Chem. J. Chinese Universities ›› 2020, Vol. 41 ›› Issue (1): 145.doi: 10.7503/cjcu20190430

• Physical Chemistry • Previous Articles Next Articles

DENG Anqiang1,2,3,LUO Yongchun1,2,*( ),XIA Yuanhua4,PENG Sihui2,MA Weiqin2,ZHAO Xudong2,YANG Yang2,HOU Xiaodong2

),XIA Yuanhua4,PENG Sihui2,MA Weiqin2,ZHAO Xudong2,YANG Yang2,HOU Xiaodong2

Received:2019-07-31

Online:2020-01-10

Published:2019-11-04

Contact:

Yongchun LUO

E-mail:luoyc@lut.cn

Supported by:CLC Number:

TrendMD:

DENG Anqiang,LUO Yongchun,XIA Yuanhua,PENG Sihui,MA Weiqin,ZHAO Xudong,YANG Yang,HOU Xiaodong. Effect of Annealing Treatment on Structure and Electrochemical Properties of New Mg-free Y0.7La0.3Ni3.25Al0.1Mn0.15 Hydrogen Storage Alloys †[J]. Chem. J. Chinese Universities, 2020, 41(1): 145.

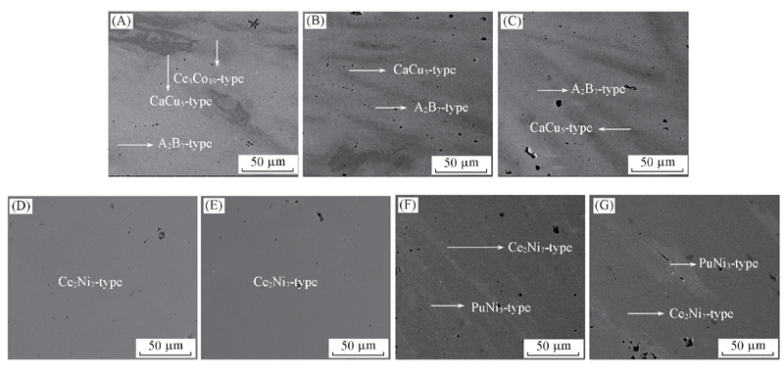

Fig.1 Backscattered SEM images of the as-cast(A) and annealed(B—G) alloys Y0.7La0.3Ni3.25Al0.1Mn0.15 Annealing temperature/℃: (B) 800; (C) 850; (D) 900; (E) 950; (F) 1000; (G) 1050.

| Sample | Phase | Atomic fraction(%) | Stoichiometric B/A | ||||

|---|---|---|---|---|---|---|---|

| La | Y | Ni | Al | Mn | |||

| As-cast | | 0.3106 | 0.6894 | 3.2298 | 0.1021 | 0.1560 | 3.49 |

| As-cast | A2B7 | 0.2806 | 0.7194 | 3.2273 | 0.0711 | 0.1302 | 3.43 |

| Ce5Co19 | 0.2525 | 0.7475 | 3.5112 | 0.1121 | 0.1595 | 3.78 | |

| CaCu5 | 0.2147 | 0.7853 | 4.6011 | 0.1791 | 0.1638 | 4.94 | |

| Annealed at 800 ℃ | A2B7 | 0.3359 | 0.6641 | 3.1878 | 0.0804 | 0.1329 | 3.40 |

| CaCu5 | 0.2021 | 0.7979 | 4.3549 | 0.2176 | 0.1536 | 4.73 | |

| Annealed at 850 ℃ | A2B7 | 0.3020 | 0.6980 | 3.2045 | 0.0943 | 0.1388 | 3.44 |

| CaCu5 | 0.2090 | 0.7910 | 4.3423 | 0.2736 | 0.1642 | 4.78 | |

| Annealed at 900 ℃ | Ce2Ni7 | 0.2596 | 0.7404 | 3.1830 | 0.1106 | 0.1617 | 3.46 |

| Annealed at 950 ℃ | Ce2Ni7 | 0.3075 | 0.6925 | 3.1879 | 0.0961 | 0.1423 | 3.43 |

| Annealed at 1000 ℃ | Ce2Ni7 | 0.2958 | 0.7042 | 3.1633 | 0.1175 | 0.1317 | 3.41 |

| PuNi3 | 0.3704 | 0.6296 | 2.7189 | 0.1099 | 0.1164 | 2.95 | |

| Annealed at 1050 ℃ | Ce2Ni7 | 0.2600 | 0.7400 | 3.1340 | 0.1080 | 0.1280 | 3.37 |

| PuNi3 | 0.3312 | 0.6688 | 2.7239 | 0.0942 | 0.1051 | 2.92 | |

| Sample | Phase | Atomic fraction(%) | Stoichiometric B/A | ||||

|---|---|---|---|---|---|---|---|

| La | Y | Ni | Al | Mn | |||

| As-cast | | 0.3106 | 0.6894 | 3.2298 | 0.1021 | 0.1560 | 3.49 |

| As-cast | A2B7 | 0.2806 | 0.7194 | 3.2273 | 0.0711 | 0.1302 | 3.43 |

| Ce5Co19 | 0.2525 | 0.7475 | 3.5112 | 0.1121 | 0.1595 | 3.78 | |

| CaCu5 | 0.2147 | 0.7853 | 4.6011 | 0.1791 | 0.1638 | 4.94 | |

| Annealed at 800 ℃ | A2B7 | 0.3359 | 0.6641 | 3.1878 | 0.0804 | 0.1329 | 3.40 |

| CaCu5 | 0.2021 | 0.7979 | 4.3549 | 0.2176 | 0.1536 | 4.73 | |

| Annealed at 850 ℃ | A2B7 | 0.3020 | 0.6980 | 3.2045 | 0.0943 | 0.1388 | 3.44 |

| CaCu5 | 0.2090 | 0.7910 | 4.3423 | 0.2736 | 0.1642 | 4.78 | |

| Annealed at 900 ℃ | Ce2Ni7 | 0.2596 | 0.7404 | 3.1830 | 0.1106 | 0.1617 | 3.46 |

| Annealed at 950 ℃ | Ce2Ni7 | 0.3075 | 0.6925 | 3.1879 | 0.0961 | 0.1423 | 3.43 |

| Annealed at 1000 ℃ | Ce2Ni7 | 0.2958 | 0.7042 | 3.1633 | 0.1175 | 0.1317 | 3.41 |

| PuNi3 | 0.3704 | 0.6296 | 2.7189 | 0.1099 | 0.1164 | 2.95 | |

| Annealed at 1050 ℃ | Ce2Ni7 | 0.2600 | 0.7400 | 3.1340 | 0.1080 | 0.1280 | 3.37 |

| PuNi3 | 0.3312 | 0.6688 | 2.7239 | 0.0942 | 0.1051 | 2.92 | |

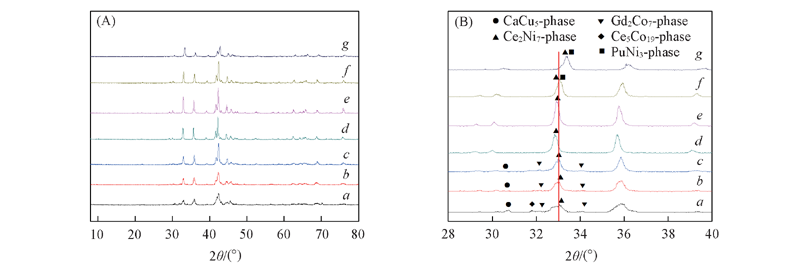

Fig.2 XRD patterns of as-cast and annealed alloys(A) and its partial magnification(B) a. As-cast; b. 800 ℃; c. 850 ℃; d. 900 ℃; e. 950 ℃; f. 1000 ℃; g. 1050 ℃.

| Condition | Phase | Space group(No.) | Phase abundance(%) | Lattice constant | V/nm3 | Strain(%) | Ce2Ni7 | |

|---|---|---|---|---|---|---|---|---|

| a/nm | c/nm | |||||||

| As-cast | Ce2Ni7 | P63/mmc(194) | 65.78 | 0.50173 | 2.43745 | 0.53138 | 1.29 | 1.674 |

| Gd2Co7 | R | 15.80 | 0.44902 | 3.93293 | 0.68672 | |||

| Ce5Co19 | R | 8.37 | 0.50579 | 4.80588 | 1.06470 | |||

| CaCu5 | P6/mmm(191) | 10.05 | 0.49621 | 0.40003 | 0.08530 | |||

| Annealed at 800 ℃ | Ce2Ni7 | P63/mmc(194) | 82.03 | 0.50191 | 2.43675 | 0.53161 | 0.80 | 1.247 |

| Gd2Co7 | R | 9.01 | 0.44832 | 3.96713 | 0.69054 | |||

| CaCu5 | P6/mmm(191) | 8.96 | 0.50048 | 0.40145 | 0.08708 | |||

| Annealed at 850 ℃ | Ce2Ni7 | P63/mmc(194) | 89.16 | 0.50172 | 2.44092 | 0.53211 | 0.55 | 1.116 |

| Gd2Co7 | R | 6.45 | 0.44669 | 4.04017 | 0.69813 | |||

| CaCu5 | P6/mmm(191) | 4.39 | 0.49996 | 0.40513 | 0.08770 | |||

| Annealed at 900 ℃ | Ce2Ni7 | P63/mmc(194) | 100.00 | 0.50281 | 2.44133 | 0.53451 | 0.17 | 1.030 |

| Annealed at 950 ℃ | Ce2Ni7 | P63/mmc(194) | 100.00 | 0.50202 | 2.43837 | 0.53219 | 0.20 | 1.030 |

| Annealed at 1000 ℃ | Ce2Ni7 | P63/mmc(194) | 89.92 | 0.50161 | 2.43729 | 0.53108 | 0.22 | 1.028 |

| PuNi3 | R | 10.08 | 0.49521 | 2.43776 | 0.51772 | |||

| Annealed at 1050 ℃ | Ce2Ni7 | P63/mmc(194) | 84.68 | 0.50158 | 2.43659 | 0.53087 | 0.24 | 1.020 |

| PuNi3 | R | 15.32 | 0.49448 | 2.43004 | 0.51456 | |||

| Condition | Phase | Space group(No.) | Phase abundance(%) | Lattice constant | V/nm3 | Strain(%) | Ce2Ni7 | |

|---|---|---|---|---|---|---|---|---|

| a/nm | c/nm | |||||||

| As-cast | Ce2Ni7 | P63/mmc(194) | 65.78 | 0.50173 | 2.43745 | 0.53138 | 1.29 | 1.674 |

| Gd2Co7 | R | 15.80 | 0.44902 | 3.93293 | 0.68672 | |||

| Ce5Co19 | R | 8.37 | 0.50579 | 4.80588 | 1.06470 | |||

| CaCu5 | P6/mmm(191) | 10.05 | 0.49621 | 0.40003 | 0.08530 | |||

| Annealed at 800 ℃ | Ce2Ni7 | P63/mmc(194) | 82.03 | 0.50191 | 2.43675 | 0.53161 | 0.80 | 1.247 |

| Gd2Co7 | R | 9.01 | 0.44832 | 3.96713 | 0.69054 | |||

| CaCu5 | P6/mmm(191) | 8.96 | 0.50048 | 0.40145 | 0.08708 | |||

| Annealed at 850 ℃ | Ce2Ni7 | P63/mmc(194) | 89.16 | 0.50172 | 2.44092 | 0.53211 | 0.55 | 1.116 |

| Gd2Co7 | R | 6.45 | 0.44669 | 4.04017 | 0.69813 | |||

| CaCu5 | P6/mmm(191) | 4.39 | 0.49996 | 0.40513 | 0.08770 | |||

| Annealed at 900 ℃ | Ce2Ni7 | P63/mmc(194) | 100.00 | 0.50281 | 2.44133 | 0.53451 | 0.17 | 1.030 |

| Annealed at 950 ℃ | Ce2Ni7 | P63/mmc(194) | 100.00 | 0.50202 | 2.43837 | 0.53219 | 0.20 | 1.030 |

| Annealed at 1000 ℃ | Ce2Ni7 | P63/mmc(194) | 89.92 | 0.50161 | 2.43729 | 0.53108 | 0.22 | 1.028 |

| PuNi3 | R | 10.08 | 0.49521 | 2.43776 | 0.51772 | |||

| Annealed at 1050 ℃ | Ce2Ni7 | P63/mmc(194) | 84.68 | 0.50158 | 2.43659 | 0.53087 | 0.24 | 1.020 |

| PuNi3 | R | 15.32 | 0.49448 | 2.43004 | 0.51456 | |||

| Subunit | Atom | Site | x | y | z | 102Biso/nm2 | Occ |

|---|---|---|---|---|---|---|---|

| Laves | Y | 4f | 0.33333 | 0.66667 | 0.02776 | 1.24 | 1.00 |

| CaCu5 | Y | 4f | 0.33333 | 0.66667 | 0.16953 | 0.78 | 0.40 |

| La | 4f | 0.33333 | 0.66667 | 0.16953 | 0.78 | 0.60 | |

| Laves | Ni | 2a | 0 | 0 | 0 | 0.66 | 0.92 |

| Al | 2a | 0 | 0 | 0 | 0.66 | 0.02 | |

| Mn | 2a | 0 | 0 | 0 | 0.66 | 0.06 | |

| CaCu5 | Ni | 4e | 0 | 0 | 0.17051 | 1.60 | 0.83 |

| Al | 4e | 0 | 0 | 0.17051 | 1.60 | 0.08 | |

| Mn | 4e | 0 | 0 | 0.17051 | 1.60 | 0.09 | |

| CaCu5 | Ni | 4f | 0.66667 | 0.33333 | 0.1681 | 0.39 | 0.90 |

| Al | 4f | 0.66667 | 0.33333 | 0.1681 | 0.39 | 0.05 | |

| Mn | 4f | 0.66667 | 0.33333 | 0.1681 | 0.39 | 0.06 | |

| CaCu5 | Ni | 6h | 0.1692 | 0.33838 | 0.75 | 0.35 | 0.77 |

| Al | 6h | 0.1692 | 0.33838 | 0.75 | 0.35 | 0.10 | |

| Mn | 6h | 0.1692 | 0.33838 | 0.75 | 0.35 | 0.13 | |

| Laves/CaCu5 | Ni | 12k | 0.167 | 0.33406 | 0.91513 | 0.21 | 0.81 |

| Al | 12k | 0.167 | 0.33406 | 0.91513 | 0.21 | 0.06 | |

| Mn | 12k | 0.167 | 0.33406 | 0.91513 | 0.21 | 0.12 |

| Subunit | Atom | Site | x | y | z | 102Biso/nm2 | Occ |

|---|---|---|---|---|---|---|---|

| Laves | Y | 4f | 0.33333 | 0.66667 | 0.02776 | 1.24 | 1.00 |

| CaCu5 | Y | 4f | 0.33333 | 0.66667 | 0.16953 | 0.78 | 0.40 |

| La | 4f | 0.33333 | 0.66667 | 0.16953 | 0.78 | 0.60 | |

| Laves | Ni | 2a | 0 | 0 | 0 | 0.66 | 0.92 |

| Al | 2a | 0 | 0 | 0 | 0.66 | 0.02 | |

| Mn | 2a | 0 | 0 | 0 | 0.66 | 0.06 | |

| CaCu5 | Ni | 4e | 0 | 0 | 0.17051 | 1.60 | 0.83 |

| Al | 4e | 0 | 0 | 0.17051 | 1.60 | 0.08 | |

| Mn | 4e | 0 | 0 | 0.17051 | 1.60 | 0.09 | |

| CaCu5 | Ni | 4f | 0.66667 | 0.33333 | 0.1681 | 0.39 | 0.90 |

| Al | 4f | 0.66667 | 0.33333 | 0.1681 | 0.39 | 0.05 | |

| Mn | 4f | 0.66667 | 0.33333 | 0.1681 | 0.39 | 0.06 | |

| CaCu5 | Ni | 6h | 0.1692 | 0.33838 | 0.75 | 0.35 | 0.77 |

| Al | 6h | 0.1692 | 0.33838 | 0.75 | 0.35 | 0.10 | |

| Mn | 6h | 0.1692 | 0.33838 | 0.75 | 0.35 | 0.13 | |

| Laves/CaCu5 | Ni | 12k | 0.167 | 0.33406 | 0.91513 | 0.21 | 0.81 |

| Al | 12k | 0.167 | 0.33406 | 0.91513 | 0.21 | 0.06 | |

| Mn | 12k | 0.167 | 0.33406 | 0.91513 | 0.21 | 0.12 |

| Alloy | Na | Cmax/(mA·h·g-1) | S100(%) | Ecorr/V | icorr/(mA·cm-2) |

|---|---|---|---|---|---|

| As-cast | 2 | 307.6 | 66.0 | -0.933 | 21.34 |

| Annealed at 800 ℃ | 5 | 347.3 | 68.1 | -0.925 | 18.56 |

| Annealed at 850 ℃ | 3 | 372.8 | 79.2 | -0.921 | 18.25 |

| Annealed at 900 ℃ | 2 | 393.1 | 80.0 | -0.906 | 14.06 |

| Annealed at 950 ℃ | 3 | 371.8 | 88.0 | -0.913 | 14.71 |

| Annealed at 1000 ℃ | 3 | 366.4 | 87.5 | -0.917 | 14.71 |

| Annealed at 1050 ℃ | 6 | 366.4 | 88.5 | -0.92 | 14.84 |

| Alloy | Na | Cmax/(mA·h·g-1) | S100(%) | Ecorr/V | icorr/(mA·cm-2) |

|---|---|---|---|---|---|

| As-cast | 2 | 307.6 | 66.0 | -0.933 | 21.34 |

| Annealed at 800 ℃ | 5 | 347.3 | 68.1 | -0.925 | 18.56 |

| Annealed at 850 ℃ | 3 | 372.8 | 79.2 | -0.921 | 18.25 |

| Annealed at 900 ℃ | 2 | 393.1 | 80.0 | -0.906 | 14.06 |

| Annealed at 950 ℃ | 3 | 371.8 | 88.0 | -0.913 | 14.71 |

| Annealed at 1000 ℃ | 3 | 366.4 | 87.5 | -0.917 | 14.71 |

| Annealed at 1050 ℃ | 6 | 366.4 | 88.5 | -0.92 | 14.84 |

| [1] |

Kadir K., Sakai T., Uehara I ., J. Alloys Compd., 1997,257(1/2), 115— 121

doi: 10.1016/S0925-8388(96)03132-5 URL |

| [2] |

Zhao Y. M ., Wang W. F.,Han S. M.,Guo W.,Li Y.,Zhang L.,Xu G. C., J. Alloys Compd., 2019,775, 259— 269

doi: 10.1016/j.jallcom.2018.10.079 URL |

| [3] |

Denys R. V ., Riabov A. B.,Yartys V. A.,Sato M.,Delaplane R. G., J. Solid State Chem., 2008,181(4), 812— 821

doi: 10.1016/j.jssc.2007.12.041 URL |

| [4] |

Gal L., Charbonnier V., Zhang J., Goubault L., Int. J. Hydrogen Energy, 2015,40(47), 17017— 17020

doi: 10.1016/j.ijhydene.2015.06.068 URL |

| [5] |

Deng A. Q., Fan J. B.,Qian K. N.,Luo Y. C., Acta Phys. Chim. Sin., 2011,27(1), 103— 107

doi: 10.3866/PKU.WHXB20110133 URL |

|

( 邓安强, 樊静波, 钱克农, 罗永春. 物理化学学报, 2011,27(1), 103— 107)

doi: 10.3866/PKU.WHXB20110133 URL |

|

| [6] |

Baddour-Hadjean R., Meyer L., Pereira-Ramos J. P ., Latroche M.,Percheron-Guegan A., Electrochim. Acta, 2001,46(15), 2385— 2393

doi: 10.1016/S0013-4686(01)00440-6 URL |

| [7] |

Aoki K., Masumoto T ., J. Alloys Compd., 1995,231(1/2), 20— 28

doi: 10.1016/0925-8388(95)01832-8 URL |

| [8] |

Charbonnier V., Zhang J., Monnier J., Goubault L., Bernard P., Magén C., Serin V., Latroche M ., J. Phys. Chem. C, 2015,119(22), 12218— 12225

doi: 10.1021/acs.jpcc.5b03096 URL |

| [9] |

Berezovets’ V. V ., Denys R. V.,Ryabov O. B.,Zavalii I. Y., Mater. Sci., 2007,43(4), 499— 507

doi: 10.1007/s11003-007-0058-4 URL |

| [10] |

Lartigue C., Percheron-Guégan A., Achard J. C ., Tasset F., J. Less. Common. Met., 1980,75(11), 23— 29

doi: 10.1016/0022-5088(80)90365-3 URL |

| [11] |

Takeshita T., Gschneidner K. A ., Lakner J. F., J. Less. Common. Met., 1981,78(1), 43— 47

doi: 10.1016/0022-5088(81)90142-9 URL |

| [12] |

Subramanian P. R ., Smith J. F., Metall. Trans. B, 1985,16(3), 577— 584

doi: 10.1007/BF02654856 URL |

| [13] | Roisnel T., Rodríquez-Carvajal J., Mater. Sci. Forum., 2001, 378—381(1), 118— 123 |

| [14] | Will G ., Powder Diffraction: the Rietveld Method and the Two-stage Method to Determine and Refine Crystal Structures from Powder Diffraction Data, Springer,. Berlin, 2006 |

| [15] |

Latroche M., Baddour-Hadjean R., Percheron-Guégan A ., J. Solid State Chem., 2003,173(1), 236— 243

doi: 10.1016/S0022-4596(03)00038-0 URL |

| [16] |

Yasuoka S., Ishida J. Kai T., Kajiwara T., Doi S.,Yamazaki T.,Kishida K.,Inui H., Int. J. Hydrogen Energy, 2017, 42(16), 11574—11583

doi: 10.1016/j.ijhydene.2017.02.150 URL |

| [17] |

Denys R. V., Riabov B., Yartys V. A., Delaplane R. .,Sato M., J. Alloys Compd., 2007,446/447(1), 166— 172

doi: 10.1016/j.jallcom.2006.12.137 URL |

| [18] |

Liu J. J ., Li Y.,Han D.,Yang S. Q.,Chen X. C.,Zhang L.,Han S. M., J. Power Sources, 2015,300(12), 77— 86

doi: 10.1016/j.jpowsour.2015.09.058 URL |

| [19] |

Senoh H., Takeichi N., Takeshita H. T ., Tanaka H.,Kiyobayashi T.,Kuriyama N.,. Materials Science and Engineering: B, 2004,108(1/2), 96— 99

doi: 10.1016/j.mseb.2003.10.055 URL |

| [20] |

Iwase K., Mori K., Hoshikawa A., Ishigaki T., Int. J. Hydrogen Energy, 2012,37(6), 5122— 5127

doi: 10.1016/j.ijhydene.2011.12.108 URL |

| [21] | Liu Y. R ., Yuan H. P.,Guo M.,Jiang L. J., Int.J. Hydrogen Energy, 2019,44(39), 22064— 22073 |

| [22] |

Fang F., Chen Z. L ., Wu D. Y.,Liu H.,Dong C. K.,Song Y.,Sun D. L., J. Power Sources, 2019,427(7), 145— 153

doi: 10.1016/j.jpowsour.2019.04.072 URL |

| [1] | WANG Sicong, PANG Beibei, LIU Xiaokang, DING Tao, YAO Tao. Application of XAFS Technique in Single-atom Electrocatalysis [J]. Chem. J. Chinese Universities, 2022, 43(9): 20220487. |

| [2] | JIANG Bowen, CHEN Jingxuan, CHENG Yonghua, SANG Wei, KOU Zongkui. Recent Progress of Single-atom Materials in Electrochemical Biosensing [J]. Chem. J. Chinese Universities, 2022, 43(9): 20220334. |

| [3] | WU Yushuai, SHANG Yingxu, JIANG Qiao, DING Baoquan. Research Progress of Controllable Self-assembled DNA Origami Structure as Drug Carrier [J]. Chem. J. Chinese Universities, 2022, 43(8): 20220179. |

| [4] | LI Lin, QI Fenglian, QIU Lili, MENG Zihui. Dynamic Amorphous Photonic Structure Patterns Assembled by Hexagonal Magnetic Nanosheets [J]. Chem. J. Chinese Universities, 2022, 43(8): 20220123. |

| [5] | JIA Yanggang, SHAO Xia, CHENG Jie, WANG Pengpeng, MAO Aiqin. Preparation and Lithium Storage Performance of Pseudocapacitance-controlled Perovskite High-entropy Oxide La(Co0.2Cr0.2Fe0.2Mn0.2Ni0.2)O3 Anode Materials [J]. Chem. J. Chinese Universities, 2022, 43(8): 20220157. |

| [6] | YANG Dan, LIU Xu, DAI Yihu, ZHU Yan, YANG Yanhui. Research Progress in Electrocatalytic CO2 Reduction Reaction over Gold Clusters [J]. Chem. J. Chinese Universities, 2022, 43(7): 20220198. |

| [7] | ZHAO Yingzhe, ZHANG Jianling. Applications of Metal-organic Framework-based Material in Carbon Dioxide Photocatalytic Conversion [J]. Chem. J. Chinese Universities, 2022, 43(7): 20220223. |

| [8] | CHEN Weiqin, LYU Jiamin, YU Shen, LIU Zhan, LI Xiaoyun, CHEN Lihua, SU Baolian. Preparation of Organic Hybrid Mesoporous Beta Zeolite for Alkylation of Mesitylene with Benzyl Alcohol [J]. Chem. J. Chinese Universities, 2022, 43(6): 20220086. |

| [9] | LIU Qingqing, WANG Pu, WANG Yongshuai, ZHAO Man, DONG Huanli. Synthesis and Topochemical Polymerization Study of Naphthalene/perylene Imides Substituted Diacetylene Derivatives [J]. Chem. J. Chinese Universities, 2022, 43(6): 20220091. |

| [10] | SHI Naike, ZHANG Ya, SANSON Andrea, WANG Lei, CHEN Jun. Uniaxial Negative Thermal Expansion and Mechanism in Zn(NCN) [J]. Chem. J. Chinese Universities, 2022, 43(6): 20220124. |

| [11] | ZHU Kai, LI Jie, WU Xiaoyi, HU Weiwei, WU Dongmei, YU Chengxiao, GE Zhiwei, YE Xingqian, CHEN Shiguo. Combined PGC-Triple-Tof-MS Enables the Separation, Identification of Sugar Beet Pectin Derived Oligomers [J]. Chem. J. Chinese Universities, 2022, 43(6): 20220023. |

| [12] | XIA Tian, WAN Jiawei, YU Ranbo. Progress of the Structure-property Correlation of Heteroatomic Coordination Structured Carbon-based Single-atom Electrocatalysts [J]. Chem. J. Chinese Universities, 2022, 43(5): 20220162. |

| [13] | GU Yu, XI Baojuan, LI Jiangxiao, XIONG Shenglin. Structure Regulation of Single-atom Catalysts in Oxygen Reduction Reactions [J]. Chem. J. Chinese Universities, 2022, 43(5): 20220036. |

| [14] | XU Siran, YIN Hengbo, XUE Dongping, XIA Huicong, ZHAO Shuyan, YAN Wenfu, MU Shichun, ZHANG Jianan. Atomically Dispersed Metal-Nitrogen-Carbon Catalysts for Oxygen Reduction Reaction [J]. Chem. J. Chinese Universities, 2022, 43(5): 20220028. |

| [15] | GUO Jinchang, LIU Fanglin. Planar Pentacoordinate Silicon and Germanium in XBe5H6(X=Si, Ge) Clusters [J]. Chem. J. Chinese Universities, 2022, 43(4): 20210807. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||