高等学校化学学报 ›› 2020, Vol. 41 ›› Issue (2): 331.doi: 10.7503/cjcu20190439

韩洪晶( ),葛芹,陈彦广,王海英,赵宏志,王怡真,张亚男,邓冀童,宋华,张梅

),葛芹,陈彦广,王海英,赵宏志,王怡真,张亚男,邓冀童,宋华,张梅

收稿日期:2019-08-05

出版日期:2020-02-10

发布日期:2019-12-04

通讯作者:

韩洪晶

E-mail:hongjing_han@163.com

基金资助:

HAN Hongjing( ),GE Qin,CHEN Yanguang,WANG Haiying,ZHAO Hongzhi,WANG Yizhen,ZHANG Yanan,DENG Jitong,SONG Hua,ZHANG Mei

),GE Qin,CHEN Yanguang,WANG Haiying,ZHAO Hongzhi,WANG Yizhen,ZHANG Yanan,DENG Jitong,SONG Hua,ZHANG Mei

Received:2019-08-05

Online:2020-02-10

Published:2019-12-04

Contact:

Hongjing HAN

E-mail:hongjing_han@163.com

Supported by:摘要:

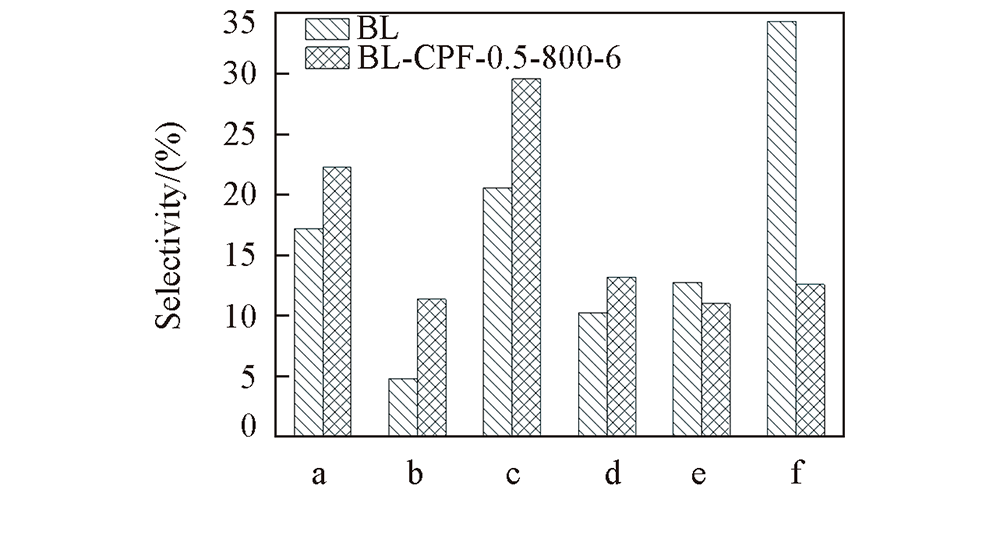

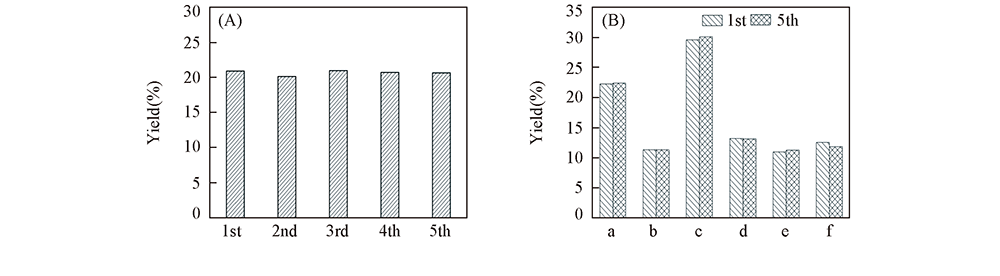

采用溶胶-凝胶法合成了一系列镨掺杂的铁酸钙氧化物(Ca1-xPrxFeO3, 简称CPF-x), 优化了其焙烧机制, 研究了其对甘蔗渣木质素(BL)的催化热解作用, 考察了其再生性能. 研究结果表明, CPF-x适宜的合成及焙烧参数分别为: x=0.5, 焙烧温度为800 ℃, 焙烧时间为6 h, 在该条件下得到的CPF-0.5-800-6呈立方晶相, 为疏松多孔结构; 掺杂Pr后, 其比表面积提高了近3倍. CPF-0.5-800-6对BL催化热解最佳工艺参数为: m(CPF-0.5-800-6)∶m(BL)=1∶3, 热解温度为650 ℃, 液相收率最大可达20.73%, 其中主要产物为紫丁香酚类、 苯酚类及愈创木酚类, 其总选择性为63.21%. 以CPF-0.5-800-6为催化剂, 紫丁香酚类化合物选择性由20.60%增大到29.59%, 实现了提高BL催化热解中某种单酚化合物的选择性. CPF-0.5-800-6经5次催化热解-再生循环反应后, 仍具有良好的反应活性和结构稳定性.

中图分类号:

TrendMD:

韩洪晶,葛芹,陈彦广,王海英,赵宏志,王怡真,张亚男,邓冀童,宋华,张梅. Ca1-xPrxFeO3催化热解甘蔗渣木质素制备酚类化合物. 高等学校化学学报, 2020, 41(2): 331.

HAN Hongjing,GE Qin,CHEN Yanguang,WANG Haiying,ZHAO Hongzhi,WANG Yizhen,ZHANG Yanan,DENG Jitong,SONG Hua,ZHANG Mei. Production of Phenolic Compounds from Bagasse Lignin via Catalytic Pyrolysis of Ca1-xPrxFe

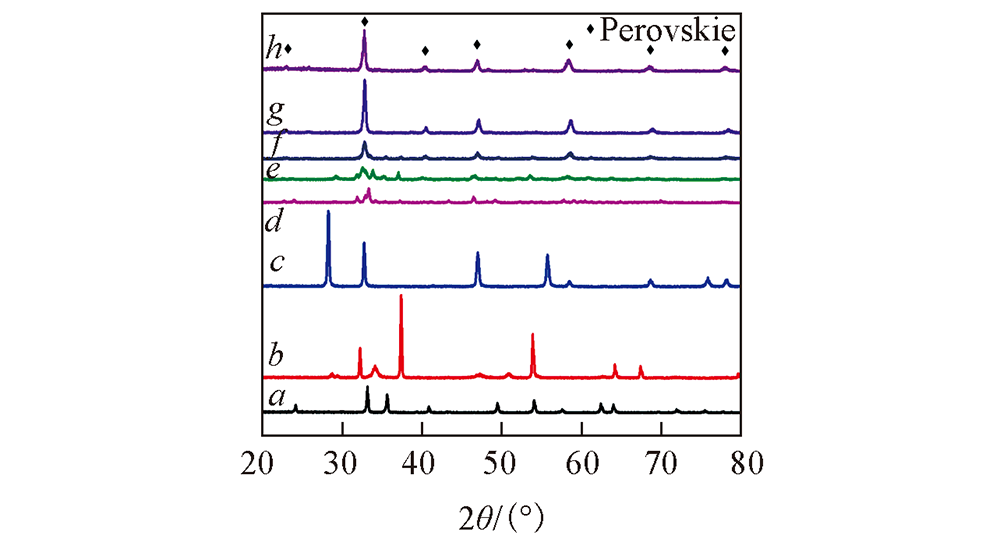

Fig.1 XRD patterns of metal oxides and Ca1-xPrxFeO3 with different Pr loading a. Fe2O3; b. CaO; c. Pr6O11; d. CPF-0; e. CPF-0.1; f. CPF-0.3; g. CPF-0.5; h. CPF-0.7.

| Sample | SBET/(m2·g-1) | Vp/(cm3·g-1) | Dp/nm |

|---|---|---|---|

| CF | 17.37 | 0.1155 | 26.60 |

| CPF-0.5 | 66.65 | 0.3800 | 22.80 |

Table 1 Parameters of CF and CPF-0.5-800-6 determined by BET

| Sample | SBET/(m2·g-1) | Vp/(cm3·g-1) | Dp/nm |

|---|---|---|---|

| CF | 17.37 | 0.1155 | 26.60 |

| CPF-0.5 | 66.65 | 0.3800 | 22.80 |

| No. | t/min | Compound | Type | Content of liquid product(%) | |

|---|---|---|---|---|---|

| BL | BL+CPF-0.5-800-6 | ||||

| 1 | 7.467 |  | Phenolic | 2.73 | 3.82 |

| 2 | 8.687 |  | Phenolic | —— | 1.32 |

| 3 | 9.017 |  | Phenolic | —— | 1.86 |

| 4 | 9.229 |  | Phenolic | 9.41 | 10.18 |

| 5 | 10.098 |  | Ether | —— | 2.30 |

| 6 | 10.434 |  | Phenolic | —— | 1.27 |

| 7 | 10.62 |  | Guaiacol | —— | 1.04 |

| 8 | 10.831 |  | Guaiacol | 2.37 | 3.61 |

| 9 | 11.195 |  | Ether | 7.37 | 4.89 |

| 10 | 11.476 |  | Ether | —— | 1.43 |

| 11 | 12.084 |  | Ether | 3.02 | 2.39 |

| 12 | 12.574 |  | Ketone | 3.22 | 11.47 |

| No. | t/min | Compound | Type | Content of liquid product(%) | |

| BL | BL+CPF-0.5-800-6 | ||||

| 13 | 13.069 |  | Syringol | 14.79 | 22.63 |

| 14 | 13.733 |  | Guaiacol | 2.45 | 2.18 |

| 15 | 13.742 |  | Ether | 2.39 | —— |

| 16 | 14.317 |  | Phenolic | 5.06 | 3.82 |

| 17 | 14.374 |  | Guaiacol | —— | 2.06 |

| 18 | 15.393 |  | Ketone | 4.66 | —— |

| 19 | 15.78 |  | Ketone | 2.34 | 1.74 |

| 20 | 16.228 |  | Syringol | —— | 1.29 |

| 21 | 16.307 |  | Ester | —— | 1.03 |

| 22 | 16.901 |  | Guaiacol | —— | 2.46 |

| 23 | 17.344 |  | Syringol | —— | 1.73 |

| 24 | 17.717 |  | Syringol | 3.57 | 1.38 |

| 25 | 18.118 |  | Syringol | 2.24 | 2.56 |

| 26 | 20.046 |  | Ester | —— | 1.37 |

Table 2 Contents of aromatic compounds in liquid products by GC/MS analyses

| No. | t/min | Compound | Type | Content of liquid product(%) | |

|---|---|---|---|---|---|

| BL | BL+CPF-0.5-800-6 | ||||

| 1 | 7.467 |  | Phenolic | 2.73 | 3.82 |

| 2 | 8.687 |  | Phenolic | —— | 1.32 |

| 3 | 9.017 |  | Phenolic | —— | 1.86 |

| 4 | 9.229 |  | Phenolic | 9.41 | 10.18 |

| 5 | 10.098 |  | Ether | —— | 2.30 |

| 6 | 10.434 |  | Phenolic | —— | 1.27 |

| 7 | 10.62 |  | Guaiacol | —— | 1.04 |

| 8 | 10.831 |  | Guaiacol | 2.37 | 3.61 |

| 9 | 11.195 |  | Ether | 7.37 | 4.89 |

| 10 | 11.476 |  | Ether | —— | 1.43 |

| 11 | 12.084 |  | Ether | 3.02 | 2.39 |

| 12 | 12.574 |  | Ketone | 3.22 | 11.47 |

| No. | t/min | Compound | Type | Content of liquid product(%) | |

| BL | BL+CPF-0.5-800-6 | ||||

| 13 | 13.069 |  | Syringol | 14.79 | 22.63 |

| 14 | 13.733 |  | Guaiacol | 2.45 | 2.18 |

| 15 | 13.742 |  | Ether | 2.39 | —— |

| 16 | 14.317 |  | Phenolic | 5.06 | 3.82 |

| 17 | 14.374 |  | Guaiacol | —— | 2.06 |

| 18 | 15.393 |  | Ketone | 4.66 | —— |

| 19 | 15.78 |  | Ketone | 2.34 | 1.74 |

| 20 | 16.228 |  | Syringol | —— | 1.29 |

| 21 | 16.307 |  | Ester | —— | 1.03 |

| 22 | 16.901 |  | Guaiacol | —— | 2.46 |

| 23 | 17.344 |  | Syringol | —— | 1.73 |

| 24 | 17.717 |  | Syringol | 3.57 | 1.38 |

| 25 | 18.118 |  | Syringol | 2.24 | 2.56 |

| 26 | 20.046 |  | Ester | —— | 1.37 |

| Compound | BL | BL+CPF-015-800-6 |

|---|---|---|

| Phenolics | 17.20 | 22.27 |

| Guaiacols | 4.82 | 11.35 |

| Syringols | 20.60 | 29.59 |

| Ketones | 10.22 | 13.21 |

| Ethers | 12.78 | 11.01 |

| Others | 34.38 | 12.57 |

Table 3 Content of every type compounds(%)

| Compound | BL | BL+CPF-015-800-6 |

|---|---|---|

| Phenolics | 17.20 | 22.27 |

| Guaiacols | 4.82 | 11.35 |

| Syringols | 20.60 | 29.59 |

| Ketones | 10.22 | 13.21 |

| Ethers | 12.78 | 11.01 |

| Others | 34.38 | 12.57 |

Fig.11 Selectivities of various components in liquid products under different pyrolysis conditions a. Phenolics; b. guaiacols; c. syringols; d. ketones; e. ethers; f. others.

Fig.12 Liquid yields of catalytic pyrolysis of BL by CPF-0.5-800-6 after 5 redox recycles(A) and selectivities of various components in liquid products at 1st and 5th pyrolysis reaction(B) a. Phenolics; b. guaiacols; c. syringols; d. ketones; e. ethers; f. others.

| [1] | Chen L., Chen H. P., Lu Q., Song Y., Ding X. J., Wang X. H., Yang H. P., J. Chem. Ind. Eng.(China), 2014,65(9), 3626— 3633 |

| ( 陈磊, 陈汉平, 陆强, 宋扬, 丁学杰, 王贤华, 杨海平 . 化工学报, 2014,65(9), 3626— 3633) | |

| [2] |

Tobimatsu Y., Schuetz M., Curr. Opin. Biotech, 2019,56, 75— 81

doi: 10.1016/j.copbio.2018.10.001 URL |

| [3] |

Gindl-Altmutter W., Köhnkea J., Unterwegerb C., Gierlingerc N., Keckesd J., Zalesakd J., Rojase O. J., Compos. Part. A: Appl. S, 2019,121, 175— 179

doi: 10.1016/j.compositesa.2019.03.026 URL |

| [4] | Fu F. B., Wang H., Zhong R. S., Qiu X. Q., Yang D. J., Chem. J. Chinese Universities, 2018,39(10), 2335— 2342 |

| ( 符方宝, 王欢, 钟锐生, 邱学青, 杨东杰 . 高等学校化学学报, 2018,39(10), 2335— 2342) | |

| [5] |

Xiong W. L., Yang D. J., Zhong R. S., Li Y., Zhou H. F., Qiu X. Q., Ind. Crop. Prod., 2015,74, 285— 292

doi: 10.1016/j.indcrop.2015.05.021 URL |

| [6] |

Dhyani V., Bhaskar T., Renew. Energ., 2018,129, 695— 716

doi: 10.1016/j.renene.2017.04.035 URL |

| [7] |

Xi Y. B., Yang D. J., Liu W. F., Qiu Y. L., Qiu X. Q., Electrochim. Acta, 2019,303, 1— 8

doi: 10.1016/j.electacta.2019.01.094 URL |

| [8] |

Tribot A., Amer G., Alio M. A., Baynast H., Delattre C., Pons A., Mathias J. D., Callois J. M., Vial C., Michaud P., Dussap C. G., Eur. Polym. J., 2019,112, 228— 240

doi: 10.1016/j.eurpolymj.2019.01.007 URL |

| [9] |

Britt P. F., Buchanan A. C., Cooney M. J., Martineau D. R., J. Org. Chem, 2000,65(5), 1376— 1389

doi: 10.1021/jo991479k URL |

| [10] |

Han H. J., Li J. X., Wang H. Y., Han J. Y., Chen Y. G., Li J. Y., Zhang Y. N., Wang Y. Z., Wang B. H., Energ. Fuel, 2019,33, 4302— 4309

doi: 10.1021/acs.energyfuels.9b00332 URL |

| [11] | Wang W. L., Geng J., Li L. F., Chang J. M., Chem. J. Chinese Universities, 2016,37(4), 736— 744 |

| ( 王文亮, 耿晶, 李露霏, 常建民 . 高等学校化学学报, 2016,37(4), 736— 744) | |

| [12] | Ouyang X. P., Tan Y. D., Qiu X. Q., Journal of Fuel Chemistry and Technology, 2014,42(6), 677— 682 |

| [13] | Chen Y. G., Wang X. H., Han H. J., Wang H. Y., An H. Y., Song H., Gong X. Z., Zhang J., Chem. J. Chinese Universities, 2017,38(2), 252— 260 |

| ( 陈彦广, 王新惠, 韩洪晶, 王海英, 安宏宇, 宋华, 公旭中, 张健 . 高等学校化学学报, 2017,38(2), 252— 260) | |

| [14] |

Li F. L., Guo L., Xian H., Meng M., Li Z. J., Bao J., Li X. G., Acta Phys-Chim. Sin., 2013,29(3), 605— 611

doi: 10.3866/PKU.WHXB201212241 URL |

|

( 李锋丽, 郭丽, 贤晖, 孟明, 李志军, 鲍骏, 李新刚 . 物理化学学报, 2013,29(3), 605— 611)

doi: 10.3866/PKU.WHXB201212241 URL |

|

| [15] | Yang L. B., Jing L. Q., Li Z. D., Jinag B. J., Fu W., Fu H. G., Chem. J. Chinese Universities, 2007,28(3), 415— 418 |

| ( 杨立滨, 井立强, 李姝丹, 蒋保江, 付薇, 付宏刚 . 高等学校化学学报, 2007,28(3), 415— 418) | |

| [16] |

Li Y. C., Wang X. H., Shao J. A., Li P., Yang H. P., Chen H. P., Energ. Source Part A, 2016,38(11), 1520— 1529

doi: 10.1080/15567036.2014.940093 URL |

| [17] | Fang L., Ding X. L., Song Y., Liu D. M., Li Y. T., Zhang Q. A., Chem. J. Chinese Universities, 2019,40(7), 1456— 1463 |

| ( 方亮, 丁晓丽, 宋云, 柳东明, 李永涛, 张庆安 . 高等学校化学学报, 2019,40(7), 1456— 1463) | |

| [18] | Jinag Y. L., Yuan L., Wang X. Y., Huang K. K., Feng S. H., Chem. J. Chinese Universities, 2018,39(3), 416— 421 |

| ( 蒋一兰, 袁龙, 王西阳, 黄科科, 冯守华 . 高等学校化学学报, 2018,39(3), 416— 421) | |

| [19] | Li D., Li P., Wang X. H., Shao J. A., Yang H. P., Chen H. P., Journal of Fuel Chemistry & Technology, 2016,38(11), 1520— 1529 |

| [20] | Zhang X. H., Perovskite Composite Oxides Catalytic Bagasse High-Pressure Liquefaction Research Study on Catalytic Reaction of Biomass High-Pressure Liquefaction, Nanchang University, Nanchang, 2016 |

| ( 张晓华 . 钙钛矿型复合氧化物催化蔗渣高压液化反应的研究, 南昌: 南昌大学, 2016) | |

| [21] |

Wang H. Y., Han H. Y., Sun E. H., Zhang Y. ., Li J. X., Chen Y. G., Song H., Zhao H. Z., Chinese. J. Chem. Eng., 2019,27(8), 1939— 1944

doi: 10.1016/j.cjche.2019.01.023 URL |

| [22] |

Li C. H., Soh K. C. K., Wu P., J. Alloy. Compd., 2004,372(1), 40— 48

doi: 10.1016/j.jallcom.2003.10.017 URL |

| [23] |

Chen Y. G., Galinsky N., Wang Z. R., Li F. X., Fuel, 2014,134(9), 521— 530

doi: 10.1016/j.fuel.2014.06.017 URL |

| [24] | Chen Y. H., Wei Y. J., Liu X. Q., Meng G. Y., Chinese. J. Inorg. Chem., 2005,21(5), 673— 678, 611 |

| ( 陈永红, 魏亦军, 刘杏芹, 孟广耀 . 无机化学学报, 2005,21(5), 673— 678, 611) | |

| [25] | Guo H. R., Investgation On Preparation Magnetic and Electrical Properties of Perovskite Manganite Pr1-xCaxMnO3, Beijing University of Technology, Beijing, 2011 |

| ( 郭宏瑞 . 钙钛矿锰氧化物Pr1-xCaxMnO3结构及磁电性能研究, 北京: 北京工业大学, 2011) | |

| [26] | Chen Y. H., Tong Y., Wei Y. J., Liu X. Q., Meng G. Y., Rare Metals, 2007,31(1), 57— 62 |

| ( 陈永红, 童悦, 魏亦军, 刘杏芹, 孟广耀 , 稀有金属, 2007,31(1), 57— 62) | |

| [27] | Mei D. F., Zhao H. B., Ma Z. J., Zheng C. G., Journal of Fuel Chemistry and Technology(in Chin.), 2012,40(7), 795— 802 |

| [28] | Guo J. W., Preparation of Lanthanum Manganese Perovskite Catalysts and Their Catalytic Performance for Methane Combustion, Hefei University of Technology, Hefei, 2016 |

| ( 郭谨玮 . 镧锰钙钛矿型催化剂制备及其甲烷燃烧催化性能, 合肥: 合肥工业大学, 2016) | |

| [29] | Guo X. J., Wang S. R., Wang K. G., Luo Z. Y., Chem. Res. Chinese Univerisities, 2011,27(3), 426— 430 |

| [30] |

Nair V., Vinu R ., J. Anal. Appl. Pyrol., 2016,119, 31— 39

doi: 10.1016/j.jaap.2016.03.020 URL |

| [31] |

Boeriu C. G., Bravo1 D., Gosselink R. J. A., Dam J. E. G., Ind. Crop. Prod., 2004,20(2), 205— 218

doi: 10.1016/j.indcrop.2004.04.022 URL |

| [32] |

Ye Y. Y., Zhang Y., Fan J., Chang J., Ind. Eng. Chem. Res., 2012,51(1), 103— 110

doi: 10.1021/ie202118d URL |

| [33] |

Kim K. H., Bai X. L., Brown R. C., J. Anal. Appl. Pyrol., 2014,110, 254— 263

doi: 10.1016/j.jaap.2014.09.008 URL |

| [34] |

Huang J. B., Liu C., Wu D., Tong H., Ren L. R., J. Anal. Appl. Pyrol., 2014,109, 98— 108

doi: 10.1016/j.jaap.2014.07.007 URL |

| [35] |

Sun J., Karim A. M., Zhang H., Kovarik L., Li S. X. h., Hensley A. J., McEwen J. S., Wang Y., J. Catal., 2013,306, 47— 57

doi: 10.1016/j.jcat.2013.05.020 URL |

| [1] | 贾洋刚, 邵霞, 程婕, 王朋朋, 冒爱琴. 赝电容控制型钙钛矿高熵氧化物La(Co0.2Cr0.2Fe0.2Mn0.2Ni0.2)O3负极材料的制备及储锂性能[J]. 高等学校化学学报, 2022, 43(8): 20220157. |

| [2] | 蒋小康, 周琦, 周恒为. Gd2ZnTiO6∶Dy3+, Eu3+单基质白光荧光粉的制备与发光性能[J]. 高等学校化学学报, 2022, 43(6): 20220029. |

| [3] | 袁萌, 赵英杰, 吴雨辰, 江雷. 钙钛矿阵列化组装及其多功能探测器的应用[J]. 高等学校化学学报, 2022, 43(11): 20220448. |

| [4] | 高中楠, 郭丽红, 赵东越, 李新刚. A位缺陷对La-Sr-Co-O钙钛矿结构和催化氧化性能的影响[J]. 高等学校化学学报, 2021, 42(9): 2869. |

| [5] | 李艳艳, 段林瑞, 罗景山. 水分辅助对无机钙钛矿CsPbI3薄膜结晶的影响[J]. 高等学校化学学报, 2021, 42(6): 1785. |

| [6] | 岳胜利, 武光宝, 李星, 李康, 黄高胜, 唐翌, 周惠琼. 准二维钙钛矿太阳能电池的研究进展[J]. 高等学校化学学报, 2021, 42(6): 1648. |

| [7] | 李义山, 郭亮, 彭思凡, 张庆茂, 张瑜皓, 徐诗淇. 钴掺杂锰酸镧光催化剂的第一性原理与可见光响应光催化性能研究[J]. 高等学校化学学报, 2021, 42(6): 1881. |

| [8] | 王坤华, 姚纪松, 杨俊楠, 宋永慧, 刘雨莹, 姚宏斌. 金属卤化物钙钛矿纳米晶高效发光二极管的制备与器件性能优化[J]. 高等学校化学学报, 2021, 42(5): 1464. |

| [9] | 韩延东, 韩明勇, 杨文胜. 溶胶-凝胶法构筑介孔二氧化硅纳微结构[J]. 高等学校化学学报, 2021, 42(4): 965. |

| [10] | 董璐铭, 苏衍跃, 王春征, 乔亚飞, 陈雅君, 马海云. 微纳米钙钛矿型羟基锡酸钙的合成及对环氧树脂的阻燃性能[J]. 高等学校化学学报, 2021, 42(3): 937. |

| [11] | 刘瑶, 邓正涛. 反溶剂法快速合成高效发光二维锡卤钙钛矿材料[J]. 高等学校化学学报, 2021, 42(12): 3774. |

| [12] | 王婷婷, 雷宇涵, 林宇娟, 黄加玲, 刘翠娥, 郑凤英, 李顺兴. 脂质体封端CsPbX3(X=Cl,Br,I)纳米晶体的制备及在发光二极管中的应用[J]. 高等学校化学学报, 2020, 41(8): 1896. |

| [13] | 成荣敏,徐虹,单瑞平,詹从红. La掺杂钛酸钙光催化剂在可见光下分解水制氢的影响因素[J]. 高等学校化学学报, 2020, 41(6): 1345. |

| [14] | 贺进禄, 龙闰, 方维海. 非绝热分子动力学模拟A位阳离子对钙钛矿热载流子弛豫的影响[J]. 高等学校化学学报, 2020, 41(3): 439. |

| [15] | 姜叶芳, 董茹, 蔡雪刁, 冯江山, 刘治科, 刘生忠. 两亲性季铵盐对钙钛矿太阳能电池效率和稳定性的影响[J]. 高等学校化学学报, 2019, 40(8): 1697. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||