Chem. J. Chinese Universities ›› 2014, Vol. 35 ›› Issue (4): 791.doi: 10.7503/cjcu20131241

• Physical Chemistry • Previous Articles Next Articles

LI Jing1,2, YANG Yong3, CAO Xulong3, ZHANG Jichao3, ZHANG Lei1,*( ), ZHANG Lu1,*(

), ZHANG Lu1,*( ), ZHAO Sui1

), ZHAO Sui1

Received:2013-12-18

Online:2014-04-10

Published:2014-02-25

Contact:

ZHANG Lei,ZHANG Lu

E-mail:zl2558@163.com;luyiqiao@hotmail.com

Supported by:CLC Number:

TrendMD:

LI Jing, YANG Yong, CAO Xulong, ZHANG Jichao, ZHANG Lei, ZHANG Lu, ZHAO Sui. Interfacial Shear Rheological Properties of Enhanced Oil Recovery Polymers with Different Structures†[J]. Chem. J. Chinese Universities, 2014, 35(4): 791.

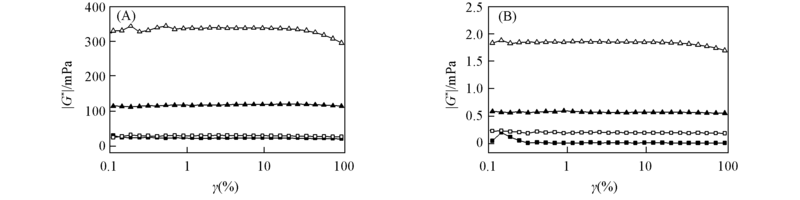

Fig.2 Effect of strain on the bulk(A) and interface-bulk(B) shear complex moduli for different concentrations of HMPAM solutions Concentration of HMPAM/(mg·L-1): ■ 500; □ 1000; ▲ 2000; △ 3000. Frequency: 0.03 Hz. (B) oil: kerosene aqueous; aqueous: HMPAM.

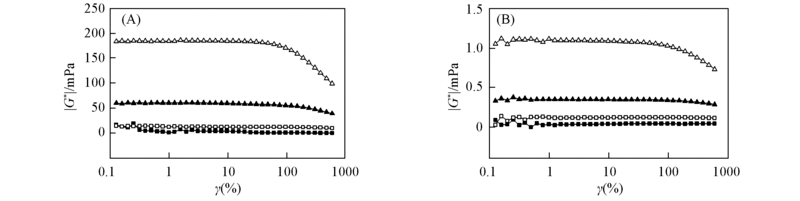

Fig.3 Effect of strain on the bulk(A) and interface-bulk(B) shear complex moduli for different concentrations of PHPAM solutions Concentration of PHPAM/(mg·L-1): ■ 100; □ 1000; ▲ 2000; △ 3000. Frequency: 0.03 Hz. (B) oil: kerosene aqueous; aqueous: PHPAM.

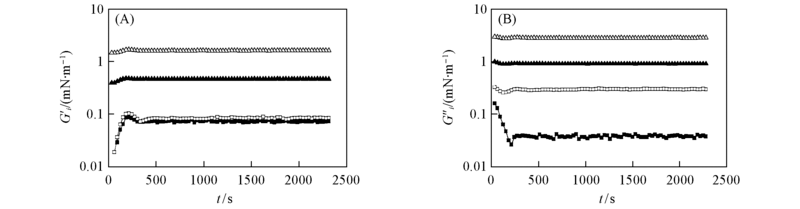

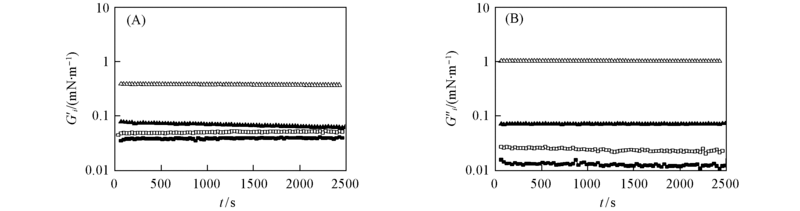

Fig.4 Dynamic interfacial shear elastic(A) and viscous moduli(B) for different concentrations of HMPAMConcentration of HMPAM in the interface of kerosene-HMPAM/(mg·L-1): ■ 500; □ 1000; ▲ 2000; △ 3000. Frequency: 0.03 Hz.

Fig.5 Dynamic interfacial shear elastic(A) and viscous moduli(B) for different concentrations of PHPAMConcentration of PHPAM in the interface of kerosene-PHPAM/(mg·L-1): ■ 100; □ 1000; ▲ 2000; △ 3000. Frequency: 0.1 Hz.

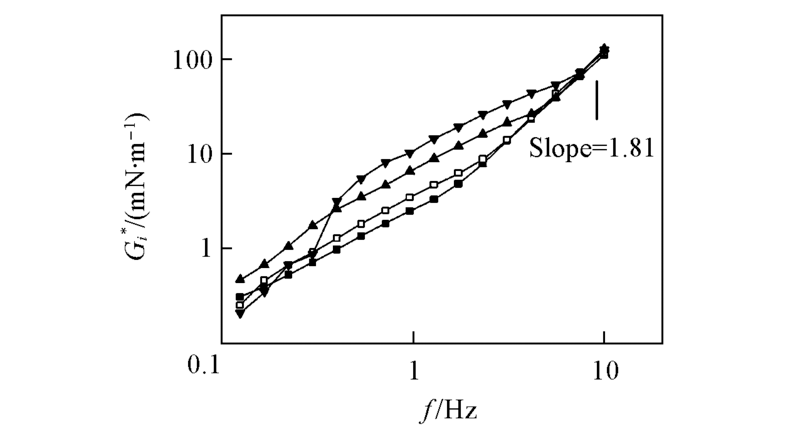

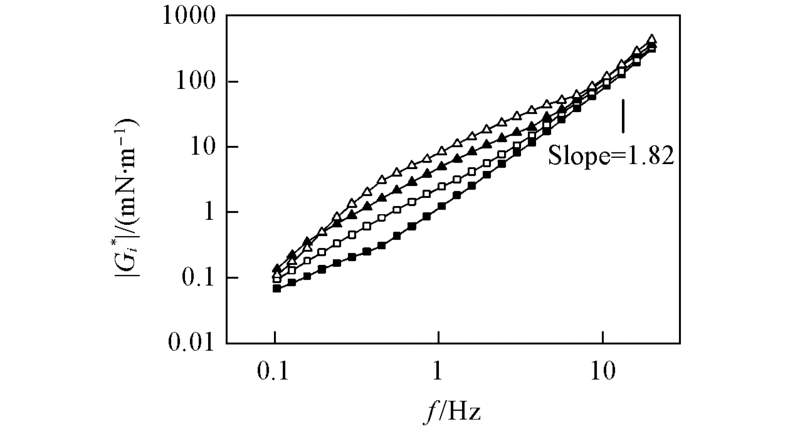

Fig.6 Effect of frequency on interfacial shear complex moduli for different concentrations of HMPAM Concentration of HMPAM in the interface of kerosene-HMPAM/(mg·L-1): ■ 500; □ 1000; ▲ 2000; △ 3000.

Fig.7 Effect of frequency on interfacial shear complex moduli for different concentrations of PHPAMConcentration of PHPAM in the interface of kerosene-HMPAM/(mg·L-1): ■ 100; □ 1000; ▲ 2000; △ 3000.

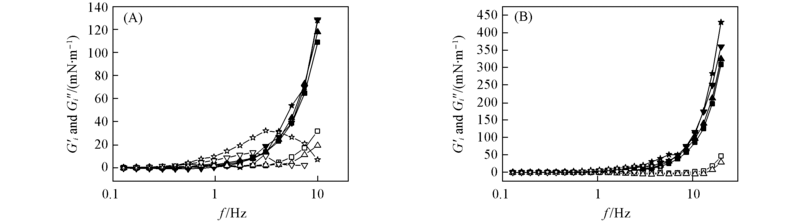

Fig.9 Effect of frequency on the interfacial shear elastic and viscous moduli of HMPAM(A) and PHPAM(B) (A) Concentration of HMPAM in the interface of kerosene-HMPAM/(mg·L-1): ■, □ 500; ▲, △ 1000; ▼, ▽ 2000; ★, ☆ 3000. (B) Concentration of PHPAM in the interface of kerosene-PHPAM/(mg·L-1): ■, □ 100; ▲, △ 1000; ▼, ▽ 2000; ★, ☆ 3000.

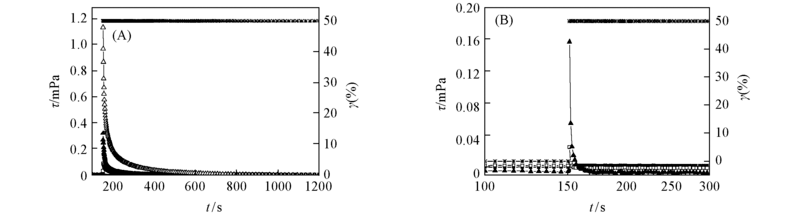

Fig.10 Decay curves of shear stress for different concentrations of HMPAM(A) and PHPAM(B) solutions Oil; kerosene; *train. (A) Concentration of HMPAM/(mg·L-1): ■ 500; □ 1000; ▲ 2000; △ 3000. (B) Concentration of PHPAM/(mg·L-1): ■ 1000; □ 2000; ▲ 3000.

| EOR polymer | Concentration/ (mg·L-1) | Δτ1/ (mN·m-1) | T1/s | Δτ2/ (mN·m-1) | T2/s | Δτ3/ (mN·m-1) | T3/s | Δτ/ (mN·m-1) |

|---|---|---|---|---|---|---|---|---|

| HMPAM | 2000 | 0.12 | 1.8 | 0.14 | 13.5 | 0.06 | 90.9 | 0.32 |

| 3000 | 0.54 | 3.6 | 0.42 | 25.6 | 0.17 | 181.8 | 1.13 | |

| PHPAM | 2000 | 0.01 | 0.3 | 0.02 | 1.1 | 0.03 | ||

| 3000 | 0.12 | 0.7 | 0.04 | 4.2 | 0.16 |

Table 1 Characteristic parameters of interfacial relaxation for EOR polymers with different structures

| EOR polymer | Concentration/ (mg·L-1) | Δτ1/ (mN·m-1) | T1/s | Δτ2/ (mN·m-1) | T2/s | Δτ3/ (mN·m-1) | T3/s | Δτ/ (mN·m-1) |

|---|---|---|---|---|---|---|---|---|

| HMPAM | 2000 | 0.12 | 1.8 | 0.14 | 13.5 | 0.06 | 90.9 | 0.32 |

| 3000 | 0.54 | 3.6 | 0.42 | 25.6 | 0.17 | 181.8 | 1.13 | |

| PHPAM | 2000 | 0.01 | 0.3 | 0.02 | 1.1 | 0.03 | ||

| 3000 | 0.12 | 0.7 | 0.04 | 4.2 | 0.16 |

| [1] | Taylor K. C., Nasr El-Din H. A., J. Petrol. Sci. Eng., 1998, 19, 265 |

| [2] | Taylor K. C., Nasr El-Din H. A., Colloids Surf. A,1998, 108, 49 |

| [3] | Wang H. X., Yao L., Ding B., Luo J. H., Zhou G., Jiang B., Chem. J. Chinese Universities,2013, 34(5), 1295—1302 |

| (王惠厦, 姚林, 丁彬, 罗健辉, 周歌, 江波. 高等学校化学学报, 2013, 34(5), 1295—1302) | |

| [4] | Shen P.P., Yu J. Y., Fundamental Study on Extensively Enhanced Petroleum Recovery, Petroleum Industry Press, Beijing, 2001, 38—92 |

| (沈平平, 俞稼镛. 大幅度提高石油采收率的基础研究, 北京: 石油工业出版社, 2001, 38—92) | |

| [5] | Wever D. A. Z., Picchioni F., Broekhuis A. A., Progress in Polymer Sci., 2011, 36(11), 1558—1628 |

| [6] | Abidin A. Z., Puspasari T., Nugroho W. A., Procedia Chemistry,2012, 4, 11—16 |

| [7] | James J., Enhanced Oil Recovery Field Case Studies, 2013, 5, 117—142 |

| [8] | Zhu Y. Y., Xu G. Y., Gong H. J., Wu D., Wang Y. J., Colloids and Surfaces A: Physicochemical and Engineering Aspects,2009, 332(23), 90—97 |

| [9] | Liu M. X., Xu G. Y., Li G. Z., Mao H. Z., Li F., Acta Phys. Chim. Sin., 1995, 11, 1040—1043 |

| [10] | Xu G. Y., Wang F. H., Liu M. X., Mao H. Z., Oilfield Chem., 1993, 10, 57—61 |

| [11] | Aske N., Orr R., Sjoblom J., J. Dispersion Sci. Technol., 2002, 23, 809—825 |

| [12] | Bouriat P., Elkerri N., Graciaaa A., Lachaise J., Langmuir,2004, 20, 7459—7464 |

| [13] | Freer E. M., Radke C. J., J. Adhes., 2004, 80, 481—496 |

| [14] | Miller R., Ferri J. K., Javadi A., Kragel J., Mucic N., Wustneck R., Colloid and Polymer Science,2010, 288(9), 937—950 |

| [15] | Sun H. Q., Zhang L., Li Z. Q., Zhang L., Luo L., Zhao S., Soft Matter,2011, 7, 7601—7611 |

| [16] | Tang L., Luo L., Fang H. B., Zong H., Zhang L., Zhang L., Zhao S., Chem. J. Chinese Universities,2013, 34(6), 1434—1440 |

| (唐黎, 罗澜, 方洪波, 宗华, 张磊, 张路, 赵濉. 高等学校化学学报, 2013, 34(6), 1434—1440) | |

| [17] | Ao M., Xu G., Kang W., Meng L., Gong H., Zhou T., Soft Matter,2011, 7(3), 1199—1206 |

| [18] | Philipp E., Peter F., Erich J. W., Review of Scientific Instruments,2003, 74(11), 4916—4924 |

| [19] | Soo G. O., Jone C. S., Journal of Colloid and Interface Science,1978, 67(12), 516—525 |

| [20] | Lauger J., Huck S.R., In Proceedings of the ⅩⅢth International Congress on Rheology, Cambridge University Press, Cambridge, U. K., 2000, 10—12 |

| [21] | Lauger J., Wollny K., Huck S. R., Rheol. Acta,2002, 41, 356—361 |

| [22] | Kragel J., Derkatch S. R., Miller R., Advances in Colloid and Interface Science,2008, 144(12), 38—53 |

| [23] | Guillermic R. M., Saint J. A., Soft Matter,2013, 9(4), 1344—1353 |

| [24] | Wang Y., Dai Y., Zhang L., Luo L., Zhao S., Li M., Wang E., Yu J., Macromolecules,2004, 37, 2930—2937 |

| [25] | Wang D. X., Luo L., Zhang L., Wang Y. Y., Zhao S., Yu J. Y., Acta Phys. Chim. Sin., 2005, 21 (11), 1205—1210 |

| (王东贤, 罗澜, 张路, 王宜阳, 赵濉, 俞稼镛. 物理化学学报, 2005, 21 (11), 1205—1210) | |

| [26] | Zong H., Wang L., Fang H. B., Mao L. T., Wang Y. H., Zang L., Zhao S., Yu J. Y., Acta Phys. Chim. Sin., 2010, 26(11), 2982—2988 |

| (宗华, 王磊, 方洪波, 毛雷霆, 王宇慧, 张路, 赵濉, 俞稼镛. 物理化学学报, 2010, 26(11), 2982—2988) | |

| [27] | Sun H.Q., Zhang L., Li Z. Q., Zhang L., Zhao S., Yu J. Y., In Polymer Relaxation, Nova Science Publishers Inc., New York, 2011, 137—159 |

| [1] | LI Wei, LUO Piao, HUANG Lianzhan, CUI Zhiming. Lithium Polystyrene Sulfonate Based Interfacial Protective Layer for Lithium Metal Anodes [J]. Chem. J. Chinese Universities, 2022, 43(8): 20220166. |

| [2] | TIAN Zhen, DU Na, LI Haiping, SONG Shue, HOU Wanguo. Points of Zero Charge and Surface Acid-base Reaction Equilibrium Constants of Mg-Al-Ti Layered Double Hydroxides [J]. Chem. J. Chinese Universities, 2022, 43(4): 20210833. |

| [3] | XUE Jin, CAO Xiaowei, LIU Yifan, WANG Min. Preparation of Paper Hollow Gold Nanocage SERS Sensor and Its Rapid and Highly Sensitive Detection for miRNAs in Sputum of Patients with Non-small Cell Lung Cancer [J]. Chem. J. Chinese Universities, 2021, 42(8): 2393. |

| [4] | WANG Yimeng, LIU Kai, WANG Baoguo. Coating Strategies of Ni-rich Layered Cathode in LIBs [J]. Chem. J. Chinese Universities, 2021, 42(5): 1514. |

| [5] | WANG Zengqiang, SUN Yiling, QIAN Zhengfang, WANG Renheng. Advances in Lithium Metal Batteries Based on Surface Interface Reaction and Optimization [J]. Chem. J. Chinese Universities, 2021, 42(4): 1017. |

| [6] | XIA Jiahao, XU Huaping. Selenium-containing Surface/interface Chemistry [J]. Chem. J. Chinese Universities, 2021, 42(4): 997. |

| [7] | ZOU Junyan, ZHANG Yanyan, CHEN Shi, SHAO Huaiyu, TANG Yuxin. Recent Development on Surface-interface Chemistry of All-solid-state Lithium Batteries [J]. Chem. J. Chinese Universities, 2021, 42(4): 1005. |

| [8] | FAN Wenqian, ZHONG Zhengxiang, TIAN Gongwei, WANG Yu, GONG Guifen, QI Dianpeng. Application of Conductive Polymer in Nerve Interface Electrode [J]. Chem. J. Chinese Universities, 2021, 42(4): 1146. |

| [9] | ZHANG Jun, LIU Yixuan, DU Xiaohui, YANG Hui. Highly Adhesive and Stretchable Polymers for the Interface of Cyber-human Interaction [J]. Chem. J. Chinese Universities, 2021, 42(4): 1093. |

| [10] | BA Zhichen, LIANG Daxin, XIE Yanjun. Progress of MXenes Composites: Interface Modification and Structure Design [J]. Chem. J. Chinese Universities, 2021, 42(4): 1225. |

| [11] | GAO Xiaoya, ZUO Zicheng, LI Yuliang. Construction of Graphdiyne Interface in Electrochemical Batteries [J]. Chem. J. Chinese Universities, 2021, 42(2): 321. |

| [12] | ZHANG Jiayi, DING Zhenyao, WANG Dandan, CHEN Liping, FENG Xinjian. Fabrication of Triphase Enzyme Electrode Based on Porous Gold Substrate for High-performance Electrochemical Biosensor [J]. Chem. J. Chinese Universities, 2021, 42(10): 3167. |

| [13] | TANG Wentao, LI Shengkai, WANG Shen, CHEN Long, CHEN Zhuo. Laser-mediated Enrichment Based Surface Enhanced Raman Analysis [J]. Chem. J. Chinese Universities, 2021, 42(10): 3054. |

| [14] | ZHOU Molin, JIANG Xin, YI Ting, YANG Xiangguang, ZHANG Yibo. Improvement of Interface Stability Between Sulfide Solid Electrolyte Li10GeP2S12 and Lithium Metal [J]. Chem. J. Chinese Universities, 2020, 41(8): 1810. |

| [15] | LI Yefei, LIU Zhipan. Structure Prediction of Heterojunction Interfaces and the Application of AutoInterface Program [J]. Chem. J. Chinese Universities, 2020, 41(11): 2383. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||