高等学校化学学报 ›› 2020, Vol. 41 ›› Issue (2): 349.doi: 10.7503/cjcu20190473

收稿日期:2019-09-02

出版日期:2020-02-10

发布日期:2019-12-31

通讯作者:

张鸿

E-mail:zhang_hong1234@sina.com

基金资助:

YAN Ming,ZHOU Weidong,ZHANG Hong( ),SHI Junfeng,ZHAO Yunhe,YE Yongming,GUO Jing,YU Yue

),SHI Junfeng,ZHAO Yunhe,YE Yongming,GUO Jing,YU Yue

Received:2019-09-02

Online:2020-02-10

Published:2019-12-31

Contact:

Hong ZHANG

E-mail:zhang_hong1234@sina.com

Supported by:摘要:

为了提高海藻酸钠(SA)纤维的断裂强度和断裂伸长率, 以丙烯酸(AA)为化学交联组分, SA为离子交联组分, 聚乙烯醇(PVA)为微晶交联组分, 采用湿法纺丝和冻融循环方法制备含有PVA微晶交联点和海藻酸钠/聚丙烯酸(SA/PAA)双网络结构的海藻酸钠/聚丙烯酸/聚乙烯醇(SA/PAA/PVA)复合纤维. 通过流变性能、 力学性能、 红外光谱、 X射线衍射仪(XRD)和扫描电子显微镜(SEM)测试研究了交联剂N,N-亚甲基双丙烯酰胺(MBA)含量和PVA微晶交联对SA/PAA/PVA纺丝原液和复合纤维的结构与性能的影响. 结果表明, 当MBA质量分数为0.5%时, 纺丝原液的损耗模量(G″)最小, 可纺性最好, 复合纤维的断裂强度达到2.83 cN/dtex, 断裂伸长率达到9.38%, 比再生SA纤维分别提高了15.98%和38.96%; PVA冷冻之后形成微晶交联点并且PAA和PVA已经复合到体系中; PAA和PVA的加入提高了复合纤维的结晶度; 复合纤维的表面形貌趋于光滑和规整, 纤维断面更加致密.

中图分类号:

TrendMD:

闫铭,周炜东,张鸿,石军峰,赵云鹤,叶泳铭,郭静,于跃. PVA微晶交联和SA/PAA双网络协效增强增韧SA纤维. 高等学校化学学报, 2020, 41(2): 349.

YAN Ming,ZHOU Weidong,ZHANG Hong,SHI Junfeng,ZHAO Yunhe,YE Yongming,GUO Jing,YU Yue. PVA Microcrystalline Cross-linking and SA/PAA Double Network Synergistic Modification of SA Fiber †. Chem. J. Chinese Universities, 2020, 41(2): 349.

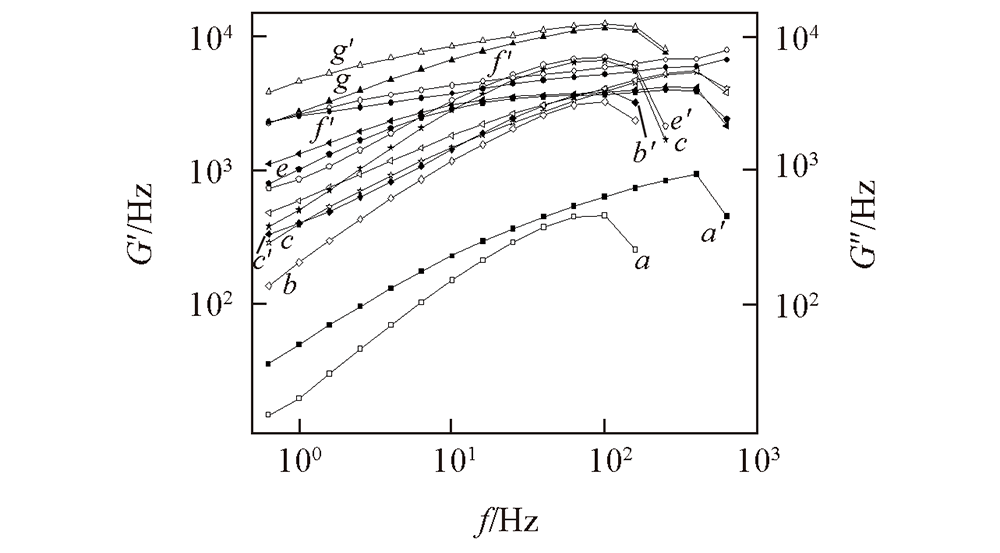

Fig.1 Characterization of rheological properties of SA/PAA/PVA blend solution a—g. Loss modulus; a'—g' storage modulus. a, a'. Regenerated SA; b, b'. SA/PAA/PVA, not frozen; c, c'. SA/PAA/PVA, already frozen; d, d'. SA/PAA/PVA, 0.25%MBA; e, e'. SA/PAA/PVA, 0.5%MBA; f, f'. SA/PAA/PVA, 0.75%MBA; g, g'. SA/PAA/PVA, 1%MBA.

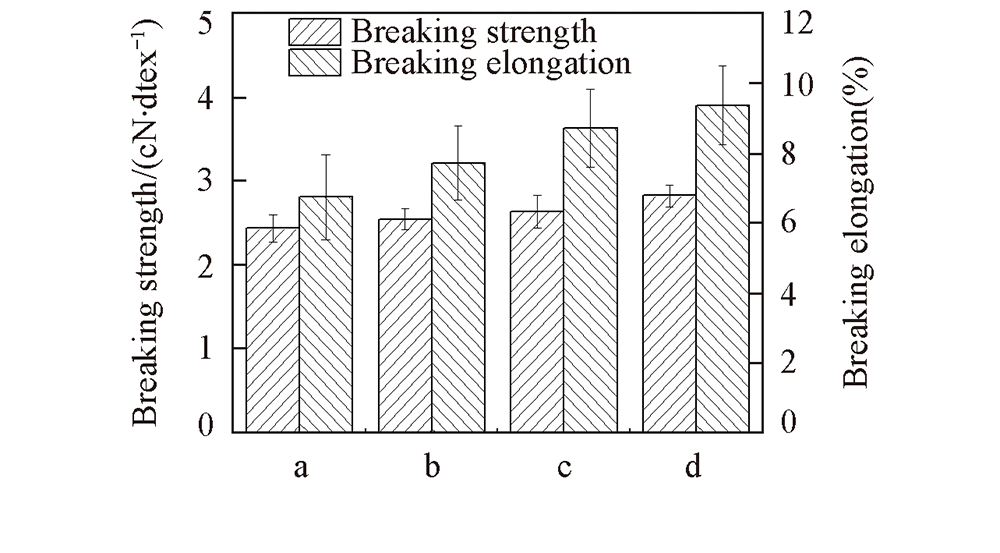

Fig.3 Mechanical properties of regenerated SA fiber and SA/PAA/PVA composite fibers treated under different conditions a. Regenerated SA; b. not frozen, SA/PAA/PVA; c. 0.25% MB and already frozen, SA/PAA/PVA; d. 0.5% MBA and already frozen, SA/PAA/PVA.

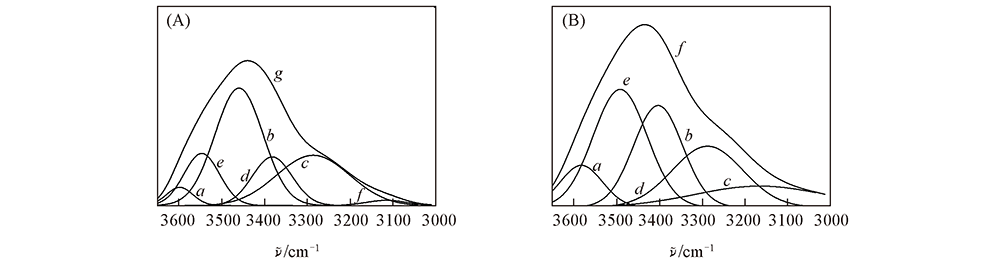

Fig.5 Fitted IR curves of regenerated SA fiber(A) and SA/PAA/PVA composite fiber(B) (A) a—f. Fitted curves 1—6; g. originaL curve. (B) a—e. Fitted curves 1—5; f. original curve.

| Sapmle | Type of hydrogen bond | Structural formula | Peak area | Relative Strength(%) | |

|---|---|---|---|---|---|

| Regenerated SA fiber | Free hydroxyl | —OH | 3599 | 1.55 | 3.5 |

| Intramolecular hydrogen bond | OH…OH | 3442 | 18.33 | 54.2 | |

| Four association | 3097 | 5.99 | |||

| Intermolecular hydrogen bond | OH…O(in ether) | 3266 | 12.10 | 42.3 | |

| OH…π | 3543 | 6.25 | |||

| OH…N | 3126 | 0.68 | |||

| SA/PAA/PVAComposite fiber | Free hydroxyl | —OH | 3582 | 5.21 | 8.9 |

| Intramolecular hydrogen bond | OH…OH | 3403 | 14.85 | 37.1 | |

| Four association | 3165 | 6.95 | |||

| Intermolecular hydrogen bond | OH…O(in ether) | 3287 | 12.80 | 54.0 | |

| OH…π | 3492 | 18.90 |

Table 1 Fractal peak fitting results of infrared spectrum of regenerated SA fiber and SA/PAA/PVA composite fiber

| Sapmle | Type of hydrogen bond | Structural formula | Peak area | Relative Strength(%) | |

|---|---|---|---|---|---|

| Regenerated SA fiber | Free hydroxyl | —OH | 3599 | 1.55 | 3.5 |

| Intramolecular hydrogen bond | OH…OH | 3442 | 18.33 | 54.2 | |

| Four association | 3097 | 5.99 | |||

| Intermolecular hydrogen bond | OH…O(in ether) | 3266 | 12.10 | 42.3 | |

| OH…π | 3543 | 6.25 | |||

| OH…N | 3126 | 0.68 | |||

| SA/PAA/PVAComposite fiber | Free hydroxyl | —OH | 3582 | 5.21 | 8.9 |

| Intramolecular hydrogen bond | OH…OH | 3403 | 14.85 | 37.1 | |

| Four association | 3165 | 6.95 | |||

| Intermolecular hydrogen bond | OH…O(in ether) | 3287 | 12.80 | 54.0 | |

| OH…π | 3492 | 18.90 |

| [1] |

Sarikaya E., Çallioglu H., Demirel H., Composites Part B: Engineering, 2019,167, 461— 466

doi: 10.1016/j.compositesb.2019.03.020 URL |

| [2] |

Sow L. C., Yu Toh N. Z., Wong C. W., Yang H., Food Hydrocolloids, 2019,94, 459— 467

doi: 10.1016/j.foodhyd.2019.03.041 URL |

| [3] |

Bai Y. Y., Lei Y. H., Shen X. J., Luo J., Yao C. L., Sun R. C., Carbohydrate Polymers, 2017,174, 610— 616

doi: 10.1016/j.carbpol.2017.06.091 URL |

| [4] |

Varaprasad K., Raghavendra G. M., Jayaramudu T., Seo J., Carbohydrate Polymers, 2016,135, 349— 355

doi: 10.1016/j.carbpol.2015.08.078 URL |

| [5] |

Wu N. J., Niu F. K., Lang W. C., Xia M. F., Carbohydrate Polymers, 2019,221, 221— 230

doi: 10.1016/j.carbpol.2019.06.007 URL |

| [6] |

Li X. L., Chen M. J., Chen H. B., Composites Part B: Engineering, 2019,164, 18— 25

doi: 10.1016/j.compositesb.2018.11.055 URL |

| [7] | Qin H. H., Fang X. X., Zhao X., Song F. J., You J. X., Industrial Textiles, 2018,36(4), 1— 6 |

| ( 秦洪花, 房学祥, 赵霞, 宋福杰, 尤金秀 . 产业用纺织品, 2018,36(4), 1— 6) | |

| [8] |

Zhang K., Zhu P., Sui S. Y., Dong C. H., Zhang X. Y., Wuhan University Journal of Natural Sciences, 2017,22(3), 197— 200

doi: 10.1007/s11859-017-1235-4 URL |

| [9] | Helmiyati, Aprilliza M ., IOP Conference Series Materials Science and Engineering, 2017,188(1), 1— 5 |

| [10] | You W. T., Dan W. H., Dan N. H., Liang Y. X., Liu B. W., Wen H. T., China Leather, 2017,4(8), 19— 24 |

| ( 尤伟婷, 但卫华, 但年华, 梁永贤, 刘博文, 温会涛 . 中国皮革, 2017,4(8), 19— 24) | |

| [11] | Ran Q., Liu X. P., Zhang C., Xiang X. L., Yunnan Chemical Technology, 2019,46(3), 127— 129 |

| ( 冉青, 刘信平, 张驰, 向戌连 . 云南化工, 2019,46(3), 127— 129) | |

| [12] |

Summa M., Russo D., Penna I., Margaroli N., Bayer I. S., Bandiera T., Athanassiou A., Bertorelli R., European Journal of Pharmaceutics and Biopharmaceutics, 2018,122, 17— 24

doi: 10.1016/j.ejpb.2017.10.004 URL |

| [13] |

Yuan N. N., Li S. J., Li G. Q., Journal of Drug Delivery Science and Technology, 2018,46, 348— 353

doi: 10.1016/j.jddst.2018.05.026 URL |

| [14] |

Yang M. L., Wang L., Xia Y. Z., International Journal of Biological Macromolecules, 2019,124, 1238— 1245

doi: 10.1016/j.ijbiomac.2018.12.012 URL |

| [15] |

Lacoste C., Hage R. E., Bergeret A., Corn S., Lacroix P., Carbohydrate Polymers, 2018,184, 1— 8

doi: 10.1016/j.carbpol.2017.12.019 URL |

| [16] |

Zou X. Q., Zhang H., Chen T., Li H. T., Meng C. H., Xia Y., Guo J., Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2019,567, 184— 192

doi: 10.1016/j.colsurfa.2018.12.019 URL |

| [17] |

Megan S., Chris R., Julien B., Johan F. E., Journal of Applied Polymer Science, 2018,135(7), 45857— 45866

doi: 10.1002/app.45857 URL |

| [18] |

Li X. F., Wang H., Li D. P., Long S. J., Zhang G. W., Wu Z. L., ACS Applied Materials & Interfaces, 2018,10(37), 31198— 31207

doi: 10.1021/acsami.8b13038 URL |

| [19] | Rao Z. L., Liu S. M., Wu R. Y., Wang G. L., Sun Z. X., Bai L. J., Wang W. X., Chen H., Yang H. W., Wei D. L., Niu Y. Z., International Journal of Biological Macromolecules, DOI: 10.1016/j.ijbiomac, 2019,129 916— 926 |

| [20] |

Gong J. P., Katsuyama Y., Kurokawa T., Osada Y., Advanced Materials, 2003,15(14), 1155— 1158

doi: 10.1002/adma.200304907 URL |

| [21] | Sun T. W., Yang R. H., Ma C. W., Liang Z., Acta Universitatis Medicinalis Anhui, 2018,53(7), 1139— 1142 |

| ( 孙天文, 杨润怀, 马长望, 梁振 . 安徽医科大学学报, 2018,53(7), 1139— 1142) | |

| [22] |

Bahrami Z., Akbari A., Eftekhari-Sis B ., International Journal of Biological Macromolecules, 2019,129, 187— 197

doi: 10.1016/j.ijbiomac.2019.02.046 URL |

| [23] | Yang M. L., Shi Y. L., Yu Z. H., Liu J. W., Bai Y. X., Shi J. S., Food Science and Technology, 2019,44(4), 274— 280 |

| ( 杨曼丽, 石云龙, 于志浩, 刘佳伟, 白映雪, 师进生 . 食品科技, 2019,44(4), 274— 280) | |

| [24] | Zhu G. F., Zhang H., Li H. T., Chen T., Yu Y., Guo J., Acta Materiae Compositae Sinica, 2017,34(11), 2571— 2579 |

| ( 祝国富, 张鸿, 李会涛, 陈涛, 于跃, 郭静 . 复合材料学报, 2017,34(11), 2571— 2579) | |

| [25] | Zhang Y ., Study on Rheological Properties of Carbon Nanotubes/Sodium Alginate Solution and Preparation of Composite Fibers, Qingdao University, Qingdao, 2013 |

| ( 张杨 . 碳纳米管/海藻酸钠溶液流变性能的研究及复合纤维的制备, 青岛: 青岛大学, 2013) | |

| [26] | Tuo C., Morden Salt Science & Technology, 2017,44(3), 1— 2) |

| ( 庹超 . 现代盐化工, 2017,44(3), 1— 2) | |

| [27] |

Lei Z. Y., Wang Q. K., Sun S. T., Zhu W. C., Wu P. Y., Advanced Materials, 2017,29, 1700321— 1700326

doi: 10.1002/adma.v29.22 URL |

| [28] | Jiang Y. P., Yang T., Fei G. X., Xia H. S., Polymer Materials Science & Engineering, 2018,34(7), 150— 155 |

| ( 蒋瑶珮, 杨涛, 费国霞, 夏和生 . 高分子材料科学与工程, 2018,34(7), 150— 155) | |

| [29] | Guo Y., Wang X. H., Xie H. Y., Journal of Xinjiang Agricultural University, 2017,40(3), 198— 203 |

| ( 郭渊, 王晓焕, 谢海燕 . 新疆农业大学学报, 2017,40(3), 198— 203) | |

| [30] | Gao D. G., Zang Y. H., Lv B., Ma J. Z., Fine Chemicals, 2018,35(2), 298— 302 |

| ( 高党鸽, 张亚红, 吕斌, 马建中 . 精细化工, 2018,35(2), 298— 302) | |

| [31] | Wang Z., Wang Y., Liu G., Dong W. F., Plastic, 2017,46(6), 17— 19 |

| ( 王竹, 汪洋, 刘耘, 东为富 . 塑料, 2017,46(6), 17— 19) | |

| [32] | Wang Z. L., Xing S. L., Yin C. P., Yang J. S., Engineering Plastics Application, 2018,46(8), 131— 137 |

| ( 王子龙, 邢素丽, 尹昌平, 杨金水 . 工程塑料应用, 2018,46(8), 131— 137) |

| [1] | 张勇, 许俊, 鲍雨, 崔树勋. 非极性有机溶剂对分子内氢键弱化程度的单分子力谱定量研究[J]. 高等学校化学学报, 2022, 43(4): 20210863. |

| [2] | 杨兆华, 成鸿静, 杨弋, 刘辉, 杜飞鹏, 张云飞. 聚乙烯醇载银海绵的制备及界面光热驱动水蒸发性能[J]. 高等学校化学学报, 2022, 43(10): 20220181. |

| [3] | 白景奇, 白珊, 任丽霞, 朱孔营, 赵蕴慧, 李晓晖, 袁晓燕. 海藻糖改性聚乙烯醇及其防雾/防霜涂层[J]. 高等学校化学学报, 2021, 42(8): 2683. |

| [4] | 王杰, 李莹, 邵亮, 白阳, 马忠雷, 马建中. 聚乙烯醇/聚吡咯复合导电水凝胶应变传感器的制备及性能[J]. 高等学校化学学报, 2021, 42(3): 929. |

| [5] | 倪卿盛, 杜淼, 单国荣, 宋义虎, 吴子良, 郑强. 一维粒子对聚乙烯醇水溶液流变行为的调控[J]. 高等学校化学学报, 2021, 42(12): 3738. |

| [6] | 王明霞, 刘志辉, 朱镇, 李凌锋, 王博蔚. 纳米硅酸镁锂-壳聚糖-海藻酸钠复合支架材料的制备与性能[J]. 高等学校化学学报, 2021, 42(10): 3240. |

| [7] | 王博蔚, 马瑞, 吴凡, 刘志辉, 李凌锋, 张骁, 刘定坤, 杨楠, 李美慧, 杨德峰, 孙琪. 氧化石墨烯-海藻酸钠-壳聚糖复合支架的制备及表征[J]. 高等学校化学学报, 2020, 41(9): 2099. |

| [8] | 宫宇宁, 王奇, 王红蕾, 关爽. 聚乙烯醇/聚乙烯吡咯烷酮/碘复合水凝胶的制备与性能[J]. 高等学校化学学报, 2020, 41(9): 2078. |

| [9] | 孙孟莹,吕景春,徐红,张琳萍,钟毅,陈支泽,隋晓锋,毛志平. 磷腈-紫精聚合物的合成与电致变色性能[J]. 高等学校化学学报, 2020, 41(6): 1399. |

| [10] | 任宸锐, 刘根起, 秦夏彤, 刘晨辉, 范晓东. 聚乙烯醇二维光子晶体水凝胶的制备及乙醇响应行为[J]. 高等学校化学学报, 2019, 40(7): 1520. |

| [11] | 李宇杰,刘勇,赵奇志,郑春满. 石墨负极表面聚合物功能保护膜对锂离子电池存储寿命的提升[J]. 高等学校化学学报, 2019, 40(12): 2542. |

| [12] | 王秋娴, 李凯, 杨贝宁, 岳红云, 杨书廷. 海藻酸钠引导合成纳微复合结构ZnFe2O4及其在锂离子电池中的应用[J]. 高等学校化学学报, 2018, 39(9): 2039. |

| [13] | 罗大军, 邵会菊, 靳进波, 谢高艺, 崔振宇, 于杰, 秦舒浩. 熔融-拉伸法制备亲水聚丙烯/聚乙烯醇缩丁醛中空纤维膜[J]. 高等学校化学学报, 2018, 39(8): 1838. |

| [14] | 龙世军, 陈明敏, 赵友姣, 王小涛, 李学锋, 廖永贵. Gemini对PVA分散螺吡喃有机凝胶薄膜光致变色行为的调控[J]. 高等学校化学学报, 2018, 39(5): 1078. |

| [15] | 刘志辉, 邱添源, 杜留熠, 杨军星, 柳康, 王博蔚. 海藻酸壳聚糖可塑性支架材料的制备及表征[J]. 高等学校化学学报, 2018, 39(5): 1105. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||