Chem. J. Chinese Universities ›› 2016, Vol. 37 ›› Issue (12): 2306.doi: 10.7503/cjcu20160429

• Polymer Chemistry • Previous Articles Next Articles

WU Linghui1,2, WANG Bin1,2, WANG Jiaona1,2, LI Congju1,2,3,*( )

)

Received:2016-06-13

Online:2016-12-10

Published:2016-11-18

Contact:

LI Congju

E-mail:congjuli2014@126.com

Supported by:CLC Number:

TrendMD:

WU Linghui, WANG Bin, WANG Jiaona, LI Congju. Preparation and Filtration Performance of Antifouling PVA/PVDF Composite Ultrafiltration Membrane Based on Electrospinning Technology†[J]. Chem. J. Chinese Universities, 2016, 37(12): 2306.

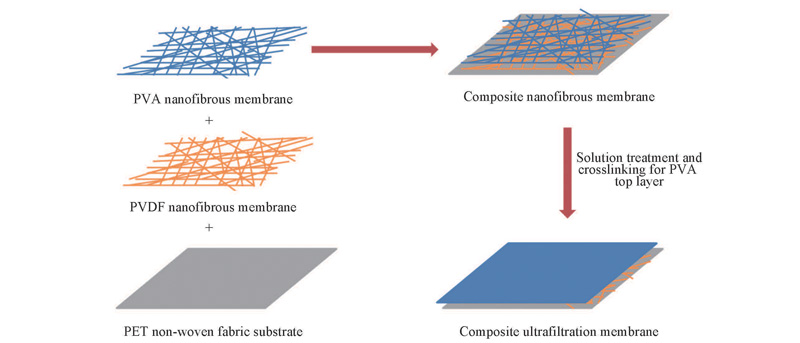

Scheme 1 Fabrication flow chart of the composite ultrafiltration membrane with PET non-woven fabric as substrate and PVDF nanofibers as middle layer and PVA nanofibers as the barrier layer

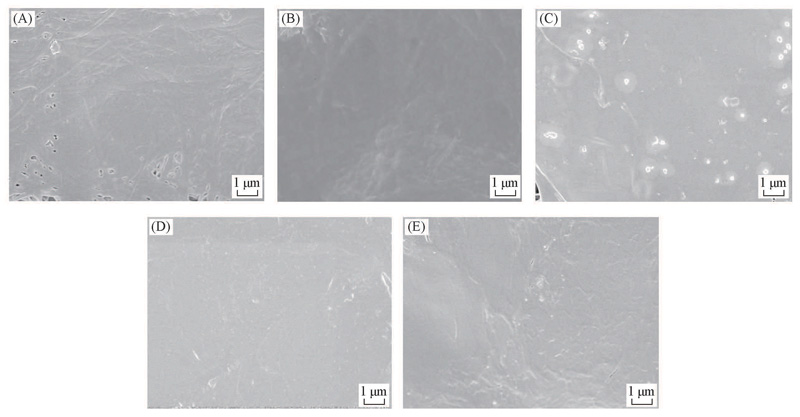

Fig.3 SEM images of composite ultrafiltration membrane surface morphology with different PVA nanofibers electrospinning timeTime/h: (A) 1; (B) 2; (C) 3; (D) 4; (E) 5.

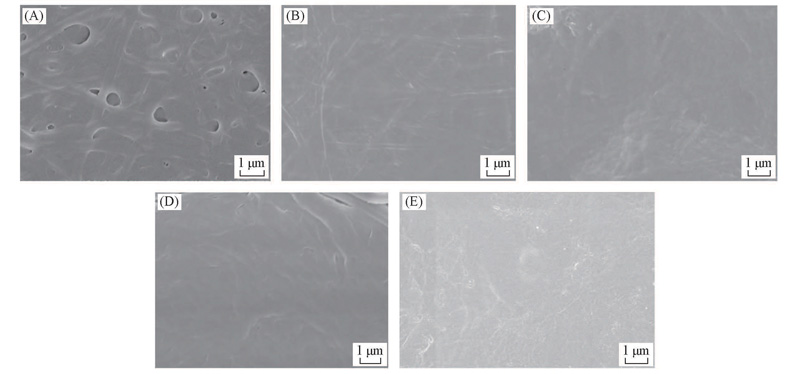

Fig.4 Surface morphology of composite ultrafiltration membrane at different crosslinked temperatures Temperature/℃: (A) 20; (B) 30; (C) 40; (D) 50 ; (E) 60.

| Temperature/℃ | 20 | 30 | 40 | 50 | 60 |

|---|---|---|---|---|---|

| mL(%) | 0.38 | 0 | 0.35 | 0.13 | 0.25 |

| mS(%) | 80.08 | 70.82 | 74.35 | 73.15 | 69.59 |

Table 1 Massloss rates and swelling degrees of the composite ultrafiltration membranes under different crosslinking temperatures

| Temperature/℃ | 20 | 30 | 40 | 50 | 60 |

|---|---|---|---|---|---|

| mL(%) | 0.38 | 0 | 0.35 | 0.13 | 0.25 |

| mS(%) | 80.08 | 70.82 | 74.35 | 73.15 | 69.59 |

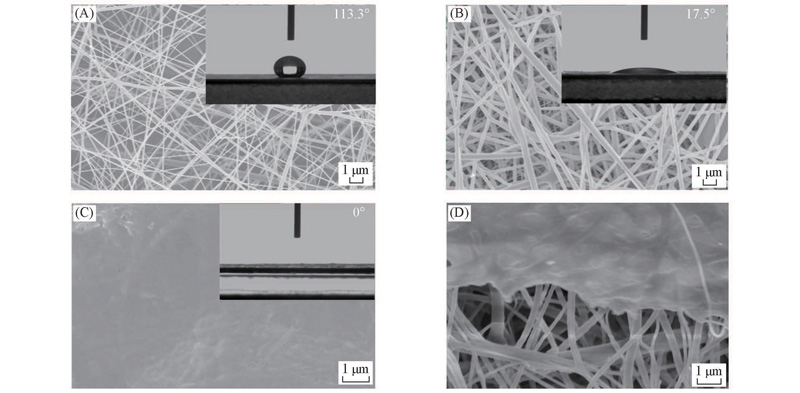

Fig.6 Water contact angles of different nanofiber layers(A) PVDF layer; (B) PVA layer; (C) crosslinked PVA layer; (D) cross-section morphology of (C).

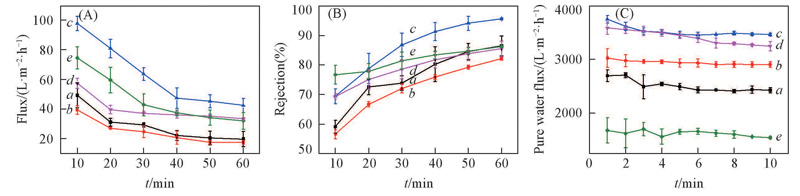

Fig.7 Separation of the dead-end filtration usingthe composite ultrafiltration membrane with different PVA electrospinning time(A) Change of the flux by filter oil/water emulsions; (B) change of the rejection rate by filter oil/water emulsions; (C) change of the flux by filter pure water. Time/h: a. 1; b. 2; c. 3; d. 4; e. 5.

| Number of recycle | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| Rl(%) | 26.17 | 28.99 | 27.97 | 26.73 | |

| Rr(%) | 73.83 | 71.01 | 72.03 | 73.27 |

Table 2 The loss rate(Rl) and flux recovery rate(Rr) of the composite ultrafiltration membrane after recycling

| Number of recycle | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| Rl(%) | 26.17 | 28.99 | 27.97 | 26.73 | |

| Rr(%) | 73.83 | 71.01 | 72.03 | 73.27 |

| [1] | Kaur S., Sundarrajan S., Rana D., Sridhar R., Gopal R., Matsuura T., Ramakrishna S., J. Member. Sci., 2014, 49(18), 6143—6159 |

| [2] | Tabe S., Nanotechnology for Water Treatment and Purification, Springer International Publishing, Switzerland, 2014, 111—143 |

| [3] | Chigome S., Darko G., Torto N., Analyst, 2011, 136(14), 2879—2889 |

| [4] | Park C. G., Kim E., Park M., Choy Y. B., J. Controlled Release, 2011, 149(3), 250—257 |

| [5] | Ravanchi M. T., Kaghazchi T., Kargari A., Desalination, 2009, 235(1—3), 199—244 |

| [6] | Liu Y.J., Wang J. N., Li C. J.,Acta Polym., 2013, (9), 1137—1142 |

| (刘燕君, 王娇娜, 李从举. 高分子学报, 2013, (9), 1137—1142) | |

| [7] | Zhao D., Jaroniec M., Hsiao B. S., J. Mater. Chem., 2010, 20(22), 4476—4477 |

| [8] | Wang X. F., Min M. H., Liu Z. Y., Yang Y., Zhou Z., Zhu M. F., Chen Y. M., Hsiao B. S., J. Member. Sci., 2011, 379(1), 191—199 |

| [9] | Liu B., Chen C., Zhang W., Crittenden J., Chen Y., Desalination, 2012, 307, 26—33 |

| [10] | Khayet M., Mengual J. I., Matsuura T., J. Member. Sci., 2005, 252(1), 101—113 |

| [11] | Li Q., Xu Z. L., Liu M., Polym. Adv. Technol., 2011, 22(5), 520—531 |

| [12] | Prince J. A., Singh G., Rana D., Matsuura T., Anbharasi V., Shanmugasundaram T. S., J. Member. Sci., 2012, 397, 80—86 |

| [13] | Ma L.C., Wang J. N., Li C. J.,New Chem. Mater., 2015, (11), 226—228 |

| (马利婵, 王娇娜, 李从举. 化工新型材料, 2015, (11), 226—228) | |

| [14] | Ahn S. M., Ha J. W., Kim J. H., Lee Y. T., Lee S. B., J. Member. Sci., 2005, 247(1), 51—57 |

| [15] | Zhao W.M., Study on the Filtration of Electrospun PVDF Nanofiber and Its Modified Membrane to Oily Wastewater, Donghua University,Shanghai, 2015 |

| (赵文敏. 静电纺PVDF及其改性纳米纤维膜对含油污水的过滤性能研究, 上海: 东华大学, 2015) |

| [1] | WU Yu, LI Xuan, YANG Hengpan, HE Chuanxin. Construction of Cobalt Single Atoms via Double-confinement Strategy for High-performance Electrocatalytic Reduction of Carbon Dioxide [J]. Chem. J. Chinese Universities, 2022, 43(9): 20220343. |

| [2] | TONG Cheng, WU Wentao, WANG Ting. Preparation of Small Mesoporous SiO2 Particles with Asymmetric Tunnel Structure and Fabrication of the Resulting Hybrid Membranes [J]. Chem. J. Chinese Universities, 2021, 42(3): 946. |

| [3] | WANG Yupeng, ZHAO Yang, LI Mohan, SHI Suqing, GONG Yongkuan. Fabrication of Antifouling-antibacterial Dual Functional Polymer Coating via Dopamine-based Multiple Interactions [J]. Chem. J. Chinese Universities, 2021, 42(3): 811. |

| [4] | QIN Chunping, WANG Xianliu, TANG Han, YI Bingcheng, LIU Chang, ZHANG Yanzhong. Osteogenesis-promoting Effects of the Electrospun Nanofibers Containing Decellularized Bone Matrix † [J]. Chem. J. Chinese Universities, 2020, 41(4): 780. |

| [5] | WANG Xia, LIU Yanji, JIA Yongfeng, JI Lei, HU Quanli, DUAN Limei, LIU Jinghai. Preparative Chemistry of N-containing Porous Carbon Nanofibers for Capacity Improvement in Lithium-sulfur Battery † [J]. Chem. J. Chinese Universities, 2020, 41(4): 829. |

| [6] | WANG Yongpeng,XU Zibo,LIU Mengzhu,ZHANG Haibo,JIANG Zhenhua. Non-enzymatic Glucose Sensor Based on the Electrospun Porous Foamy Copper Oxides Micro-nanofibers† [J]. Chem. J. Chinese Universities, 2019, 40(6): 1310. |

| [7] | CAI Jiao,YU Qiongwei,HE Xiaomei,XU Jing,DING Qiong,FENG Yuqi. Preparation of SiW11 Incorporated SiO2 Nanofibers(SiW11/SiO2) and Its Application in the Analysis of Polyamines in Arabidopsis† [J]. Chem. J. Chinese Universities, 2019, 40(5): 901. |

| [8] | ZHAO Yuxuan,CHEN Yanjun,PAN Guxin,WANG Chang,PENG Zhenbo,SUN Zongxu,LIANG Yongri,SHI Qisong. Preparation and Performance of Novel Tb-PEG+Eu-PEG/PANI/PAN Luminescent-electrical-phase Change Composite Fibers by Electrospinning† [J]. Chem. J. Chinese Universities, 2019, 40(4): 824. |

| [9] | GAO Ningxiao,XU Yulong,LIU Yong. Preparation of Carbon Dots from Soy Milk Powder and Fluorescent Nanofibers Containing Carbon Dots† [J]. Chem. J. Chinese Universities, 2019, 40(3): 555. |

| [10] | ZHANG Xinmu,CUI Xiangxu,YAOMA Kangyue,LI Tingting,ZHANG Zhiming. Electrospinning Preparation and Photocatalytic Activity of H4SiW12O40/Ethylene Vinyl Alcohol Copolymer Nanofibrous Membrane† [J]. Chem. J. Chinese Universities, 2019, 40(2): 372. |

| [11] | ZHANG Jiayi,JIA Mengyang,JIANG Xiaohui,ZHANG Zhiming,YU Liangmin,WANG Xuan. Antifouling Properties of Dodecyl Benzene Sulfonic Acid Doped Polypyrrole Under Alternating Anodic-cathodic Polarization † [J]. Chem. J. Chinese Universities, 2019, 40(11): 2396. |

| [12] | LIU Zihao,XIAO Han,YAO Yuan,WANG Ting,WU Liguang,ZHANG Xueyang. Fabrication of PVDF Hybrid Blending Membrane via Microemulsion Polymerization Coupling with Blending Method † [J]. Chem. J. Chinese Universities, 2019, 40(10): 2248. |

| [13] | XU Dan,DING Yadan,WANG Xue,CONG Tie,LIU Junping,HONG Xia,PAN Ying. Microdroplet Detection of Protein Based on Superhydrophobic Polystyrene Film† [J]. Chem. J. Chinese Universities, 2018, 39(9): 1913. |

| [14] | ZHOU Ying, WANG Xianliu, YI Bingcheng, YU Zhepao, YANG Shangying, SHEN Yanbing, ZHANG Yanzhong. Engineering Shape Memory Enabled Composite Nanofibers for Bone Tissue Engineering† [J]. Chem. J. Chinese Universities, 2018, 39(7): 1554. |

| [15] | CONG Fei, SUN Xiuhua, WANG Ke, GUI Taijiang, GAO Changlu. Characterization of Tertiary Amine-Cu Complex and Application in Copper Ion Slow-release Coatings† [J]. Chem. J. Chinese Universities, 2018, 39(7): 1602. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||