高等学校化学学报 ›› 2020, Vol. 41 ›› Issue (4): 789.doi: 10.7503/cjcu20190540

收稿日期:2019-10-21

出版日期:2020-04-10

发布日期:2020-02-07

通讯作者:

邵华锋

E-mail:hfshao_sjtu@163.com

基金资助:

GUO Qinrui,SHAO Huafeng( ),HE Aihua

),HE Aihua

Received:2019-10-21

Online:2020-04-10

Published:2020-02-07

Contact:

Huafeng SHAO

E-mail:hfshao_sjtu@163.com

Supported by:摘要:

研究了反式-1,4-丁二烯-异戊二烯共聚橡胶(TBIR)应用于航空轮胎胎侧胶[天然橡胶(NR)/顺丁橡胶(BR)/TBIR]的耐热氧老化性能. 结果表明, 与NR/BR硫化胶相比, 10~20份质量的TBIR取代BR后, NR/BR/TBIR硫化胶的交联密度明显提高, 压缩温升降低2.2~3.4 ℃, 耐屈挠疲劳性能提高约100%, 填料分散性改善, 填料团聚体体尺寸减小, 拉伸性能基本不变. 随热氧老化时间延长, 硫化胶的交联密度先增加后降低, 并用TBIR的硫化胶交联密度在老化48 h后趋于平缓. 与NR/BR相比, 老化后的NR/BR/TBIR硫化胶生热最低, 耐屈挠疲劳性最高.

中图分类号:

TrendMD:

国钦瑞, 邵华锋, 贺爱华. TBIR应用于航空胎侧胶的热氧老化性能. 高等学校化学学报, 2020, 41(4): 789.

GUO Qinrui, SHAO Huafeng, HE Aihua. Thermal-oxidative Aging Performance of TBIR Modified NR/BR Vulcanizates in Aircraft Tire Sidewall †. Chem. J. Chinese Universities, 2020, 41(4): 789.

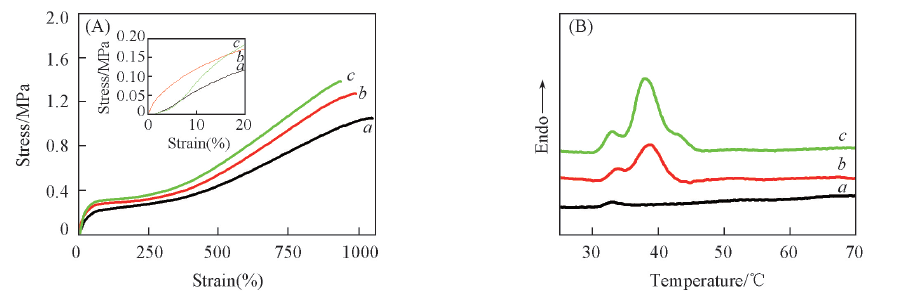

Fig.1 Stress-strain curves(A) and DSC curves(B) of NR/BR/TBIR compoundsm(NR)/m(BR)/m(TBIR): a. 80∶20∶0; b. 80∶10∶10; c. 80∶0∶20. Inset of(A): partially enlarged stress-strain curves.

| m(NR)/m(BR)/m(TBIR) | ML/(dN·m-1) | MH/(dN·m-1) | MH-ML/(dN·m-1) | t10/min | t90/min | vr/min-1 |

|---|---|---|---|---|---|---|

| 80∶20∶0 | 2.35 | 22.65 | 20.30 | 15.45 | 47.40 | 3.12 |

| 80∶10∶10 | 2.39 | 23.55 | 21.16 | 15.19 | 60.99 | 2.18 |

| 80∶0∶20 | 2.73 | 25.83 | 23.10 | 14.58 | 70.72 | 1.78 |

Table 1 Cure characteristic data of NR/BR/TBIR compounds

| m(NR)/m(BR)/m(TBIR) | ML/(dN·m-1) | MH/(dN·m-1) | MH-ML/(dN·m-1) | t10/min | t90/min | vr/min-1 |

|---|---|---|---|---|---|---|

| 80∶20∶0 | 2.35 | 22.65 | 20.30 | 15.45 | 47.40 | 3.12 |

| 80∶10∶10 | 2.39 | 23.55 | 21.16 | 15.19 | 60.99 | 2.18 |

| 80∶0∶20 | 2.73 | 25.83 | 23.10 | 14.58 | 70.72 | 1.78 |

| Sample | NR/BR/TBIR(80∶20∶0) | NR/BR/TBIR(80∶10∶10) | NR/BR/TBIR(80∶0∶20) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Aging time/h | 0 | 24 | 48 | 72 | 0 | 24 | 48 | 72 | 0 | 24 | 48 | 72 |

| Tensile strength/MPa | 21.6 | 23.3 | 19.2 | 19.9 | 22.6 | 21.9 | 21.2 | 19.6 | 21.9 | 22.7 | 20.3 | 18.8 |

| Modulus at 100%/MPa | 2.63 | 3.83 | 4.72 | 5.14 | 2.36 | 3.37 | 4.72 | 4.69 | 3.37 | 4.51 | 5.49 | 5.89 |

| Modulus at 300%/MPa | 12.2 | 15.6 | 17.0 | 18.5 | 11.0 | 13.4 | 17.5 | | 14.3 | 16.8 | 18.8 | 17.2 |

| Elongation at break(%) | 491 | 518 | 350 | 324 | 553 | 487 | 372 | 294 | 468 | 427 | 330 | 334 |

| Rebound(%) | 47.7 | 50.3 | 48.6 | 48.3 | 46.2 | 48.8 | 48.7 | 47.2 | 46.1 | 48.3 | 48.2 | 47.3 |

| Shore A hardness/(°) | 71 | 75 | 77 | 77 | 73 | 75 | 77 | 78 | 73 | 76 | 77 | 80 |

Table 2 Mechanical properties of the NR/BR/TBIR vulcanizates with different aging time

| Sample | NR/BR/TBIR(80∶20∶0) | NR/BR/TBIR(80∶10∶10) | NR/BR/TBIR(80∶0∶20) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Aging time/h | 0 | 24 | 48 | 72 | 0 | 24 | 48 | 72 | 0 | 24 | 48 | 72 |

| Tensile strength/MPa | 21.6 | 23.3 | 19.2 | 19.9 | 22.6 | 21.9 | 21.2 | 19.6 | 21.9 | 22.7 | 20.3 | 18.8 |

| Modulus at 100%/MPa | 2.63 | 3.83 | 4.72 | 5.14 | 2.36 | 3.37 | 4.72 | 4.69 | 3.37 | 4.51 | 5.49 | 5.89 |

| Modulus at 300%/MPa | 12.2 | 15.6 | 17.0 | 18.5 | 11.0 | 13.4 | 17.5 | | 14.3 | 16.8 | 18.8 | 17.2 |

| Elongation at break(%) | 491 | 518 | 350 | 324 | 553 | 487 | 372 | 294 | 468 | 427 | 330 | 334 |

| Rebound(%) | 47.7 | 50.3 | 48.6 | 48.3 | 46.2 | 48.8 | 48.7 | 47.2 | 46.1 | 48.3 | 48.2 | 47.3 |

| Shore A hardness/(°) | 71 | 75 | 77 | 77 | 73 | 75 | 77 | 78 | 73 | 76 | 77 | 80 |

| [1] | Yang X. S ., Rubber Composition for Aircraft Tire Treads, US 20120252929, 2012 -10-04 |

| [2] | Yang H., You C J. ., Tire, Chemical Industry Press, Beijing, 2013 |

| ( 杨慧, 游长江 . 轮胎, 北京: 化学工业出版社, 2013) | |

| [3] | Roland C. M., Rubber Chem. Tech., 2003, 77, 542— 551 |

| [4] | Wu C. Q., Yu H. Y., Liu R ., A kind of Tread Compound for Low Heat Aircraft Tire, CN 201210220677.7, 2012 -06-29 |

| ( 吴春齐, 俞华英, 刘蓉 . 一种低生热航空轮胎胎面胶, CN 201210220677.7, 2012 -06-29) | |

| [5] | Yu H. Y., Wu C. Q., Liu R., Chin. Tire Ind., 2013, 33 10), 604— 608 |

| ( 俞华英,吴春齐,刘蓉.轮胎工业, 2013, 33(10), 604— 608) | |

| [6] | Fang Q. H., Wang J., Kang H. L., Yang F ., An Aerial Side Rubber of Eucommia Ulmoides Oliv. and Its Preparation Method, CN 201610851575.3, 2016-09-27 |

| ( 方庆红, 王琎, 康海澜, 杨凤 . 一种杜仲胶航空胎侧胶及其制备方法,CN 201610851575.3, 2016 -09-27) | |

| [7] | Yu H. Y., Liu R., Wu C. Q., Advanced Rubber Technology, 2015, 4, 31— 34 |

| ( 俞华英, 刘蓉, 吴春齐 . 现代橡胶技术, 2015, 4, 31— 34) | |

| [8] | Yager T. J., Rubber World, 1974, 33, 51— 54 |

| [9] | Zhang Y. F., Shao H. F., Wang R. G., He A. H., Chem. J. Chinese Universities, 2019, 40 8), 1733— 1739 |

| ( 张跃发,邵华锋,王日国,贺爱华.高等学校化学学报, 2019, 40(8), 1733— 1739) | |

| [10] | Liu R., Yu H. Y., Wu C. Q ., A Kind of Aircraft Sidewall Rubber with Good Solar Radiation Resistance, CN 201510222445.9, 2015-08-19 |

| ( 刘蓉, 俞华英, 吴春齐 . 一种耐太阳辐射性能好的航空轮胎胎侧胶,CN 201510222445.9, 2015-08-19) | |

| [11] | Kim H. J., Hamed G. R., Rubber Chem. Technol., 2000, 73( 4), 743— 752 |

| [12] | Hamed G. R., Kim H. J, Gent A. N., Rubber Chem. Technol., 1996, 69( 5), 807— 818 |

| [13] | He A. H., Huang B. C., Jiao S. K., Hu Y. L., J Appl. Polym. Sci., 2003, 89( 7), 1800— 1807 |

| [14] | He A. H., Yao W., Huang B. C., Jiao S. K., J Appl. Polym. Sci., 2004, 92( 5), 2941— 2948 |

| [15] | Niu Q T ., Jiang X. B., He A. H., Polymer, 2014, 55, 2146— 2152 |

| [16] | Zhang Q. F., Jiang X. B., He A. H., Chinese J. Polym. Sci., 2014, 32( 8), 1068— 1076 |

| [17] | Jiang X. B., Zhang Q. F., He A. H., Chinese J. Polym. Sci., 2015, 33( 6), 815— 822 |

| [18] | Niu Q. T., Zou C., Liu X. Y., Wang R. G., He A. H ., Polymer, 2017, 109, 197— 204 |

| [19] | Liu X. Y., Li W. T., Niu Q. T., Wang R. G., He A. H ., Polymer, 2018, 140, 255— 268 |

| [20] | Niu Q. T., Li W. T., Liu X. Y., Wang R. G., He A. H ., Polymer, 2018, 143, 173— 183 |

| [21] | Niu Q. T., Zhang J. Y., Peng W., Fan Z. Q., He A. H., Mol. Catal., 2019, 471, 1— 8 |

| [22] | Li W. T., Peng W., Ren S. T., He A. H., Ind. Eng. Chem. Res., 2019, 58( 24), 10609— 10617 |

| [23] | Li W. T., Nie H. R., Shao H. F., Ren H. C., He A. H ., Polymer, 2018, 156, 148— 161 |

| [24] | Wang H., Song L Y., Ma Y. S., Wang R. G., He A. H., Acta Polym. Sin., 2018, ( 3), 419— 428 |

| ( 王浩, 宋丽媛, 马韵升, 王日国, 贺爱华 . 高分子学报, 2018, ( 3), 419— 428) | |

| [25] | Wang H., Song L. Y., Wang R. G., He A. H., Chin. Rubb. Ind., 2018, 65 3), 313— 317 |

| ( 王浩,宋丽媛,王日国,贺爱华.橡胶工业, 2018, 65(3), 313— 317) | |

| [26] | Wang H., Cui H .H., Ma Y. S., hang J. P., Song L. Y .,He A. H., Chin. Polym. Bull., 2016, ( 10) , 61— 67 |

| ( 王浩, 崔虹虹, 马韵升, 张剑平, 宋丽媛, 贺爱华 . 高分子通报, 2016, ( 10), 61— 67) | |

| [27] | Zhang J. P., Song L. Y., Wang H., Wang R. G., He A. H., Chem. J. Chinese Universities, 2018, 39 6), 1334— 1341 |

| ( 张剑平,宋丽媛,王浩,王日国,贺爱华.高等学校化学学报, 2018, 39(6), 1334— 1341) | |

| [28] | Wang H., Zou C., He A H., . Acta Polym. Sin., 2015, ( 12), 1387— 1395 |

| ( 王浩, 邹陈, 贺爱华 . 高分子学报, 2015, ( 12), 1387— 1395) | |

| [29] | Zhang X. P., Cui H. H., Song L. Y., Ren H. C., Wang R. G., He A. H., Compos. Sci. Technol., 2018, 158, 156— 163 |

| [30] | Song L.Y., Zhang J. P.,Wang R. G.,He A. H., Chin. Polym. Bull., 2018, ( 4), 44— 52 |

| ( 宋丽媛, 张剑平, 王日国, 贺爱华 . 高分子通报, 2018, ( 4), 44— 52) | |

| [31] | Wang H., Zhang X. P., Nie H. R., Wang R. G., He A. H., Compos. Part A-Appl. S., 2019, 116, 197— 205 |

| [32] | Zhang X. P., Wang H., Ren H. C., Wang R. G., He A. H., Ind. Eng. Chem. Res., 2019, 58( 2), 917— 925 |

| [33] | Zhang Y. F., Shao H. F., Wang R. G., He A. H., Chin. Rubb. Ind., 2019, 66 4), 270— 274 |

| ( 张跃发,邵华锋,王日国,贺爱华.橡胶工业, 2019, 66(4), 270— 274) | |

| [34] | Wang H., Wang R. G., Ma Y. S., Luan B., He A. H., Chinese J. Polym. Sci., 2019, 37( 10), 966— 973 |

| [35] | Sandstrom P. H., Yang X. P., Hua K. C., Golden J. J., Beha D. R ., Rubbery Blend Containingtrans Isoprene-Butadiene Copolymer, EP 2860047B1, 2015 -04-15 |

| [36] | Sandstrow P. H., Balogh G. F., Cronin S. W., Aircraft Tire ZL 200510106322.5 , 2005-09-23 |

| [37] | GB/T 16584-1996,Rubber-Measurement of Vulcanization Characteristics with Rotorless Curemeters, Standards Press of China, Beijing, 1996 |

| ( 中国国家标准化管理委员会,GB/T 16584-1996,橡胶用无转子硫化仪测定硫化特性, 北京: 中国标准出版社, 1996) | |

| [38] | ISO 9026-2007, Raw Rubber or Unvulcanized Compounds determination of Green Strength, International Standards Organization, Technical Committee ISO/TC45/SC2, Geneva, 2007 |

| [39] | GB/T 528-2009 , Rubber, Vulcanized or Thermoplastic Determination of Tensile Stress-strain Properties, Standards Press of China,Beijing, 2009 |

| ( 中国国家标准化管理委员会. GB/T 528-2009,硫化橡胶或热塑性橡胶拉伸应力应变性能的测定,北京: 中国标准出版社, 2009) | |

| [40] | GB/T 531 B/T 531.1-2008, Rubber, Vulcanized or Thermoplastic-Determination of Indentation Hardness,Part 1: Duromerer Method(Shore Hardness) ,Standards Press of China,Beijing, 2008 |

| ( 中国国家标准化管理委员会. GB/T 531.1-2008, 硫化橡胶或热塑性橡胶压入硬度试验方法第1部分: 邵氏硬度计法(邵尔硬度), 北京: 中国标准出版社, 2008) | |

| [41] | G B/T 1681-2009, Rubber-Determination of Rebound Resilience of Vulcanizates, Standards Press of China, Beijing, 2009 |

| ( 中国国家标准化管理委员会. GB/T 1681-2009, 硫化橡胶回弹性的测定, 北京: 中国标准出版社, 2009) | |

| [42] | G B/T 13934-2006, Rubber, Vulcanized or Thermoplastic Determination of Flex Cracking and Crack Growth(De Mattia), Standards Press of China, Beijing, 2006 |

| ( 中国国家标准化管理委员会. 硫化橡胶或热塑性橡胶屈挠龟裂和裂口增长的测定(德墨西亚型), 北京: 中国标准出版社, 2006) | |

| [43] | Yao W., Huang B . C., Chin. Synth. Rubb. Ind., 1998,( 5), 296— 299 |

| ( 姚薇, 黄宝琛 . 合成橡胶工业, 1998,( 5), 296— 299) | |

| [44] | Sun J. T., Qu L., Wang W., Chin. Elastom., 2011, 21 4), 1— 4 |

| ( 孙举涛,曲丽,王威.弹性体, 2011, 21(4), 1— 4 ) | |

| [45] | Li A., Special Rubber Products, 2009, 30 5), 56— 67 |

| ( 李昂. 特种橡胶制品, 2009, 30 5), 56— 67) | |

| [46] | Na H. D., World Rubber Industry, 1996, 69 2), 22— 26 |

| ( 那洪东. 世界橡胶工业, 1996, 69 2), 22— 26 | |

| [47] | Knappe P. D. W., Yamamoto O., Kolloid-Zeitschrift and Zeitschrift Für Polymer ,1970, 240( 1/2), 775— 783 |

| [48] | ( 张小冬 . 橡胶动态压缩屈挠生热与导热的研究, 广州: 华南理工大学, 2015) |

| Zhang X D .., Study on Heat Generation and Thermal Conduction of the Rubber under Dynamic Compression Flex, South China University of Technology, Guangzhou, 2015 |

| [1] | 武营飞,李洪昱,蔡磊,贺爱华. 高耐磨低生热NBR/TBIR复合材料的结构与性能[J]. 高等学校化学学报, 2020, 41(3): 565. |

| [2] | 张跃发, 邵华锋, 王日国, 贺爱华. 反式丁戊橡胶改性航空轮胎侧胶的结构与性能[J]. 高等学校化学学报, 2019, 40(8): 1733. |

| [3] | 张新萍, 张剑平, 蔡磊, 宗鑫, 贺爱华. 高疲劳寿命氯丁橡胶基减振材料的结构与性能[J]. 高等学校化学学报, 2019, 40(7): 1571. |

| [4] | 蔡磊,赵远进,张新萍,贺爱华,丁涛,李小红,张治军. 表面改性SiO2对SSBR/BR绿色轮胎胎面胶结构与性能的影响[J]. 高等学校化学学报, 2019, 40(11): 2388. |

| [5] | 张剑平, 宋丽媛, 王浩, 王日国, 贺爱华. TBIR改性BIIR/NR共混物的结构与性能[J]. 高等学校化学学报, 2018, 39(6): 1334. |

| [6] | 任惠成, 武营飞, 刘丹丹, 聂华荣, 贺爱华. SSBR/TPI共混体系中TPI的结晶、 成核及动力学研究[J]. 高等学校化学学报, 2018, 39(5): 1091. |

| [7] | 王浩, 张剑平, 马韵升, 王日国, 贺爱华. 反式异戊橡胶合金改性溶聚丁苯橡胶/顺丁橡胶轿车胎面胶[J]. 高等学校化学学报, 2017, 38(11): 2095. |

| [8] | 刘尧华, 林宇, 张栋葛, 陈春蕾, 吴国章, 张衍, 栾伟玲. 天然橡胶/石墨烯纳米复合材料的制备及耐核辐射性能[J]. 高等学校化学学报, 2016, 37(7): 1402. |

| [9] | 薛兵 蒋引珊 杨殿范 史晓迪. 碳化处理高烧失量硅藻土及对天然橡胶的性能补强[J]. 高等学校化学学报, 2011, 32(7): 1617. |

| [10] | 王君, 刘振荣, 张向东, 贾卫国. K3[GdⅢ(nta)2(H2O)]·6H2O和(NH4)·[GdⅢ(Cydta)(H2O)2]·5H2O的合成及晶体结构[J]. 高等学校化学学报, 2002, 23(11): 2052. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||