高等学校化学学报 ›› 2020, Vol. 41 ›› Issue (3): 565.doi: 10.7503/cjcu20190459

武营飞,李洪昱,蔡磊,贺爱华

收稿日期:2019-08-19

出版日期:2020-02-26

发布日期:2020-02-07

通讯作者:

贺爱华

作者简介:贺爱华, 女, 博士, 教授, 博士生导师, 主要从事定向聚合制备橡塑新材料的基础与应用研究. E-mail: aihuahe@iccas.ac.cn

基金资助:WU Yingfei,LI Hongyu,CAI Lei,HE Aihua

Received:2019-08-19

Online:2020-02-26

Published:2020-02-07

Contact:

Aihua HE

Supported by:摘要:

采用高反式-1,4-丁二烯-异戊二烯共聚橡胶(TBIR)对丁腈橡胶(NBR)进行改性, 制备了高耐磨、 低生热输送轮用白炭黑填充的NBR/TBIR橡胶纳米复合材料. 研究了NBR/TBIR橡胶纳米复合材料的交联密度、 物理力学性能及填料分散性, 探讨了材料的结构对性能的影响. 研究结果表明, 与纯NBR相比, NBR/TBIR橡胶纳米复合材料的硫化速率和交联密度随TBIR用量的增加而增大; 在保持NBR硫化胶基本力学性能、 耐老化性能和耐溶剂性能基本不变的前提下, TBIR的加入使NBR/TBIR硫化胶的耐磨性提高15%, 动态压缩生热降低5%, 动态压缩永久变形降低22%, 白炭黑分散水平提高; 与丁腈橡胶/顺丁橡胶[NBR/BR(80/20), 质量份数比]硫化胶相比, NBR/TBIR(80/20, 质量份数比)硫化胶具有更低的动态压缩生热和动态压缩永久变形及更好的填料分散性.

中图分类号:

TrendMD:

武营飞,李洪昱,蔡磊,贺爱华. 高耐磨低生热NBR/TBIR复合材料的结构与性能. 高等学校化学学报, 2020, 41(3): 565.

WU Yingfei,LI Hongyu,CAI Lei,HE Aihua. Structure and Properties of NBR/TBIR Composites with High Abrasion Resistance and Low Heat Built-up †. Chem. J. Chinese Universities, 2020, 41(3): 565.

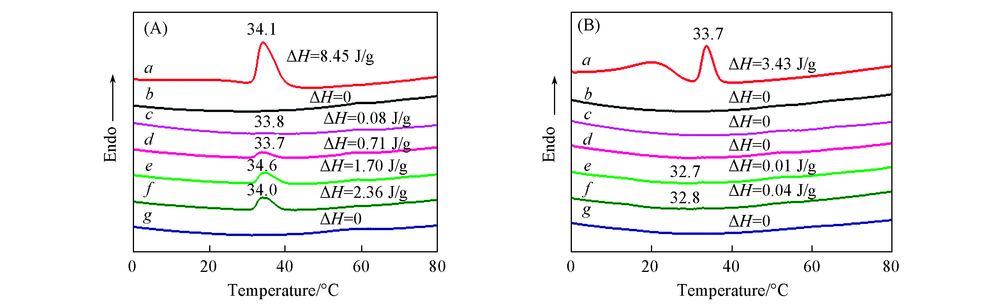

Fig.1 DSC curves of TBIR, NBR, NBR/TBIR and NBR/BR compounds(A) and vulcanizates(B) m(NBR)/m(TBIR)/m(BR): a. 0/100/0; b. 100/0/0; c. 95/5/0; d. 90/10/0; e. 85/15/0; f. 80/20/0; g. 80/0/20.

| m(NBR)/m(TBIR)/m(BR) | 100/0/0 | 95/5/0 | 90/10/0 | 85/15/0 | 80/20/0 | 80/0/20 |

|---|---|---|---|---|---|---|

| ML/(dN·m) | 1.50 | 1.72 | 1.97 | 2.29 | 2.47 | 2.54 |

| MH/(dN·m) | 15.81 | 16.17 | 17.70 | 18.52 | 19.96 | 20.88 |

| (MH-ML)/(dN·m) | 14.31 | 14.45 | 15.73 | 16.23 | 17.49 | 18.34 |

| t10/min | 2.40 | 2.09 | 1.72 | 1.39 | 1.21 | 1.18 |

| t90/min | 42.58 | 42.26 | 41.35 | 41.41 | 38.83 | 38.57 |

| 104 Crosslink density/(mol·cm-3) | 1.601 | 1.714 | 1.802 | 1.837 | 1.878 | 1.692 |

| Tensile strength/MPa | 27.94 | 23.23 | 24.58 | 22.34 | 20.74 | 20.76 |

| Modulus at 100%/MPa | 1.96 | 1.96 | 1.98 | 2.07 | 2.03 | 2.43 |

| Modulus at 300%/MPa | 6.86 | 6.08 | 6.86 | 6.71 | 6.24 | 8.71 |

| Elongation at break(%) | 735 | 747 | 769 | 651 | 651 | 576 |

| Tear strength/(kN·m-1) | 45.09 | 44.52 | 41.41 | 40.02 | 38.41 | 38.10 |

| Shore A hardness/(°) | 64.5 | 62.7 | 63.8 | 64.6 | 66.0 | 67.2 |

| Rebound(%) | 22.8 | 23.7 | 24.3 | 25.3 | 26.4 | 28.1 |

Table 1 Physical and mechanical properties of NBR/TBIR and NBR/BR vulcanizates

| m(NBR)/m(TBIR)/m(BR) | 100/0/0 | 95/5/0 | 90/10/0 | 85/15/0 | 80/20/0 | 80/0/20 |

|---|---|---|---|---|---|---|

| ML/(dN·m) | 1.50 | 1.72 | 1.97 | 2.29 | 2.47 | 2.54 |

| MH/(dN·m) | 15.81 | 16.17 | 17.70 | 18.52 | 19.96 | 20.88 |

| (MH-ML)/(dN·m) | 14.31 | 14.45 | 15.73 | 16.23 | 17.49 | 18.34 |

| t10/min | 2.40 | 2.09 | 1.72 | 1.39 | 1.21 | 1.18 |

| t90/min | 42.58 | 42.26 | 41.35 | 41.41 | 38.83 | 38.57 |

| 104 Crosslink density/(mol·cm-3) | 1.601 | 1.714 | 1.802 | 1.837 | 1.878 | 1.692 |

| Tensile strength/MPa | 27.94 | 23.23 | 24.58 | 22.34 | 20.74 | 20.76 |

| Modulus at 100%/MPa | 1.96 | 1.96 | 1.98 | 2.07 | 2.03 | 2.43 |

| Modulus at 300%/MPa | 6.86 | 6.08 | 6.86 | 6.71 | 6.24 | 8.71 |

| Elongation at break(%) | 735 | 747 | 769 | 651 | 651 | 576 |

| Tear strength/(kN·m-1) | 45.09 | 44.52 | 41.41 | 40.02 | 38.41 | 38.10 |

| Shore A hardness/(°) | 64.5 | 62.7 | 63.8 | 64.6 | 66.0 | 67.2 |

| Rebound(%) | 22.8 | 23.7 | 24.3 | 25.3 | 26.4 | 28.1 |

| m(NBR)/m(TBIR)/m(BR) | 100/0/0 | 95/5/0 | 90/10/0 | 85/15/0 | 80/20/0 | 80/0/20 |

|---|---|---|---|---|---|---|

| Tensile strength/MPa | 32.30 | 28.51 | 28.23 | 25.32 | 23.13 | 23.31 |

| Modulus at 100%/MPa | 3.24 | 3.25 | 2.88 | 3.17 | 3.06 | 3.98 |

| Modulus at 300%/MPa | 12.59 | 12.14 | 10.97 | 11.35 | 10.37 | 13.80 |

| Elongation at break(%) | 593 | 566 | 569 | 521 | 528 | 459 |

| Ageing coefficient(%) | 93 | 93 | 92 | 91 | 90 | 89 |

Table 2 Physical and mechanical properties of NBR/TBIR and NBR/BR vulcanizates after aging*

| m(NBR)/m(TBIR)/m(BR) | 100/0/0 | 95/5/0 | 90/10/0 | 85/15/0 | 80/20/0 | 80/0/20 |

|---|---|---|---|---|---|---|

| Tensile strength/MPa | 32.30 | 28.51 | 28.23 | 25.32 | 23.13 | 23.31 |

| Modulus at 100%/MPa | 3.24 | 3.25 | 2.88 | 3.17 | 3.06 | 3.98 |

| Modulus at 300%/MPa | 12.59 | 12.14 | 10.97 | 11.35 | 10.37 | 13.80 |

| Elongation at break(%) | 593 | 566 | 569 | 521 | 528 | 459 |

| Ageing coefficient(%) | 93 | 93 | 92 | 91 | 90 | 89 |

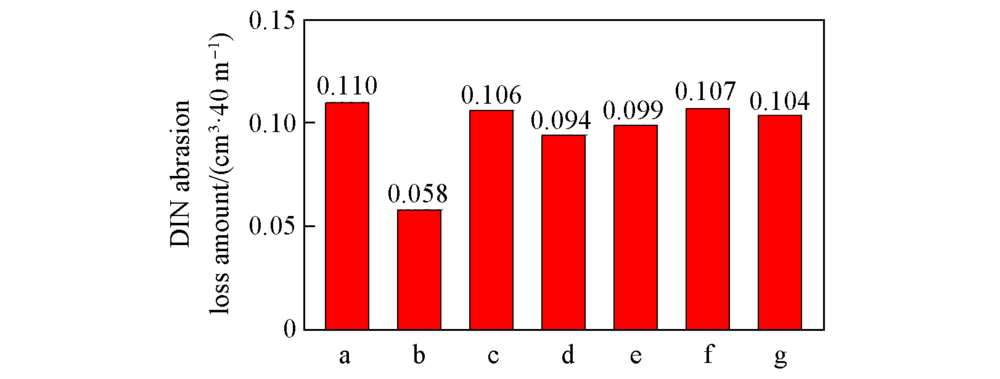

Fig.2 DIN abrasion loss amounts of NBR/TBIR and NBR/BR vulcanizates m(NBR)/m(TBIR)/m(BR): a. 100/0/0; b. 0/100/0; c. 95/5/0; d. 90/10/0; e. 85/15/0; f. 80/20/0; g. 80/0/20.

| m(NBR)/m(TBIR)/m(BR) | 100/0/0 | 95/5/0 | 90/10/0 | 85/15/0 | 80/20/0 | 80/0/20 |

|---|---|---|---|---|---|---|

| Heat built-up/℃ | 62.2 | 59.7 | 59.2 | 58.3 | 58.2 | 59.0 |

| Dynamic compression set(%) | 9.8 | 8.9 | 7.6 | 7.9 | 8.5 | 7.9 |

| Compression set(%) | 10.7 | 10.4 | 10.9 | 12.0 | 12.3 | 10.6 |

Table 3 Heat built-up and compression set of NBR/TBIR and NBR/BR vulcanizates

| m(NBR)/m(TBIR)/m(BR) | 100/0/0 | 95/5/0 | 90/10/0 | 85/15/0 | 80/20/0 | 80/0/20 |

|---|---|---|---|---|---|---|

| Heat built-up/℃ | 62.2 | 59.7 | 59.2 | 58.3 | 58.2 | 59.0 |

| Dynamic compression set(%) | 9.8 | 8.9 | 7.6 | 7.9 | 8.5 | 7.9 |

| Compression set(%) | 10.7 | 10.4 | 10.9 | 12.0 | 12.3 | 10.6 |

| m(NBR)/m(TBIR)/m(BR) | 100/0/0 | 95/5/0 | 90/10/0 | 85/15/0 | 80/20/0 | 80/0/20 |

|---|---|---|---|---|---|---|

| Δm100(%) | 1.7 | 3.1 | 4.6 | 7.5 | 12.1 | 16.4 |

| ΔV100(%) | 2.1 | 3.9 | 7.2 | 9.1 | 14.8 | 20.2 |

Table 4 Oil resistance(70 ℃, 72 h) of NBR/TBIR and NBR/BR vulcanizates

| m(NBR)/m(TBIR)/m(BR) | 100/0/0 | 95/5/0 | 90/10/0 | 85/15/0 | 80/20/0 | 80/0/20 |

|---|---|---|---|---|---|---|

| Δm100(%) | 1.7 | 3.1 | 4.6 | 7.5 | 12.1 | 16.4 |

| ΔV100(%) | 2.1 | 3.9 | 7.2 | 9.1 | 14.8 | 20.2 |

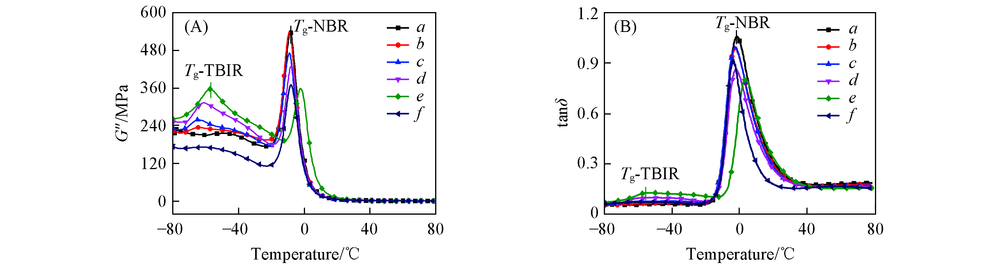

Fig.3 Loss modulus(G", A) and loss factor(tanδ, B) of NBR/TBIR and NBR/BR vulcanizates m(NBR)/m(TBIR)/m(BR): a. 100/0/0; b. 95/5/0; c. 90/10/0; d. 85/15/0; e. 80/20/0; f. 80/0/20.

| m(NBR)/m(TBIR)/m(BR) | 100/0/0 | 95/5/0 | 90/10/0 | 85/15/0 | 80/20/0 | 80/0/20 |

|---|---|---|---|---|---|---|

| Dispersiona(%) | 99.89 | 99.87 | 99.63 | 99.85 | 99.92 | 99.75 |

| Mean aggregate sizea/μm | 10.12 | 9.79 | 9.97 | 8.77 | 7.68 | 8.32 |

| Dispersionb(%) | 99.84 | 99.78 | 99.72 | 99.74 | 99.87 | 99.47 |

| Mean aggregate sizeb/μm | 10.77 | 9.27 | 10.00 | 8.84 | 8.12 | 8.77 |

Table 5 Filler dispersion and mean aggregate size in NBR/TBIR and NBR/BR vulcanizates

| m(NBR)/m(TBIR)/m(BR) | 100/0/0 | 95/5/0 | 90/10/0 | 85/15/0 | 80/20/0 | 80/0/20 |

|---|---|---|---|---|---|---|

| Dispersiona(%) | 99.89 | 99.87 | 99.63 | 99.85 | 99.92 | 99.75 |

| Mean aggregate sizea/μm | 10.12 | 9.79 | 9.97 | 8.77 | 7.68 | 8.32 |

| Dispersionb(%) | 99.84 | 99.78 | 99.72 | 99.74 | 99.87 | 99.47 |

| Mean aggregate sizeb/μm | 10.77 | 9.27 | 10.00 | 8.84 | 8.12 | 8.77 |

| [1] | Wu C. R., Wang Z. B., Chen Y. X ., Nucl. Elec. & Detect. Tech., 2013, 33( 3), 392— 394 |

| ( 吴朝润, 王召巴, 陈友兴 . 核电子学与探测技术, 2013, 33( 3), 392— 394) | |

| [2] | Zhou Y. F., Zhu W. M., Wang L ., Spec. Purp. Rub. Prod., 2014, 35( 3), 42— 46 |

| ( 周一帆, 朱卫明, 王岚 . 特种橡胶制品, 2014, 35( 3), 42— 46) | |

| [3] | Wang H. M., Lv X. R., Wang S. J ., Lubr. Eng., 2015, 40( 9), 30— 34 |

| ( 王慧明, 吕晓仁, 王世杰 . 润滑与密封, 2015, 40( 9), 30— 34) | |

| [4] | Li M., Wan C. R ., Spe. Purp. Rub. Prod., 2009, 30( 1), 46— 48 |

| ( 李蒙, 万昌瑞 . 特种橡胶制品, 2009, 30( 1), 46— 48) | |

| [5] | Zhang J., Li Q. J ., China Syn. Rub. Ind., 1991, ( 4), 287— 290 |

| ( 张军, 李乔钧 . 合成橡胶工业, 1991, ( 4), 287— 290) | |

| [6] | Syed I. H., Stratmann P., Hempel G., Kluppel M., Saalwachter K ., Macromolecules, 2016, 49( 23), 9004— 9016 |

| [7] | Shaltout N. A., Abouzeid M. M., Mohamed M. A., Mohamed A., Miligy E ., J. Macromol. Sci: Part A -Chem., 2008, 45( 3), 225— 231 |

| [8] | He A. H., Yao W., Jia Z. F., Huang B. C., Jiao S. K ., Acta. Polym. Sin., 2002, ( 1), 19— 24 |

| ( 贺爱华, 姚微, 贾志峰, 黄宝琛, 焦书科 . 高分子学报, 2002, ( 1), 19— 24) | |

| [9] | He A. H., Huang B. C., Jiao S. K., Hu Y. L ., J. Appl. Polym. Sci., 2003, 89( 7), 1800— 1807 |

| [10] | Zhang X. P., Cui H. H., Song L. Y ., Compos. Sci. Technol., 2018, 158, 156— 163 |

| [11] | Niu Q. T., Zou C., Liu X. Y., Wang R. G., He A. H ., Polymer, 2017, 109, 197— 204 |

| [12] | Wang H., Cui H. H., Ma Y. S., Zhang J. P., Song L. Y., He A. H ., Chinese Polym. Bull., 2016, ( 10), 61— 67 |

| ( 王浩, 崔虹虹, 马韵升, 张剑平, 宋丽媛, 贺爱华 . 高分子通报, 2016, ( 10), 61— 67) | |

| [13] | Zhang J. P., Song L. Y., Wang H., Wang R. G., He A. H ., Chem. J. Chinese Universities, 2018, 39( 6), 1334— 1341 |

| ( 张剑平, 宋丽媛, 王浩, 王日国, 贺爱华 . 高等学校化学学报, 2018, 39( 6), 1334— 1341) | |

| [14] | Ren H. C., Wu Y. F., Liu D. D., Nie H. R., He A. H ., Chem. J. Chinese Universities, 2018, 39( 5), 1091— 1097 |

| ( 任惠成, 武营飞, 刘丹丹, 聂华荣, 贺爱华 . 高等学校化学学报, 2018, 39( 5), 1091— 1097) | |

| [15] | Wang H., Zhang J. P., Ma Y. S., Wang R. G., He A. H ., Chem. J. Chinese Universities, 2017, 38( 11), 2095— 2101 |

| ( 王浩, 张剑平, 马韵升, 王日国, 贺爱华 . 高等学校化学学报, 2017, 38( 11), 2095— 2101) | |

| [16] | Wang H., Zou C., He A. H ., Acta Polym. Sin., 2015, ( 12), 1387— 1395 |

| ( 王浩, 邹陈, 贺爱华 . 高分子学报, 2015, ( 12), 1387— 1395) | |

| [17] | Zhang X. P., Cai L., Wang C. W., He A. H ., Compos. Sci. Technol., 2019, 184, 1— 9 |

| [18] | GB/T 25268-2010, Rubber-Measurement of Vulcanization Characteristics with Rotorless Curemeters, Standards Press of China, Beijing, 1996 |

| ( 中国国家标准化管理委员会. GB/T 25268-2010, 橡胶用无转子硫化仪测定硫化特性, 北京: 中国标准出版社, 1996) | |

| [19] | ASTM Committee D11, ASTM D7723-11, Standard Test Method for Rubber Property-Macro-dispersion of Fill, American Societ for Testing and Materials, New York, 2011 |

| [20] | GB/T 528-2009, Rubber, Vulcanized or Thermoplastic Deter Mination of Tensile Stress-strain Properties, Standards Press of China, Beijing, 2009 |

| ( 中国国家标准化管理委员会. GB/T 528-2009, 硫化橡胶或热塑性橡胶拉伸应力应变性能的测定, 北京: 中国标准出版社, 2009) | |

| [21] | GB/T 529-2008, Rubber, Vulcanized or Thermoplastic Deter Mination of Tear Strength, Standards Press of China, Beijing, 2008 |

| ( 中国国家标准化管理委员会. GB/T 529-2008, 硫化橡胶或热塑性橡胶撕裂强度的测定, 北京: 中国标准出版社, 2008) | |

| [22] | GB/T 531.1-2008, Rubber, Vulcanized or Thermoplastic-Determination of Indentation Hardness—Part 1: Duromerer Method(Shore hardness), Standards Press of China, Beijing, 2008 |

| ( 中国国家标准化管理委员会. GB/T 531.1-2008, 硫化橡胶或热塑性橡胶压入硬度试验方法第1部分: 邵氏硬度计法(邵尔硬度), 北京: 中国标准出版社, 2008) | |

| [23] | GB/T 1681-2009, Rubber, Determination of Rebound Resilience of Vulcanizates, Standards Press of China, Beijing, 2009 |

| ( 中国国家标准化管理委员会. GB/T 1681-2009 硫化橡胶回弹性的测定, 北京: 中国标准出版社, 2009) | |

| 24 | GB/T 9867-2008, Rubber, Vulcanized or Thermoplastic-determination of Abrasion Resistance Using a Rotating Cylindrical Drum Device, Standards Press of China, Beijing, 2008 |

| ( 中国国家标准化管理委员会. GB/T 9867-2008, 硫化橡胶或热塑性橡胶耐磨性能的测定(旋转辊筒式磨耗机法), 北京: 中国标准出版社, 2008) | |

| [25] | GB/T 3512-2001, Rubber, Vulcanized or Thermoplastic-accelerated Ageing and Heat Resistance Tests-air-oven Method, Standards Press of China, Beijing, 2001 |

| ( 中国国家标准化管理委员会. GB/T 3512-2001, 硫化橡胶或热塑性橡胶热空气加速老化和耐热试验, 北京: 中国标准出版社, 2001) | |

| [26] | GB/T 1690-2010, Rubber, Vulcanized or Thermoplastic-Determination of the Effect of Liquids, Standards Press of China, Beijing, 2010 |

| ( 中国国家标准化管理委员会. GB/T 1690-2010, 硫化橡胶或热塑性橡胶耐液体试验方法. 北京: 中国标准出版社, 2010) | |

| [27] | GB/T 7759.1-2015, Rubber, Vulcanized or Thermoplastic-Determination of Compression Set—Part 1: At Ambient or Elevated Temperatures, Standards Press of China, Beijing, 2015 |

| ( 中国国家标准化管理委员会. GB/T 7759.1-2015, 硫化橡胶或热塑性橡胶压缩永久变形的测定第1部分: 在常温及高温条件下, 北京: 中国标准出版社, 2015) | |

| [28] | Medalia A. I., Heckman F. A ., Carbon, 1969, 7( 5), 567— 582 |

| [29] | Song L. Y., Zhang J. P., Wang R. G., He A. H ., Chinese Polym. Bull., 2018, ( 4), 44— 52 |

| ( 宋丽媛, 张剑平, 王日国, 贺爱华 . 高分子通报, 2018, ( 4), 44— 52) | |

| [30] | Wang H., Zhang J. P., Wang R. G., He A. H ., China Rub. Ind., 2018, 65( 2), 167— 172 |

| ( 王浩, 张剑平, 王日国, 贺爱华 . 橡胶工业, 2018, 65( 2), 167— 172) | |

| [31] | Zhang Y. F., Shao H. F., Wang R. G., He A. H ., Chem. J. Chinese Universities, 2019, 40( 8), 1733— 1739 |

| ( 张跃发, 邵华锋, 王日国, 贺爱华 . 高等学校化学学报, 2019, 40( 8), 1733— 1739) |

| [1] | 宁湫洋, 李万程. 平面型乙醇快速响应气敏传感器的制备[J]. 高等学校化学学报, 2020, 41(8): 1745. |

| [2] | 国钦瑞, 邵华锋, 贺爱华. TBIR应用于航空胎侧胶的热氧老化性能[J]. 高等学校化学学报, 2020, 41(4): 789. |

| [3] | 张继华,王超,皂伟涛,李莉,刘小艳,杨元,王昊. 利用静电界面制备高性能蒙脱石/氢化丁腈橡胶[J]. 高等学校化学学报, 2020, 41(4): 803. |

| [4] | 王乙涵,尹强,杜凯,殷勤俭. 聚吡咯/聚苯胺二元复合纳米管及其热电性能[J]. 高等学校化学学报, 2020, 41(1): 175. |

| [5] | 毛龙, 刘跃军, 范淑红. 聚吡咯改性层状黏土/聚己内酯抗菌纳米复合材料的制备与性能[J]. 高等学校化学学报, 2019, 40(8): 1726. |

| [6] | 张新萍, 张剑平, 蔡磊, 宗鑫, 贺爱华. 高疲劳寿命氯丁橡胶基减振材料的结构与性能[J]. 高等学校化学学报, 2019, 40(7): 1571. |

| [7] | 张克杰, 李宇, 夏源, 韩烁, 曹静, 王瀚漾, 罗文韬, 周志萍. 核壳结构CdS/CuS纳米复合材料的制备及光催化性能[J]. 高等学校化学学报, 2019, 40(3): 489. |

| [8] | 蔡磊,赵远进,张新萍,贺爱华,丁涛,李小红,张治军. 表面改性SiO2对SSBR/BR绿色轮胎胎面胶结构与性能的影响[J]. 高等学校化学学报, 2019, 40(11): 2388. |

| [9] | 韩东来,李博珣,杨硕,闫永胜,杨丽丽,刘洋,李春香. Fe3O4@Au核-壳纳米复合材料的制备及对农药福美双的SERS检测研究[J]. 高等学校化学学报, 2019, 40(10): 2067. |

| [10] | 康媛媛, 郭泽清, 周剑平. MoS2/Na2Fe2Ti6O16的水热制备及吸附性能[J]. 高等学校化学学报, 2018, 39(7): 1364. |

| [11] | 张剑平, 宋丽媛, 王浩, 王日国, 贺爱华. TBIR改性BIIR/NR共混物的结构与性能[J]. 高等学校化学学报, 2018, 39(6): 1334. |

| [12] | 王海丹, 王丽, 徐梅, 黄丽晨, 宋贤良. Bi2WO6/TiO2纳米复合材料对乙烯的光催化降解[J]. 高等学校化学学报, 2018, 39(5): 996. |

| [13] | 任惠成, 武营飞, 刘丹丹, 聂华荣, 贺爱华. SSBR/TPI共混体系中TPI的结晶、 成核及动力学研究[J]. 高等学校化学学报, 2018, 39(5): 1091. |

| [14] | 刘星, 王文俊, 邵自强, 李磊. 纳米纤维素/聚乳酸全绿色纳米复合材料的制备及性能[J]. 高等学校化学学报, 2018, 39(2): 373. |

| [15] | 王雪丽, 王振新. 基于部分还原氧化石墨烯纳米复合材料的肿瘤靶向光动力-光热联合治疗剂的制备[J]. 高等学校化学学报, 2018, 39(10): 2185. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||