高等学校化学学报 ›› 2019, Vol. 40 ›› Issue (11): 2388.doi: 10.7503/cjcu20190378

蔡磊1,赵远进1,张新萍1,贺爱华1,*( ),丁涛2,李小红2,张治军2

),丁涛2,李小红2,张治军2

收稿日期:2019-07-07

出版日期:2019-11-10

发布日期:2019-10-24

通讯作者:

贺爱华

E-mail:aihuahe@iccas.ac.cn

基金资助:

CAI Lei1,ZHAO Yuanjin1,ZHANG Xingping1,HE Aihua1,*( ),DING Tao2,LI Xiaohong2,ZHANG Zhijun2

),DING Tao2,LI Xiaohong2,ZHANG Zhijun2

Received:2019-07-07

Online:2019-11-10

Published:2019-10-24

Contact:

HE Aihua

E-mail:aihuahe@iccas.ac.cn

Supported by:摘要:

采用4种含不同官能基团修饰剂改性的二氧化硅SiO2增强溶聚丁苯橡胶(SSBR)/顺丁橡胶(BR)共混体系, 制备了SSBR/BR/SiO2橡胶纳米复合材料, 研究了其结构与性能. 结果表明, 在混炼胶体系中, 与未改性SiO2填充的SSBR/BR相比, 改性SiO2填充的SSBR/BR门尼黏度及结合橡胶含量显著增大, 表明填料-橡胶相互作用显著提高; 硫化焦烧时间缩短60%, 硫化速度增大了35%~40%. 在硫化胶体系中改性SiO2填充的SSBR/BR具有更大的交联密度, 填料分散性明显改善, 同时也表现出更为优异的物理机械性能, 100%和300%定伸模量提高47%以上, 旋转滚筒式磨耗机法(DIN)磨耗降低5%~12%, 生热降低了约7%~13%, 热空气老化性能提升4%~22%, 代表滚动阻力的tanδ在60 ℃降低8%~13%. 此外, 与SSBR/BR/1165MP硫化胶相比, 用90 mmol/kg氨基改性SiO2填充的SSBR/BR硫化胶的抗湿滑性能提高6.9%, 表现出最优的综合性能. 填料的良好分散及填料与聚合物的相互作用增强对于提高SSBR/BR/SiO2胎面胶综合力学性能具有重要意义.

中图分类号:

TrendMD:

蔡磊,赵远进,张新萍,贺爱华,丁涛,李小红,张治军. 表面改性SiO2对SSBR/BR绿色轮胎胎面胶结构与性能的影响. 高等学校化学学报, 2019, 40(11): 2388.

CAI Lei,ZHAO Yuanjin,ZHANG Xingping,HE Aihua,DING Tao,LI Xiaohong,ZHANG Zhijun. Structure and Properties of SSBR/BR/Surface-modified SiO2 Green Tire Tread Stock †. Chem. J. Chinese Universities, 2019, 40(11): 2388.

| SiO2Brand | 1165MP | HB 2105N | HB 2205N | HB 2200D |

|---|---|---|---|---|

| Functional group in the modifier | None | Amino | Amino | Double bond |

| Contents of modifier/(mmol·kg-1) | 0 | 90 | 140 | 260 |

| Apparent density/(g·mL-1) | 0.88 | 0.28 | 0.13 | 0.16 |

| Mass loss at 950 ℃(%) | 4.50 | 7.52 | 8.17 | 5.61 |

| Oil absorption/(mL·100 g-1) | 160 | 168 | 196 | 207 |

| Specific surface area(BET)/(m2·g-1) | 155 | 151 | 125 | 121 |

Table 1 Basic parameters of four kinds of SiO2

| SiO2Brand | 1165MP | HB 2105N | HB 2205N | HB 2200D |

|---|---|---|---|---|

| Functional group in the modifier | None | Amino | Amino | Double bond |

| Contents of modifier/(mmol·kg-1) | 0 | 90 | 140 | 260 |

| Apparent density/(g·mL-1) | 0.88 | 0.28 | 0.13 | 0.16 |

| Mass loss at 950 ℃(%) | 4.50 | 7.52 | 8.17 | 5.61 |

| Oil absorption/(mL·100 g-1) | 160 | 168 | 196 | 207 |

| Specific surface area(BET)/(m2·g-1) | 155 | 151 | 125 | 121 |

| System | S/B-1165MP | S/B-HB 2105N | S/B-HB 2205N | S/B-HB 2200D |

|---|---|---|---|---|

| Mooney viscosity | 72 | 79 | 74 | 80 |

| Boundrubber(%) | 16 | 23 | 20 | 22 |

| Green strength/MPa | 0.41 | 0.40 | 0.39 | 0.41 |

| Modulus at 100%/MPa | 0.40 | 0.39 | 0.36 | 0.41 |

| Modulus at 300%/MPa | 0.36 | 0.37 | 0.35 | 0.32 |

| Elongation at break(%) | 935 | 1119 | 662 | 695 |

| Shore A hardness/(°) | 32 | 32 | 33 | 31 |

Table 2 Physical and mechanical properties of the SSBR/BR/SiO2 compounds

| System | S/B-1165MP | S/B-HB 2105N | S/B-HB 2205N | S/B-HB 2200D |

|---|---|---|---|---|

| Mooney viscosity | 72 | 79 | 74 | 80 |

| Boundrubber(%) | 16 | 23 | 20 | 22 |

| Green strength/MPa | 0.41 | 0.40 | 0.39 | 0.41 |

| Modulus at 100%/MPa | 0.40 | 0.39 | 0.36 | 0.41 |

| Modulus at 300%/MPa | 0.36 | 0.37 | 0.35 | 0.32 |

| Elongation at break(%) | 935 | 1119 | 662 | 695 |

| Shore A hardness/(°) | 32 | 32 | 33 | 31 |

| System | S/B-1165MP | S/B-HB 2105N | S/B-HB 2205N | S/B-HB 2200D |

|---|---|---|---|---|

| ML/(dN·m) | 2.53 | 2.96 | 2.83 | 3.10 |

| MH/(dN·m) | 20.2 | 24.7 | 23.7 | 24.4 |

| MH-ML/(dN·m) | 17.7 | 21.8 | 20.8 | 21.3 |

| tc10/min | 6.24 | 2.40 | 2.48 | 2.40 |

| tc90/min | 28.9 | 18.9 | 18.1 | 17.4 |

| Swelling ratio, Q | 1.75 | 1.45 | 1.52 | 1.45 |

Table 3 Cross-linking characteristics of the SSBR/BR/SiO2 compounds

| System | S/B-1165MP | S/B-HB 2105N | S/B-HB 2205N | S/B-HB 2200D |

|---|---|---|---|---|

| ML/(dN·m) | 2.53 | 2.96 | 2.83 | 3.10 |

| MH/(dN·m) | 20.2 | 24.7 | 23.7 | 24.4 |

| MH-ML/(dN·m) | 17.7 | 21.8 | 20.8 | 21.3 |

| tc10/min | 6.24 | 2.40 | 2.48 | 2.40 |

| tc90/min | 28.9 | 18.9 | 18.1 | 17.4 |

| Swelling ratio, Q | 1.75 | 1.45 | 1.52 | 1.45 |

| System | S/B-1165MP | S/B-HB 2105N | S/B-HB 2205N | S/B-HB 2200D |

|---|---|---|---|---|

| Dispersion(%) | 99.3 | 99.7 | 99.8 | 99.7 |

| White area(%) | 1.0 | 0.1 | 0.1 | 0.2 |

Table 4 Filler dispersion of SSBR/BR/SiO2 vulcanizates

| System | S/B-1165MP | S/B-HB 2105N | S/B-HB 2205N | S/B-HB 2200D |

|---|---|---|---|---|

| Dispersion(%) | 99.3 | 99.7 | 99.8 | 99.7 |

| White area(%) | 1.0 | 0.1 | 0.1 | 0.2 |

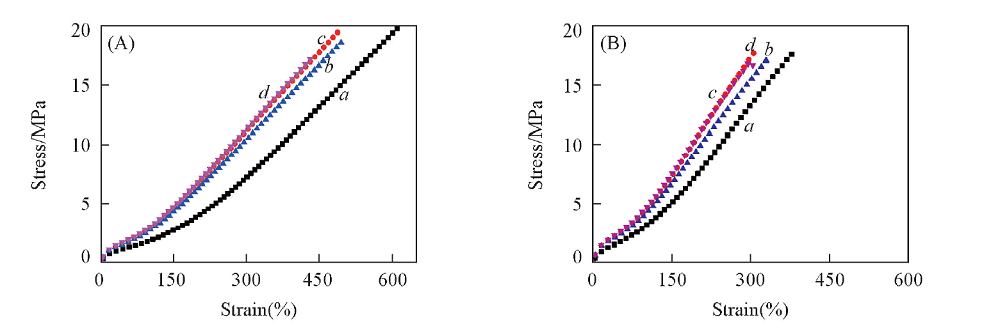

Fig.3 Stress-strain curves of SSBR/BR/SiO2 vulcanizates before(A) and after hot air ageing(100 ℃, 72 h)(B) a. S/B-1165MP; b. S/B-HB 2105N; c. S/B-HB 2205N; d. S/B-HB 2200D.

| System | S/B-1165MP | S/B-HB 2105N | S/B-HB 2205N | S/B-HB 2200D |

|---|---|---|---|---|

| Tensile strength/MPa | 19.9 | 19.5 | 17.7 | 17.6 |

| Modulus at 100%/MPa | 1.8 | 2.9 | 2.7 | 3.0 |

| Modulus at 300%/MPa | 7.2 | 11.2 | 10.7 | 11.3 |

| Elongation at break(%) | 613 | 487 | 460 | 438 |

| Shore A hardness/(°) | 63 | 72 | 70 | 72 |

| Tear strength/(kN·m-1) | 45.3 | 44.2 | 43.3 | 40.7 |

| DIN abrasion/(cm3·40 m-1) | 0.135 | 0.123 | 0.119 | 0.128 |

| Rebound(%) | 37.0 | 40.2 | 39.0 | 42.5 |

| Heat built-up/℃ | 31.5 | 29.4 | 27.8 | 29.0 |

| Compression set(%) | 5.00 | 5.19 | 4.93 | 5.69 |

| Tensile fatigue at 125% | 193×104 | >500×104 | >500×104 | >500×104 |

| tanδ at 60 ℃ | 0.142 | 0.130 | 0.123 | 0.131 |

| tanδ at 0 ℃ | 0.233 | 0.249 | 0.212 | 0.230 |

| Properties after hot air ageing(100 ℃, 72 h) | ||||

| Tensile strength/MPa | 18.0 | 18.1 | 17.1 | 17.4 |

| Modulus at 100%/MPa | 3.1 | 4.4 | 4.1 | 4.6 |

| Modulus at 300%/MPa | 13.3 | 17.4 | 15.5 | 17.1 |

| Elongation at break(%) | 386 | 311 | 330 | 304 |

| Swelling ratio, Q | 1.66 | 1.41 | 1.35 | 1.36 |

| Ageing coefficient(%) | 56.9 | 69.3 | 68.7 | 59.3 |

Table 5 Physical and mechanical properties of SSBR/BR/SiO2 vulcanizates

| System | S/B-1165MP | S/B-HB 2105N | S/B-HB 2205N | S/B-HB 2200D |

|---|---|---|---|---|

| Tensile strength/MPa | 19.9 | 19.5 | 17.7 | 17.6 |

| Modulus at 100%/MPa | 1.8 | 2.9 | 2.7 | 3.0 |

| Modulus at 300%/MPa | 7.2 | 11.2 | 10.7 | 11.3 |

| Elongation at break(%) | 613 | 487 | 460 | 438 |

| Shore A hardness/(°) | 63 | 72 | 70 | 72 |

| Tear strength/(kN·m-1) | 45.3 | 44.2 | 43.3 | 40.7 |

| DIN abrasion/(cm3·40 m-1) | 0.135 | 0.123 | 0.119 | 0.128 |

| Rebound(%) | 37.0 | 40.2 | 39.0 | 42.5 |

| Heat built-up/℃ | 31.5 | 29.4 | 27.8 | 29.0 |

| Compression set(%) | 5.00 | 5.19 | 4.93 | 5.69 |

| Tensile fatigue at 125% | 193×104 | >500×104 | >500×104 | >500×104 |

| tanδ at 60 ℃ | 0.142 | 0.130 | 0.123 | 0.131 |

| tanδ at 0 ℃ | 0.233 | 0.249 | 0.212 | 0.230 |

| Properties after hot air ageing(100 ℃, 72 h) | ||||

| Tensile strength/MPa | 18.0 | 18.1 | 17.1 | 17.4 |

| Modulus at 100%/MPa | 3.1 | 4.4 | 4.1 | 4.6 |

| Modulus at 300%/MPa | 13.3 | 17.4 | 15.5 | 17.1 |

| Elongation at break(%) | 386 | 311 | 330 | 304 |

| Swelling ratio, Q | 1.66 | 1.41 | 1.35 | 1.36 |

| Ageing coefficient(%) | 56.9 | 69.3 | 68.7 | 59.3 |

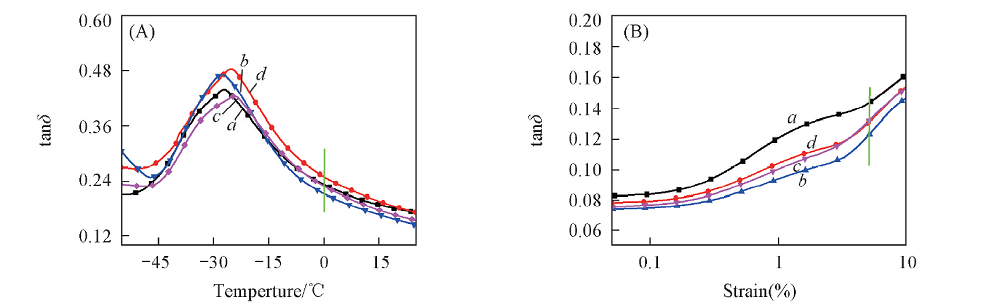

Fig.4 DMA curves of SSBR/BR vulcanizates filled with different SiO2 (A) tanδ versus temperature with a strain of 0.5%; (B) tanδ versus strain at 60 ℃. a. S/B-1165MP; b. S/B-HB 2105N; c. S/B-HB 2205N; d. S/B-HB 2200D.

| [1] | Panko J., Kreider M., Unice K., Non-Exhaust Emissions., 2018, 147— 160 |

| [2] | Schuring D. J ., Tire. Sci. Technol., 1994,22, 148— 161 |

| [3] | Georgios F., Samaras Z., Energ Policy., 2010,38, 1826— 1833 |

| [4] | Wang H., Song L. Y., Ma Y. S., Wang R. G., He A. H., Acta. Polym. Sin., 2018,3, 419— 428 |

| ( 王浩, 宋丽媛, 马韵升, 王日国, 贺爱华 . 高分子学报, 2018,3, 419— 428) | |

| [5] | Liu L., Zhang L. Q., Rubb. Ind., 1999,4, 245— 248 |

| ( 刘力, 张立群 . 橡胶工业, 1999,4, 245— 248) | |

| [6] | Ansarifara A., Azharb A., Ibrahima N., Shiaha S. F., Lawtonc J. M. D., Int. J. Adhes. Adhes., 2005,25(1), 77— 86 |

| [7] | Sombatsompop N., Thongsang S., Markpin T., Wimolmala E ., J. Appl. Polym. Sci., 2004,93(5), 2119— 2130 |

| [8] | Yang L. C., Ma H. W., Han L., Hao X. Y., Liu P. B., Shen H. Y., Li Y., Polym. Chem., 2017,9, 1— 15 |

| [9] | Rattanasom N., Saowapark T., Deeprasertkul C ., Polym. Test, 2007,26(3), 369— 377 |

| [10] | Liu X., Zhao S. H., J. Appl. Polym. Sci., 2008,109(6), 3900— 3907 |

| [11] | Shen M., Zhao F., Wang S. W., Zhao S. G., J. Macromol. Sci. Part B., 2013,52(2), 398— 406 |

| [12] | Wang Y. X., Wu Y. P., Li W. J., Zhang L. Q., Appl. Surf. Sci., 2011,257(6), 2058— 2065 |

| [13] | Ou Y. C., Yu Z. Z., Vidal A. Donnet J. B., J. Appl. Polym. Sci., 1996,59(8), 1321— 1328 |

| [14] | Yatsuyanagi F., Nozomu S., Masayoshi I., Hiroyuki K., Polym. J., 2002,34(5), 332— 339 |

| [15] | Wu Y. P., Dong J., Yuan R., Wan H. Q., Chen L., Li J. L., Zhou H. D., Chen J. M., Polym. Adv. Technol., 2018,29(10), 1— 9 |

| [16] | Wang H., Zhang X. P., Nie H. R., Wang R. G., He A. H., Compos. Part A: Appl. Sci. Manufac., 2019,116, 197— 205 |

| [17] | Yang L. C., Ma H. W., Han L., Hao X. Y., Liu P. B., Shen H. Y., Li Y., Polym. Chem., 2017,9, 1— 15 |

| [18] | Liu P. B., Ma H. W., Han L., Yang L.C., Shen H. Y., Li C., Li Y., Polymer, 2018,147, 153— 163 |

| [19] | Wang H., Zhang J. P., Ma Y. S., Wang R. G., He A. H., Chem. J. Chinese. Universities, 2017,38(11), 2095— 2101 |

| ( 王浩, 张剑平, 马韵升, 王日国, 贺爱华 . 高等学校化学学报, 2017,38(11), 2095— 2101) | |

| [20] | Zhang X. P., Cui H., Song L. Y., Ren H. C., Wang R. G., He A. H., Compos. Sci. Technol., 2018,158, 156— 163 |

| [21] | Ismail H., Suzaimah S ., Polym. Test, 2000,19(8), 879— 888 |

| [22] | Stöckelhuber K. W., Das A., Jurk R., Heinrich G., Polymer, 2010,51(9), 1954— 1963 |

| [23] | Ryu C., Yang J. K., Park W., Seo Y., Kim S. J., Kim D., Park S., Seo1 G., J. Appl. Polym. Sci., 2017,134(22), 1— 14 |

| [24] | Li Y., Han B. Y., Liu L., Zhang F. Z., Zhang L. Q., Wen S. P., Lu Y. L., Yang H. B., Shen J., Compos. Sci. Technol., 2013,88, 69— 75 |

| [25] | Stockelhuber K. W., Svistkov A. S., Pelevin A. G., Heinrich G., Macromolecules, 2011,44(11), 4366— 4381 |

| [26] | Ramier J., Gauthier C., Chazeau L., Stelander L., Guy L ., J. Polym. Sci. Part B., 2007,45(3), 286— 298 |

| [27] | Choi S. S., Kim I. S., . Eur. Polym. J., 2002,38, 1265— 1269 |

| [28] | Park S. J., Cho K. S., . J. Colloid. Interf. Sci., 200, 267(1), 86— 91 |

| [29] | Standardization Administration of the People’s Republic of China, GB/T 1332.1-2000, Rubber: Measurement Mooney Viscosity with Shearing Discvis Viscometer, Standards Press of China, Beijing, 2000 |

| ( 中国国家标准化管理委员会. GB/T 1232.1-2000, 橡胶用门尼粘度仪测定门尼粘度, 北京: 中国标准出版社, 2000) | |

| [30] | Standardization Administration of the People’s Republic of China, GB/T 25268-2010, Rubber:Measurement of Vulcanization Characteristics with RotorlessCuremeters, Standards Press of China, Beijing, 2010 |

| ( 中国国家标准化管理委员会. GB/T 25268-2010, 橡胶用无转子硫化仪测定硫化特性, 北京: 中国标准出版社, 2010) | |

| [31] | Standardization Administration of the People’s Republic of China, GB/T 9026-2007, Rubber:Measurement of Green-Strength, Standards Press of China, Beijing, 2007 |

| ( 中国国家标准化管理委员会.GB / T 9026-2007, 混炼橡胶的格林强度测试, 北京: 中国标准出版社, 2007) | |

| [32] | Standardization Administration of the People’s Republic of China, GB/T 528-2009, Vulcanized or Thermoplastic:Determination of Tensile Stress-train Properties, Standards Press of China, Beijing, 2009 |

| ( 中国国家标准化管理委员会. GB/T 528-2009, 硫化橡胶或热塑性橡胶拉伸应力应变性能的测定, 北京: 中国标准出版社, 2009) | |

| [33] | Standardization Administration of the People’s Republic of China,GB/T 529-2008, Vulcanized or Thermoplastic:Determination of Tear Strength, Standards Press of China, Beijing, 2008 |

| ( 中国国家标准化管理委员会. GB/T 529-2008, 硫化橡胶或热塑性橡胶撕裂强度的测定, 北京: 中国标准出版社, 2008) | |

| [34] | Standardization Administration of the People’s Republic of China, GB/T 1681-2009, Rubber:Determination of Rebound Reslience of Vulcanizates, Standards Press of China, Beijing, 2009 |

| ( 中国国家标准化管理委员会.GB/T 1681-2009, 硫化橡胶回弹性能的测定, 北京: 中国标准出版社, 2009) | |

| [35] | Standardization Administration of the People’s Republic of China, GB/T 9867-2008, Rubber: Determination of DIN Abrasion Resistance of Vulcanizates , Standards Press of China,Beijing, 2008 |

| ( 中国国家标准化管理委员会.GB/T 9867-2008 , 硫化橡胶DIN磨耗性能的测定, 北京: 中国标准出版社, 2008) | |

| [36] | Standardization Administration of the People’s Republic of China, GB/T 3512-2014, Vulcanized or Thermoplastic: Accelerated Ageing and Heat Resistance Tests: Air-Oven Method , Standards Press of China, Beijing, 2014 |

| ( 中国国家标准化管理委员会. GB/T 3512-2014, 硫化橡胶或热塑性橡胶热空气加速老化和耐热实验, 北京: 中国标准出版社, 2014) | |

| [37] | Standardization Administration of the People’s Republic of China, GB/T 1689-2016, Vulcanized or Thermoplastic: Determination of Tensile Fatigue, Standards Press of China, Beijing, 2016 |

| ( 中国国家标准化管理委员会. GB/T 1689-2016, 硫化橡胶或热塑性橡胶伸张疲劳性能测定(德默西亚), 北京: 中国标准出版社, 2016) | |

| [38] | Qi L. J., Zhao Z. C., Huang B. C., Spec. Rubb. Prod., 2009,30(6), 6— 9 |

| ( 齐立杰, 赵志超, 黄宝琛 . 特种橡胶工业, 2009,30(6), 6— 9) | |

| [39] | Zhang X. P., Wang H., Ren H. C., Wang R. G., He A. H., Ind. Eng. Chem. Res., 2019,58, 917— 925 |

| [40] | Gong K. C., Li G. J., Hu Q. X., J. Polym. Sci. Part A., 2010,29(9), 1225— 1230 |

| [41] | Suzana S. J., Vojislav J., Gordana M., Gordana M., Ivana Z., Milena M. C., Sci. World J., 2014,267(1), 1— 9 |

| [42] | Pourhossaini M. R., Razzaghi-Kashani M., Polymer, 2014,55(9), 2279— 2284 |

| [43] | Berriot J., Montes H., Lequeux F., Long D., Sottaet P ., Macromolecules, 2002,35(26), 9756— 9762 |

| [44] | Yan F. H., Zhang X. B., Liu F., Zhang Z. J., . Compos. Part B., 2015,75, 47— 52 |

| [1] | 赵盛, 霍志鹏, 钟国强, 张宏, 胡立群. 改性钆/硼/聚乙烯纳米复合材料的制备及对中子和伽马射线的屏蔽性能[J]. 高等学校化学学报, 2022, 43(6): 20220039. |

| [2] | 张洁, 银波, 刘玮欣, 刘兴平, 连文贤, 唐韶坤. 勃姆石纤维增强二氧化硅气凝胶的制备及性能[J]. 高等学校化学学报, 2022, 43(11): 20220483. |

| [3] | 石颖, 胡广剑, 吴敏杰, 李峰. 低温等离子体在锂离子电池材料中的应用[J]. 高等学校化学学报, 2021, 42(5): 1315. |

| [4] | 韩延东, 韩明勇, 杨文胜. 溶胶-凝胶法构筑介孔二氧化硅纳微结构[J]. 高等学校化学学报, 2021, 42(4): 965. |

| [5] | 童诚, 吴文韬, 王挺. 具有不对称孔道结构的小介孔二氧化硅粒子的合成及其高分子杂化膜的构建[J]. 高等学校化学学报, 2021, 42(3): 946. |

| [6] | 王博东, 潘美辰, 卓颖. 二氧化硅纳米颗粒表面原位还原银纳米簇电化学发光传感界面的构建与分子识别[J]. 高等学校化学学报, 2021, 42(11): 3519. |

| [7] | 宋文尧, 周张浪, 杨鑫莉, 陈岚, 葛广路. 介孔二氧化硅对映选择性吸附的手性印迹调控[J]. 高等学校化学学报, 2021, 42(10): 3144. |

| [8] | 王欢, 所金泉, 王春艳, 王润伟. 氨基化树枝状介孔二氧化硅固定葡萄糖氧化酶用于检测葡萄糖[J]. 高等学校化学学报, 2020, 41(8): 1731. |

| [9] | 彭新艳, 刘云鸿, 李嘉文, 冯乙胧, 王汉春. 单宁酸/两性离子改性油-水分离膜的制备及性能[J]. 高等学校化学学报, 2020, 41(6): 1337. |

| [10] | 陈良丹,邹伟,吴亮,夏凡杰,胡执一,李昱,苏宝连. 纳米Al2O3包覆富锂锰基正极材料Li1.2Ni0.13Co0.13Mn0.54O2的性能研究[J]. 高等学校化学学报, 2020, 41(6): 1329. |

| [11] | 刘帅卓,张骞,刘宁,肖文艳,范雷倚,周莹. 三聚氰胺海绵的一步式协同超疏水改性及在油水分离中的应用[J]. 高等学校化学学报, 2020, 41(3): 521. |

| [12] | 陈静,陈进华,尹德忠,张伟. 己二酸二酯原位功能化SiO2稳定Pickering乳液的相反转研究[J]. 高等学校化学学报, 2020, 41(1): 140. |

| [13] | 王星火,汤钧,杨英威. 由聚合物门控的介孔二氧化硅基刺激响应性药物递送系统[J]. 高等学校化学学报, 2020, 41(1): 28. |

| [14] | 王振宇, 李健华, 郭慧君, 杨春才. 原位合成纳米SiO2增强阴离子聚酯型上浆剂及其对碳纤维复合材料层间剪切强度的影响[J]. 高等学校化学学报, 2019, 40(9): 2005. |

| [15] | 宋艺超, 胡满成, 李淑妮, 翟全国, 蒋育澄. 基于中心辐射树枝状介孔二氧化硅构筑CPO固定化酶反应器及应用[J]. 高等学校化学学报, 2019, 40(9): 1805. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||