Chem. J. Chinese Universities ›› 2016, Vol. 37 ›› Issue (8): 1565.doi: 10.7503/cjcu20160224

• Polymer Chemistry • Previous Articles Next Articles

YAN Kaibo, GUO Guibao*( ), LIU Jinyan

), LIU Jinyan

Received:2016-04-08

Online:2016-07-13

Published:2016-07-13

Contact:

GUO Guibao

E-mail:ggb66733@sohu.com

Supported by:CLC Number:

TrendMD:

YAN Kaibo,GUO Guibao,LIU Jinyan. Synthesis of Oil/Water Separation Membranes via Grafting Acrylic Acid onto Poly(vinylidene fluoride) Modified by Tetraethyl Ammonium Hydroxide†[J]. Chem. J. Chinese Universities, 2016, 37(8): 1565.

| Sample | Elemental content(%) | ||

|---|---|---|---|

| C | F | O | |

| PVDF | 63.81 | 36.19 | 0 |

| PVDF-g-PAA | 64.78 | 26.10 | 9.12 |

Table 1 Element relative atomic percentage as determined by XPS analysis

| Sample | Elemental content(%) | ||

|---|---|---|---|

| C | F | O | |

| PVDF | 63.81 | 36.19 | 0 |

| PVDF-g-PAA | 64.78 | 26.10 | 9.12 |

| Membrane | ε(%) | rm/nm |

|---|---|---|

| PVDF | 58.2 | 42.5 |

| PVDF-g-PAA | 65.3 | 78.0 |

Table 2 Porosity and pore size of pure PVDF membrane and PVDF-g-PAA(GD=20.1%) membrane

| Membrane | ε(%) | rm/nm |

|---|---|---|

| PVDF | 58.2 | 42.5 |

| PVDF-g-PAA | 65.3 | 78.0 |

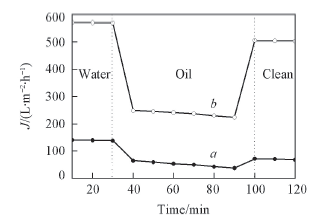

Fig.9 Time-dependent flux of pure PVDF membrane(a) and PVDF-g-PAA(GD=20.1%)(b) membrane during water filtration, oil/water emulsion filtration, water filtration after being clean

| [1] |

Zhu X., Y. , Tu W., T. , Wee K., H. , Bai R., B. , J. Membr. Sci., 2014, 466, 36- 44

doi: 10.1016/j.eurpolymj.2014.03.021 URL |

| [2] | Kang G., D. , Cao Y., M. , J. Membr. Sci., 2014, 463, 145- 165 |

| [3] |

Pereira V., R. , Isloor A., M. , Bhat U., K. , Ismail A., F. , Desalination, 2014, 351, 220- 227

doi: 10.1016/j.desal.2014.08.002 URL |

| [4] | Huang, X. , Zhang, J. , Wang W., P. , Liu Y., D. , Zhang Z., B. , Li, L. , Fan W., L. , RSC Adv., 2015, 5, 18258- 18266 |

| [5] |

吴超超, 刘根, 徐君莉, 张霞. 高等学校化学学报, 2014, 35( 4), 784- 790

doi: 10.7503/cjcu20131265 |

|

Wu C., C. , Liu, G. , Xu J., L. , Zhang, X. , Chem. J. Chinese Universities, 2014, 35( 4), 784- 790

doi: 10.7503/cjcu20131265 |

|

| [6] |

Zhu Y., Z. , Zhang, F. , Wang, D. , Pei X., F. , Zhang W., B. , Jin, J. , J. Mater. Chem. A, 2013, 1, 5758- 5765

doi: 10.1039/C3TA01598J URL |

| [7] |

Liu, F. , Hashim N., A. , Liu Y., T. , Abed M. R., M. , Li, K. , J. Membr. Sci., 2011, 375, 1- 27

doi: 10.1177/0192623311407213 URL pmid: 21571946 |

| [8] |

Liu T., Y. , Zhang R., X. , Li, Q. , Bruggen B., V. , Wang X., L. , J. Membr. Sci., 2014, 472, 119- 132

doi: 10.1016/j.memsci.2014.08.028 URL |

| [9] | Lee J., W. , Jung J., Y. , Cho Y., H. , Yadav S., K. , Baek K., Y. , Park H., B. , Hong S., M. , Koo C., M. , ACS Appl. Mater. Inter., 2014, 6, 14600- 14607 |

| [10] |

Tao M., M. , Liu, F. , Xue L., X. , J. Mater. Chem., 2012, 22, 9131- 9137

doi: 10.1039/C2JM30695F URL |

| [11] |

Wang, L. , Pan, K. , Li, L. , Cao, B. , Ind. Eng. Chem. Res., 2014, 53, 6401- 6408

doi: 10.1021/ie4042388 URL |

| [12] | Liu, J. , Shen, X. , Zhao Y., P. , Chen, L. , Ind. Eng. Chem Res., 2013, 52, 18392- 18400 |

| [13] | Yang X., X. , Deng, B. , Liu Z., Y. , Shi L., Q. , Bian X., K. , Yu, M. , Li L., F. , Li J., Y. , Lu X., F. , J. Membr. Sci., 2010, 362, 298- 305 |

| [14] | Yin, gL. , Yu W., H. , Kang E., T. , Neoh K., G. , Langmuir, 2004, 20, 6032- 6040 |

| [15] |

Li L., L. , Yin Z., H. , Li F., L. , Xiang, T. , Chen, Y. , Zhao, C.S. , J. Membr. Sci., 2010, 349, 56- 64

doi: 10.1016/j.memsci.2009.11.018 URL |

| [16] |

Hua H., L. , Xiong, Y. , Fu C., J. , Li, N. , RSC Adv., 2014, 4, 39273- 39279

doi: 10.1039/c4ra06368f URL |

| [17] |

Tsarevsky, N. , V., Matyjaszewski, K. , Chem. Rev., 2007, 107, 2270- 2299

doi: 10.1002/chin.200736258 URL |

| [18] |

Zhao X., D. , Song L., Z. , Fu, J. , Tang, P. , Liu, F. , Surf. Sci., 2011, 605, 1005- 1015

doi: 10.1016/j.susc.2011.02.022 URL |

| [19] | 林先凯, 冯霞, 陈莉. 高等学校化学学报, 2010, 31( 2), 402- 405 |

| Lin X., K. , Feng, X. , Chen, L. , Chem. J. Chinese Universities, 2010, 31( 2), 402- 405 | |

| [20] |

Ross G., J. , Watts J., F. , Hill M. P. Morrissey, P. , Polymer, 2000, 41, 1685- 1696

doi: 10.1016/S0032-3861(99)00343-2 URL |

| [21] |

Ross G., J. , Watts J., F. , Hill M. P. Morrissey, P. , Polymer, 2001, 42, 403- 413

doi: 10.1016/S0032-3861(00)00328-1 URL |

| [22] | Zhang, X. , Wang, Y. , Liu Y., F. , Xu J., L. , Han Y., D. , Xu X., X. , Appl. Surf. Sci., 2014, 316, 333- 340 |

| [23] |

Yang, J. , Mei, S. , Ferreira José, M. F. , J. Am. Ceram. Soc., 2001, 84, 1696- 1702

doi: 10.1111/j.1151-2916.2001.tb00901.x URL |

| [24] | Xing Q. Y., Pei W. W., Xu R. Q., Pei J., Basic Organic Chemistry, 3rd Ed., Senior Education Press, Beijing, 2005, 290— 291 |

| ( 刑其毅, 裴伟伟, 徐瑞秋, 裴坚. 基础有机化学, 第3版, 北京: 高等教育出版社, 2005, 290— 291) | |

| [25] |

Shi F., M. , Ma Y., X. , Ma, J. , Wang P., P. , Sun W., X. , J. Membr. Sci., 2012, 389, 522- 531

doi: 10.1073/pnas.1109912109 URL pmid: 22307610 |

| [26] | Deng, B. , Yu, M. , Yang X., X. , Zhang B., W. , Li F., L. , Xie L., D. , Li J., Y. , Lu X., F. , J. Membr. Sci., 2010, 350, 252- 258 |

| [27] | Qin A., W. , Wu X., L. , Ma B., M. , Zhao X., Z. , He C., J. , J. Membr. Sci., 2014, 49, 7797- 7808 |

| [28] | Pan Z. R., Macromolecule Chemistry(Enhanced Editions), Chemical Industry Press, Beijing, 2007, 80— 81 |

| ( 潘祖仁. 高分子化学(增强版), 北京: 化学工业出版社, 2007, 80— 81) | |

| [29] |

Yan, L. , Li Y., S. , Xiang C., B. , Polymer, 2005, 46, 7701- 7706

doi: 10.1016/j.polymer.2005.05.155 URL |

| [30] |

Yu H., Q. , Li Y., H. , Zhao H., J. , Membr. Sci. Technol., 2010, 30, 29- 33

doi: 10.1016/j.jhazmat.2010.06.029 URL pmid: 20621418 |

| [1] | ZHANG Shuting, AN Qi. Progress on the Design and Fabrication of High Performance Piezoelectric Flexible Materials Based on Polyvinylidene Fluoride [J]. Chem. J. Chinese Universities, 2021, 42(4): 1114. |

| [2] | QU Dawei, LI Xin, CHEN Guangming. Fabrication and Properties of Flexible Thermoelectric Devices† [J]. Chem. J. Chinese Universities, 2019, 40(4): 617. |

| [3] | LUO Dajun, SHAO Huiju, JIN Jinbo, XIE Gaoyi, CUI Zhenyu, YU Jie, QIN Shuhao. Preparation of Hydrophilic Polypropylene/Polyvinyl Butyral Hollow Fiber Membranes by Melt-spinning-stretching† [J]. Chem. J. Chinese Universities, 2018, 39(8): 1838. |

| [4] | WANG Peng, WU Xian, ZHANG Hanyu, YOU Kaiyuan, LIU Zhenchao, LIU Baijun. Preparation of the Blend Membranes Based on Sulfonated Polyetheretherketoneketone and Amine-terminated Hyperbranched Polyimide† [J]. Chem. J. Chinese Universities, 2018, 39(3): 405. |

| [5] | JIN Lin, XU Qinwei, HU Bin, HUANG Jingbin, ZHANG Yilei, WANG Zhenling. Tuneable Three-dimensional Cytocompatible Micro-environments Designed by Controlled Alignment of PVDF Electrospun Fibres [J]. Chem. J. Chinese Universities, 2017, 38(6): 1002. |

| [6] | LIU Xuewu,CHEN Shuhua,ZHAN Shiping. Experimental Study and Theoretical Phase Diagram Calculation for Polystyrene Membranes Prepared by Supercritical CO2-induced Phase Inversion† [J]. Chem. J. Chinese Universities, 2016, 37(8): 1573. |

| [7] | GAO Hong, DUAN Yueqin, YUAN Zhihao. Preparation of Superhydrophilic and Underwater Superoleophobic PVDF-g-PAA Porous Membranes and Their Oil-water Separation Performance† [J]. Chem. J. Chinese Universities, 2016, 37(6): 1208. |

| [8] | LIU Rong, ZHA Fei, YANG Aimei, CHANG Yue. Synthesis of Light Olefins from CO2 Hydrogenation Catalyzed over Rare Earths Modified CuO-ZnO-ZrO2/SAPO-34† [J]. Chem. J. Chinese Universities, 2016, 37(5): 964. |

| [9] | CHEN Xiaolin, WU Hao, LIU Lifen, GAO Congjie. Synthesis and Characterization of Trimesoylamidoamine† [J]. Chem. J. Chinese Universities, 2016, 37(5): 983. |

| [10] | XING Chenyang, WANG Yanyuan, LI Yongjin, LI Jingye. Crystallization Behavior of Nanostructured Poly(vinylidene fluoride)/1-Vinyl-3-butylimidazolium Chloride Ionic Liquid Composites† [J]. Chem. J. Chinese Universities, 2016, 37(4): 775. |

| [11] | QIN Yichao, YE Jian, JIANG Binbo, WANG Jingdai, YANG Yongrong. Ethylene Oligomerization and Friedel-Crafts Alkylation Tandem Action Catalyzed by Aryloxy Zirconium Catalysts† [J]. Chem. J. Chinese Universities, 2015, 36(9): 1825. |

| [12] | ZHAO Xiaoxia, GAO Xiaoya, ZHANG Xiaochao, LI Rui, WANG Yawen, WANG Yunfang, FAN Caimei. Tunable Synthesis of Hierarchical BiOCl Microspheres for Efficient Photocatalytic Degradation of Pharmaceutical Wastewater† [J]. Chem. J. Chinese Universities, 2015, 36(5): 955. |

| [13] | DUAN Xinli, ZHANG Xin, LEI Ming. QM/MM Molecular Dynamics Simulation on the Mechanisms for the Hydrolytic Deamination of Nicotinamidase† [J]. Chem. J. Chinese Universities, 2015, 36(12): 2491. |

| [14] | SONG Min, ZHANG Linping, ZHONG Yi, XU Hong, MAO Zhiping. Catalytic Properties of Manganese Complex of Cyclic Polyamine Encapsulated in Ethyl Cellulose Microcapsules† [J]. Chem. J. Chinese Universities, 2014, 35(9): 1941. |

| [15] | GE Kaikai, QIU Wenfeng, HAN Weijian, YE Li, ZHAO Aijun, ZHAO Tong. Synthesis, Characterization and Pyrolysis Behavior of ZrB2/SiC Precursor† [J]. Chem. J. Chinese Universities, 2014, 35(9): 2050. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||