Chem. J. Chinese Universities ›› 2018, Vol. 39 ›› Issue (8): 1838.doi: 10.7503/cjcu20170784

• Polymer Chemistry • Previous Articles Next Articles

LUO Dajun1,2, SHAO Huiju1,2, JIN Jinbo2, XIE Gaoyi2, CUI Zhenyu2, YU Jie1,2,*( ), QIN Shuhao2,*(

), QIN Shuhao2,*( )

)

Received:2017-12-01

Online:2018-08-10

Published:2018-06-11

Contact:

YU Jie,QIN Shuhao

E-mail:qinshgz@163.com;yujiegz@126.com

CLC Number:

TrendMD:

LUO Dajun, SHAO Huiju, JIN Jinbo, XIE Gaoyi, CUI Zhenyu, YU Jie, QIN Shuhao. Preparation of Hydrophilic Polypropylene/Polyvinyl Butyral Hollow Fiber Membranes by Melt-spinning-stretching†[J]. Chem. J. Chinese Universities, 2018, 39(8): 1838.

| Sample | w(PP)(%) | w(PP-g-MAH)(%) | w(PVB)(%) |

|---|---|---|---|

| Pure PP | 100 | 0 | 0 |

| PP/PVB2.5 | 97.5 | 2 | 2.5 |

| PP/PVB5 | 95 | 2 | 5 |

| PP/PVB7.5 | 92.5 | 2 | 7.5 |

| PP/PVB10 | 90 | 2 | 10 |

Table 1 Compositions of the PP/PVB blends

| Sample | w(PP)(%) | w(PP-g-MAH)(%) | w(PVB)(%) |

|---|---|---|---|

| Pure PP | 100 | 0 | 0 |

| PP/PVB2.5 | 97.5 | 2 | 2.5 |

| PP/PVB5 | 95 | 2 | 5 |

| PP/PVB7.5 | 92.5 | 2 | 7.5 |

| PP/PVB10 | 90 | 2 | 10 |

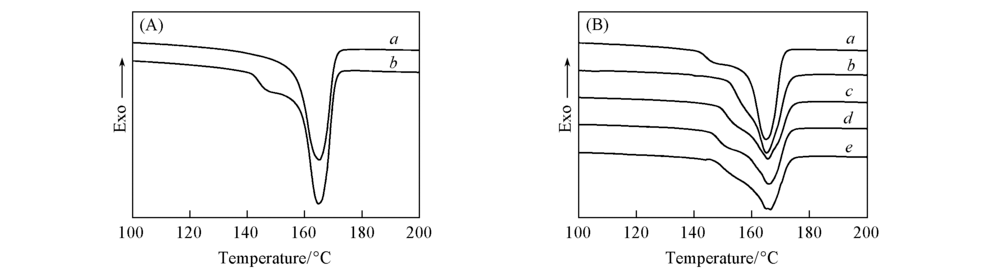

Fig.3 DSC thermograms of hollow fibers(A) a. Pure PP; b. annealed PP; (B) a. annealed PP; b. annealed PP/PVB2.5; c. annealed PP/PVB5;d. annealed PP/PVB7.5; e. annealed PP/PVB10.

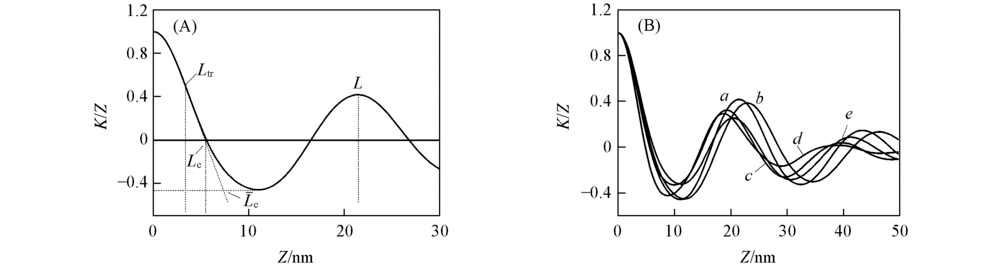

Fig.9 Curve of one-dimensional correlation function for pure PP(A) and PP/PVB blends(B) annealed hollow fibers(B) a. Pure PP; b. PP/PVB2.5; c. PP/PVB5; d. PP/PVB7.5; e. PP/PVB10.

| Sample | L/nm | Lc/nm | Ltr/nm | La/nm |

|---|---|---|---|---|

| Pure PP | 21.6 | 5.4 | 3.4 | 9.4 |

| PP/PVB2.5 | 20.5 | 5.9 | 3.4 | 7.8 |

| PP/PVB5 | 22.8 | 5.7 | 3.8 | 9.5 |

| PP/PVB7.5 | 19.2 | 5.0 | 3.4 | 7.2 |

| PP/PVB10 | 18.7 | 4.2 | 3.5 | 7.0 |

Table 2 Microstructure characteristics of pure PP and PP/PVB annealed hollow fibers

| Sample | L/nm | Lc/nm | Ltr/nm | La/nm |

|---|---|---|---|---|

| Pure PP | 21.6 | 5.4 | 3.4 | 9.4 |

| PP/PVB2.5 | 20.5 | 5.9 | 3.4 | 7.8 |

| PP/PVB5 | 22.8 | 5.7 | 3.8 | 9.5 |

| PP/PVB7.5 | 19.2 | 5.0 | 3.4 | 7.2 |

| PP/PVB10 | 18.7 | 4.2 | 3.5 | 7.0 |

| Sample | Do/μm | Di/μm | Thickness/μm | Porosity(%) | Flux/(L·m-2·h-1) |

|---|---|---|---|---|---|

| Pure PP | 478 | 370 | 54 | 55 | 181 |

| PP/PVB2.5 | 482 | 372 | 55 | 66 | 320 |

| PP/PVB5 | 420 | 321 | 50 | 51 | 210 |

| PP/PVB7.5 | 344 | 258 | 43 | 33 | 64 |

| PP/PVB10 | 273 | 197 | 38 | 19 | 25 |

Table 3 Structure parameters and pure water flux of pure PP and PP/PVB hollow fiber membranes*

| Sample | Do/μm | Di/μm | Thickness/μm | Porosity(%) | Flux/(L·m-2·h-1) |

|---|---|---|---|---|---|

| Pure PP | 478 | 370 | 54 | 55 | 181 |

| PP/PVB2.5 | 482 | 372 | 55 | 66 | 320 |

| PP/PVB5 | 420 | 321 | 50 | 51 | 210 |

| PP/PVB7.5 | 344 | 258 | 43 | 33 | 64 |

| PP/PVB10 | 273 | 197 | 38 | 19 | 25 |

| [1] | Ni Y., Wang M., Chen H.Z., J. Mater. Sci. Eng., 2011, 29(3), 351—354 |

| (倪阳, 汪茫, 陈红征. 材料科学与工程学报, 2011, 29(3), 351—354) | |

| [2] | Lv Y.X., Yu X. H., Tu S. T., Yan J. Y., Dahlquist E., Applied Energy, 2012, 97(9), 283—288 |

| [3] | Duan Y.F., Pan F., J. Textile Res., 2005, 26(3), 29—31 |

| (段亚峰, 潘峰. 纺织学报, 2005, 26(3), 29—31) | |

| [4] | Fan L.H., Harris J. L., Roddick F. A., Booker N. A, Water Res., 2001, 35(18), 4455—4463 |

| [5] | Luo D.J., Xiao D. R., Huang W. J., Zhong J. C., Wei F. J., Plastics, 2015, 44(2), 99—103 |

| (罗大军, 肖登荣, 黄伟江, 钟金成, 韦福建, 秦舒浩. 塑料, 2015, 44(2), 99—103) | |

| [6] | Mafrosovich M.N., Andreev V. G., Kostrov Y. A., Butnitskii G. A, Fiber Chem., 1983, 15(4), 1214—1217 |

| [7] | Sadeghi F., Ajji A., Carreau P.J., J. Membr. Sci., 2007, 292(1/2), 62—71 |

| [8] | Li N.N., Xiao C. F., Mei S, Zhang S. J., Desalination, 2011, 274(1—3), 284—291 |

| [9] | Chen H., Shi X., Zhu Y., Xu J., J. Appl. Polym. Sci., 2009, 114(4), 2461—2468 |

| [10] | Xu M., Shi X., Chen H., Xiao T., Appl. Surf. Sci., 2010, 256(10), 3240—3244 |

| [11] | Zhang C., Bai Y., Sun Y., Gu J., Xu Y., J. Membr. Sci., 2010, 365(1), 216—224 |

| [12] | Hester J.F., Banerjee P., Won Y. Y., Akthakul A., Acar M. H., Mayeset A. M., Macromolecules, 2002, 35(20), 7652—7661 |

| [13] | Meier-Haack J., Valko M., Lunkwitz K., Bleha M., Desalination, 2004, 163(1—3), 215—221 |

| [14] | Saffar A., Ajji A., Carreau P.J., Musa R., J. Membr. Sci., 2014, 462(28), 50—61 |

| [15] | Tabatabaei S.H., Carreau P. J., Ajji A., J. Membr. Sci., 2008, 325(2), 772—782 |

| [16] | Fan Q.C., Duan F. H., Guo H. B., Wu T., Chinese J. Chem. Eng., 2015, 23(2), 441—445 |

| [17] | Zhou H.M., Ying J. R., Liu F., Xie X. L., Li D. Q., Polym. Testing, 2010, 29(6), 640—647 |

| [18] | Qiu Y.R., Matsuyama H., Desalination, 2010, 25(7), 117—123 |

| [19] | Qiu Y. R., Qi J., J. Membr. Sci., 2013, 425—426(1), 71—76 |

| [20] | Zhao Z.N., Zhang N., J. Tianjin University Sci. & Tech., 2007, 22(3), 36—39 |

| (赵梓年, 张楠. 天津科技大学学报, 2007, 22(3), 36—39) | |

| [21] | Qiu Y.R., Rahman N. A., Matsuyama H., Separation & Purification Tech., 2008, 61(1), 1—8 |

| [22] | Cascone E., David D.J., Di. Lorenzo M. L., Karasz F. E., Macknight W. J., Martuscelli E., Raimo M., J. Appl. Polym. Sci., 2001, 82(12), 2934—2946 |

| [23] | Bagheriasl D., Carreau P.J., Dubois C., Riedl B., Composites Sci. Tech., 2015, 117, 357—363 |

| [24] | Wu N.J., Yang P., Acta Polymerica Sinica, 2010, (3), 316—323 |

| (吴宁晶, 杨鹏. 高分子学报, 2010, (3), 316—323) | |

| [25] | Park I.K., Noether H. D., Colloid Polym. Sci., 1975, 253(10), 824—839 |

| [26] | Yu T H., Processing and Structure-property Behavior of Microporous Polyethylene: from Resin to Final Film, Virginia Polytechnic Institute and State University, Virginia, 1996 |

| [27] | Shao H.J., Wei F. J., Wu B., Zhang K. Z., Yao Y., Liang S. M., Qin S. H., RSC Advances, 2016, 6(6), 4271—4279 |

| [28] | Shao C.G., Zhou R. R., Li Q., Cao W., Zhang Y., Zhang R. J., Liu C. G., Shen C. Y., Chem. J. Chinese Universities, 2013, 34(2), 485—490 |

| (邵春光, 卓然然, 李倩, 曹伟, 张阳, 张瑞静, 刘成刚, 申长雨. 高等学校化学学报, 2013, 34(2), 485—490) |

| [1] | JIA Hongjun, ZHANG Jiatao, MA Zhuoli, WANG Heng, YANG Xinyu, YANG Jiazhi. Preparation of PTFE/PAA/Nafion Composite Membrane by Aqueous Polymerization of Acrylic Acid and Its Properties [J]. Chem. J. Chinese Universities, 2022, 43(11): 20220350. |

| [2] | GAO Yifei, XIAO Changfa, JI Dawei, HUANG Yangzheng. Preparation of PVDF Hollow Fiber Membranes via Melt Spinning-stretching Method and Its Oil-water Separation Performance [J]. Chem. J. Chinese Universities, 2021, 42(6): 2065. |

| [3] | QU Dawei, LI Xin, CHEN Guangming. Fabrication and Properties of Flexible Thermoelectric Devices† [J]. Chem. J. Chinese Universities, 2019, 40(4): 617. |

| [4] | WANG Peng, WU Xian, ZHANG Hanyu, YOU Kaiyuan, LIU Zhenchao, LIU Baijun. Preparation of the Blend Membranes Based on Sulfonated Polyetheretherketoneketone and Amine-terminated Hyperbranched Polyimide† [J]. Chem. J. Chinese Universities, 2018, 39(3): 405. |

| [5] | YOU Yanwei, XIAO Changfa, WANG Chun, HUANG Qinglin, CHEN Mingxing, HUANG Yan. Preparation and Properties of Poly(tetrafluoroethylene-co-hexafluoropropylene) Hollow Fiber Membranes† [J]. Chem. J. Chinese Universities, 2017, 38(9): 1678. |

| [6] | LIU Xuewu,CHEN Shuhua,ZHAN Shiping. Experimental Study and Theoretical Phase Diagram Calculation for Polystyrene Membranes Prepared by Supercritical CO2-induced Phase Inversion† [J]. Chem. J. Chinese Universities, 2016, 37(8): 1573. |

| [7] | YAN Kaibo,GUO Guibao,LIU Jinyan. Synthesis of Oil/Water Separation Membranes via Grafting Acrylic Acid onto Poly(vinylidene fluoride) Modified by Tetraethyl Ammonium Hydroxide† [J]. Chem. J. Chinese Universities, 2016, 37(8): 1565. |

| [8] | LIU Rong, ZHA Fei, YANG Aimei, CHANG Yue. Synthesis of Light Olefins from CO2 Hydrogenation Catalyzed over Rare Earths Modified CuO-ZnO-ZrO2/SAPO-34† [J]. Chem. J. Chinese Universities, 2016, 37(5): 964. |

| [9] | CHEN Xiaolin, WU Hao, LIU Lifen, GAO Congjie. Synthesis and Characterization of Trimesoylamidoamine† [J]. Chem. J. Chinese Universities, 2016, 37(5): 983. |

| [10] | QIN Yichao, YE Jian, JIANG Binbo, WANG Jingdai, YANG Yongrong. Ethylene Oligomerization and Friedel-Crafts Alkylation Tandem Action Catalyzed by Aryloxy Zirconium Catalysts† [J]. Chem. J. Chinese Universities, 2015, 36(9): 1825. |

| [11] | ZHAO Xiaoxia, GAO Xiaoya, ZHANG Xiaochao, LI Rui, WANG Yawen, WANG Yunfang, FAN Caimei. Tunable Synthesis of Hierarchical BiOCl Microspheres for Efficient Photocatalytic Degradation of Pharmaceutical Wastewater† [J]. Chem. J. Chinese Universities, 2015, 36(5): 955. |

| [12] | DUAN Xinli, ZHANG Xin, LEI Ming. QM/MM Molecular Dynamics Simulation on the Mechanisms for the Hydrolytic Deamination of Nicotinamidase† [J]. Chem. J. Chinese Universities, 2015, 36(12): 2491. |

| [13] | SONG Min, ZHANG Linping, ZHONG Yi, XU Hong, MAO Zhiping. Catalytic Properties of Manganese Complex of Cyclic Polyamine Encapsulated in Ethyl Cellulose Microcapsules† [J]. Chem. J. Chinese Universities, 2014, 35(9): 1941. |

| [14] | GE Kaikai, QIU Wenfeng, HAN Weijian, YE Li, ZHAO Aijun, ZHAO Tong. Synthesis, Characterization and Pyrolysis Behavior of ZrB2/SiC Precursor† [J]. Chem. J. Chinese Universities, 2014, 35(9): 2050. |

| [15] | ZHANG Lingna, TAO Jinhui, JI Kaiji, YUE Qunfeng. Synthesis of Mesoporous Carbon/Iron Carbide Material and Its Hydrogen Storage Capacity† [J]. Chem. J. Chinese Universities, 2014, 35(6): 1318. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||