Chem. J. Chinese Universities ›› 2019, Vol. 40 ›› Issue (2): 201.doi: 10.7503/cjcu20180374

• Inorganic Chemistry • Previous Articles Next Articles

HUI Longfei1,2, LI Jianguo1,2, GONG Ting1,2, SUN Daoan3, LÜ Jian3, HU Shenlin4, FENG Hao1,2,3,*( )

)

Received:2018-05-21

Online:2019-02-10

Published:2018-10-08

Contact:

FENG Hao

E-mail:fenghao98@hotmail.com

Supported by:CLC Number:

TrendMD:

HUI Longfei,LI Jianguo,GONG Ting,SUN Daoan,LÜ Jian,HU Shenlin,FENG Hao. Fabrication of Silica and Titania Anti-coking Passivation Layers in High Aspect-ratio Tubular Reactors by Atomic Layer Deposition†[J]. Chem. J. Chinese Universities, 2019, 40(2): 201.

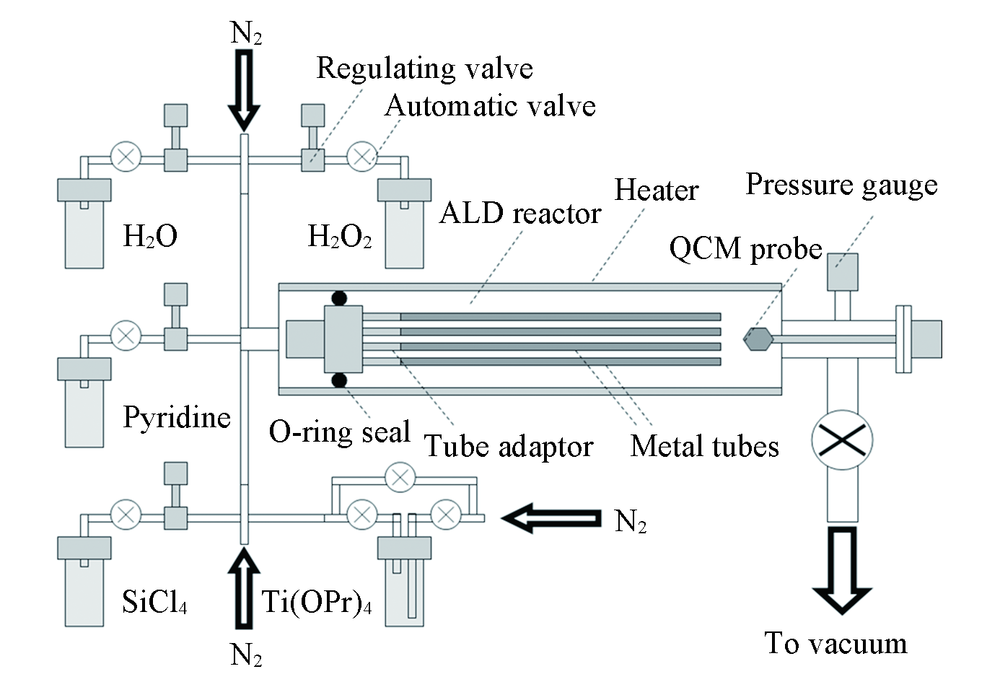

Fig.1 Schematic of the ALD system customized for fabricating anti-coking passivation layers on the internal walls of high aspect-ratio tubular reactors

| Element | Surface coated with 1000 cycles ALD SiO2 | Surface coated with 1000 cycles ALD TiO2 | ||||

|---|---|---|---|---|---|---|

| Inlet | Middle | Outlet | Inlet | Middle | Outlet | |

| O | 52.1 | 49.4 | 46.8 | 48.0 | 43.1 | 45.5 |

| Si | 12.0 | 11.4 | 10.6 | N.A.* | N.A.* | N.A.* |

| Ti | N.A.* | N.A.* | N.A.* | 21.0 | 18.4 | 19.5 |

| Cr | 9.3 | 10.1 | 12.2 | 9.6 | 13.8 | 10.1 |

| Fe | 22.5 | 24.4 | 25.6 | 19.9 | 21.8 | 23.2 |

| Ni | 2.7 | 3.3 | 3.2 | 0.7 | 1.7 | 1.0 |

| Mn | 0.3 | 0.6 | 0.8 | 0.8 | 1.2 | 0.7 |

| Cl | 1.1 | 0.8 | 1.0 | N.A.* | N.A.* | N.A.* |

Table 1 Surface composition(molar fraction, %) measured at different position of the internal tube walls by EDS

| Element | Surface coated with 1000 cycles ALD SiO2 | Surface coated with 1000 cycles ALD TiO2 | ||||

|---|---|---|---|---|---|---|

| Inlet | Middle | Outlet | Inlet | Middle | Outlet | |

| O | 52.1 | 49.4 | 46.8 | 48.0 | 43.1 | 45.5 |

| Si | 12.0 | 11.4 | 10.6 | N.A.* | N.A.* | N.A.* |

| Ti | N.A.* | N.A.* | N.A.* | 21.0 | 18.4 | 19.5 |

| Cr | 9.3 | 10.1 | 12.2 | 9.6 | 13.8 | 10.1 |

| Fe | 22.5 | 24.4 | 25.6 | 19.9 | 21.8 | 23.2 |

| Ni | 2.7 | 3.3 | 3.2 | 0.7 | 1.7 | 1.0 |

| Mn | 0.3 | 0.6 | 0.8 | 0.8 | 1.2 | 0.7 |

| Cl | 1.1 | 0.8 | 1.0 | N.A.* | N.A.* | N.A.* |

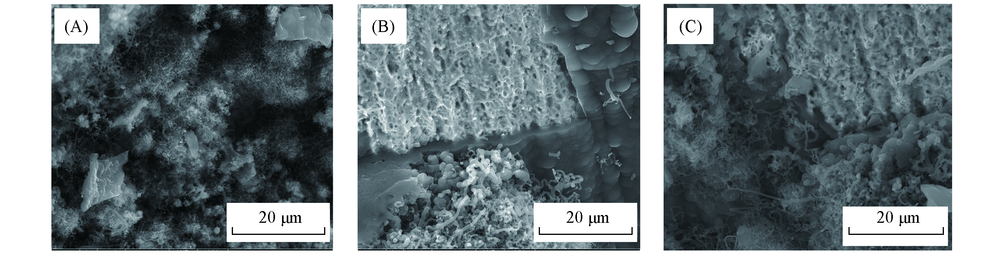

Fig.8 SEM images of ALD SiO2 passivated metal surface after the coking experiments(A) 500 cycles ALD SiO2(destroyed oxide film); (B) 1000 cycles ALD SiO2(partially-destroyed oxide film); (C) 1500 cycles ALD SiO2(partially-destroyed oxide film).

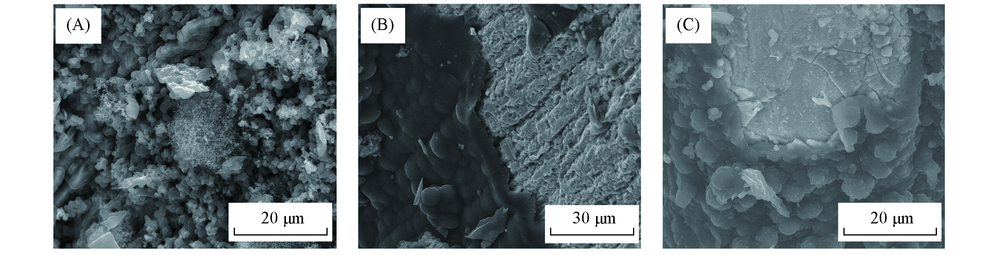

Fig.9 SEM images of ALD TiO2 passivated metal surface after the coking experiments(A) 500 cycles ALD TiO2(destroyed oxide film); (B) 1000 cycles ALD TiO2(intact oxide film); (C) 1500 cycles ALD TiO2(partially-cracked oxide film).

| [1] | Albright L. F., Marek J. C., Ind. Eng. Chem. Res.,1988, 27, 755-759 |

| [2] | Froment G. F., Chem. Eng. Sci., 1981, 36(8), 1271-1282 |

| [3] | Shen L. M., Gong J. M., Liu H. S., Huang Y. X., J. Shanghai Jiaotong Univ.,2014, 48(8), 1159-1163 |

| (沈利民, 巩建鸣, 刘焕胜, 黄玉霞. 上海交通大学学报, 2014, 48(8), 1159-1163) | |

| [4] | Kumar P., Kunzru D., Can. J. Chem. Eng.,1987, 65(2), 280-285 |

| [5] | Huang Y. F., Zhu Y. L., Xiong C. J., Pan Y. J., J. Beijing Univ. Aeron. Astron.,2011, 37(6), 753-756 |

| (黄艳斐, 朱岳麟, 熊常健, 潘英杰. 北京航空航天大学学报, 2011, 37(6), 753-756) | |

| [6] | Wauters S., Marin G. B., Ind. Eng. Chem. Res.,2002, 41(10), 2379-2391 |

| [7] | Mohamadalizadeh A., Towfighi J., Karimzadeh R., J. Anal. Appl. Pyrol.,2008, 82(1), 134-139 |

| [8] | Abghari S. Z., J. Petrol. Sci. Eng., 2013, 2(2), 82-91 |

| [9] | Jiang R. P., Liu G. Z., He X. Y., Yang C. H., Wang L., Zhang X. W., Mi Z. T., J. Anal. Appl. Pyrol.,2011, 92(2), 292-306 |

| [10] | Edwards T., Combust. Sci. Technol., 2006, 178(1-3), 307-334 |

| [11] | Guo Y. S., Fang W. J., Lin R. S., J. Zhejiang Univ-Sci. A,2005, 39(4), 538-541 |

| (郭永胜, 方文军, 林瑞森. 浙江大学学报(工学版), 2005, 39(4), 538-541) | |

| [12] | Liu G., Han Y., Wang L., Zhang X., Mi Z., Energ. Fuel,2009, 23(1), 356-365 |

| [13] | Hu W. X., Shen J., Zhou R. J., Dang Y. X., J. Petrochemical Universities,2017, 30(1), 1-7 |

| (胡文学, 沈健, 周如金, 党迎喜. 石油化工高等学校学报, 2017, 30(1), 1-7) | |

| [14] | Wickham D. T., Engel J. R., Karpuk M. R., Preprint Paper Am. Chem. Soc. Div. Petrol. Chem.,2000, 45(3), 459-464 |

| [15] | Mohan A. R., Eser S., Ind. Eng. Chem. Res.,2011, 50(12), 7290-7304 |

| [16] | Zhou J., Xu H., Liu J., Qi X., Zhang L., Jiang Z., Mater. Lett.,2007, 61(29), 5087-5090 |

| [17] | Yang C., Liu G., Wang X., Jiang R., Wang L., Zhang X., Ind. Eng. Chem. Res.,2012, 51(3), 1256-1263 |

| [18] | Tang S., Hu S., Zhang Y., Wang J., Zhu Q., Chen Y., Li X., J. Anal. Appl. Pyrol.,2014, 107(5), 197-203 |

| [19] | Tang S., Gao S., Wang S., Wang J., Zhu Q., Surf. Coat. Tech.,2014, 258(7), 1060-1067 |

| [20] | Chien Y. Y., Chien F. L., Exp. Therm. Fluid. Sci., 2013, 47, 40-47 |

| [21] | Jia S. Y., Yang W. G., Zhang B., Modern Paint & Finishing,2011, 14(1), 25-27 |

| (贾思洋, 杨万国, 张波. 现代涂料与涂装, 2011, 14(1), 25-27) | |

| [22] | George S. M., Chem. Rev., 2010, 110(1), 111-131 |

| [23] | Clark M. D., Maschmann M. R., Patel R. J., Leever B. J., Sol. Energ. Mat. Sol. C,2014, 128(5), 178-183 |

| [24] | Díaz B., Härkönen E., $\acute{S}$wiatowska J., Maurice V., Seyeux A., Marcus P., Ritala M., Corros. Sci.,2011, 53(6), 2168-2175 |

| [25] | Han D. S., Choi D. K., Park J. W., Thin Solid Films,2014, 552, 155-158 |

| [26] | Hirvikorpi T., Vähä-Nissi M., Mustonen T., Liskola E., Karppinen M., Thin Solid Films,2010, 518(10), 2654-2658 |

| [27] | Marin E., Lanzutti A., Lekka M., Guzman L., Ensinger W., Fedrizzi L., Surf. Coat. Tech.,2014, 211(3), 84-88 |

| [28] | Roy A. K., Schulze S., Hietschold M., Goedel W. A., Carbon,2012, 50(3), 761-770 |

| [29] | Gong T., Hui L. F., Zhang J. W., Sun D. A., Qin L. J., Du Y. M., Li C. Y., Lu J., Hu S. L., Feng H., Ind. Eng. Chem. Res.,2015, 54(15), 3746-3753 |

| [30] | Gao S., Hu S. W., Zhu Q., Zhang Q. Y., Wang J. L., Li X. Y., J. Fuel Chem. Techno.,2014, 42(8), 1010-1017 |

| (高爽, 胡生望, 朱权, 张其翼, 王健礼, 李象远. 燃料化学学报, 2014, 42(8), 1010-1017) | |

| [31] | Luan X. J., Xu H., Wang Z. Y., Zhou J. X., Zhu W., Chinese Petrol. Processing Petrochem. Technol.,2011, 42(5), 75-80 |

| (栾小建, 徐宏, 王志远, 周建新, 朱巍. 石油炼制与化工, 2011, 42(5), 75-80) | |

| [32] | Tang S., Wang J., Zhu Q., Chen Y., Li X., ACS Appl. Mater. Inter.,2014, 6(19), 17157-17165 |

| [33] | Du Y., Du X., George S. M., J. Phys. Chem. C,2007, 111(1), 219-226 |

| [34] | Thielsch R., Gatto A., Kaiser N., Appl. Optics,2002, 41(16), 3211-3217 |

| [35] | Du Y., Du X., George S. M., Thin Solid Films,2005, 491(1), 43-53 |

| [36] | Foong T. R. B., Shen Y., Hu X., Sellinger A., Adv. Funct. Mater.,2010, 20(9), 1390-1396 |

| [37] | Sun D. A., Du Y. M., Zhang J. W., Jiao Y., Li Y., Wang Z. X., Li C. Y., Feng H., Lu J., Fuel,2017, 194, 266-273 |

| [1] | HE Beibei, YANG Kuihua, LYU Rui. Construction of Mn-Cu Bimetal Containing Phyllosilicate Nanozyme and Evaluation of the Enzyme-like Properties [J]. Chem. J. Chinese Universities, 2022, 43(8): 20220150. |

| [2] | YAN Zhixuan, MA Ji, QU Jinlei, LIU Li, SUN Chong, LIU Jiwen, LIU Guangye, SUN Lishui, HE Lixia. Synthesis and Application of Modified Low Molecular Weight Polyisoprene [J]. Chem. J. Chinese Universities, 2022, 43(6): 20220066. |

| [3] | ZHANG Jie, YIN Bo, LIU Weixin, LIU Xingping, LIAN Wenxian, TANG Shaokun. Fabrication of Boehmite Fiber-reinforced Silica Aerogels and Their Performances [J]. Chem. J. Chinese Universities, 2022, 43(11): 20220483. |

| [4] | LI Yichuan, ZHU Guofu, WANG Yu, CHAI Yongming, LIU Chenguang, HE Shengbao. Effects of Substrate Surface Properties and Precursor Chemical Environment on In⁃situ Oriented Construction of Titanium Silicalite Zeolite Membranes [J]. Chem. J. Chinese Universities, 2021, 42(9): 2934. |

| [5] | WANG Yuxiang, YU Shen, LIU Zhan, LYU Jiamin, LI Xiaoyun, CHEN Lihua, SU Baolian. One-step Synthesis of Amorphous Silica Aluminum Support Materials with Controllable Acidity and Porosity and Catalytic Performance of Their Pd-based Catalysts [J]. Chem. J. Chinese Universities, 2021, 42(6): 1826. |

| [6] | HAN Yandong, HAN Mingyong, YANG Wensheng. Sol-gel Construction of Mesoporous Silica Nanomicrostructures [J]. Chem. J. Chinese Universities, 2021, 42(4): 965. |

| [7] | WANG Bodong, PAN Meichen, ZHUO Ying. Construction of Electrochemiluminescence Sensing Interface Based on Silver Nanoclusters-Silica Nanoparticles and Biomolecular Recognition [J]. Chem. J. Chinese Universities, 2021, 42(11): 3519. |

| [8] | WANG Mingxia, LIU Zhihui, ZHU Zhen, LI Lingfeng, WANG Bowei. Preparation and Properties of Nano Lithium Magnesium Silicate-chitosan-sodium Alginate Composite Scaffold Materials [J]. Chem. J. Chinese Universities, 2021, 42(10): 3240. |

| [9] | SONG Wenyao, ZHOU Zhanglang, YANG Xinli, CHEN Lan, GE Guanglu. Tunable Enantioselective Adsorption of the As⁃synthesized Mesoporous Silica Through Chiral Imprinting [J]. Chem. J. Chinese Universities, 2021, 42(10): 3144. |

| [10] | WANG Juan, WANG Linying, ZHU Dali, CUI Wenhao, WANG Yifeng, TIAN Peng, LIU Zhongmin. Progress in Direct Synthesis of High Silica Zeolite Y [J]. Chem. J. Chinese Universities, 2021, 42(1): 1. |

| [11] | WANG Jianyu, ZHANG Qiang, YAN Wenfu, YU Jihong. Roles of Hydroxyl Radicals in Zeolite Synthesis [J]. Chem. J. Chinese Universities, 2021, 42(1): 11. |

| [12] | WU Qinming, WANG Yeqing, MENG Xiangju, XIAO Fengshou. Reconsideration of Crystallization Process for Aluminosilicate Zeolites [J]. Chem. J. Chinese Universities, 2021, 42(1): 21. |

| [13] | JIAO Meichen, JIANG Jingang, XU Hao, WU Peng. Structural Stabilization, Modification and Catalytic Applications of Germanosilicates [J]. Chem. J. Chinese Universities, 2021, 42(1): 29. |

| [14] | WANG Huan, SUO Jinquan, WANG Chunyan, WANG Runwei. Glucose Oxidase Immobilization with Amino Dendritic Mesoporous Silica Nanoparticles and Its Application in Glucose Detection [J]. Chem. J. Chinese Universities, 2020, 41(8): 1731. |

| [15] | WANG Tingting, LEI Yuhan, LIN Yujuan, HUANG Jialing, LIU Cuie, ZHENG Fengying, LI Shunxing. Preparation of Liposome-terminated CsPbX3(X=Cl,Br,I) Nanocrystals and Applications in Light-emitting Diode Devices [J]. Chem. J. Chinese Universities, 2020, 41(8): 1896. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||