Chem. J. Chinese Universities ›› 2019, Vol. 40 ›› Issue (9): 1888.doi: 10.7503/cjcu20190185

• Organic Chemistry • Previous Articles Next Articles

WU Rong1,2,DONG Qihui1,2,SUN Yiyi1,SU Erzheng1,2,*( )

)

Received:2019-03-27

Online:2019-09-10

Published:2019-07-29

Contact:

SU Erzheng

E-mail:ezhsu@njfu.edu.cn

Supported by:CLC Number:

TrendMD:

WU Rong, DONG Qihui, SUN Yiyi, SU Erzheng. Efficient Enzyme Immobilization by Combining Adsorption and Cellulose Membrane Coating †[J]. Chem. J. Chinese Universities, 2019, 40(9): 1888.

| Adsorption material | Protein immobilization yield(%) | Immobilized enzyme activity/(U·g-1) | Enzyme activity recovery rate(%) |

|---|---|---|---|

| D130 | 94.91±0.07 | 11.68±0.040 | 41.91±1.57 |

| HPD-450 | 99.01±0.06 | 12.18±0.016 | 40.49±0.27 |

| ADS-17 | 95.95±0.18 | 25.68±0.054 | 66.51±0.59 |

| HPD-417 | 95.11±0.07 | 28.57±0.032 | 60.33±0.46 |

| D101 | 96.21±0.33 | 9.38±0.042 | 30.38±0.34 |

| AB-8 | 95.65±0.03 | 10.34±0.12 | 39.63±0.90 |

| Activated carbon(30 mesh) | 34.12±0.49 | 6.01±0.012 | 43.29±1.34 |

| Activated carbon(40 mesh) | 35.49±0.33 | 6.09±0.022 | 37.64±0.46 |

| Zeolite | 38.69±0.25 | 9.44±0.026 | 42.96±0.61 |

| Kaolin | 55.55±0.25 | 29.07±0.016 | 98.13±1.12 |

| Imvite | 100.00 | 32.76±0.026 | 99.47±1.28 |

| Attapulgite | 58.92±0.40 | 13.05±0.032 | 53.08±1.76 |

| Diatomite | 51.47±0.09 | 30.61±0.022 | 98.38±2.62 |

| Adsorption material | Protein immobilization yield(%) | Immobilized enzyme activity/(U·g-1) | Enzyme activity recovery rate(%) |

|---|---|---|---|

| D130 | 94.91±0.07 | 11.68±0.040 | 41.91±1.57 |

| HPD-450 | 99.01±0.06 | 12.18±0.016 | 40.49±0.27 |

| ADS-17 | 95.95±0.18 | 25.68±0.054 | 66.51±0.59 |

| HPD-417 | 95.11±0.07 | 28.57±0.032 | 60.33±0.46 |

| D101 | 96.21±0.33 | 9.38±0.042 | 30.38±0.34 |

| AB-8 | 95.65±0.03 | 10.34±0.12 | 39.63±0.90 |

| Activated carbon(30 mesh) | 34.12±0.49 | 6.01±0.012 | 43.29±1.34 |

| Activated carbon(40 mesh) | 35.49±0.33 | 6.09±0.022 | 37.64±0.46 |

| Zeolite | 38.69±0.25 | 9.44±0.026 | 42.96±0.61 |

| Kaolin | 55.55±0.25 | 29.07±0.016 | 98.13±1.12 |

| Imvite | 100.00 | 32.76±0.026 | 99.47±1.28 |

| Attapulgite | 58.92±0.40 | 13.05±0.032 | 53.08±1.76 |

| Diatomite | 51.47±0.09 | 30.61±0.022 | 98.38±2.62 |

| Cellulose | Adsorption material | Immobilized enzyme activity by adsorption/(U·g-1) | Immobilized enzyme activity after coating/(U·g-1) | Residual enzyme activity after coating(%) |

|---|---|---|---|---|

| Cellulose acetate | Diatomite | 30.94±0.27 | 18.68±0.88 | 60.37±0.73 |

| ADS-17 | 25.56±1.92 | 17.60±0.93 | 68.88±0.39 | |

| HPD-417 | 27.66±0.83 | 19.91±1.21 | 71.99±1.38 | |

| Diacetate cellulose | Diatomite | 30.94±0.27 | 20.90±0.96 | 67.54±1.91 |

| ADS-17 | 25.56±1.92 | 18.76±0.77 | 73.41±1.28 | |

| HPD-417 | 27.66±0.83 | 20.78±0.35 | 75.11±0.93 | |

| Methyl cellulose | Diatomite | 30.94±0.27 | 21.03±0.93 | 67.97±1.36 |

| 40000—50000 | ADS-17 | 25.56±1.92 | 19.26±1.24 | 75.34±1.21 |

| HPD-417 | 27.66±0.83 | 21.55±0.82 | 77.91±0.63 | |

| Methyl cellulose | Diatomite | 30.94±0.27 | 21.47±0.69 | 69.38±1.91 |

| 12000—13000 | ADS-17 | 25.56±1.92 | 20.36±0.79 | 79.67±0.86 |

| HPD-417 | 27.66±0.83 | 21.18±0.83 | 76.56±1.22 |

| Cellulose | Adsorption material | Immobilized enzyme activity by adsorption/(U·g-1) | Immobilized enzyme activity after coating/(U·g-1) | Residual enzyme activity after coating(%) |

|---|---|---|---|---|

| Cellulose acetate | Diatomite | 30.94±0.27 | 18.68±0.88 | 60.37±0.73 |

| ADS-17 | 25.56±1.92 | 17.60±0.93 | 68.88±0.39 | |

| HPD-417 | 27.66±0.83 | 19.91±1.21 | 71.99±1.38 | |

| Diacetate cellulose | Diatomite | 30.94±0.27 | 20.90±0.96 | 67.54±1.91 |

| ADS-17 | 25.56±1.92 | 18.76±0.77 | 73.41±1.28 | |

| HPD-417 | 27.66±0.83 | 20.78±0.35 | 75.11±0.93 | |

| Methyl cellulose | Diatomite | 30.94±0.27 | 21.03±0.93 | 67.97±1.36 |

| 40000—50000 | ADS-17 | 25.56±1.92 | 19.26±1.24 | 75.34±1.21 |

| HPD-417 | 27.66±0.83 | 21.55±0.82 | 77.91±0.63 | |

| Methyl cellulose | Diatomite | 30.94±0.27 | 21.47±0.69 | 69.38±1.91 |

| 12000—13000 | ADS-17 | 25.56±1.92 | 20.36±0.79 | 79.67±0.86 |

| HPD-417 | 27.66±0.83 | 21.18±0.83 | 76.56±1.22 |

| Cellulose | Adsorption material | Immobilized enzyme activity by adsorption/(U·g-1) | Immobilized enzyme activity after coating/(U·g-1) | Residual enzyme activity after coating(%) |

|---|---|---|---|---|

| Cellulose acetate | Diatomite | 30.94±0.27 | 19.64±0.91 | 63.47±0.72 |

| ADS-17 | 25.56±1.92 | 17.24±1.21 | 67.47±0.69 | |

| HPD-417 | 27.66±0.83 | 19.29±0.66 | 69.74±1.35 | |

| Diacetate cellulose | Diatomite | 30.94±0.27 | 21.02±0.71 | 67.93±1.22 |

| ADS-17 | 25.56±1.92 | 17.30±1.92 | 67.69±0.82 | |

| HPD-417 | 27.66±0.83 | 19.89±1.25 | 71.89±0.69 | |

| Methylcellulose | Diatomite | 30.94±0.27 | 21.44±0.52 | 69.35±0.77 |

| 40000—50000 | ADS-17 | 25.56±1.92 | 18.79±1.12 | 73.51±0.96 |

| HPD-417 | 27.66±0.83 | 20.31±0.57 | 73.42±1.02 | |

| Methylcellulose | Diatomite | 30.94±0.27 | 21.60±0.82 | 69.81±1.28 |

| 12000—13000 | ADS-17 | 25.56±1.92 | 18.56±0.72 | 72.61±0.65 |

| HPD-417 | 27.66±0.83 | 21.04±0.91 | 76.07±0.74 |

| Cellulose | Adsorption material | Immobilized enzyme activity by adsorption/(U·g-1) | Immobilized enzyme activity after coating/(U·g-1) | Residual enzyme activity after coating(%) |

|---|---|---|---|---|

| Cellulose acetate | Diatomite | 30.94±0.27 | 19.64±0.91 | 63.47±0.72 |

| ADS-17 | 25.56±1.92 | 17.24±1.21 | 67.47±0.69 | |

| HPD-417 | 27.66±0.83 | 19.29±0.66 | 69.74±1.35 | |

| Diacetate cellulose | Diatomite | 30.94±0.27 | 21.02±0.71 | 67.93±1.22 |

| ADS-17 | 25.56±1.92 | 17.30±1.92 | 67.69±0.82 | |

| HPD-417 | 27.66±0.83 | 19.89±1.25 | 71.89±0.69 | |

| Methylcellulose | Diatomite | 30.94±0.27 | 21.44±0.52 | 69.35±0.77 |

| 40000—50000 | ADS-17 | 25.56±1.92 | 18.79±1.12 | 73.51±0.96 |

| HPD-417 | 27.66±0.83 | 20.31±0.57 | 73.42±1.02 | |

| Methylcellulose | Diatomite | 30.94±0.27 | 21.60±0.82 | 69.81±1.28 |

| 12000—13000 | ADS-17 | 25.56±1.92 | 18.56±0.72 | 72.61±0.65 |

| HPD-417 | 27.66±0.83 | 21.04±0.91 | 76.07±0.74 |

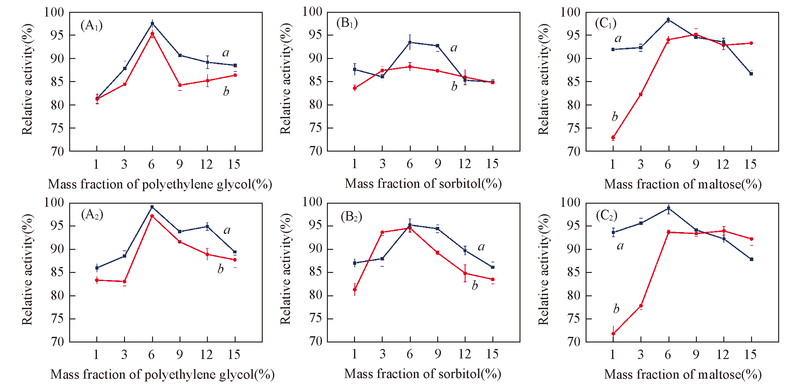

Fig.1 Effects of polyethylene glycol(A1, A2), sorbitol(B1, B2) and maltose(C1, C2) as protectants on immobilized papain with methyl cellulose(12000—13000)(A1—C1) and methyl cellulose(40000—50000)(A2—C2) dissolved in acetone as coating solution a. Diatomite; b. HPD-417.

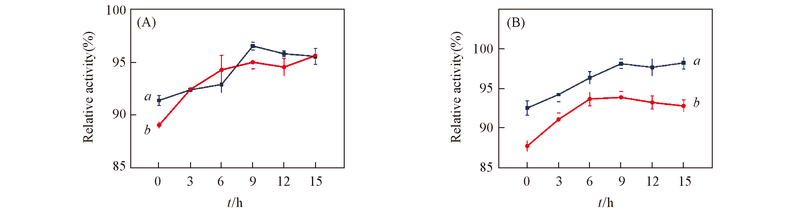

Fig.3 Effect of drying time on the immobilization of papain (A) Polyethylene glycol as the protectant; (B) maltose as the protectant. a. Diatomite; b. HPD-417.

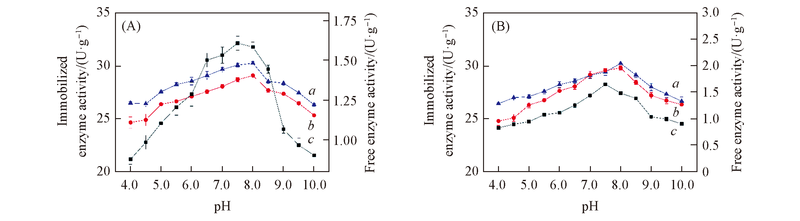

Fig.4 Optimal pH(A) and pH stability(B) of free and immobilized papain by adsorbing-cellulose membrane coating method a. Diatomite; b. HPD-417; c. free enzyme.

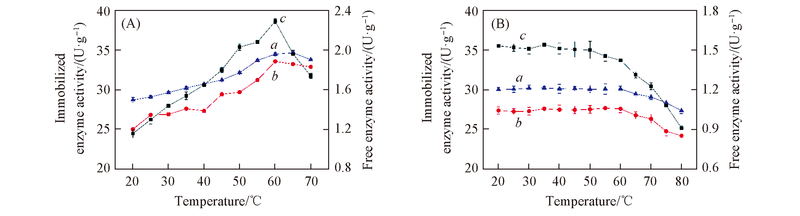

Fig.5 Optimum temperature(A) and thermal stability(B) of free and immobilized papain by adsorbing-cellulose membrane coating method a. Diatomite; b. HPD-417; c. free enzyme.

| [35] |

(雷青娟, 高保娇, 张正国.物理化学学报, 2011, 27( 11), 2697— 2704)

doi: 10.3866/PKU.WHXB20111122 |

| [36] | Raviyan P., Tang J., Rasco B. A ., J. Agric. Food Chem 2003, 51( 18), 5462— 5466 |

| [37] | Xiang X. R., Wan X. M., Suo H. B., Hu Y., ., Acta Phys.-Chim. Sin, 2018, 34( 1), 99— 107 |

| (相欣然, 万晓梅, 索红波, 胡燚.物理化学学报,2018,34(1), 99— 107) | |

| [1] | Hu Y., Yang J., Tang S. S., Chu X. M., Zou B., Huang H., ., Chem. J. Chinese Universities 2013, 34( 5), 1195— 1202 |

| (胡燚, 杨姣, 唐苏苏, 初旭明, 邹彬, 黄和. 高等学校化学学报, 2013, 34(5), 1195— 1202) | |

| [2] | Zheng G. W., Xu J. H ., Curr. Opin Biotechnol, 2011, 22( 6), 784— 792 |

| [3] | Sheldon R. A ., Adv. Synth Catal, 2007, 349( 8/9), 1289— 1307 |

| [4] | Datta S., Christena L. R., Rajaram Y. R. S., 3 Biotech , 2013, 3( 1), 1— 9 |

| [5] | Mateo C., Palomo J. M., Fernandez-Lorente G., Guisan J. M., Fernandez-Lafuente R ., Enzyme Microb Technol, 2007, 40( 4), 1451— 1463 |

| [6] | Rodrigues R. C., Ortiz C., Berenguer-Murcia Á., Torres R., Fernández-Lafuente R ., Chem. Soc Rev, 2013, 42( 15), 6290— 6307 |

| [7] | Wang M. F., Qi W., Su R. X., He Z. M., ., Chem. J. Chinese Universities 2010, 31( 9), 1774— 1779 |

| (王梦凡, 齐崴, 苏荣欣, 何志敏.高等学校化学学报, 2010, 31(9), 1774— 1779) | |

| [8] | Jesionowski T., Zdarta J., Krajewska B ., Adsorption, 2014, 20( 5/6), 801— 821 |

| [9] | Brady D., Jordaan J ., Biotechnol Lett, 2009, 31( 5), 1639 |

| [10] | Hanefeld U., Gardossi L., Magner E ., Chem. Soc Rev, 2009, 38( 2), 453— 468 |

| [11] | Sheldon R. A., Pelt S. V ., Chem. Soc Rev, 2013, 42( 15), 6223— 6235 |

| [12] | Ke C. X., Fan Y. L., Su F., Xu L., Yan Y. J., ., Chin. J. Biotech 2018, 34, 188— 203 |

| ( 柯彩霞, 范艳利, 苏枫, 徐莉, 闫云君 . 生物工程学报, 2018, 34, 188— 203) | |

| [13] | Su E. Z., Yang M., Ning C. X., Ma X. Q., Deng S. W ., J Biotechnol, 2018, 271( 1— 7 |

| [14] | Bradford M. M ., Anal Biochem, 1976, 72( 248— 254 |

| [15] | Li M. L., Su E. Z., You P. Y., Gong X. Y., Sun M. Xu D. S., Wei D. Z ., Plos One, 2010, 5( 12), e15168 |

| [16] | Singhania T., Sinha H., Das P., Mukherjee A. K ., Food Technol Biotechnol, 2015, 53( 1), 91— 95 |

| [17] | Qu Y., Sun L., Li X., Zhou S., Zhang Q., Sun L., Yu D., Jiang L., Tian B ., Food Sci Technol, 2016, 73( 290— 295 |

| [18] | Jesionowski T., Zdarta J., Krajewska B ., Adsorption, 2014, 20( 5/6), 801— 821 |

| [19] | Sheldon R. A., Van P. S ., ChemInform, 2013, 44( 38), 6223— 6235 |

| [20] | Lin K., Li S. X., Xu J. H., Pan J ., Food and Drug, 2011, 13( 5), 153— 156 |

| (林康, 李素霞, 许建和, 潘江.食品与药品,2011,13(5), 153— 156) | |

| [21] | Mateo C., Palomo J. M., Fernandez-Lorente G., Guisan J. M., Fernandez-Lafuente R ., Enzyme Microb Technol, 2007, 40( 4), 1451— 1463 |

| [22] | Sassolas A., Blum L. J., Leca-Bouvier B. D ., Biotechnol Adv, 2012, 30( 3), 489— 511 |

| [23] | Mislovi c ˙ ová D. , Masárová J., Vikartovská A., Gemeiner P., Michalková E ., J Biotechnol, 2004, 110( 1), 11— 19 |

| [24] | Drozd R., Rakoczy R., Wasak A., Junka A., Fija-Kowski K ., Int. J. Biol Macromol, 2018, 108( 462— 470 |

| [25] | Yan C Y., . Microporous Structure Control and Mechanical Performance Study of Micro/nanofibrillated cellulose Films, South China University of Technology, Guangzhou, 2018 |

| ( 闫长媛 . 微/纳米纤维素膜的微孔结构调控及力学性能研究, 广州: 华南理工大学, 2018) | |

| [26] | Hu Y. H., Dai R. J., Liu X. J., Chen Y. L., An J., Wang H. H., Deng Y. L., ., Fine Chem, 2015, 32( 7), 736— 740 |

| (胡英慧, 戴荣继, 刘秀洁, 陈彦丽, 安静, 王慧亨, 邓玉林.精细化工,2015,32(7), 736— 740) | |

| [27] | He P., Huang J. L., Shi Q. C., Wu G. H., Chu Z. Z., Huang Z. L., ., Journal of Northwest A&F University( Nat. Sci. Ed), 2009, 37(3),223—229, 234 |

| ( 何平, 黄家乐, 史清翠, 巫光宏, 初志战, 黄卓烈 . 西北农林科技大学学报(自然科学版), 2009, 37(3),223—229, 234) | |

| [28] | Yang J. C., Dong S., Yang X. M., ., J. Chem. Eng, 2000, 51( 2), 193— 197 |

| (杨基础, 董燊, 杨小民.化工学报,2000, 51( 2), 193— 197) | |

| [29] | Wang H. Y., Gao J., Wang H. O., ., Chin. J.Process Eng, 2008, 8( 6), 1190— 1194 |

| (王红玉, 高静, 王海鸥.过程工程学报, 2008, 8( 6), 1190— 1194) | |

| [30] | Yu M., Zhou H. Y., Ren L. W., Jiang Z. H., Zhou H., Wei P., ., Chin. J. Bioprocess Eng, 2015, 6, 18— 23 |

| ( 于敏, 周海燕, 任立伟, 蒋振华, 周华, 韦萍 . 生物加工过程, 2015, 6, 18— 23) | |

| [31] | Reetz M. T., Zonta A., Vijayakrishnan V., Schimossek K ., J. Mol. Catal A-Chem, 1998, 134( s1—3), 251— 258 |

| [32] | Levin Y., Pecht M., Goldstein L., Katchalski K ., Biochemistry, 1964, 3, 1905— 1913 |

| [33] | Sun X, Wang X ., Biosens Bioelectron, 2010, 25( 11), 2611— 2614 |

| [34] | Shao J J., . Studies on the Methods of Phytoesterase Immobilization and Its Application, Jilin Agricultural University, Changchun, 2008 |

| ( 邵佳甲 . 大豆酯酶的固定化及应用研究, 长春: 吉林农业大学, 2008) | |

| [35] |

Lei Q. J., Gao B. J., Zhang Z. G., ., Acta Phys.-Chim. Sin, 2011, 27( 11), 2697— 2704

doi: 10.3866/PKU.WHXB20111122 |

| [1] | JIANG Hongbin, DAI Wenchen, ZHANG Rao, XU Xiaochen, CHEN Jie, YANG Guang, YANG Fenglin. Research on Co3O4/UiO-66@α-Al2O3 Ceramic Membrane Separation and Catalytic Spraying Industry VOCs Waste Gas [J]. Chem. J. Chinese Universities, 2022, 43(6): 20220025. |

| [2] | HAO Honglei, MENG Fanyu, LI Ruoyu, LI Yingqiu, JIA Mingjun, ZHANG Wenxiang, YUAN Xiaoling. Biomass Derived Nitrogen Doped Porous Carbon Materials as Adsorbents for Removal of Methylene Blue in Water [J]. Chem. J. Chinese Universities, 2022, 43(6): 20220055. |

| [3] | WANG Hongning, HUANG Li, QING Jiang, MA Tengzhou, JIANG Wei, HUANG Weiqiu, CHEN Ruoyu. Activation of Biochar from Cattail and the VOCs Adsorption Application [J]. Chem. J. Chinese Universities, 2022, 43(4): 20210824. |

| [4] | MENG Xianglong, YANG Ge, GUO Hailing, LIU Chenguang, CHAI Yongming, WANG Chunzheng, GUO Yongmei. Synthesis of Nano-zeolite and Its Adsorption Performance for Hydrogen Sulfide [J]. Chem. J. Chinese Universities, 2022, 43(3): 20210687. |

| [5] | CHEN Xiaolu, YUAN Zhenyan, ZHONG Yingchun, REN Hao. Preparation of Triphenylamine Based PAF-106s via Mechanical Ball Milling and C2 Hydrocarbons Adsorption Property [J]. Chem. J. Chinese Universities, 2022, 43(3): 20210771. |

| [6] | TAN Lejian, ZHONG Xuanshu, WANG Jin, LIU Zongjian, ZHANG Aiying, YE Lin, FENG Zengguo. Low Critical Dissolution Temperature Behavior of β⁃Cyclodextrin and Its Application in the Preparation of β⁃Cyclodextrin Sheet Crystal with Ordered Nano⁃channel [J]. Chem. J. Chinese Universities, 2022, 43(11): 20220405. |

| [7] | ZHU Haotian, JIN Meixiu, TANG Wensi, SU Fang, LI Yangguang. Properties of Transition Metal-biimidazole-Dawson-type Tungstophosphate Hybrid Compounds as Supports for Enzyme Immobilization [J]. Chem. J. Chinese Universities, 2022, 43(11): 20220328. |

| [8] | TIAN Xiaokang, ZHANG Qingsong, YANG Shulin, BAI Jie, CHEN Bingjie, PAN Jie, CHEN Li, WEI Yen. Porous Materials Inspired by Microbial Fermentation: Preparation Method and Application [J]. Chem. J. Chinese Universities, 2022, 43(10): 20220216. |

| [9] | ZHENG Meiqi, MAO Fangqi, KONG Xianggui, DUAN Xue. Layered Double Hydroxides as Sorbent for Remediation of Radioactive Wastewater [J]. Chem. J. Chinese Universities, 2022, 43(10): 20220456. |

| [10] | MA Jianxin, LIU Xiaodong, XU Na, LIU Guocheng, WANG Xiuli. A Multi-functional Zn(II) Coordination Polymer with Luminescence Sensing, Amperometric Sensing, and Dye Adsorption Performance [J]. Chem. J. Chinese Universities, 2022, 43(1): 20210585. |

| [11] | ZHANG Chi, SUN Fuxing, ZHU Guangshan. Synthesis, N2 Adsorption and Mixed-matrix Membrane Performance of Bimetal Isostructural CAU-21 [J]. Chem. J. Chinese Universities, 2022, 43(1): 20210578. |

| [12] | LIU Changhui, LIANG Guojun, LI Yanlu, CHENG Xiufeng, ZHAO Xian. Density Functional Theory Study of NH3 Adsorption on Boron Nanotubes [J]. Chem. J. Chinese Universities, 2021, 42(7): 2263. |

| [13] | WANG Hongning, HUANG Li, SONG Fujiao, ZHU Ting, HUANG Weiqiu, ZHONG Jing, CHEN Ruoyu. Synthesis and VOCs Adsorption Properties of Hollow Carbon Nanospheres [J]. Chem. J. Chinese Universities, 2021, 42(6): 1704. |

| [14] | WANG Longjie, FAN Hongchuan, QIN Yu, CAO Qiue, ZHENG Liyan. Research Progress of Metal-organic Frameworks in the Field of Chemical Separation and Analysis [J]. Chem. J. Chinese Universities, 2021, 42(4): 1167. |

| [15] | YAN Yanhong, WU Simin, YAN Yilun, TANG Xihao, CAI Songliang, ZHENG Shengrun, ZHANG Weiguang, GU Fenglong. Sulfonic Acid-functionalized Spherical Covalent Organic Framework with Ultrahigh Capacity for the Removal of Cationic Dyes [J]. Chem. J. Chinese Universities, 2021, 42(3): 956. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||