高等学校化学学报 ›› 2022, Vol. 43 ›› Issue (3): 20210739.doi: 10.7503/cjcu20210739

收稿日期:2021-10-22

出版日期:2022-03-10

发布日期:2021-12-21

通讯作者:

肖小华,李攻科

E-mail:xiaoxhua@mail.sysu.edu.cn;cesgkl@mail.sysu.edu.cn

基金资助:

BI Gening, XIAO Xiaohua( ), LI Gongke(

), LI Gongke( )

)

Received:2021-10-22

Online:2022-03-10

Published:2021-12-21

Contact:

XIAO Xiaohua,LI Gongke

E-mail:xiaoxhua@mail.sysu.edu.cn;cesgkl@mail.sysu.edu.cn

Supported by:摘要:

以姜科类植物草豆蔻中山姜素为模拟对象, 基于微波辅助萃取(MAE)过程中微波场、 温度场及浓度场等物理场之间的耦合关系, 利用Comsol软件构建了MAE多物理场耦合模型. 模拟了不同萃取时间、 微波功率下萃取体系的电磁场分布、 温度分布以及山姜素扩散分布; 通过比较萃取液温度和山姜素浓度的模拟值与实验值, 结合误差分析对模型进行了验证, 以同类植物砂仁中的异槲皮苷为萃取目标验证了模型的适用性. 结果表明, 微波功率越大, 电磁场强度越强, 萃取液温度越高, 山姜素扩散越明显, 越有利于萃取; MAE萃取山姜素和异槲皮苷的萃取液温度模拟值与实验值之间的相对均方根误差(RRMSE)分别在1.9%~4.5%和1.9%~2.8%之间, 其浓度RRMSE分别在1.7%~3.2%及1.6%~4.1%之间, 均小于5.0%, 表明建立的模型准确、 可靠, 且适用性良好. 该模型综合考虑了MAE过程中的多个物理场及其耦合关系, 可为深入研究其萃取机理提供参考.

中图分类号:

TrendMD:

闭格宁, 肖小华, 李攻科. 微波辅助萃取多物理场耦合模型的构建及验证. 高等学校化学学报, 2022, 43(3): 20210739.

BI Gening, XIAO Xiaohua, LI Gongke. Development and Validation of Multiple Physical Fields Coupling Model for Microwave-assisted Extraction. Chem. J. Chinese Universities, 2022, 43(3): 20210739.

| Variable symbol | Variable name | Values and units |

|---|---|---|

| wo | The width of microwave cavity | 348 mm |

| do | The depth of microwave cavity | 366 mm |

| ho | The height of microwave cavity | 248 mm |

| wg | The width of waveguide | 50 mm |

| dg | The depth of waveguide | 78 mm |

| hg | The height of waveguide | 18 mm |

| R_bottom_tube | The bottom diameter of sample bottle | 17.5 mm |

| H_bottom_tube | The height of sample holder bottom | 10 mm |

| R_bottom_hold | The radius of sample location | 35 mm |

| R_tube | The radius of flask circular cavity | 38.5 mm |

| tube2hold | Distance from bottom of beaker to top of support frame | 22 mm |

| R_tube_neck | The radius of the bottleneck | 14 mm |

| t_glass | The thickness of Glass wall | 1.3 mm |

| H_liquid | The height of liquid level | 30 mm |

| H_sample | The sample height | 1 mm |

| Mole_Mass | The molar mass of the target molecule | 270.2 g/mol |

| Mass | The sample quality | 1 g |

Table 1 Geometric parameters of the multiple physical fields coupling model for MAE

| Variable symbol | Variable name | Values and units |

|---|---|---|

| wo | The width of microwave cavity | 348 mm |

| do | The depth of microwave cavity | 366 mm |

| ho | The height of microwave cavity | 248 mm |

| wg | The width of waveguide | 50 mm |

| dg | The depth of waveguide | 78 mm |

| hg | The height of waveguide | 18 mm |

| R_bottom_tube | The bottom diameter of sample bottle | 17.5 mm |

| H_bottom_tube | The height of sample holder bottom | 10 mm |

| R_bottom_hold | The radius of sample location | 35 mm |

| R_tube | The radius of flask circular cavity | 38.5 mm |

| tube2hold | Distance from bottom of beaker to top of support frame | 22 mm |

| R_tube_neck | The radius of the bottleneck | 14 mm |

| t_glass | The thickness of Glass wall | 1.3 mm |

| H_liquid | The height of liquid level | 30 mm |

| H_sample | The sample height | 1 mm |

| Mole_Mass | The molar mass of the target molecule | 270.2 g/mol |

| Mass | The sample quality | 1 g |

| Physical field | Initial condition | Boundary condition and equation |

|---|---|---|

| Microwave field | t=0, E=0, H=0 | (1) The boundary between the microwave cavity and the waveguide wall: |

(2) The boundary of glass, solvent and air: | ||

| Temperature field | t=0, | |

| Concentration field | t=0, | Interface between solvent and glass: |

Table 2 Initial conditions, boundary conditions and equations

| Physical field | Initial condition | Boundary condition and equation |

|---|---|---|

| Microwave field | t=0, E=0, H=0 | (1) The boundary between the microwave cavity and the waveguide wall: |

(2) The boundary of glass, solvent and air: | ||

| Temperature field | t=0, | |

| Concentration field | t=0, | Interface between solvent and glass: |

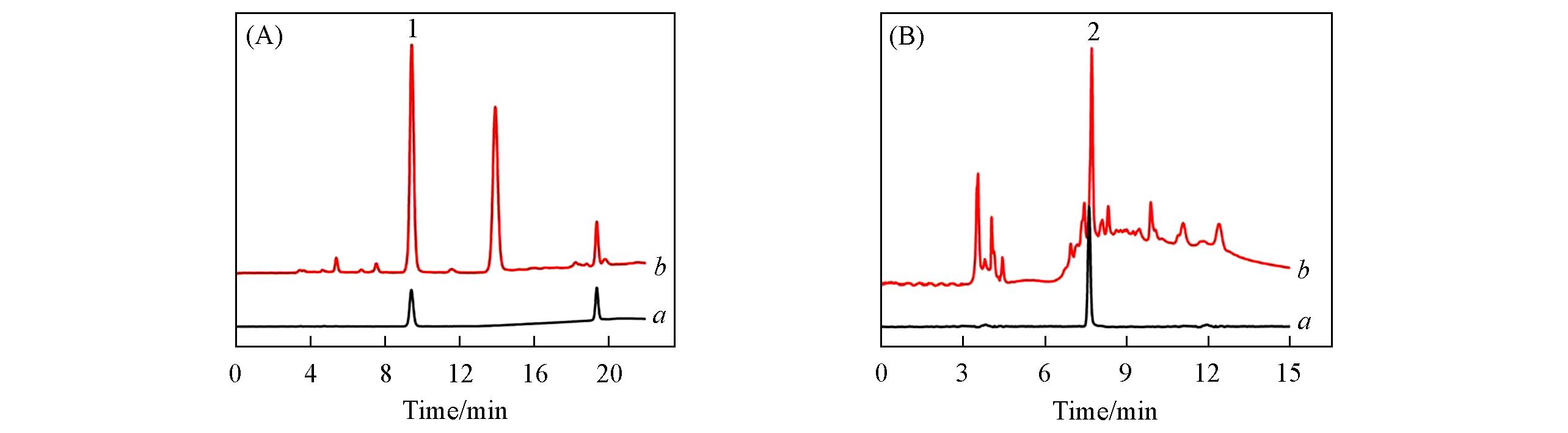

Fig.4 Typical chromatograms obtained by HPLC of 95.4 mg/L alpinetin standard solution(a) and extract of Alpinia katsumadai Hayata by MAE(b)(A) and 103.6 mg/L isoquercitrin standard solution(a) and extract of Amomum villosum by MAE(b)(B)Peak 1: alpinetin; peak 2: isoquercitrin.

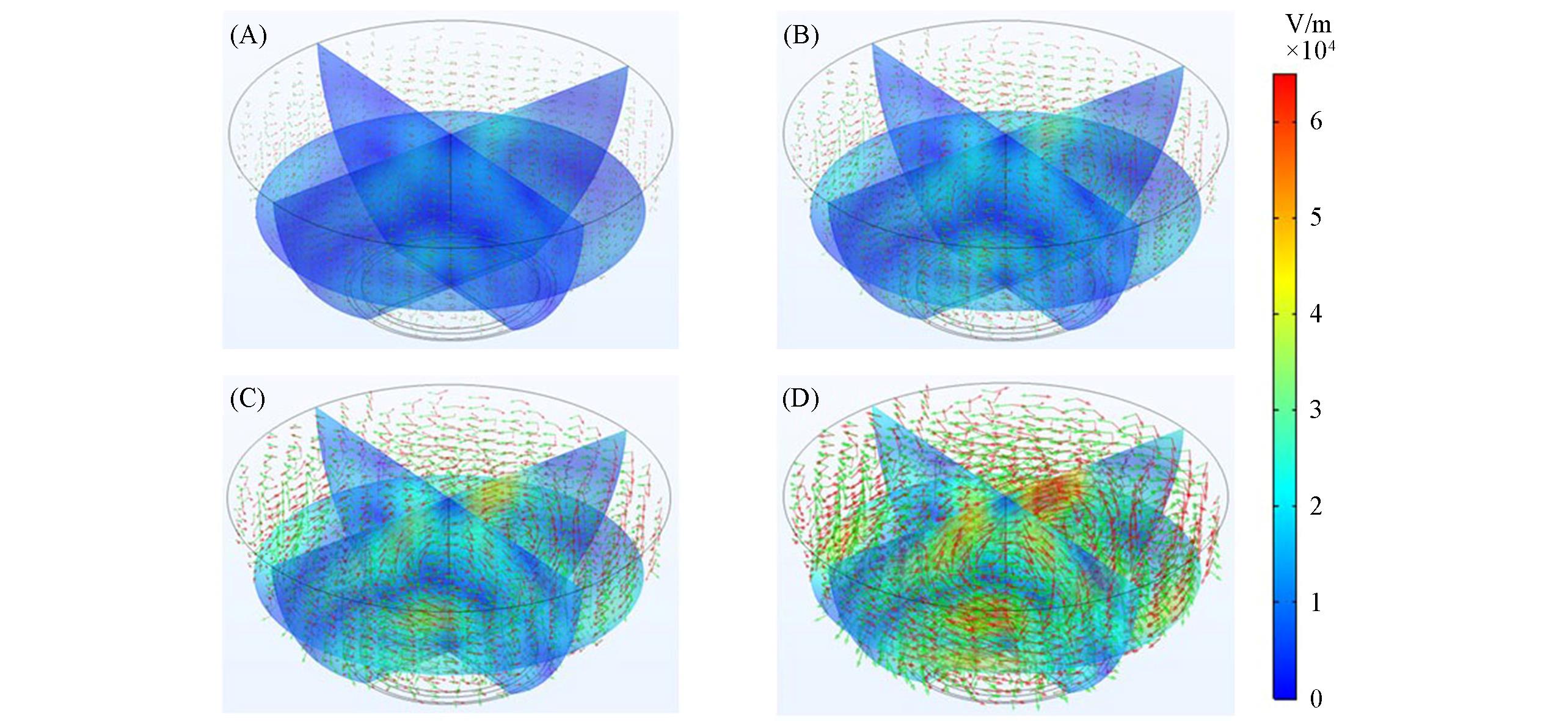

Fig.8 Simulation nephogram of electromagnetic field distribution of MAE under 100 s with microwave powers of 100 W(A), 200 W(B), 400 W(C) and 800 W(D)

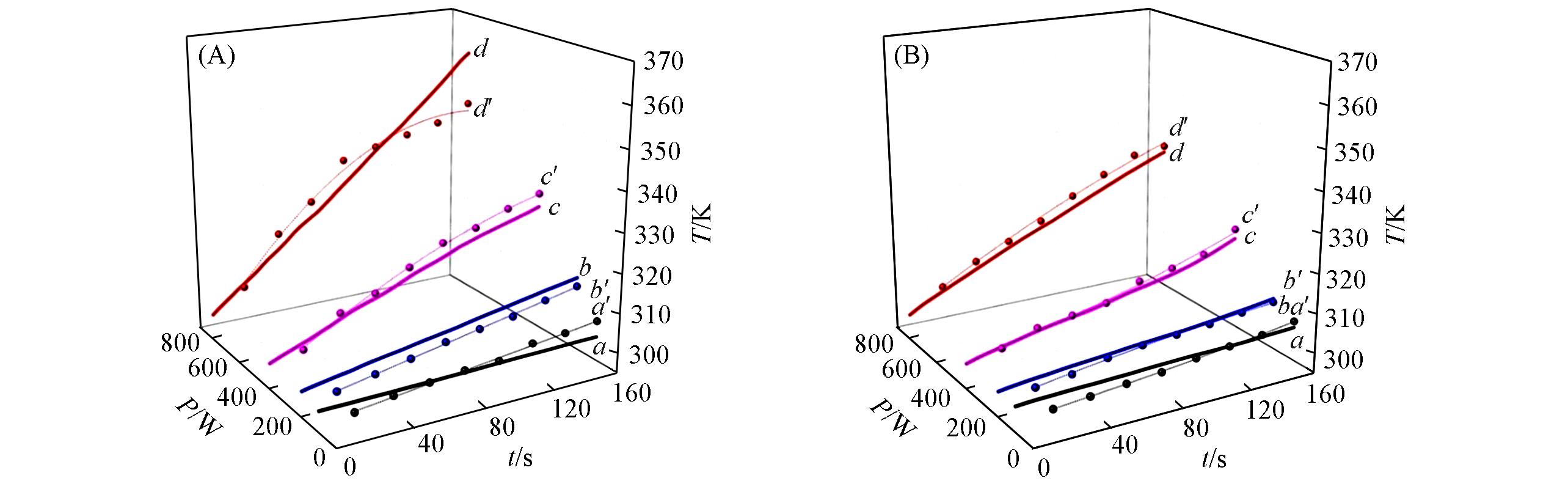

Fig.11 Comparison between simulated and experimental temperature evolutions for MAE alpinetin(A) and isoquercitrin(B)Simulation values: 100 W(a), 200 W(b), 400 W(c), 800 W(d); experimental values: 100 W(a′), 200 W(b′), 400 W(c′), 800 W(d′).

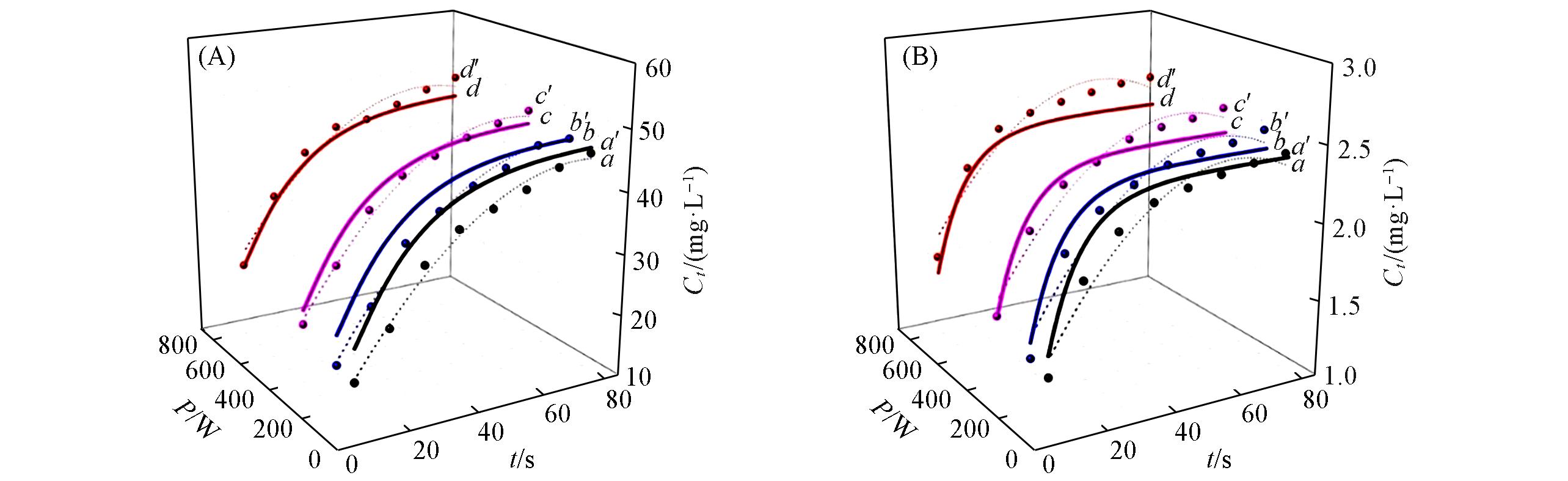

Fig.12 Comparison between simulated and experimental concentration evolutions for MAE alpinetin(A) and isoquercitrin(B)Simulation values: 100 W(a), 200 W(b), 400 W(c), 800 W(d); experimental values: 100 W(a′), 200 W(b′), 400 W(c′), 800 W(d′).

| 1 | Jiang H., Liu Z. G., Wang S. J., Criti. Rev. Food Sci. Nutr., 2018, 58(14), 2476―2489 |

| 2 | Kostas E. T., Beneroso D., Robinson J. P., Renew. Sust. Energ. Rev., 2017, 77, 12―27 |

| 3 | Li Y., Huang K. M., Yang C., Gu M. J., J. Microwaves, 1999, 15(4), 345―353 |

| 4 | Pound R. V., Rev. Sci. Instrum., 1946, 17(11), 490―505 |

| 5 | Zhang F. S., Zhao Q., Yan X., Li H. L., Zhang P., Wang L., Zhou T. Y., Li Y., Ding L., Food Chem., 2016, 197, 943―949 |

| 6 | Li G. J., Zhang X., Liu T. T., Fan H. X., Liu H. C., Li S. Y., Wang D. W., Ding L., Food Sci. Hum. Well., 2021, 10, 375―382 |

| 7 | Llompart M., Celeiro M., Dagnac., TrAC. Trends Anal. Chem., 2019, 116, 136―150 |

| 8 | Liu Z. Y., Hu X. L., Bu F. Q., Ding L., Zhang H. Q., Chem. J. Chinese Universities, 2007, 28(3), 431―435(刘忠英, 胡秀丽, 卜凤泉, 丁兰, 张寒琦. 高等学校化学学报, 2007, 28(3), 431―435) |

| 9 | Song W. T., Cai H. R., Du L. P., Zhao Q., Chen H. Y., Li G. J., Wang H., Xu Y., Ding L., Ren N. Q., Chromatographia, 2012, 75, 747―753 |

| 10 | Mirzadeh M., Arianejad M. R., Khedmat L., Carbohydr. Polym., 2020, 229, 115421 |

| 11 | Zhang H. F., Yang X. H., Wang Y., Trends Food Sci. Technol., 2011, 22(12), 672―688 |

| 12 | Franco⁃Vega A., Ramírez⁃Corona N., López⁃Malo A., Palou E., J. Food Eng., 2019, 247, 1―8 |

| 13 | Albarri R., Toprakçı İ., Kurtulbaş E., Şahin S., Biomass Convers. Biorefin., 2021, doi: 10.1007/s13399⁃021⁃014438 |

| 14 | Fan H. J., Xiao X. H., Li G. K., Chem. J. Chinese Universities, 2007, 28(6), 1049―1054(范华均, 肖小华, 李攻科. 高等学校化学学报, 2007, 28(6), 1049―1054) |

| 15 | Fan H. J., Lin G. X., Xiao X. H., Li G. K., Chem. J. Chinese Universities, 2006, 27(12), 2271―2276(范华均, 林广欣, 肖小华, 李攻科. 高等学校化学学报, 2006, 27(12), 2271―2276) |

| 16 | Zin M. M., Anucha C. B., Bánvölgyi S., Foods, 2020, 9(7), 918 |

| 17 | Bagade S. B., Patil M., Crit. Rev. Anal. Chem., 2021, 51(2), 138―149 |

| 18 | Zhao J. H., Yan X., Li H. Y., Zhang P., Zhou T. Y., Li Y., Cheng Y. H., Ding L., Anal. Methods, 2016, 8(45), 8015―8021 |

| 19 | Wang N. N., Zheng T., Jiang J. P., Wang P., Energy Conserv., 2020, 8, 98―102 |

| 20 | Pitchai K., Chen J., Birla S., Gonzalez R., Jones D., Subbiah J., J. Food Eng., 2014, 128, 60―71 |

| 21 | Laura A. C., Carlos A. P., Rodolfo H. M., Food Bioproc. Tech., 2012, 5(2), 738―749 |

| 22 | Chumnanpaisont N., Niamnuy C., Devahastin S., Chem. Eng. Sci., 2014, 116, 442―451 |

| 23 | Liu C. H., Xue H. K., Shen L. Y., Liu C., Zheng X. Z., Shi J., Xue S., Sep. Purif. Technol., 2019, 226, 286―298 |

| 24 | Pozar D., Microwave Engineering., 3rd Edition, Wiley, New York, 2005 |

| 25 | Jian Y., Yang X. Q., Huang K. M., Prog. Electromagn. Res. C, 2010, 17, 105―119 |

| 26 | Clark D. E., Folz D. C., West J. K., Mater. Sci. Eng., 2000, 287(2), 153―158 |

| 27 | Zhu H. C., He J. B., Hong T., Yang Q. Z., Wu Y., Yang Y., Huang K. M., Appl. Therm. Eng., 2018, 141, 648―658 |

| 28 | Wang J., Wang W., Guan Q., J. Beijing Jiaotong Univ., 2014, 38(5), 49―53 |

| 29 | Budd C. J., Hill A. D. C., Int. J. Heat Mass Transfer., 2011, 54(4), 807―817 |

| 30 | Thuto W., Banjong K., Processes, 2019, 7(8), 545 |

| 31 | Liu S. X., Ogiwara Y., Fukuoka M., Sakai N., J. Food Eng., 2014, 131, 142―153 |

| 32 | Yi Z. K., Gu W. J., Xu H. X., Cheng Y. D., Jin Y. Z., Sci. Technol. Food Ind., 2018, 39(24), 350―356 |

| 33 | Xiao X. H., Si X. X., Tong X., Li G. K., Sep. Purif. Technol., 2011, 81(3), 265―269 |

| 34 | Zhou Y. L., Lv H. T., Chinese Tradit. Pat. Med., 2011, 33(1), 145―148 |

| 35 | Li Z. Z., Pan R. L., Li Z., Zhao X. H., Si J. Y., Sci. Technol. Rev., 2009, 27(9), 30―33 |

| 36 | Lee C. S., Binner E., Winkworth-Smith C., John R., Gomes R., Robinson J., Chem. Eng. Sci., 2016, 149, 97―103 |

| 37 | Yeong S. P., Law M. C., Lee C. C. V., Chan Y. S., Int. Conf. Mater. Technol. Energy, 2017, 217, 012035 |

| 38 | González-Rivera J., Spepi A., Ferrari C., Duce C., Longo I., Falconieri D., Piras A., Tinè M. R., Green Chem., 2016, 18(24), 6482―6492 |

| 39 | Deng X., Huang H. H., Mod. Food Sci. Technol., 2011, 27(6), 626―629 |

| 40 | Jin Q. H., Chin. J. Anal. Chem., 1988, 16(7), 668―674 |

| [1] | 孙哲韬, 何英杰, 陈邵杰, 聂璐, 黄缘齐, 刘巍. 全固态锂金属电池多物理场耦合下的电化学过程仿真模拟[J]. 高等学校化学学报, 2021, 42(5): 1598. |

| [2] | 李建伟, 李想, 张傑, 雷志刚. [Bmim][DBP]离子液体与甲醇分子间的氢键作用机理及在萃取分离混合C4烃/甲醇中的应用[J]. 高等学校化学学报, 2018, 39(5): 983. |

| [3] | 张帆,杨屹,郭振库 . 微波辅助萃取鬼箭羽叶中芦丁和槲皮素[J]. 高等学校化学学报, 2007, 28(8): 1480. |

| [4] | 杨屹, 侯翔燕, 郭振库. 微波辅助萃取新鲜芦荟叶中芦荟甙的研究[J]. 高等学校化学学报, 2005, 26(9): 1623. |

| [5] | 周新, 汪子明, 郑健, 赵丽巍, 刘忠英, 李绪文, 毕淑云, 宴国全, 张寒琦. 中草药中槲皮素的毛细管电泳法测定[J]. 高等学校化学学报, 2005, 26(4): 657. |

| [6] | 李敏晶, 游景艳, 刘忠英, 张寒琦. 微波辅助流动萃取槐花中的黄酮类成分[J]. 高等学校化学学报, 2004, 25(5): 850. |

| [7] | 陈雷, 杨屹, 张新祥, 郭振库. 密闭微波辅助萃取丹参中有效成分的研究[J]. 高等学校化学学报, 2004, 25(1): 35. |

| [8] | 丁兰, 李毅, 李敏晶, 刘忠英, 张寒琦. 一种新型微波辅助萃取法用于中药刺五加中总黄酮萃取的研究[J]. 高等学校化学学报, 2003, 24(8): 1403. |

| [9] | 曾平, 胡净宇. 伯胺N1923萃取钼的机理研究[J]. 高等学校化学学报, 1994, 15(11): 1588. |

| [10] | 章开诚, 蔡青云. 两相滴定法研究溶剂萃取机理的通用计算机程序[J]. 高等学校化学学报, 1989, 10(2): 135. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||