Chem. J. Chinese Universities ›› 2015, Vol. 36 ›› Issue (3): 499.doi: 10.7503/cjcu20140707

• Organic Chemistry • Previous Articles Next Articles

WANG Songmei, KUAN Dingyaw, DU Wei*( ), ZHAO Xuebing, LIU Dehua*(

), ZHAO Xuebing, LIU Dehua*( )

)

Received:2014-07-29

Online:2015-03-10

Published:2015-01-30

Contact:

DU Wei,LIU Dehua

E-mail:duwei@tsinghua.edu.cn;dhliu@tsinghua.edu.cn

Supported by:CLC Number:

TrendMD:

WANG Songmei, KUAN Dingyaw, DU Wei, ZHAO Xuebing, LIU Dehua. Effect of Organic Acid Treatment on Microalgae Lipid Extraction†[J]. Chem. J. Chinese Universities, 2015, 36(3): 499.

| Method | Bead-beating | Microwaves | Sonication | Steam explosion | HCl | Formic acid* | No disruption |

|---|---|---|---|---|---|---|---|

| Total lipid yield(mass fraction, %) | 28.9±3.1 | 6.0±0.5 | 15.4±1.1 | 7.4±0.8 | 47.2±2.6 | 46.7±0.8 | 5.7±0.4 |

| FAME yield(mass fraction, %) | 54.0±5.8 | NA | 27.1±1.9 | NA | 91.0±5.1 | 83.9±1.5 | NA |

Table 1 Lipid extraction efficiency according to cell disruption method from Chlorella protothecoides*

| Method | Bead-beating | Microwaves | Sonication | Steam explosion | HCl | Formic acid* | No disruption |

|---|---|---|---|---|---|---|---|

| Total lipid yield(mass fraction, %) | 28.9±3.1 | 6.0±0.5 | 15.4±1.1 | 7.4±0.8 | 47.2±2.6 | 46.7±0.8 | 5.7±0.4 |

| FAME yield(mass fraction, %) | 54.0±5.8 | NA | 27.1±1.9 | NA | 91.0±5.1 | 83.9±1.5 | NA |

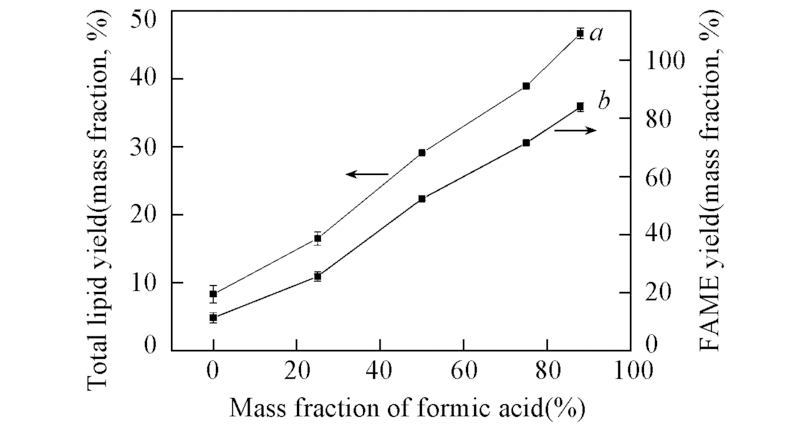

Fig.1 Effects of formic acid concentrations on total lipid yield(a) and FAME yield(b) from Chlorella protothecoides Ratio of liquid to solid: 10 mL/g, temperature: 100 ℃, time: 30 min, stirring rate: 250 r/min.

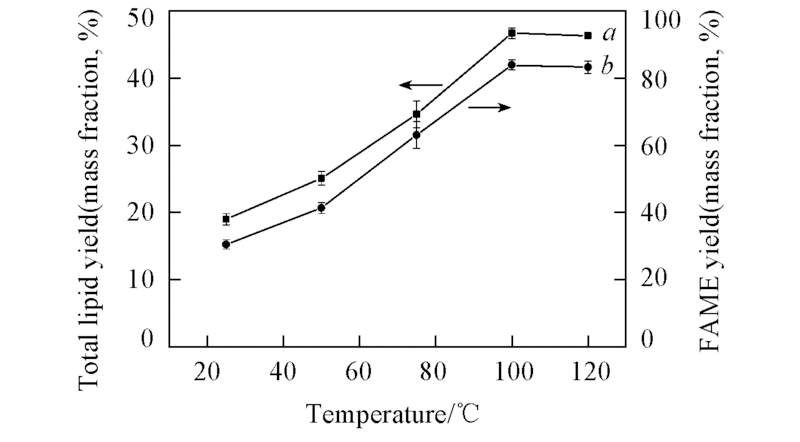

Fig.2 Effect of temperature on total lipid yield(a) and FAME yield(b) from Chlorella proto-thecoides Mass fraction of formic acid: 88%, ratio of liquid to solid: 10 mL/g, time: 30 min, stirring rate: 250 r/min.

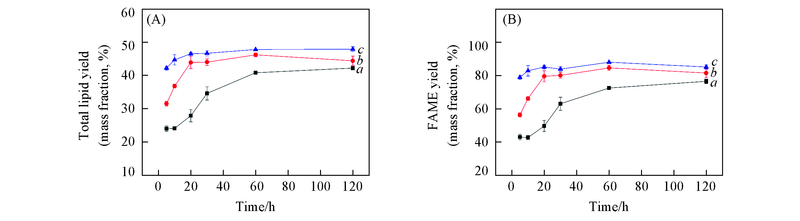

Fig.3 Effect of time on total lipid yield(A) and FAME yield(B) from Chlorella protothecoides Mass fraction of formic acid: 88%, ratio of liquid to solid: 10 mL/g, stirring rate: 250 r/min, temperature/℃: a. 75; b. 90; c. 100.

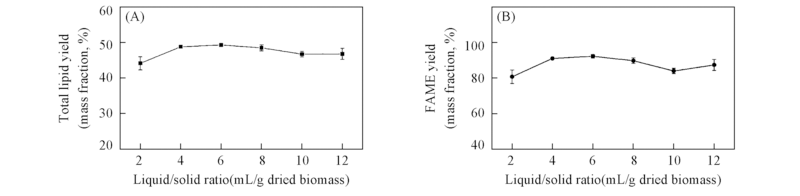

Fig.4 Effect of liquid/solid ratio on total lipid yield(A) and FAME yield(B) from Chlorella protothecoides Mass fraction of formic acid: 88%, ratio of liquid to solid: 100 ℃, time: 30 min, stirring rate: 250 r/min.

| Fatty acid | Amount of fatty acid(%) | Fatty acid | Amount of fatty acid(%) | ||

|---|---|---|---|---|---|

| Formic acid | HCl | Formic acid | HCl | ||

| C16:0 | 7.6±0.0 | 7.6±0.1 | C18:2 | 15.9±0.1 | 16.0±0.0 |

| C18:0 | 4.2±0.1 | 4.0±0.0 | C20:0 | 1.7±0.0 | 1.6±0.0 |

| C18:1 | 70.6±0.0 | 70.8±0.1 | |||

Table 2 Fatty acid composition of Chlorella protothecoides*

| Fatty acid | Amount of fatty acid(%) | Fatty acid | Amount of fatty acid(%) | ||

|---|---|---|---|---|---|

| Formic acid | HCl | Formic acid | HCl | ||

| C16:0 | 7.6±0.0 | 7.6±0.1 | C18:2 | 15.9±0.1 | 16.0±0.0 |

| C18:0 | 4.2±0.1 | 4.0±0.0 | C20:0 | 1.7±0.0 | 1.6±0.0 |

| C18:1 | 70.6±0.0 | 70.8±0.1 | |||

| Series | Chlorella protothecoides | Nannochlorum sp | Nannochloropsis oceanic | |||

|---|---|---|---|---|---|---|

| Formic acid | HCl | Formic acid | HCl | Formic acid | HCl | |

| Total lipid yield(mass fraction, %) | 49.2±0.0 | 47.2±2.6 | 21.3±0.7 | 14.7±0.4 | 26.0±0.0 | 21.7±0.1 |

| FAME yield(mass fraction, %) | 92.1±0.93 | 91.0±5.1 | 92.9±3.1 | 89.5±2.6 | 96.2±0.1 | 97.8±0.7 |

Table 3 Lipid extraction efficiency according to species with formic acid treatment method*

| Series | Chlorella protothecoides | Nannochlorum sp | Nannochloropsis oceanic | |||

|---|---|---|---|---|---|---|

| Formic acid | HCl | Formic acid | HCl | Formic acid | HCl | |

| Total lipid yield(mass fraction, %) | 49.2±0.0 | 47.2±2.6 | 21.3±0.7 | 14.7±0.4 | 26.0±0.0 | 21.7±0.1 |

| FAME yield(mass fraction, %) | 92.1±0.93 | 91.0±5.1 | 92.9±3.1 | 89.5±2.6 | 96.2±0.1 | 97.8±0.7 |

| [1] | Aransiola E. F., Ojumu T. V., Oyekola O. O., Madzimbamuto T. F., Ikhu-Omoregbe D. I. O., Biomass and Bioenergy,2014, 61, 276—297 |

| [2] | Li S. H., Fang Y. M., Wang F., Li P., Li X. Y., Chem. J. Chinese Universities,2013, 34(7), 1714—1722 |

| (李树豪, 方亚梅, 王繁, 李萍, 李象远. 高等学校化学学报, 2013, 34(7), 1714—1722) | |

| [3] | Chisti Y., Biotechnol. Advances, 2007, 25(3), 294—306 |

| [4] | Rawat I., Ranjith R., Mutanda T., Bux F., Appl. Energy,2013, 103, 444—467 |

| [5] | Tong M., Zhou Z.G., Agric. Eng. Technol.:New Energy Ind., 2009, (5), 19—26 |

| (童牧, 周志刚. 农业工程技术: 新能源产业, 2009, (5), 19—26) | |

| [6] | Jiang X. M., Zheng Y. Z., Acta. Hydrob. Sin., 2003, 27(3), 243—247 |

| (蒋霞敏, 郑亦周. 水生生物学报, 2003, 27(3), 243—247) | |

| [7] | Halim R., Harun R., Danquah M. K., Webley P. A., Appl. Energy,2012, 91(1), 116—121 |

| [8] | Lee A. K., Lewis D. M., Ashman P. J., Biomass and Bioenergy,2012, 46, 89—101 |

| [9] | Halim R., Danquah M. K., Webley P. A., Biotechnol. Adv., 2012, 30(3), 709—732 |

| [10] | Lee J. Y., Yoo C., Jun S. Y., Ahn C. Y., Oh H. M., Bioresour. Technol., 2010, 101(1), 75—77 |

| [11] | Zheng H. L., Yin J. L., Gao Zh., Huang H., Ji X. J., Dou C., Appl. Biochem. Biotechnol., 2011, 164(7), 1215—1224 |

| [12] | Prabakaran P., Ravindran A. D., Lett. Appl. Microbiol., 2011, 53(2), 150—154 |

| [13] | Neto A. M. P., Souza R. A. S., Leon-Nino A. D., Costa J. D. A., Tiburcio R. S., Nunes T. A., Mello T. C. S., Kanemoto F. T., Saldanha F. M. P., Gianesella S. M. F., Renew. Energy,2013, 55, 525—531 |

| [14] | Kong F. M., Zhao X. Y., Tian Y. J., Guo T. Q., Liu J. J., China Brewing,2010, 29(5), 143—145 |

| (孔凡敏, 赵祥颖, 田延军, 国天庆, 刘建军. 中国酿造, 2010, 29(5), 143—145) | |

| [15] | Xu J.Y., Microbial Conversion of Crude Glycerol to Lipids by Oleaginous Yeast Rhodosporidium. Toruloides, Tsinghua University, Beijing, 2013 |

| (徐静阳. 圆红冬孢酵母转化粗甘油合成油脂及其调控, 北京: 清华大学, 2013) | |

| [16] | Zhang H., Tang B. K., Row K., Chem. Res. Chinese Universities,2014, 30(1), 37—41 |

| [17] | Steriti A., Rossi R., Concas A., Cao G., Bioresour. Technol., 2014, 164, 70—77 |

| [18] | Lam H. Q., Bigot Y. L., Delmas M., Avignon G., Ind. Crops Prod., 2001, 14, 65—71 |

| [19] | Ligero P., Vega A., Bao M., Ind. Crops Prod., 2005, 21(2), 235—240 |

| [20] | Zhao X. B., Wang L., Liu D. H., J. Chem. Technol. Biotechnol., 2007, 82(12), 1115—1121 |

| [21] | Zhao X.B., Pulping and Pretreatment of Lignocellulosic Biomass with Organic Acids, Tsinghua University, Beijing, 2009 |

| (赵雪冰. 木质纤维原料的有机酸制浆及生物转化的预处理, 北京: 清华大学, 2009) | |

| [22] | Bligh E. G., Dyer W. J., Can. J. Biochem. Physiol., 1959, 37, 911—917 |

| [23] | Laurens L. M. L., Quinn M., Van W. S., David W. T., Edward J. W., Anal. Bioanal. Chem., 2012, 403(1), 167—178 |

| [24] | Griffiths M. J., Van Hille R. P., Harrison S. T. L., Lipids,2010, 45(11), 1053—1060 |

| [1] | DING Yang, WANG Wanhui, BAO Ming. Recent Progress in Porous Framework-immobilized Molecular Catalysts for CO2 Hydrogenation to Formic Acid [J]. Chem. J. Chinese Universities, 2022, 43(7): 20220309. |

| [2] | XIAO Zhaozhong, MA Zhi, PIAO Lingyu. Co-catalytic Effect of Ni2P on Photocatalytic Formic Acid Dehydrogenation over Different Semiconductors [J]. Chem. J. Chinese Universities, 2021, 42(12): 3692. |

| [3] | LI Chuan,WANG Xinyun,WU Fengyi,LIU Tianxia,HU Xianguo. Preparation, Characterization and Water-based Lubricity of Modified Biodiesel Soot † [J]. Chem. J. Chinese Universities, 2020, 41(5): 987. |

| [4] | ZHANG Xiaofei, WU Lie, LI Shanshan, ZHU Manyu, CHENG Xiaowei, JIANG Xiu’e. Effect of Phase Behavior of Phospholipids on Lipid Membrane Damage Induced by Graphene Oxide † [J]. Chem. J. Chinese Universities, 2020, 41(4): 661. |

| [5] | YU Yancun, WANG Xian, GE Junjie, LIU Changpeng, XING Wei. Promoted Formic Acid Electrooxidation Using PdNx/C Catalyst Prepared with Hyperbranched Polymer† [J]. Chem. J. Chinese Universities, 2019, 40(7): 1433. |

| [6] | LI Jiahui,QIN Menghan,ZHANG Jie,DU Yi,SUN Dongmei,TANG Yawen. Fabrication of 3D Porous Core-shell PdNi@Au Nanocatalyst for Formic Acid Electro-oxidation† [J]. Chem. J. Chinese Universities, 2019, 40(5): 988. |

| [7] | JIN Yanxian, JIA Wenping, LIANG Danxia, LI Fang, LI Rongrong, ZHENG Mengmeng, GAO Weiyi, NI Jiamin, HU Jiajie, WU Tinghua. Performance of WO3 Modified Graphene Supported Pd Nanocatalysts for Formic Acid Electro-oxidation† [J]. Chem. J. Chinese Universities, 2017, 38(4): 653. |

| [8] | ZOU Tao, YI Qingfeng, ZHANG Yuanyuan, DENG Zhongliang, LEI Ming, ZHOU Xiulin. A New Formic Acid/Iron Ion Fuel Cell† [J]. Chem. J. Chinese Universities, 2017, 38(1): 101. |

| [9] | SHANG Zhongjin, YAN Liangliang, RAO Guishi, XIONG Ting, TIAN Wei, LIN Xuan, ZHONG Qiling, REN Bin. Preparation of (PtAuPt)HN/GC and Its Electrocatalytic Performance for Formic Acid Oxidation† [J]. Chem. J. Chinese Universities, 2014, 35(12): 2688. |

| [10] | WANG Yanen, CAO Shuang, WU Weihong, WU Min, TANG Yawen, LU Tianhong. Effect of Particle Size on the Electrocatalytic Activity of Pt/C Catalysts for Oxidation of Formic Acid† [J]. Chem. J. Chinese Universities, 2014, 35(11): 2455. |

| [11] | LU Liang, CHEN Tingting, GE Cunwang, TANG Yawen, CHEN Yu, LU Tianhong. Preparation of Phosphotungstic Acid-modified Carbon Supported Pd Catalyst and Its Electrocatalytic Performance for Formic Acid Oxidation† [J]. Chem. J. Chinese Universities, 2014, 35(1): 115. |

| [12] | LU Liang, TANG Ya-Wen, CHEN Yu, CHEN Ting-Ting, GE Cun-Wang, LU Tian-Hong. Effect of Ethylenediamine-tetramethylene Phosphonic Acid in Electrolyte on Electrocatalytic Performance of Carbon Supported Pd Catalyst for Formic Acid Oxidation [J]. Chem. J. Chinese Universities, 2013, 34(7): 1748. |

| [13] | GENG Xiao-Wei, WU Bing, GAO Ying. Preparation of Carbon Supported PdPb Catalysts and Its Electrocatalytic Performance in Oxidation of Formic Acid [J]. Chem. J. Chinese Universities, 2012, 33(09): 2025. |

| [14] | CHEN Ming-Hui, HE Chun-Lan, ZHANG Bin-Wei, JIANG Yan-Xia, CHEN Sheng-Pei, SUN Shi-Gang. Electrooxidation of Formic Acid on Palladium Nanoparticles Supported on Ordered Mesoporous Carbon [J]. Chem. J. Chinese Universities, 2012, 33(02): 331. |

| [15] | LI Huan-Zhi, SHEN Juan-Zhang, YANG Gai-Xiu, TANG Ya-Wen, LU Tian-Hong*. Anodic Pd Catalyst in Direct Formic Acid Fuel Cell and Its Electrocatalytic Stability [J]. Chem. J. Chinese Universities, 2011, 32(7): 1445. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||