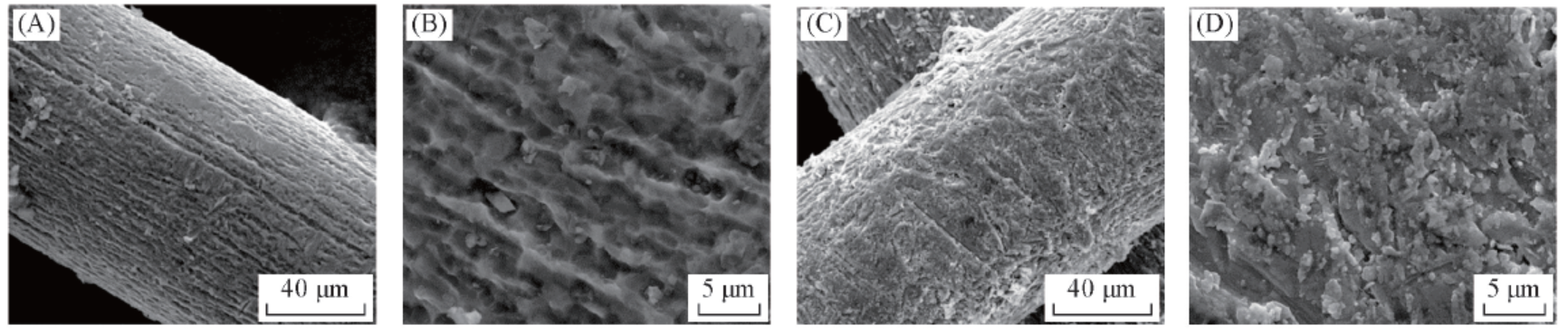

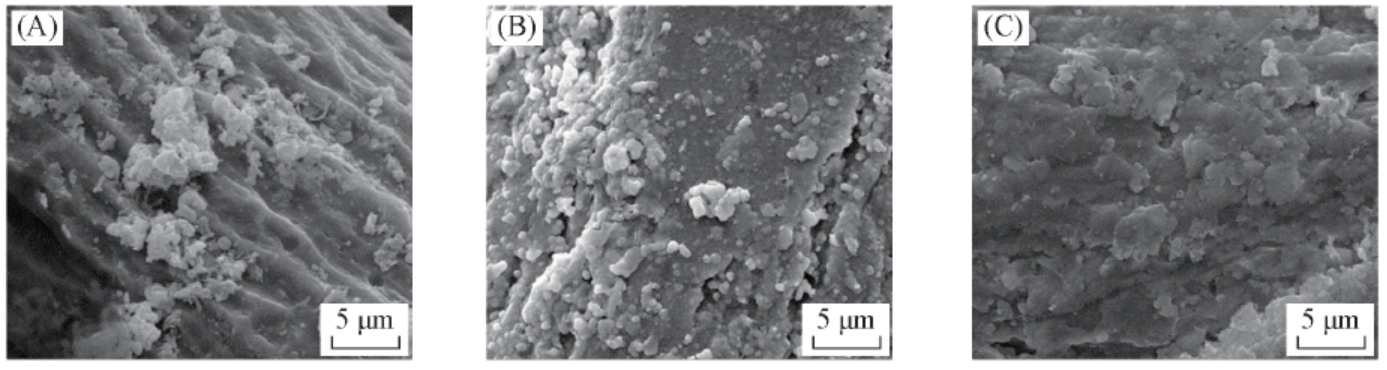

Fig.2 SEM images of Ti meshes before(A, B) and after(C, D) modification at low(A, C) and high(B, D) magnifications(A), (B) 50 mesh Ti mesh; (C), (D) 50 mesh Adams.

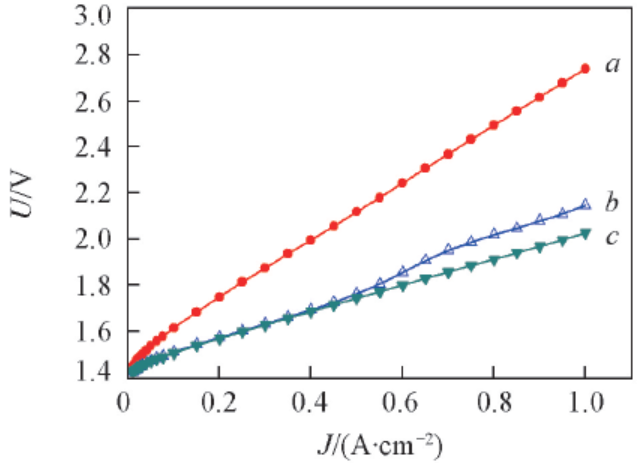

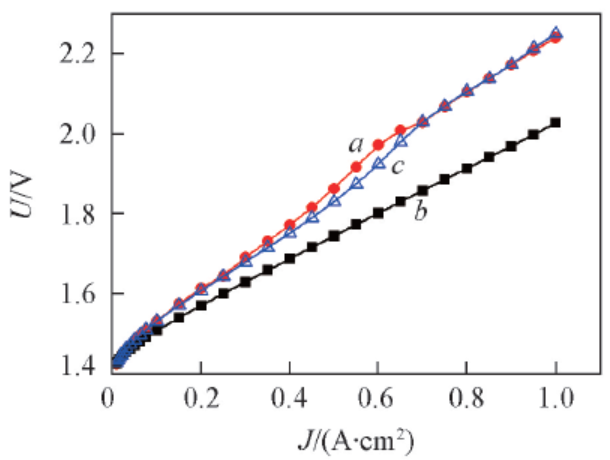

Fig.5 Polarization curves of water electrolyzers employing different anode electrode collector layersa. 50 mesh non-modified; b. 50 mesh Adams; c. 100 mesh Adams-2.

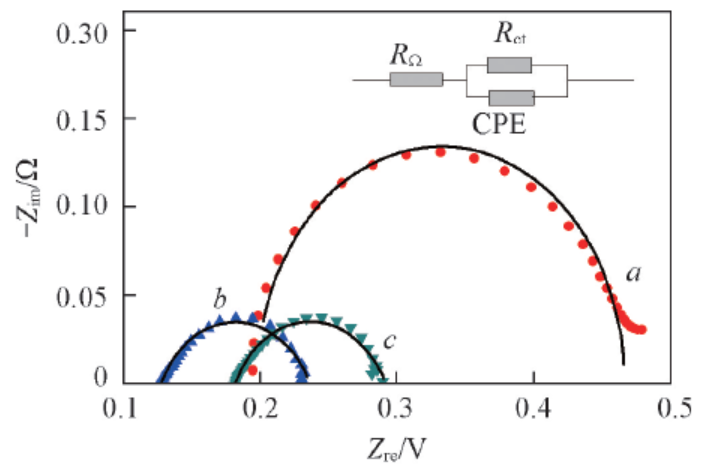

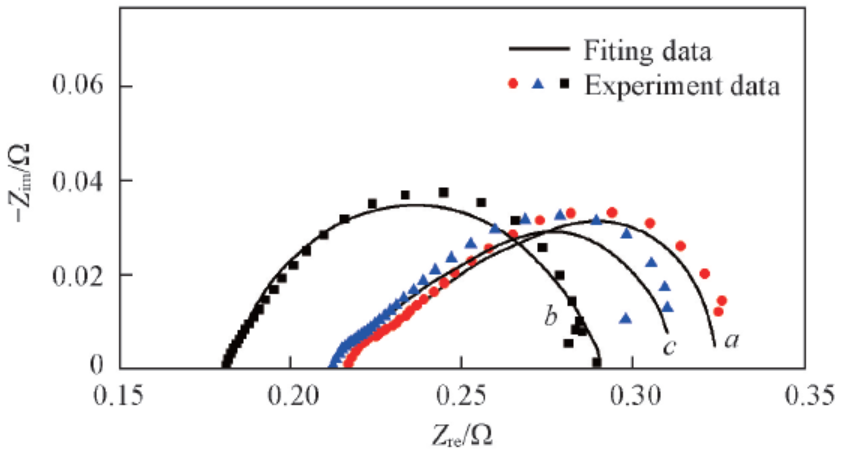

Fig.6 EIS of water electrolyzers employing diffe-rent anode electrode collector layers at 0.05 A/cm2a. 50 mesh non-modified; b. 50 mesh Adams; c. 100 mesh Adams-2.

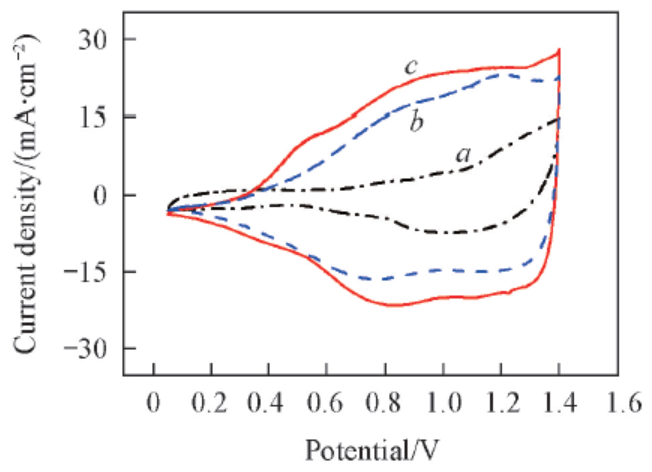

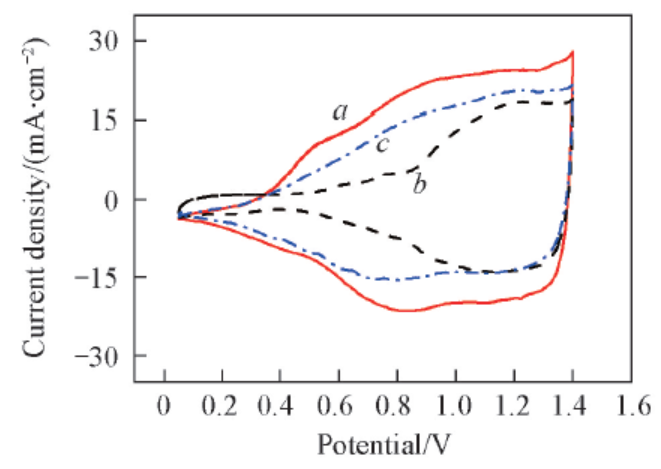

Fig.7 Repetitive cyclic voltammetry of water electrolyzers employing different anode electrode collector layersa. 50 mesh non-modified; b. 50 mesh Adams; c. 100 mesh Adams-2.

| Ti mesh | RΩ/Ω | Rct/Ω |

|---|---|---|

| 50 mesh non-modified | 0.195 | 0.272 |

| 50 mesh Adams | 0.129 | 0.105 |

| 100 mesh Adams-2 | 0.186 | 0.102 |

Table 2 Rct and RΩ of water electrolyzers employing different anode electrode collector layers

| Ti mesh | RΩ/Ω | Rct/Ω |

|---|---|---|

| 50 mesh non-modified | 0.195 | 0.272 |

| 50 mesh Adams | 0.129 | 0.105 |

| 100 mesh Adams-2 | 0.186 | 0.102 |

| Ti mesh | RΩ/Ω | Rct/Ω |

|---|---|---|

| 100 mesh Adams-1 | 0.217 | 0.110 |

| 100 mesh Adams-2 | 0.186 | 0.102 |

| 100 mesh Adams-3 | 0.211 | 0.098 |

Table 3 Rct and RΩ of water electrolyzers employing modified Ti meshes with different IrO2 loadings

| Ti mesh | RΩ/Ω | Rct/Ω |

|---|---|---|

| 100 mesh Adams-1 | 0.217 | 0.110 |

| 100 mesh Adams-2 | 0.186 | 0.102 |

| 100 mesh Adams-3 | 0.211 | 0.098 |

Fig.9 Polarization curves of water electrolyzers employing modified Ti meshes with diffe-rent IrO2 loadingsw(IrO2): a. 0.45%(100 mesh Adams-1); b. 1.38%(100 mesh Adams-2); c. 2.65%(100 mesh Adams-3).

Fig.10 EIS of water electrolyzers employing modified Ti meshes with different IrO2 loadings at 0.05 A/cm2w(IrO2): a. 0.45%(100 mesh Adams-1); b. 1.38%(100 mesh Adams-2); c. 2.65%(100 mesh Adams-3).

Fig.11 Repetitive cyclic voltammetry of water electrolyzers employing modified Ti meshes with different catalyst loadingsw(IrO2): a. 1.38%(100 mesh Adams-2); b. 0.45%(100 mesh Adams-1); c. 2.65%(100 mesh Adams-3).

Fig.12 SEM images of 100 mesh Ti meshes with different IrO2 loadingsw(IrO2): a. 0.45%(100 mesh Adams-1); b. 1.38%(100 mesh Adams-2); c. 2.65%(100 mesh Adams-3).

| [1] | Nehrir M. H., Wang C., Strunz K., Aki H., Ramakumar R., Bing J., Miao Z., Salameh Z., Ieee Transactions on Sustainable Energy, 2011, 2(4), 392—403 |

| [2] | Carmo M., Fritz D. L., Merge J., Stolten D., Int. J. Hydrogen Energy, 2013, 38(12), 4901—4934 |

| [3] | Ursua A., Gandia L. M., Sanchis P., Proceedings of the Ieee, 2012, 100(2), 410—426 |

| [4] | Ito H., Maeda T., Nakano A., Takenaka H., Int. J. Hydrogen Energy, 2011, 36(17), 10527—10540 |

| [5] | Grigoriev S. A., Millet P., Volobuev S. A., Fateev V. N., Int. J. Hydrogen Energy, 2009, 34(11), 4968—4973 |

| [6] | Liu M., Guo X. F., Wang J. M., Jiang L., Acta Phys. Chim. Sin., 2012, 28(12), 2931—2938 |

| (刘萌, 郭向飞, 王景明, 江雷. 物理化学学报,2012, 28(12), 2931—2938) | |

| [7] | Goni-Urtiaga A., Presvytes D., Scott K., Int. J. Hydrogen Energy, 2012, 37(4), 3358—3372 |

| [8] | Hu J. M., Meng H. M., Zhang J. Q., Cao C. N., Acta. Phys. Chim. Sin., 2002, 18(1), 14—20 |

| (胡吉明, 孟惠民, 张鉴清, 曹楚南. 物理化学学报,2002, 18(1), 14—20) | |

| [9] | Ren L.B., Xu Z. B., Li Y. H., Yi W., Zhang J., Liu X. J.,Chinese Journal of Power Sources, 2009, (4), 326—328 |

| (任丽彬, 徐志彬, 李勇辉, 易炜, 张军, 刘兴江. 电源技术, 2009, (4), 326—328) | |

| [10] | Jiang J. M., Liu G. Y., Xu J. Y., Wang X. D., Battery Bimonthly, 2014, 44(2), 64—67 |

| (蒋钜明, 刘高阳, 许军元, 王新东. 电池,2014, 44(2), 64—67) | |

| [11] | Adams R., Shriner R., J. Am. Chem. Soc., 1923, 45(9), 2171—2179 |

| [12] | Li G., Yu H., Song W., Dou M., Li Y., Shao Z., Yi B., Chem. Sus. Chem., 2012, 5(5), 858—861 |

| [13] | Kokoh K. B., Mayousse E., Napporn T. W., Servat K., Guillet N., Soyez E., Grosjean A., Rakotondrainibe A., Paul-Joseph J., Int. J. Hydrogen Energy, 2014, 39(5), 1924—1931 |

| [14] | Marshall A., Børresen B., Hagen G., Tsypkin M., Tunold R., Mater. Chem. Phys., 2005, 94(2), 226—232 |

| [15] | Polonsky J., Petrushina I. M., Christensen E., Bouzek K., Prag C. B., Andersen J. E. T., Bjerrum N. J., Int. J. Hydrogen. Energy, 2012, 37(3), 2173—2181 |

| [16] | Hao C. P., Lv H., Li B., Xin H. F., Ma J. X., Acta Energiae Solaris Sinica, 2013, 34(8), 1464—1470 |

| (郝传璞, 吕洪, 李冰, 辛海峰, 马建新. 太阳能学报,2013, 34(8), 1464—1470) | |

| [17] | Wang C., Mao Z. Q., Xu J. M., Xie X. F., Yang L. H., Chem. J. Chinese Universities, 2005, 26(1), 125—128 |

| (王诚, 毛宗强, 徐景明, 谢晓峰, 杨立寨. 高等学校化学学报,2005, 26(1), 125—128) | |

| [18] | Cheng H., Dong J. Z., Chao H., Yao J. H., Cao Y. A., Acta. Phys. Chim. Sin., 2012, 28(4), 850—856 |

| (程辉, 董江舟, 巢晖, 姚江宏, 曹亚安. 物理化学学报,2012, 28(4), 850—856) | |

| [19] | Su H., Bladergroen B. J., Linkov V., Pasupathi S., Ji S., Int. J. Hydrogen. Energy, 2011, 36(23), 15081—15088 |

| [20] | Guo J. W., Mao Z. L., Xu J. M., Chem. J. Chinese Universities, 2003, 24(8), 1477—1481 |

| (郭建伟, 毛宗强, 徐景明. 高等学校化学学报,2003, 24(8), 1477—1481) | |

| [21] | Banerjee W., Maikap S., Lai C. S., Chen Y. Y., Tien T. C., Lee H. Y., Chen W. S., Chen F. T., Kao M. J., Tsai M. J., Nanoscale Research Letters, 2012, 7(1), 1—12 |

| [22] | De Oliveira-Sousa A., Da Silva M., Machado S., Avaca L., de Lima-Neto P., Electrochimica Acta, 2000, 45(27), 4467—4473 |

| [23] | Trasatti S., Electrochimica Acta, 1991, 36(2), 225—241 |

| [1] | 郭彪, 赵晨灿, 刘芯辛, 于洲, 周丽景, 袁宏明, 赵震. 表面水热碳层对磁性NiFe2O4八面体光催化活性的影响[J]. 高等学校化学学报, 2022, 43(11): 20220472. |

| [2] | 董妍红, 鲁新环, 杨璐, 孙凡棋, 段金贵, 郭昊天, 张钦峻, 周丹, 夏清华. 双功能金属有机骨架材料的制备及催化烯烃环氧化性能[J]. 高等学校化学学报, 2022, 43(11): 20220458. |

| [3] | 王祖民, 孟程, 于然波. 过渡金属磷化物析氢催化剂的掺杂调控[J]. 高等学校化学学报, 2022, 43(11): 20220544. |

| [4] | 何建云 蒋云波 张爱敏 唐振艳 李鸿鹏. 新型卟啉基多孔有机聚合物COP-180负载钯催化剂的制备及应用研究[J]. 高等学校化学学报, 0, (): 20220535. |

| [5] | 夏文文 于洪晶 王时野 姚丽 李象远. 燃烧反应机理构建的极小反应网络方法—芳香烃燃烧[J]. 高等学校化学学报, 0, (): 20220616. |

| [6] | 李怀科 岳贵初 谢海韵 刘静 高松伟 侯兰兰 李帅 苗贝贝 王女 白杰 崔志民 赵勇. 静电纺丝中空纳米纤维在催化领域的应用[J]. 高等学校化学学报, 0, (): 20220625. |

| [7] | 匡华艺 陈晨. 贵金属纳米框架催化剂的设计合成及电催化性能研究[J]. 高等学校化学学报, 0, (): 20220586. |

| [8] | 王雅芝 贾显枝 张宏港 刘璐 赵彬然. 介质阻挡放电等离子制备5Ni-5La/SiO2催化剂用于甲烷干重整反应[J]. 高等学校化学学报, 0, (): 20220503. |

| [9] | 朱佶鹏 刘润辉 宋恭华. 双噁唑啉接枝的氨基酸聚合物作为手性催化中心在不对称Henry 反应中的应用[J]. 高等学校化学学报, 0, (): 20220569. |

| [10] | 程媛媛, 郗碧莹. ·OH自由基引发CH3SSC |

| [11] | 孙金时, 陈鹏, 景丽萍, 孙福兴, 刘佳. 多级孔芳香骨架材料的合成及固载硫脲催化剂的研究[J]. 高等学校化学学报, 2022, 43(10): 20220171. |

| [12] | 李学宇, 王朝, 陈雅, 李可可, 李建全, 金顺敬, 陈丽华, 苏宝连. 等离激元共振光转热增强负载纳米金对丁二烯选择性加氢的催化性能[J]. 高等学校化学学报, 2022, 43(10): 20220174. |

| [13] | 宋佳欣, 崔静, 范晓强, 孔莲, 肖霞, 解则安, 赵震. 介孔二氧化硅负载高分散钒催化剂的制备及乙烷选择氧化性能研究[J]. 高等学校化学学报, 0, (): 20220532. |

| [14] | 唐全骏, 刘颖馨, 孟蓉炜, 张若天, 凌国维, 张辰. 单原子催化在海洋能源领域的应用[J]. 高等学校化学学报, 2022, 43(9): 20220324. |

| [15] | 林治, 彭志明, 贺韦清, 沈少华. 单原子与团簇光催化: 竞争与协同[J]. 高等学校化学学报, 2022, 43(9): 20220312. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||