高等学校化学学报 ›› 2021, Vol. 42 ›› Issue (1): 1.doi: 10.7503/cjcu20200419

所属专题: 分子筛功能材料 2021年,42卷,第1期

王娟1,2, 王林英1, 朱大丽1, 崔文浩1, 王义峰1, 田鹏1( ), 刘中民1(

), 刘中民1( )

)

收稿日期:2020-06-29

出版日期:2021-01-10

发布日期:2021-01-12

通讯作者:

田鹏,刘中民

E-mail:tianpeng@dicp.ac.cn;liuzm@dicp.ac.cn

基金资助:

WANG Juan1,2, WANG Linying1, ZHU Dali1, CUI Wenhao1, WANG Yifeng1, TIAN Peng1( ), LIU Zhongmin1(

), LIU Zhongmin1( )

)

Received:2020-06-29

Online:2021-01-10

Published:2021-01-12

Contact:

TIAN Peng,LIU Zhongmin

E-mail:tianpeng@dicp.ac.cn;liuzm@dicp.ac.cn

Supported by:摘要:

Y沸石的合成及在流化催化裂化中的应用在现代石油化学工业中具有里程碑意义. Y沸石的骨架硅铝比直接影响材料的热/水热稳定性及催化性能. 提高Y沸石的骨架硅铝比、 合理减少酸中心密度、 提高酸强度, 进而改善催化裂化反应性能一直是学术界和工业界关注的重要课题. 目前工业使用的高硅Y沸石均是通过复杂的后处理方法获得的. 与复杂的后处理方法相比, 直接合成高硅Y沸石是更理想的方式, 但其难度大, 为分子筛领域具有挑战性的课题. 本文系统总结了高硅Y沸石的直接合成研究进展, 分别对无机合成体系和有机模板剂合成体系进行综合评述, 并介绍了Y沸石的晶化机理研究进展.

中图分类号:

TrendMD:

王娟, 王林英, 朱大丽, 崔文浩, 王义峰, 田鹏, 刘中民. 高硅Y沸石的合成研究进展. 高等学校化学学报, 2021, 42(1): 1.

WANG Juan, WANG Linying, ZHU Dali, CUI Wenhao, WANG Yifeng, TIAN Peng, LIU Zhongmin. Progress in Direct Synthesis of High Silica Zeolite Y. Chem. J. Chinese Universities, 2021, 42(1): 1.

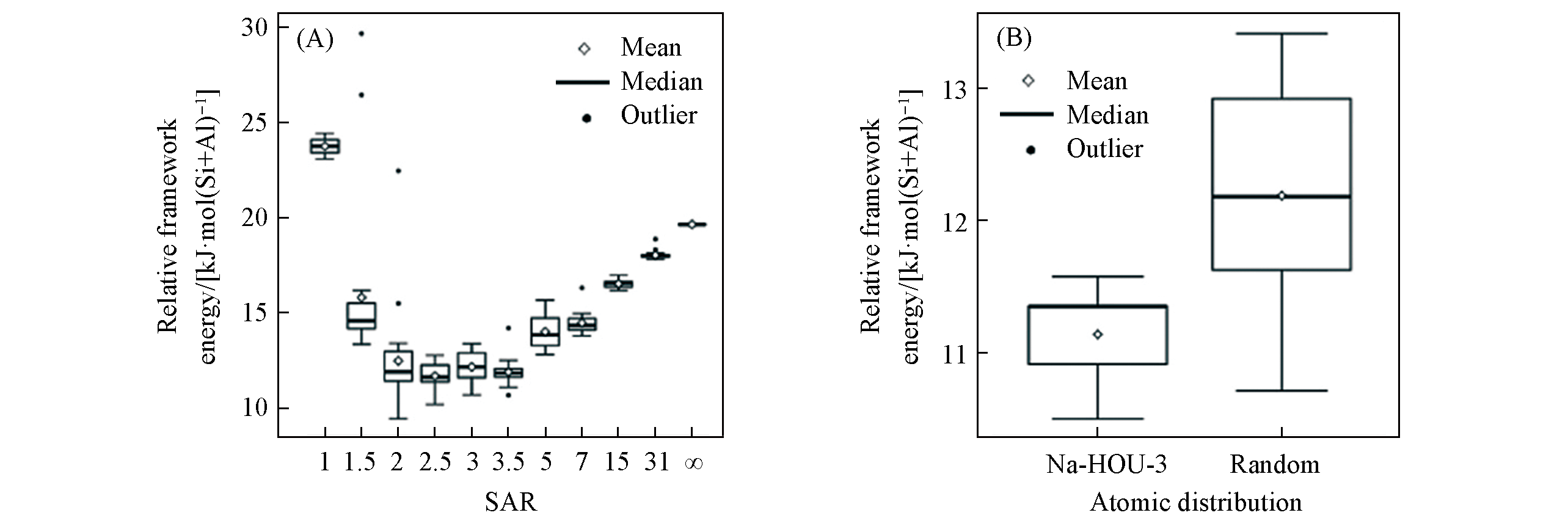

Fig.1 Statistical plot of the relative framework energy versus SiO2/Al2O3 molar ratio for Na?FAU(A) and comparison of the relative framework energy of Na?FAU(with random Al distribution) and Na?HOU?3[with spatially?biased Q4(nAl) Si speciation] at SiO2/Al2O3 molar ratio of 6(B)[34]Copyright 2017, Wiley?VCH Verlag GmbH & Co. KGaA, Weinheim.

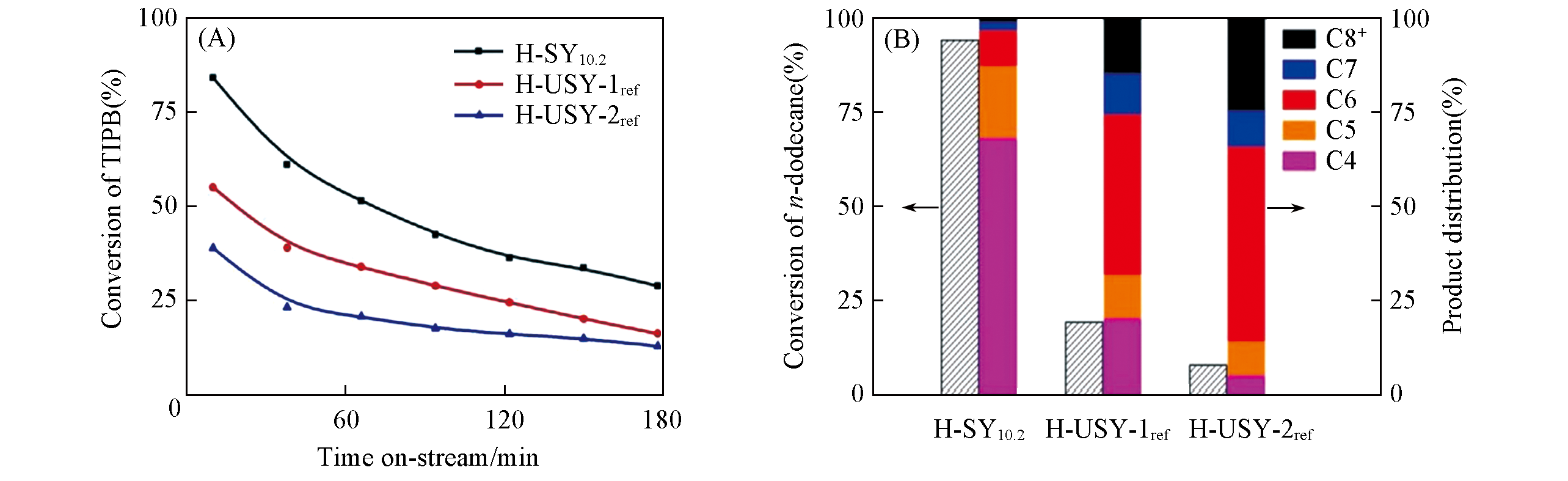

Fig.3 Catalytic cracking of hydrocarbons on H?SY10.2 compared to commercial USY(A) TIPB: 1,3,5?Triisopropylbenzene. Reaction conditions: t =160 ℃, WHSVTIPB=4.1 h-1(WHSV: weight hourly space velocity). (B) n?Dodecane conversion and products distribution. Reaction conditions: t =250 ℃, WHSVn?dodecane=50.0 h-1, TOS= 2 min[61]. Copyright 2020, Wiley?VCH Verlag GmbH & Co. KGaA, Weinheim.

| Synthetic system | Synthetic method | SAR | Reference |

|---|---|---|---|

| Inorganic system | Lowering the gel alkalinity | 5—6 | [29—34] |

| Multistep crystallization | 6—7 | [35—37] | |

| Preparation of highly efficient directing agent at low temperature | >6 | [38—40] | |

| High temperature crystallization | 5—6 | [ | |

| Hydroxyl radical?assisted synthesis | 6.35 | [ | |

| Heteroatoms?assisted synthesis | 6—7 | [ | |

| Organic template | Employing oxygen?containing compounds such as crown ethers and | 6—9 | [48,50—53] |

| system | polyols as templates | ||

| Employing quaternary alkylammonium ions as templates | 6—15.6 | [54—56,59—61] | |

| Employing pyridine derivatives as templates | 6.85 | [ | |

| Employing imidazolium-based ionic liquids as templates | 6—7 | [ |

Table 1 Summary of the synthesis methods and product SAR of high silica zeolite Y

| Synthetic system | Synthetic method | SAR | Reference |

|---|---|---|---|

| Inorganic system | Lowering the gel alkalinity | 5—6 | [29—34] |

| Multistep crystallization | 6—7 | [35—37] | |

| Preparation of highly efficient directing agent at low temperature | >6 | [38—40] | |

| High temperature crystallization | 5—6 | [ | |

| Hydroxyl radical?assisted synthesis | 6.35 | [ | |

| Heteroatoms?assisted synthesis | 6—7 | [ | |

| Organic template | Employing oxygen?containing compounds such as crown ethers and | 6—9 | [48,50—53] |

| system | polyols as templates | ||

| Employing quaternary alkylammonium ions as templates | 6—15.6 | [54—56,59—61] | |

| Employing pyridine derivatives as templates | 6.85 | [ | |

| Employing imidazolium-based ionic liquids as templates | 6—7 | [ |

| 1 | Donald W. B., Tonawanda N.Y., Crystalline Zeolite Y, USP3130007, 1964⁃04⁃21 |

| 2 | Camblor M. A., Corma A., Martinez A., Mocholi F. A., Pariente J. P., Appl. Catal., 1989, 55(1), 65—74 |

| 3 | Wang Q. L., Giannetto G., Guisnet M., J. Catalysis, 1991, 130(2), 471—482 |

| 4 | Biaglow A. I., Parrillo D. J., Kokotailo G. T., Gorte R. J., J. Catalysis, 1994, 148(1), 213—223 |

| 5 | Williams B. A., Babitz S. M., Miller J. T., Snurr R. Q., Kung H. H., Appl. Catal. A: Gen., 1999, 177(2), 161—175 |

| 6 | Corma A., Diaz⁃Cabanas M., Martinez⁃Triguero J., Rey F., Rius J., Nature, 2002, 418(6897), 514—517 |

| 7 | Corma A., Huber G. W., Sauvanaud L., O'Connor P., J. Catal., 2007, 247(2), 307—327 |

| 8 | Tao L., Wang Z. J., Yan T. H., Liu Y. M., He H. Y., Cao Y., ACS Catal., 2017, 7(2), 959—964 |

| 9 | West R. M., Holm M. S., Saravanamurugan S., Xiong J., Beversdorf Z., Taarning E., Christensen C. H., J. Catal., 2010, 269(1), 122—130 |

| 10 | Wang Q. L., Giannetto G., Guisnet M., J. Catal., 1991, 130(2), 471—482 |

| 11 | Agostini G., Lamberti C., Palin L., Milanesio M., Danilina N., Xu B., Janousch M., van Bokhoven J. A., J. Am. Chem. Soc., 2010, 132(2), 667—678 |

| 12 | Xu B., Bordiga S., Prins R., van Bokhoven J. A., Appl. Catal. A: Gen., 2007, 333(2), 245—253 |

| 13 | Zhao X. Z., Xu A. P., Wang B. J., Zhao H. J., Shen. B. J., Zhang L., Shi X. Q., Lin C. W., Petrochemical Technology & Application, 2009, 27(2), 107—111(赵晓争, 徐安平, 王宝杰, 赵红娟, 申宝剑, 张莉, 石晓庆, 刘超伟. 石化技术与应用, 2009, 27(2), 107—111) |

| 14 | Fan Y., Xiao H., Shi G., Liu H. Y., Qian Y., Wang T. H., Gon G. B., Bao X. J., J. Catal., 2011, 279(1), 27—35 |

| 15 | Verboekend D., Vilé G., Pérez⁃Ramírez J., Adv. Functional Materials,2012, 22(5), 916—928 |

| 16 | Silaghi M. C., Chizallet C., Raybaud P., Micropor. Mesopor. Mater., 2014, 191, 82—96 |

| 17 | Wang Q. L., Torrealba M., Giannetto G., Guisnet M., Perot G., Cahoreau M., Caisso J., Zeolites, 1990, 10(7), 703—706 |

| 18 | Qin Z. X., Shen B. J., Gao X. H., Lin F., Wang B. J., Xu C. M., J. Catal., 2011, 278(2), 266—275 |

| 19 | Qin Z. X., Cychosz K. A., Melinte G., El Siblani H., Gilson J. P., Thornmes M., Fernandez C., Mintova S., Ersen O., Valtchev V., J. Am. Chem. Soc., 2017, 139(48), 17273—17276 |

| 20 | Qin Z. X., Shen B. J., CIESC Journal, 2016, 67(8), 3160—3169(覃正兴, 申宝剑. 化工学报, 2016, 67(8), 3160—3169) |

| 21 | Wang R., Lu X. F., Xie F. M., Xu T. G., Jia P. F., Zhang G. J., Zhao T., Yang X. D., Inner Mongolia Petrochemical Industry, 2014,(15), 8—10(王锐, 陆雪峰, 谢方明, 徐铁刚, 贾鹏飞, 张国贾, 赵谭, 杨晓东. 内蒙古石油化工, 2014, (15), 8—10) |

| 22 | Wang Y. J., Sun Y. J., Suo Y. H., Xi H., Y., Zu X. Y., Bulletin of the Chinese Ceramic Society, 2015, 34(11), 3243—3246, 3250 |

| 23 | Xu R. R., Pang W. Q., Chemistry⁃Zeolites and Porous Materials, Science Press, Beijing, 2004, 248—249(徐如人, 庞文琴. 分子筛与多孔材料化学, 北京: 科学出版社, 2004, 248—249) |

| 24 | Thangaraj A., Kumar R., Zeolites, 1990, 10(2), 117—120 |

| 25 | Melchior M. T., Vaughan D. E. W., Pictroski C. F., J. Phy. Chem., 1995, 99(16), 6128—6144 |

| 26 | Hu H. X., Shi Q. H., J. Nanchang University(Engineering & Technology), 1998, 20(1), 81—84(胡汉祥, 施其宏. 南昌大学学报: 工科版, 1998, 20(1), 81—84) |

| 27 | Xiong G., Yu Y., Feng Z. C., Xin Q., Xiao F. S., Micropor. Mesopor. Mater., 2001, 42(2/3), 317—323 |

| 28 | Tannous M. K., Helmy M., Khalil F. H., Abadir M. F., Studies in Surface Science & Catalysis, 1985, 24, 137—145 |

| 29 | Shu X. T., Liu Z. Q., He M. Y., Li M. G., Chong Q., Luo. Y. B., Zong B. N., Mu X. H., A Preparation Method for NaY Molecular Sieve, CN1267345C, 2006⁃08⁃02 (舒兴田, 刘中清, 何鸣元, 李明罡, 崇奇, 罗一斌, 宗保宁, 慕旭宏. 一种NaY分子筛的制备方法, CN1267345C, 2006⁃08⁃02) |

| 30 | He M. Y., Liu Z. Q., Shu X. T., Luo Y. B., Chong Q., Zong B. N., Mu X. H., Preparation of Small Grain Molecular Sieve, CN1789125A, 2010⁃02⁃03(何鸣元, 刘中清, 舒兴田, 罗一斌, 崇奇, 宗保宁, 慕旭宏. 小晶粒分子筛制备方法, CN1789125A, 2010⁃02⁃03) |

| 31 | Chen H., Xu F., Lu S. X., Ouyang D. X., Wang S., Yu J. Y., A Preparation Method for NaY Zeolite with High SiO2/Al2O3 Ratio, CN101254929, 2012⁃07⁃11(陈辉, 许锋, 陆善祥, 欧阳丹霞, 王苏, 于冀勇. 一种高硅铝比NaY分子筛的制备方法, CN101254929, 2012⁃07⁃11) |

| 32 | Shen B. J., Zhu. M. Y., Qin S., Gao X. H., Wang B. J., Li Q., Zhang J. Y., Chen Y. Y., Shen W., Shen W., Zhao H. J., Liu C. H., Zhang J. H., Wang G. F., Luo J. S., Zhang Z. D., A Preparation Method for NaY Zeolite with High SiO2/Al2O3 Ratio, CN1012198950, 2013⁃03⁃27(申宝剑, 主明烨, 秦松, 高雄厚, 王宝杰, 李强, 张君屹, 陈元应, 沈文, 申伟, 赵红娟, 刘从华, 张吉华, 王国峰, 罗杰盛, 张忠东. 一种高硅铝比NaY分子筛的制备方法, CN1012198950, 2013⁃03⁃27) |

| 33 | Liu J. J., Zhang Y. M., Xu S. Y., Yu S., Zou J. W., Inorg. Chem. Industry, 2017, 49(11), 64—68(刘晶晶, 张永明, 徐树英, 于帅, 邹江文. 无机盐工业, 2017, 49(11), 64—68) |

| 34 | Oleksiak M. D., Muraoka K., Hsieh M. F., Conato M. T., Shimojima A., Okubo T., Chaikittisilp W., Rimer J. D., Angew. Chem. Int. Ed., 2017, 56(43), 13366—13371 |

| 35 | Shen B. J., Gao X. H., Zeng P. H., Wang B. J., Wang Y. C., Liu H. H., Pang X. M., Qin S., Guo J. T., Guo Q. X., Zheng J. H., Gong C. B., Zhang L., He J. L., Duan C. Y., Zhao L. H., Method for Preparing High SiO2 /Al2 O3 Ratio Small⁃grain NaY Zeolite, CN100404418, 2006⁃06⁃14(申宝剑, 高雄厚, 曾鹏晖, 王宝杰, 王玉超, 刘宏海, 庞新梅, 秦松, 郭金涛, 郭巧霞, 郑俊鹤, 龚朝兵, 张莉, 何金龙, 段长艳, 赵连鸿. 一种高硅铝比小晶粒NaY分子筛的制备方法, CN100404418, 2006⁃06⁃14) |

| 36 | Tan J., Zhang X. H., Zhao Q., Liu J., Min X. J., Li Q. S., Zhang J. M., Liu J. B., Zhang S. G., Method for Synthesizing Ultrafine NaY Zeolite with High SiO2 /Al2 O3 Ratio, CN104743572, 2015⁃07⁃01(谭涓, 张小虎, 赵强, 刘靖, 闵小健, 李全升, 张军民, 刘建斌, 张世刚. 一种合成高硅铝比超细NaY分子筛的方法, CN104743572, 2015⁃07⁃01) |

| 37 | Gu J. F., Cui L. W., Wang X. X., Yuan Z. Y., Ind. Catal., 2012, 20(1), 40—44(顾建峰, 崔楼伟, 王新星, 袁忠勇. 工业催化, 2012, 20(1), 40—44) |

| 38 | Xu R. R., Zhang J. M., Chem. J. Chinese Universities, 1982, 3(3), 7—12(徐如人, 张建民. 高等学校化学学报, 1982, 3(3),7—12) |

| 39 | Zhao Y., Liu, Z., Li W., Zhao Y., Pan H., Liu Y., Li M., Kong L., He M., Micropor. Mesopor. Mater., 2013, 167, 102—108 |

| 40 | Zhao Y. S., Liu Z. Q., He M. Y., Method for Preparing High SiO2 /Al2 O3 Ratio Small⁃grain NaY Zeolite, CN101767799, 2012⁃05⁃30(赵元生, 刘中清, 何鸣元. 一种高硅铝比小晶粒NaY分子筛的合成方法, CN101767799, 2012⁃05⁃30) |

| 41 | Li S. G., Xu R. R., Chem. J. Chinese Universities, 1983, 4(1), 1—6(李守贵, 徐如人. 高等学校化学学报, 1983, 4(1), 1—6) |

| 42 | Xiong X. Y., Li C. J., Yu H., Huang S. Y., Liang D. S., Xiao F. S., Li S. G., Chem. J. Chinese Universities, 2007, 28(9), 1634—1636(熊晓云, 李彩今, 于红, 黄世英, 梁德声, 肖丰收, 李守贵. 高等学校化学学报, 2007, 28(9), 1634—1636) |

| 43 | Shan Z. C., Liu S. Y., Li C. J., Zhu L. F., Meng X. J., Xiao F. S., Acta Physico⁃Chimica Sinica, 2011, 27(4), 959—964(单志超, 刘思宇, 李彩今, 朱龙凤, 孟祥举, 肖丰收. 物理化学学报, 2011, 27(4), 959—964) |

| 44 | Feng G., Cheng P., Yan W., Boronat M., Li X., Su J. H., Wang J., Li Y., Corma A., Xu R., Yu J., Science, 2016, 351(6278), 1188—1191 |

| 45 | Wang J., Liu P., Boronat M., Ferri P., Xu Z., Liu P., Shen B., Wang Z., Yu J., Angew. Chem. Int. Ed., 2020, 10.1002/anie. 202005715 |

| 46 | Cao F., Guo D. D., Huan M. Y., Sun H. M., Zhang B., Yang W. M., Chemical Reaction Engineering and Technology, 2017, 33(1), 21—28(曹锋, 郭冬冬, 宦明耀, 孙洪敏, 张斌, 杨为民. 化学反应工程与工艺, 2017, 33(1), 21—28) |

| 47 | Guo Y., Sun T. J., Gu Y. M., Liu X. W., Ke Q. L., Wang S. D., Chemistry an Asian Journal, 2018, 13(9), 1114—1118 |

| 48 | Delprato F., Delmotte L., Guth J. L., Huve L., Zeolites, 1990, 10(6), 546—552 |

| 49 | Feijen E. J. P., De Vadder K., Bosschaerts M. H., Lievens J. L., Martens J. A., Grobet P. J., Jacobs P. A., J. Am. Chem. Soc., 1994, 116(7), 2950—2957 |

| 50 | Dougnier F., Patarin J., Guth J. L., Anglerot D., Zeolites, 1993, 13(2), 122—127 |

| 51 | Chatelain T., Patarin J., Soulard M., Guth J. L., Schulz P., Zeolites,1995, 15(2), 90—96 |

| 52 | Karim K., Zhao J., Rawlence D., Dwyer J., Micropor. Mater., 1995, 3(6), 695—698 |

| 53 | Witte B. D., Patarin J., Nouen D. L., Delmotte L., Guth J. L., Cholley T., Micropor. Mesopor. Mater., 1998, 23(1), 11—22 |

| 54 | Vaughan D. E. W., Process for Preparing a High Silica Faujasite Aluminosilicate, ECR⁃4, US4714601, 1987⁃12⁃22 |

| 55 | Strohmaier K. G., Vaughan D. E. W., Process for Preparing a High Silica Zeolite Having the Faujasite Topology, ECR⁃32, US3574538, 1990⁃06⁃05 |

| 56 | Berger C., Gläser R., Rakoczy R. A., Weitkamp J., Micropor. Mesopor. Mater., 2005, 83(1—3), 333—344 |

| 57 | Zhu L., Ren L., Zeng S., Yang C., Zhang H., Meng X., Rigutto M., Made A., Xiao F. S., Chem. Commun.,2013, 49(89), 10495—10497 |

| 58 | Yuan D. H., He D. W., Xu S. T., Song Z. J., Zhang M. Z., Wei Y. X., He Y. L., Xu S. L., Liu Z. M., Xu Y. P., Micropor. Mesopor. Mater., 2015, 204, 1—7 |

| 59 | He D. W., Yuan D. H., Song Z. J., Tong Y. S., Liu Z. M., Chem. Commun., 2016, 52(86), 12765—12768 |

| 60 | He D. W., Yuan D. H., Song Z. J., Xu Y. P., Liu Z. M., Chin.J. Phys. Chem., 2019, 40(1), 52—59 |

| 61 | Zhu D. L., Wang L. Y., Fan D., Yan N. N., Huang S. J., Xu S. T., Yang M., Zhang J. M., Tian P., Liu Z. M., Adv. Mater.,2020, 32(26), 2000272 |

| 62 | Julien G., Hussein A., Mintova., CrystEngComm,2016, 18, 650—664 |

| 63 | Burkett Sandra L., Davis Mark E., J. Phys. Chem.,1994, 98(17), 4647—4653 |

| 64 | Smaihi M., Barida O., Valtchev V., Eur. J. Inorg. Chem., 2003, (24), 4370—4377 |

| 65 | Fan F. T., Feng Z. C., Li, C., Chem. Soc. Rev., 2010, 39(12), 4794—4801 |

| 66 | Ivanova I. I., Kolyagin Y. G., Kasyanov I. A., Yakimov A. V., Bok T. O., Zarubin D. N., Angew. Chem. Int. Ed.2017, 56, 15344—15347 |

| 67 | Fan F. T., Xu Q., Xia H. A., Sun K. J., Feng Z. C., Li C., Chinese J. Catal., 2009, 30(8), 717—739(范峰滔, 徐倩, 夏海岸, 孙科举, 冯兆池, 李灿, 催化学报, 2009, 30(8), 717—739) |

| 68 | Yu Y., Xiong G., Li C., Xiao F. S., Micropor. Mesopor. Mater., 2001, 82, 23—34 |

| 69 | Cundy C. S., Cox P. A., Micropor. Mesopor. Mater., 2005, 82(1/2), 1—78 |

| 70 | Taniguchi H., Lu J. T., Huang. J. Z., Science, 2013, 339(6115), 70—74 |

| 71 | Tosheva L, Valtchev V P., Chem. Mater.,2005, 17(10), 2494—2513 |

| 72 | Valentin P. V., Krassimir. N. B., J. Phys. Chem. B, 2004, 108(40), 15587—15598 |

| 73 | Itani L., Liu Y., Zhang W. P., Bozhiov K. N., Delmotte L., Valtchev V., J. Am. Chem. Soc., 2009, 131(29), 10127—10139 |

| 74 | Dutta Prabir K., Shieh D. C., Puri M., J. Phys. Chem., 1987, 91(9), 2332—2336 |

| 75 | Valtchev V. P., Bozhilov K. N., J. Phys. Chem. B, 2004, 108(40), 15587—15598 |

| 76 | Mintova S., Olson N. H., Bein T., Angew. Chem. Int. Ed., 2010, 38(21), 3201—3204 |

| 77 | Oleksiak M. D., Soltis J. A., Conato M. T., Penn R. L., Rimer J. D., Chem. Mater., 2016, 28(14), 4906—4916 |

| [1] | 王磊, 孙毯毯, 闫娜娜, 马超, 刘晓娜, 田鹏, 郭鹏, 刘中民. 利用适用于SAPO-34的有机结构导向剂合成SSZ-13分子筛[J]. 高等学校化学学报, 2021, 42(6): 1716. |

| [2] | 宋文尧, 周张浪, 杨鑫莉, 陈岚, 葛广路. 介孔二氧化硅对映选择性吸附的手性印迹调控[J]. 高等学校化学学报, 2021, 42(10): 3144. |

| [3] | 闻嘉丽, 张钧豪, 姜久兴. 超大孔分子筛, 十年再回顾[J]. 高等学校化学学报, 2021, 42(1): 101. |

| [4] | 薛云,晏秘,申妍铭,毛会玲,王晨,程琥,庄金亮. 锚定基团对HKUST-1/TEMPO共催化体系催化性能的影响[J]. 高等学校化学学报, 2020, 41(5): 1068. |

| [5] | 夏敦焰, 彭莉, 吴政奇, 王林之, 贾逸民, 张春, 顾学红. MFI型分子筛膜的两段变温合成及对二甲苯异构体的分离性能[J]. 高等学校化学学报, 2020, 41(12): 2813. |

| [6] | 罗东霞, 李冰, 王全义, 田鹏, 刘仲毅, 刘中民. SAPO-5分子筛的晶化过程研究[J]. 高等学校化学学报, 2020, 41(11): 2442. |

| [7] | 章凌,段宏昌,谭争国,吴勤明,孟祥举,肖丰收. 用于柴油车尾气消除反应(NH3-SCR)的八元环沸石分子筛研究进展[J]. 高等学校化学学报, 2020, 41(1): 19. |

| [8] | 赵东璞, 赵全升, 张妍, 石拓, 姚横国, 于建强. SAPO-18/SAPO-34共晶分子筛的合成及表征[J]. 高等学校化学学报, 2016, 37(2): 342. |

| [9] | 李莉, 颜岩, 王大明, 郑大方, 李激扬. 具有16元环超大孔道磷酸钒化合物的水热合成及表征[J]. 高等学校化学学报, 2014, 35(11): 2285. |

| [10] | 邵浪, 李乙, 王晓方, 于吉红. 以醚胺为模板剂合成含二价金属杂原子的开放骨架磷酸铝化合物M(Ⅱ)-CJ50[J]. 高等学校化学学报, 2013, 34(8): 1806. |

| [11] | 王亚丽, 聂艳艳, 蒋育澄, 胡满成, 李淑妮, 翟全国. 基于小分子掺杂及聚电介质模板导向的水溶性聚苯胺的CPO酶促氧化合成及结构性能表征[J]. 高等学校化学学报, 2012, 33(06): 1344. |

| [12] | 戈根武 刘美玭 倪志刚 杜红宾. 新型三维开放骨架稀土硫酸盐[Ln4(H2O)4(SO4)10](C4N2H12)4(H2O)4(Ln=Gd,Eu)的合成、结构及荧光性质[J]. 高等学校化学学报, 2011, 32(3): 644. |

| [13] | 丁红, 宋江伟, 任利敏, 肖丰收. Y沸石水热转晶为ECR-1沸石的研究[J]. 高等学校化学学报, 2009, 30(2): 255. |

| [14] | 熊晓云, 李彩今, 于红, 黄世英, 梁德声, 肖丰收, 李守贵 . 高温合成NaY沸石[J]. 高等学校化学学报, 2007, 28(9): 1634. |

| [15] | 熊晓云,范峰滔,马军,李彩今,刘淑真,冯兆池,梁德声,李守贵,肖丰收 . 用高效NaY沸石导向剂快速合成A型沸石[J]. 高等学校化学学报, 2007, 28(1): 21. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||