Chem. J. Chinese Universities ›› 2019, Vol. 40 ›› Issue (4): 849.doi: 10.7503/cjcu20180577

• Polymer Chemistry • Previous Articles

XIONG Zhengrong1, DONG Li1,2, LIU Xiangdong1, YANG Yuming1,2,*( )

)

Received:2018-08-16

Online:2019-01-12

Published:2019-01-12

Contact:

YANG Yuming

E-mail:ymyang@ciac.ac.cn

TrendMD:

XIONG Zhengrong,DONG Li,LIU Xiangdong,YANG Yuming. Preparation and Properties Characterization of PDA/PVDF UV Shielding Composite Membranes[J]. Chem. J. Chinese Universities, 2019, 40(4): 849.

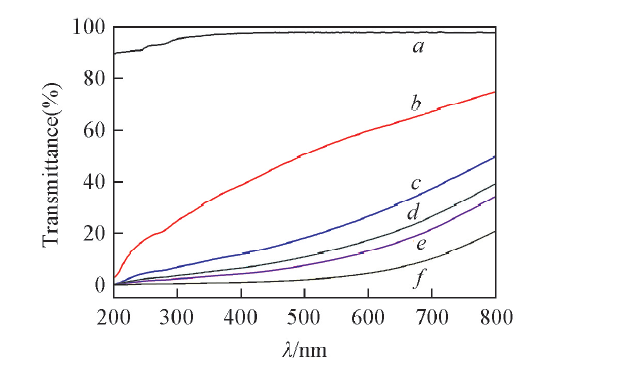

Fig.7 UV-Vis transmittance spectra of the PDA/PVDF composite membranes with different PDA contentsMass fraction of PDA(%): a. 0; b. 1; c. 2; d. 3; e. 4; f. 5.

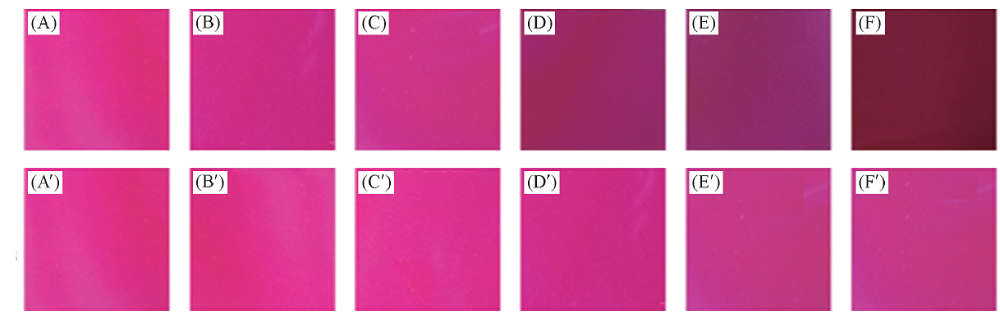

Fig.9 Photographs of the Rh B-doped PU films protected by pure PVDF film(A—F) and PDA/PVDF film(A'—F') after different time of UV irradiationIrradiation time/min: (A, A') 0; (B, B') 15; (C, C') 30; (D, D') 45; (E, E') 60; (F, F') 120.

| [1] | Kang G., Cao Y., J. Membr.Sci.,2014, 463, 145—165 |

| [2] | Ji J., Liu F., Hashim N. A., Abed M. R. M., Li K., React. Funct.Polym.,2015, 86, 134—153 |

| [3] | Zhao C. Q., Xu X. C., Chen J., Yang F. L., J. Environ. Chem.Eng.,2013, 1, 349—354 |

| [4] | Zhu Z. Y., Jiang J. L., Wang X. D., Huo X. N., Xu Y. W., Li Q. Q., Wang L., Chem. Eng.J.,2017, 314, 266—276 |

| [5] | Qin Q., Hou Z. C., Lu X. F., Bian X. K., Chen L. F., Shen L. G., Wang S., J. Membr.Sci.,2013, 427, 303—310 |

| [6] | Liu J., Shen X., Zhao Y. P., Chen L., Ind. Eng. Chem.Res.,2013, 52, 18392—18400 |

| [7] | Yang C., Li X. M., Gilron J., Kong D. F., Yin Y., Oren Y., Linder C., He T., J. Membr.Sci.,2014, 456, 155—161 |

| [8] | Zhao X. Z., Huan H. X., Qin A. W., Liu D. P., He C. J., RSC Adv.,2015, 5, 64526—64533 |

| [9] | Xu L. Q., Chen J. C., Wang R., Neoh K. G., Kang E. T., Fu G. D., RSC Adv., 2013, 3, 25204—25214 |

| [10] | Wang Z. Y., Tang Y. Y., Li B. A., J. Membr.Sci.,2017, 540, 401—410 |

| [11] | Rahimpour A., Madaeni S. S., Zereshki S., Mansourpanah Y., Appl. Surf.Sci.,2009, 255, 7455—7461 |

| [12] | Yuan H. K., Ren J., Chem. Eng. Res.Des.,2017, 121, 348—359 |

| [13] | Yang B. X., Yang X., Liu B. C., Chen Z. Q., Chen C., Liang S. M., Chu L. Y., Crittenden J., J. Membr.Sci.,2017, 541, 558—566 |

| [14] | Calvo M. E., Castro Smirnov J. R., Míguez H., J. Polym. Sci. Polym. Phys.,2012, 50(14), 945—956 |

| [15] | Jiang C., Cheng M. J., Liu H. T., Shao L., Zeng X. F., Zhang Y. J., Shi F., Ind. Eng. Chem.Res.,2013, 52, 13393—13400 |

| [16] | Ge F. J., Ding Y. Y., Yang L., Huang Y., Jiang L., Dan Y., RSC Adv.,2015, 5, 70473—70481 |

| [17] | Wang X. L., Zhou S. X., Wu L. M., J. Mater. Chem.C,2014, 2, 5752—5758 |

| [18] | Li N., Chen Y. H., Bao Y. J., Zhang Z. Q., Wu Z. X., Chen Z. M., Appl. Surf.Sci.,2015, 332, 186—191 |

| [19] | Liu X. Y., Chen Q. R., Lv L. Z., Feng X. Y., Meng X. F., Catal.Commun.,2015, 58, 30—33 |

| [20] | Senatova S. I., Senatov F. S., Kuznetsov D. V., Stepashkin A. A., Issi J. P., J. Alloy.Compd.,2017, 707, 304—309 |

| [21] | Liu X. H., Wang J. F., Li S. H., Zhuang X. W., Xu Y. Z., Wang C. P., Chu F. X., Ind. Crop.Prod.,2014, 52, 633—641 |

| [22] | Xie S. Y., Zhao J. F., Zhang B. W., Wang Z. Q., Ma H. J., Yu C. H., Yu M., Li L. F., Li J. Y., ACS Appl. Mater.Interfaces,2015, 7, 17558—17564 |

| [23] | Hess S. C., Permatasari F. A., Fukazawa H., Schneider E. M., Balgis R., Ogi T., Okuyama K., Stark W. J., J. Mater. Chem.A,2017, 5, 5187—5194 |

| [24] | Fernandes S. C. M., Alonso-Varona A., Palomares T., Zubillaga V., Labidi J., Bulone V., ACS Appl. Mater.Interfaces,2015, 7(30), 16558—16564 |

| [25] | Sheng W. B., Li W., Zhang G. X., Tong Y. B., Liu Z. Y., Jia X., New J.Chem.,2015, 39, 2752—2757 |

| [26] | Narayanan M., Loganathan S., Valapa R. B., Thomas S., Varghese T. O., Int. J. Biol.Macromol.,2017, 99, 37—45 |

| [27] | Lee H., Dellatore S. M., Miller W. M., Messersmith P. B., Science,2007, 318(5849), 426—430 |

| [28] | Yang H. C., Luo J. Q., Lv Y., Shen P., Xu Z. K., J. Membr.Sci.,2015, 483, 42—59 |

| [29] | Zuo J. H., Cheng P., Chen X. F., Yan X., Guo Y. J., Lang W. Z., Sep. Purif.Technol.,2018, 192, 348—359 |

| [30] | Dreyer D. R., Miller D. J., Freeman B. D., Paul D. R., Bielawski C. W., Chem.Sci.,2013, 4, 3796—3802 |

| [31] | Ryu J. H., Messersmith P. B., Lee H., ACS Appl. Mater.Interfaces,2018, 10, 7523—7540 |

| [1] | YU Pengdong, GUAN Xinghua, WANG Dongdong, XIN Zhirong, SHI Qiang, YIN Jinghua. Preparation and Properties of Novel Optical and Thermal Dual Response Shape Memory Polymers [J]. Chem. J. Chinese Universities, 2022, 43(6): 20220085. |

| [2] | LI Weihui, LI Haobo, ZENG Cheng, LIANG Haoyue, CHEN Jiajun, LI Junyong, LI Huiqiao. Hot-pressed PVDF-based Difunctional Protective Layer for Lithium Metal Anodes [J]. Chem. J. Chinese Universities, 2022, 43(2): 20210629. |

| [3] | GAO Yifei, XIAO Changfa, JI Dawei, HUANG Yangzheng. Preparation of PVDF Hollow Fiber Membranes via Melt Spinning-stretching Method and Its Oil-water Separation Performance [J]. Chem. J. Chinese Universities, 2021, 42(6): 2065. |

| [4] | SUN Qirui, ZHAO Nan, LIU Shuwei, XIN Hua, ZHANG Hao, ZHANG Lening. Polydopamine-coated Fe3O4/methylprednisolone/cyclophosphamide Superparticles for the Magnetic Targeting Treatment of Pulmonary Fibrosis [J]. Chem. J. Chinese Universities, 2021, 42(10): 3225. |

| [5] | WU Fengren,LIU Yongjia,LU Xuemin,ZHU Bangshang. Controllable Preparation of Polydopamine Modified Gold Nanoflowers and Its Application in Photothermal Therapy † [J]. Chem. J. Chinese Universities, 2020, 41(3): 465. |

| [6] | CHENG Jifeng,JIANG Tuanhui,ZHAN Xiaomei,QI Yating,YANG Yuanyuan,KANG Xun,QIN Shuhao. Preparation and Properties of Superhydrophilic Polyvinylidene Fluoride Hollow Fiber Membrane † [J]. Chem. J. Chinese Universities, 2020, 41(2): 358. |

| [7] | LIU Yun, LI Ting, WANG Yang, DONG Weifu. Preparation of Multi-scale Superhydrophobic Cotton/Polydopamine/Silica Composite for Selective Oil Absorption [J]. Chem. J. Chinese Universities, 2019, 40(8): 1775. |

| [8] | LIU Zihao,XIAO Han,YAO Yuan,WANG Ting,WU Liguang,ZHANG Xueyang. Fabrication of PVDF Hybrid Blending Membrane via Microemulsion Polymerization Coupling with Blending Method † [J]. Chem. J. Chinese Universities, 2019, 40(10): 2248. |

| [9] | LIU Qi,GUO Guibao,AN Shengli,LIU Jinyan. Preparation and Properties of Tetramethyl Ammonium Hydroxide Modified Polyvinylidene Fluoride with Styrene Sulfonated Membranes† [J]. Chem. J. Chinese Universities, 2018, 39(9): 2062. |

| [10] | YANG Shuting, LI Qianhui, FAN Yuchang, WANG Qiuxian, DU Ting, YUE Hongyun. Li4Ti5O12 Modification by Bifunctional Bionic Membrane as Anode Materials for Lithium-ion Batteries† [J]. Chem. J. Chinese Universities, 2018, 39(11): 2513. |

| [11] | LIU Yuwei, GUO Zhuo. Polydopamine-doxorubicin Colloidal Nanoparticles for Chemo-Photothermal Synergistic Therapy Against Cancer Cell† [J]. Chem. J. Chinese Universities, 2015, 36(7): 1389. |

| [12] | MA Lina, LIU Fuyao, GAO Jiaxue, WANG Zhenxin. Polydopamine Nanoparticle-based Fluorescence Resonance Energy Transfer Assay for microRNA Detection† [J]. Chem. J. Chinese Universities, 2015, 36(6): 1061. |

| [13] | DING Xiao-Li, ZHANG Chao, ZHANG Yu-Zhong, CAO Zhan-Ping. Fabrication of PEBAX®2533/PSf Hollow Fiber Composition Membrane and Its Transfer Resistance [J]. Chem. J. Chinese Universities, 2012, 33(11): 2591. |

| [14] | YANG Jian1,2, WANG Xiao-Lin2*, TIAN Feng1, LIN Ya-Kai2, WANG Zheng1. Diluent Selection of PVDF Membrane Prepared via Thermally Induced Phase Separation [J]. Chem. J. Chinese Universities, 2008, 29(9): 1895. |

| [15] | YANG Jian1,2, ZHAO Wen-Ming1, WANG Xiao-Lin1*. Effect of Difference of Dielectric Constants Between Polyvinylidene Fluoride and Diluents on the Morphology of Polyvinylidene Fluoride Memranes Prepared by Thermally Induced Phase Separation [J]. Chem. J. Chinese Universities, 2007, 28(12): 2413. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||