高等学校化学学报 ›› 2016, Vol. 37 ›› Issue (11): 2025.doi: 10.7503/cjcu20160390

收稿日期:2016-05-30

出版日期:2016-11-10

发布日期:2016-10-20

作者简介:联系人简介: 杨 飞, 男, 博士, 副教授, 主要从事油气储运安全技术研究. E-mail:基金资助:

LI Chuanxian, SHI Enhua, YANG Shuang, YAO Bo, YANG Fei*( ), YAN Qun

), YAN Qun

Received:2016-05-30

Online:2016-11-10

Published:2016-10-20

Contact:

YANG Fei

E-mail:yf9712220@sina.com

摘要:

采用循环伏安法(CV)在316不锈钢(316SS)表面聚合生成聚苯胺/聚吡咯-纳米二氧化硅(PAni/PPy-SiO2)共聚复合薄膜. 通过电化学工作站、 傅里叶变换红外光谱仪(FTIR)、 X射线光电子能谱仪(XPS)和扫描电子显微镜(SEM)等考察了聚苯胺(PAni)、 聚苯胺/聚吡咯(PAni/PPy)与PAni/PPy-SiO2薄膜的电化学聚合过程、 分子结构和特征形貌; 在3.5%(质量分数)NaCl水溶液中利用Tafel极化曲线和电化学阻抗谱(EIS)分别考察了PAni, PAni/PPy与PAni/PPy-SiO2薄膜对不锈钢的防腐性能. 结果表明, 通过电化学法可以在316不锈钢表面生成PAni/PPy-SiO2共聚复合薄膜; 相对于PAni薄膜与PAni/PPy薄膜, PAni/PPy-SiO2薄膜有着更密实的表面结构, 其对不锈钢的保护能力优于PAni/PPy薄膜和PAni薄膜, 纳米SiO2的掺杂通过加强膜层的机械屏蔽作用并抑制腐蚀反应过程中电荷的传递, 提高了薄膜的防腐能力.

中图分类号:

TrendMD:

李传宪, 石恩华, 杨爽, 姚博, 杨飞, 燕群. 聚苯胺/聚吡咯-纳米二氧化硅复合薄膜的合成及防腐性能. 高等学校化学学报, 2016, 37(11): 2025.

LI Chuanxian, SHI Enhua, YANG Shuang, YAO Bo, YANG Fei, YAN Qun. Synthesis and Anti-corrosion Properties of Polyaniline/Polypyrrole-nano Silicon Dioxide Composite Membrane†. Chem. J. Chinese Universities, 2016, 37(11): 2025.

| Membrane | Atomic fraction(%) | |||

|---|---|---|---|---|

| —NH— | N+ | —NH+ | —N | |

| PAni | 16 | 61 | 23 | |

| PPy | 63 | 27 | ||

| PAni/PPy | 34 | 40 | 16 | 10 |

Table 1 Components of N1s according to binding energy data from XPS

| Membrane | Atomic fraction(%) | |||

|---|---|---|---|---|

| —NH— | N+ | —NH+ | —N | |

| PAni | 16 | 61 | 23 | |

| PPy | 63 | 27 | ||

| PAni/PPy | 34 | 40 | 16 | 10 |

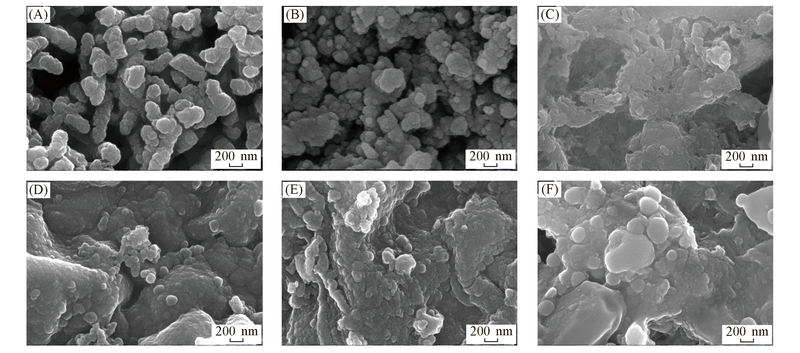

Fig.5 SEM images of PAni(A), PPy(B), PAni/PPy(C) and PAni/PPy-SiO2(D—F) with different SiO2 contents (D) PAni/PPy-SiO2(20∶1); (E) PAni/PPy-SiO2(10∶1); (F) PAni/PPy-SiO2(20∶3).

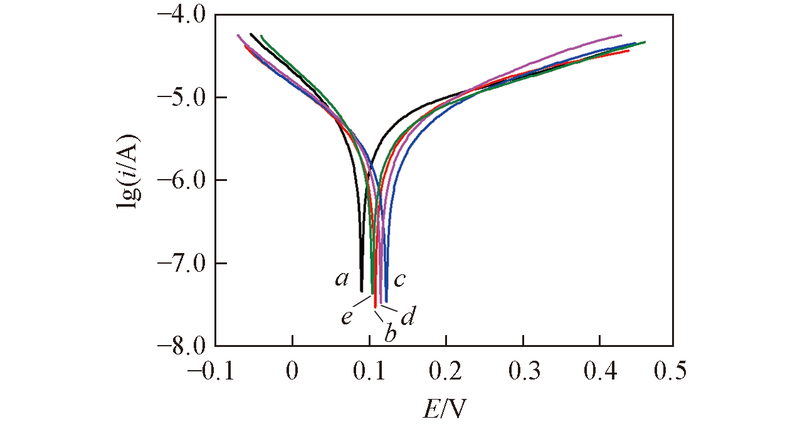

Fig.7 Tafel curves for 316SS/PAni/PPy-SiO2 electrodes with different SiO2 contents in 3.5% NaCl solution a. PAni/PPy-SiO2(20∶1); b. PAni/PPy-SiO2(40∶3); c. PAni/PPy-SiO2(10∶1); d. PAni/PPy-SiO2(40∶5); e. PAni/PPy-SiO2(20∶3).

| Membrane | Ecorr/V | icorr/(A·cm-2) |

|---|---|---|

| Bare 316SS | -0.34 | 2.827×10-4 |

| PAni | -0.17 | 6.723×10-5 |

| PAni/PPy | -0.03 | 1.891×10-5 |

| PAni/PPy-SiO2(20∶1) | 0.09 | 4.761×10-6 |

| PAni/PPy-SiO2(40∶3) | 0.108 | 3.517×10-6 |

| PAni/PPy-SiO2(10∶1) | 0.122 | 2.748×10-6 |

| PAni/PPy-SiO2(40∶5) | 0.115 | 3.138×10-6 |

| PAni/PPy-SiO2(20∶3) | 0.104 | 3.635×10-6 |

Table 2 Ecorr and icorr in accordance with Tafel curves of different membranes on 316SS

| Membrane | Ecorr/V | icorr/(A·cm-2) |

|---|---|---|

| Bare 316SS | -0.34 | 2.827×10-4 |

| PAni | -0.17 | 6.723×10-5 |

| PAni/PPy | -0.03 | 1.891×10-5 |

| PAni/PPy-SiO2(20∶1) | 0.09 | 4.761×10-6 |

| PAni/PPy-SiO2(40∶3) | 0.108 | 3.517×10-6 |

| PAni/PPy-SiO2(10∶1) | 0.122 | 2.748×10-6 |

| PAni/PPy-SiO2(40∶5) | 0.115 | 3.138×10-6 |

| PAni/PPy-SiO2(20∶3) | 0.104 | 3.635×10-6 |

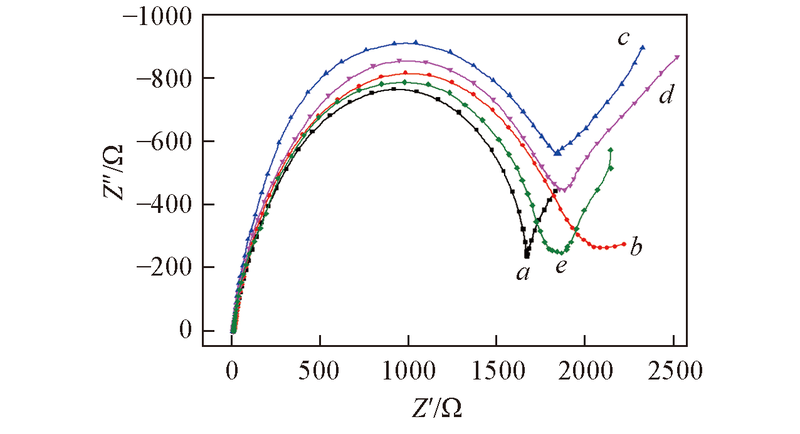

Fig.9 EIS spectra for 316SS/PAni/PPy-SiO2 electrodes with different SiO2 contents in 3.5% NaCl Solution a. PAni/PPy-SiO2(20∶1); b. PAni/PPy-SiO2(40∶3); c. PAni/PPy-SiO2(10∶1); d. PAni/PPy-SiO2(40∶5); e. PAni/PPy-SiO2(20∶3).

| Membrane | Rs/(Ω·cm2) | Cc/(F·cm-2) | n1 | Rc/(Ω·cm2) | Cdl/(F·cm-2) | n2 | Rct/(Ω·cm2) |

|---|---|---|---|---|---|---|---|

| PAni | 8.25 | 0.00041086 | 0.77961 | 136.5 | 0.0039012 | 0.76774 | 605.6 |

| PAni/PPy | 9.27 | 0.00027486 | 0.81575 | 169.2 | 0.0028021 | 0.75622 | 1029.3 |

| PAni/PPy-SiO2(20∶1) | 10.64 | 0.00020994 | 0.85938 | 202.3 | 0.0020668 | 0.82984 | 1512.8 |

| PAni/PPy-SiO2(40∶3) | 10.29 | 0.00015672 | 0.86344 | 245.6 | 0.0014717 | 0.81137 | 1773.4 |

| PAni/PPy-SiO2(10∶1) | 8.50 | 0.00012482 | 0.84834 | 296.3 | 0.0010392 | 0.85789 | 1905.2 |

| PAni/PPy-SiO2(40∶5) | 7.62 | 0.00013026 | 0.87125 | 261.7 | 0.0012971 | 0.83695 | 1835.7 |

| PAni/PPy-SiO2(20∶3) | 9.01 | 0.00018267 | 0.89767 | 214.8 | 0.0017236 | 0.84891 | 1623.1 |

Table 3 EIS fitting parameters of different membranes on 316SS

| Membrane | Rs/(Ω·cm2) | Cc/(F·cm-2) | n1 | Rc/(Ω·cm2) | Cdl/(F·cm-2) | n2 | Rct/(Ω·cm2) |

|---|---|---|---|---|---|---|---|

| PAni | 8.25 | 0.00041086 | 0.77961 | 136.5 | 0.0039012 | 0.76774 | 605.6 |

| PAni/PPy | 9.27 | 0.00027486 | 0.81575 | 169.2 | 0.0028021 | 0.75622 | 1029.3 |

| PAni/PPy-SiO2(20∶1) | 10.64 | 0.00020994 | 0.85938 | 202.3 | 0.0020668 | 0.82984 | 1512.8 |

| PAni/PPy-SiO2(40∶3) | 10.29 | 0.00015672 | 0.86344 | 245.6 | 0.0014717 | 0.81137 | 1773.4 |

| PAni/PPy-SiO2(10∶1) | 8.50 | 0.00012482 | 0.84834 | 296.3 | 0.0010392 | 0.85789 | 1905.2 |

| PAni/PPy-SiO2(40∶5) | 7.62 | 0.00013026 | 0.87125 | 261.7 | 0.0012971 | 0.83695 | 1835.7 |

| PAni/PPy-SiO2(20∶3) | 9.01 | 0.00018267 | 0.89767 | 214.8 | 0.0017236 | 0.84891 | 1623.1 |

| [1] | 陈世刚, 赵文元. 腐蚀科学与防护技术, 2009, 21( 3), 269) |

| Chen S., G. , Zhao W., Y. , Corros. Sci. Prot. Technol., 2009, 21( 3), 269 ( | |

| [2] | Slimane A., B. , Connan, C. , Vaulay M., J. , Chehimi M., M. , J. Colloids Surf. A, 2009, 332( 2), 157- 163 |

| [3] | DeBerry D., W. , J. Electrochem. Soc., 1985, 132( 5), 1022- 1026 |

| [4] | Zhang, T. , Zeng C., L. , J. Electrochim. Acta, 2005, 50( 24), 4721- 4727 |

| [5] | Mollahosseini, A. , Noroozian, E. , J. Synth. Met., 2009, 159( 13), 1247- 1254 |

| [6] | 龙晋明, 王少龙, 王静. 材料保护, 2003, 36( 12), 23- 26 |

| Long J., M. , Wang S., L. , Wang, J. , J. Mater. Prot., 2003, 36( 12), 23- 26 ( | |

| [7] | 徐慧, 王新颖, 刘小育. 腐蚀科学与防护技术, 2012, 3( 2), 127- 131 |

| Xu, H. , Wang X., Y. , Liu X., Y. , Corros. Sci. Prot. Technol., 2012, 3( 2), 127- 131 ( | |

| [8] | 李倩倩, 黄健涵, 刘素琴, 关鲁雄, 黄可龙. 化学学报, 2008, 66( 5), 571- 575 |

| Li Q., Q. , Huang J., H. , Liu S., Q. , Guan L., X. , Huang K., L. , J. Acta Chim. Sin. (Engl. Ed. ), 2008, 66( 5), 571- 575 ( | |

| [9] | Olad, A. , Barati, M. , Shirmohammadi, H. , J. Prog. Org. Coat., 2011, 72( 4), 599- 604 |

| [10] | 贾艺凡, 刘朝辉, 廖梓珺, 王飞, 叶圣天, 班国东, 丁逸栋, 林锐. 表面技术, 2016, 45( 3), 164- 168 |

| Jia Y., F. , Liu C., H. , Liao Z., J. , Wang, F. , Ye S., T. , Ban G., D. , Ding Y., D. , Lin, R. , J. Surf. Technol., 2016, 45( 3), 164- 168 ( | |

| [11] | Redondo M., I. , Breslin C., B. , J. Corros. Sci., 2007, 49( 4), 1765- 1776 |

| [12] | 吕龙飞. 苯胺-吡咯共聚物复合材料的制备、 表征及其防腐蚀性能, 镇江: 江苏科技大学, 2014) |

| Lv L., F. , Preparation, Characterization and Anti-corrosion Performance of Aniline-pyrrole Copolymer Composite Materials, Jiangsu University of Science and Technology, Zhenjiang, 2014 ( | |

| [13] | 刘万民, 何拥军, 李芝坛. 表面技术, 2010, 39( 3), 58- 60 |

| Liu W., M. , He Y., J. , Li Z., T. , J. Surf. Technol., 2010, 39( 3), 58- 60 ( | |

| [14] | Grari, O. , Dhouibi, L. , Lallemand, F. , Buron C., C. , Taouil A., E. , Hihn J., Y. , J. Ultrason. Sonochem., 2015, 22, 220- 226 |

| [15] | Chen Z. Q., Wang G. X., Xu G. Y., Colloid and Interface Chemistry, Higher Education Press, Beijing, 2001, 101— 105 |

| ( 陈宗淇, 王光信, 徐桂英. 胶体与界面化学. 北京: 高等教育出版社, 2001, 101— 115) | |

| [16] | Stilwell D., E. , Park S., M. , J. Electrochem. Soc., 1988, 135( 10), 2491- 2496 |

| [17] | Tü, ken T. , Arslan, G. , Yazı, cı B. , Erbil, M. , J. Prog. Org. Coat., 2004, 49( 2), 153- 159 |

| [18] | 李美超, 朱婉霞, 朱静娜, 莫卫民. 高等学校化学学报, 2012, 33( 1), 128- 132 |

| Li M., C. , Zhu W., X. , Zhu J., N. , Mo W., M. , Chem. J. Chinese Universities, 2012, 33( 1), 128- 132 ( | |

| [19] | 吕龙飞, 林生岭, 陈传祥, 文丹, 李潇霜. 表面技术, 2013, 42( 4), 110- 114 |

| Lv L., F. , Lin S., L. , Chen C., X. , Wen, D. , Li X., S. , J. Surf. Technol., 2013, 42( 4), 110- 114 ( | |

| [20] | 熊冬柏, 杨春明. 应用化学, 2009, 26( 9), 1054- 1059 |

| Xiong D., B. , Yang C., M. , Chin. J. Appl. Chem., 2009, 26( 9), 1054- 1059 ( | |

| [21] | Han M., G. , Cho S., K. , Oh S., G. , Im S., S. , J. Synth. Met., 2002, 126( 1), 53- 60 |

| [22] | Kang E., T. , Neoh K., G. , Zhang, X. , Zhang, X. , Tan K., L. , Liaw D., J. , J. Surf. Interface Anal., 1996, 24( 1), 51- 58 |

| [23] | Kalendová, A. , Vesel, D. , Kohl, M. , Stejskal, J. , J. Prog. Org. Coat., 2015, 78, 1- 20 |

| [24] | Sheng, N. , Lei Y., H. , Hyonoo, A. , Ueda, M. , Ohtsuka, T. , J. Prog. Org. Coat., 2014, 77( 11), 1724- 1734 |

| [25] | Huang, H. , Wu, J. , Lin, X. , Li, L. , Shang S., M. , Yuen M., C. , Yan G., P. , J. Carbohydr. Polym., 2013, 95( 1), 72- 76 |

| [26] | 陈忠平, 褚道葆, 陈君华, 过家好, 伊晓娟, 吴何珍, 高分子学报, 1900, 1( 6), 536- 540 |

| Chen Z., P. , Chu D., B. , Chen J., H. , Guo J., H. , Yin X., J. , Wu H., Z. , Acta Polym. Sin., 1900, 1( 6), 536- 540 ( | |

| [27] | 王宏智, 刘炜洪, 李剑, 姚素薇, 张卫国. 高等学校化学学报, 2012, 33( 2), 421- 425 |

| Wang H., Z. , Liu W., H. , Li, J. , Yao S., W. , Zhang W., G. , Chem. J. Chinese Universities, 2012, 33( 2), 421- 425 ( | |

| [28] | 罗正鸿, 何腾云, 蔺存国, 戴李宗. 高分子通报, 2007, 9, 9- 13 |

| Luo Z., H. , He T., Y. , Lin C., G. , Dai L., Z. , J. Polym. Bull., 2007, 9, 9- 13 ( | |

| [29] | Jeong A., Y. , Koo S., M. , Kim D., P. , J. Sol-Gel Sci. Technol., 2000, 19( 1-3), 483- 487 |

| [30] | Cook, A. , Gabriel, A. , Siew, D. , Laycock, N. , J. Curr. Appl. Phys., 2004, 4( 2-4), 133- 136 |

| [31] | 张鉴清, 曹楚南. 腐蚀与防护, 1998, 8, 32- 36 |

| Zhang J., Q. , Cao C., N. , Corros. Prot., 1998, 8, 32- 36 ( | |

| [32] | 张伟, 王佳, 赵增元, 刘学庆. 中国腐蚀与防护学报, 2011, 5, 36- 45 |

| Zhang, W. , Wang, J. , Zhao Z., Y. , Liu X., Q. , J. Chin. Soc. Corros. Prot., 2011, 5, 36-45 ( | |

| [33] | Cao C. N., Electrochemistry of Corrosion(3rd Edition), Chemical Industry Press, Beijing, 2008, 175— 179 |

| ( 曹楚南. 腐蚀电化学原理(第三版). 北京: 化学工业出版社, 2008, 175— 179) | |

| [34] | Sathiyanarayanan, S. , Azim S., S. , Venkatachari, G. , J. Synth. Met., 2007, 157( 18), 751- 757 |

| [35] | Lasia, A. , Modern Aspects of, Electrochemistry , Springer, New York, 2002, 143-248 |

| [1] | 刘树威, 晋皓, 尹万忠, 张皓. 用于卵巢癌化疗-光热联合治疗的吉西他滨/聚吡咯复合纳米粒子[J]. 高等学校化学学报, 2022, 43(8): 20220345. |

| [2] | 张洁, 银波, 刘玮欣, 刘兴平, 连文贤, 唐韶坤. 勃姆石纤维增强二氧化硅气凝胶的制备及性能[J]. 高等学校化学学报, 2022, 43(11): 20220483. |

| [3] | 杨思娴, 钟文钰, 李超贤, 苏秋瑶, 许炳佳, 何谷平, 孙丰强. 聚苯胺纳米线/SnO2复合光催化材料的光化学制备与性能[J]. 高等学校化学学报, 2021, 42(6): 1942. |

| [4] | 韩延东, 韩明勇, 杨文胜. 溶胶-凝胶法构筑介孔二氧化硅纳微结构[J]. 高等学校化学学报, 2021, 42(4): 965. |

| [5] | 童诚, 吴文韬, 王挺. 具有不对称孔道结构的小介孔二氧化硅粒子的合成及其高分子杂化膜的构建[J]. 高等学校化学学报, 2021, 42(3): 946. |

| [6] | 王杰, 李莹, 邵亮, 白阳, 马忠雷, 马建中. 聚乙烯醇/聚吡咯复合导电水凝胶应变传感器的制备及性能[J]. 高等学校化学学报, 2021, 42(3): 929. |

| [7] | 王博东, 潘美辰, 卓颖. 二氧化硅纳米颗粒表面原位还原银纳米簇电化学发光传感界面的构建与分子识别[J]. 高等学校化学学报, 2021, 42(11): 3519. |

| [8] | 宋文尧, 周张浪, 杨鑫莉, 陈岚, 葛广路. 介孔二氧化硅对映选择性吸附的手性印迹调控[J]. 高等学校化学学报, 2021, 42(10): 3144. |

| [9] | 张如强, 张国亮, 龙柱, 张丹, 李志强, 王士华, 胡爱林. 轻质柔性聚酰亚胺纸基电磁屏蔽材料的制备与性能[J]. 高等学校化学学报, 2021, 42(10): 3211. |

| [10] | 王欢, 所金泉, 王春艳, 王润伟. 氨基化树枝状介孔二氧化硅固定葡萄糖氧化酶用于检测葡萄糖[J]. 高等学校化学学报, 2020, 41(8): 1731. |

| [11] | 张启龙, 姚丽琴, 朱志才, 张钊, 杨辉. Au@PS纳米颗粒掺杂PDMS/(PVDF-TrFE)复合薄膜的制备及介电-疏水性能[J]. 高等学校化学学报, 2020, 41(6): 1269. |

| [12] | 任文, 张国立, 闫涵, 胡兴华, 李焜, 王景凤, 李瑞琦. 超疏水聚苯胺/聚四氟乙烯复合膜的制备及油-水乳液分离性能[J]. 高等学校化学学报, 2020, 41(4): 846. |

| [13] | 令旭霞, 龙柱, 王士华, 李志强, 郭帅, 张丹. 聚苯胺表面修饰芳纶浆粕及其纸基材料的导电性能[J]. 高等学校化学学报, 2020, 41(11): 2553. |

| [14] | 王乙涵,尹强,杜凯,殷勤俭. 聚吡咯/聚苯胺二元复合纳米管及其热电性能[J]. 高等学校化学学报, 2020, 41(1): 175. |

| [15] | 李勃天,邵伟,肖达,周雪,董俊伟,唐黎明. 聚吡咯纳米线凝胶的模板制备及储能与电化学传感性能[J]. 高等学校化学学报, 2020, 41(1): 183. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||