Chem. J. Chinese Universities ›› 2016, Vol. 37 ›› Issue (12): 2206.doi: 10.7503/cjcu20160467

• Physical Chemistry • Previous Articles Next Articles

YANG Yanling, DONG Lingyu, XIA Wensheng*( ), WAN Huilin*(

), WAN Huilin*( )

)

Received:2016-07-01

Online:2016-12-10

Published:2016-11-18

Contact:

XIA Wensheng,WAN Huilin

E-mail:wsxia@xmu.edu.cn;hlwan@xmu.edu.cn

Supported by:TrendMD:

YANG Yanling, DONG Lingyu, XIA Wensheng, WAN Huilin. Ca, Sr co-Doped Ceria and Its Application in Oxidative Coupling of Methane†[J]. Chem. J. Chinese Universities, 2016, 37(12): 2206.

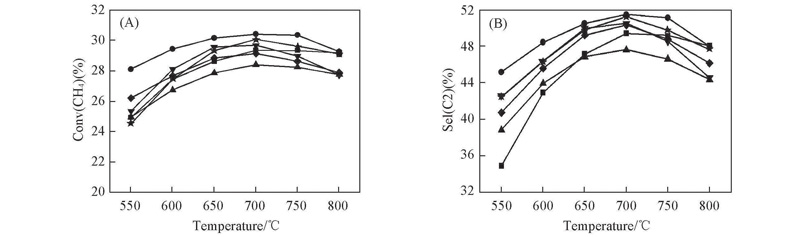

Fig.2 Catalytic performances of Ce0.5Sr0.5-mCamOx(m=0—0.25) for OCM reation■ Ce0.5Sr0.5Ox; ▲ Ce0.5Sr0.45Ca0.05Ox; ● Ce0.5Sr0.4Ca0.1Ox; ★ Ce0.5Sr0.35Ca0.15Ox;▼ Ce0.5Sr0.3Ca0.2Ox; ◆ Ce0.5Sr0.25Ca0.25Ox.

| Catalyst | T/℃ | Conv(CH4)(%) | Conv(O2)(%) | Sel(COx)(%) | Sel(C2)(%) | Y(C2)(%) |

|---|---|---|---|---|---|---|

| Blank | 750 | 1.2 | 2.3 | 59.0 | 41.0 | 0.5 |

| 800 | 2.3 | 4.5 | 61.8 | 38.3 | 0.9 | |

| CeO2 | 450 | 2.0 | 5.8 | 100.0 | 0 | 0 |

| 500 | 17.9 | 100.0 | 98.0 | 2.0 | 0.4 | |

| 550 | 18.0 | 100.0 | 97.8 | 2.2 | 0.4 | |

| 700 | 19.1 | 100.0 | 95.1 | 4.9 | 0.9 | |

| Ce0.5Sr0.5Ox | 500 | 1.1 | 2.9 | 100.0 | 0 | 0 |

| 550 | 24.9 | 93.9 | 65.1 | 34.9 | 8.7 | |

| 650 | 28.6 | 100.0 | 52.8 | 47.2 | 13.5 | |

| 700 | 29.4 | 100.0 | 50.6 | 49.4 | 14.5 | |

| Ce0.5Ca0.5Ox | 500 | 1.8 | 5.3 | 100.0 | 0 | 0 |

| 550 | 24.3 | 98.0 | 63.7 | 36.3 | 8.8 | |

| 650 | 25.1 | 100.0 | 60.8 | 39.2 | 9.8 | |

| 700 | 24.4 | 100.0 | 64.0 | 35.9 | 8.8 | |

| Ce0.5Sr0.4Ca0.1Ox | 500 | 1.2 | 3.2 | 100.0 | 0 | 0 |

| 550 | 28.1 | 97.0 | 54.8 | 45.2 | 12.7 | |

| 650 | 30.2 | 100.0 | 49.5 | 50.5 | 15.2 | |

| 700 | 30.4 | 100.0 | 48.5 | 51.5 | 15.7 | |

| Ce0.5Sr0.5Ox(MM)* | 550 | 0 | 0 | |||

| (CeO2+SrO) | 700 | 1.6 | 4.1 | 85.4 | 14.6 | 0.2 |

| 750 | 3.5 | 8.1 | 73.6 | 36.5 | 1.3 | |

| 800 | 9.3 | 19.9 | 52.0 | 48.0 | 4.5 | |

| Ce0.5Sr0.5Ox(MM)* | 550 | 19.1 | 98.5 | 92.8 | 7.2 | 1.4 |

| (CeO2+SrCO3) | 700 | 26.0 | 100.0 | 57.4 | 42.6 | 11.1 |

| 750 | 27.5 | 100.0 | 52.4 | 47.6 | 13.1 | |

| 800 | 28.0 | 100.0 | 51.2 | 48.8 | 13.6 | |

| CaO | 700 | 2.4 | 6.3 | 88.4 | 11.6 | 0.3 |

| 750 | 6.2 | 14.9 | 65.7 | 34.3 | 2.1 | |

| 800 | 24.7 | 57.9 | 58.1 | 41.9 | 10.4 | |

| SrO | 700 | 0.9 | 1.9 | 66.3 | 33.7 | 0.3 |

| 750 | 2.3 | 4.0 | 40.4 | 59.7 | 1.4 | |

| 800 | 8.9 | 14.0 | 41.3 | 58.8 | 5.3 | |

| CaCO3 | 700 | 18.1 | 53.4 | 66.4 | 33.6 | 6.1 |

| 750 | 26.9 | 85.2 | 57.4 | 42.6 | 11.5 | |

| 800 | 28.7 | 98.8 | 58.0 | 42.0 | 12.1 | |

| SrCO3 | 700 | 1.5 | 3.0 | 66.0 | 34.0 | 0.5 |

| 750 | 3.1 | 6.3 | 67.8 | 32.2 | 1.0 | |

| 800 | 9.0 | 17.4 | 54.5 | 45.5 | 4.1 |

Table 1 Comparisons of OCM performances over some Ce-based and relevant catalysts at selected temperatures

| Catalyst | T/℃ | Conv(CH4)(%) | Conv(O2)(%) | Sel(COx)(%) | Sel(C2)(%) | Y(C2)(%) |

|---|---|---|---|---|---|---|

| Blank | 750 | 1.2 | 2.3 | 59.0 | 41.0 | 0.5 |

| 800 | 2.3 | 4.5 | 61.8 | 38.3 | 0.9 | |

| CeO2 | 450 | 2.0 | 5.8 | 100.0 | 0 | 0 |

| 500 | 17.9 | 100.0 | 98.0 | 2.0 | 0.4 | |

| 550 | 18.0 | 100.0 | 97.8 | 2.2 | 0.4 | |

| 700 | 19.1 | 100.0 | 95.1 | 4.9 | 0.9 | |

| Ce0.5Sr0.5Ox | 500 | 1.1 | 2.9 | 100.0 | 0 | 0 |

| 550 | 24.9 | 93.9 | 65.1 | 34.9 | 8.7 | |

| 650 | 28.6 | 100.0 | 52.8 | 47.2 | 13.5 | |

| 700 | 29.4 | 100.0 | 50.6 | 49.4 | 14.5 | |

| Ce0.5Ca0.5Ox | 500 | 1.8 | 5.3 | 100.0 | 0 | 0 |

| 550 | 24.3 | 98.0 | 63.7 | 36.3 | 8.8 | |

| 650 | 25.1 | 100.0 | 60.8 | 39.2 | 9.8 | |

| 700 | 24.4 | 100.0 | 64.0 | 35.9 | 8.8 | |

| Ce0.5Sr0.4Ca0.1Ox | 500 | 1.2 | 3.2 | 100.0 | 0 | 0 |

| 550 | 28.1 | 97.0 | 54.8 | 45.2 | 12.7 | |

| 650 | 30.2 | 100.0 | 49.5 | 50.5 | 15.2 | |

| 700 | 30.4 | 100.0 | 48.5 | 51.5 | 15.7 | |

| Ce0.5Sr0.5Ox(MM)* | 550 | 0 | 0 | |||

| (CeO2+SrO) | 700 | 1.6 | 4.1 | 85.4 | 14.6 | 0.2 |

| 750 | 3.5 | 8.1 | 73.6 | 36.5 | 1.3 | |

| 800 | 9.3 | 19.9 | 52.0 | 48.0 | 4.5 | |

| Ce0.5Sr0.5Ox(MM)* | 550 | 19.1 | 98.5 | 92.8 | 7.2 | 1.4 |

| (CeO2+SrCO3) | 700 | 26.0 | 100.0 | 57.4 | 42.6 | 11.1 |

| 750 | 27.5 | 100.0 | 52.4 | 47.6 | 13.1 | |

| 800 | 28.0 | 100.0 | 51.2 | 48.8 | 13.6 | |

| CaO | 700 | 2.4 | 6.3 | 88.4 | 11.6 | 0.3 |

| 750 | 6.2 | 14.9 | 65.7 | 34.3 | 2.1 | |

| 800 | 24.7 | 57.9 | 58.1 | 41.9 | 10.4 | |

| SrO | 700 | 0.9 | 1.9 | 66.3 | 33.7 | 0.3 |

| 750 | 2.3 | 4.0 | 40.4 | 59.7 | 1.4 | |

| 800 | 8.9 | 14.0 | 41.3 | 58.8 | 5.3 | |

| CaCO3 | 700 | 18.1 | 53.4 | 66.4 | 33.6 | 6.1 |

| 750 | 26.9 | 85.2 | 57.4 | 42.6 | 11.5 | |

| 800 | 28.7 | 98.8 | 58.0 | 42.0 | 12.1 | |

| SrCO3 | 700 | 1.5 | 3.0 | 66.0 | 34.0 | 0.5 |

| 750 | 3.1 | 6.3 | 67.8 | 32.2 | 1.0 | |

| 800 | 9.0 | 17.4 | 54.5 | 45.5 | 4.1 |

| Catalyst | SBET/(m2·g-1) | Vp/(cm3·g-1) | Dp/nm | D/nm | a/nm |

|---|---|---|---|---|---|

| CeO2 | 12.0 | 0.075 | 20.4 | 96.6 | 0.05394 |

| Ce0.5Sr0.5Ox | 3.0 | 0.018 | 21.5 | 48.3 | 0.05440 |

| Ce0.5Sr0.4Ca0.1Ox | 5.5 | 0.028 | 18.8 | 18.7 | 0.05438 |

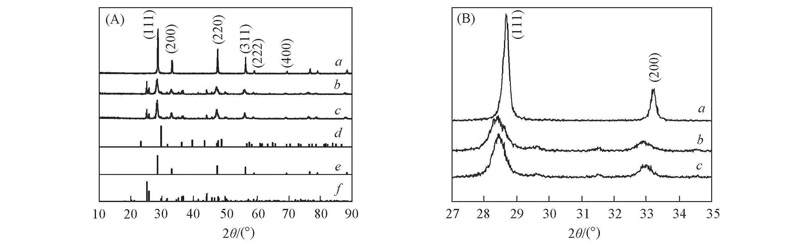

Table 2 Specific surface areas(SBET), porous volumes(Vp), porous sizes(Dp), CeO2 crystalline sizes(D) and lattice parameters(a) of the catalysts

| Catalyst | SBET/(m2·g-1) | Vp/(cm3·g-1) | Dp/nm | D/nm | a/nm |

|---|---|---|---|---|---|

| CeO2 | 12.0 | 0.075 | 20.4 | 96.6 | 0.05394 |

| Ce0.5Sr0.5Ox | 3.0 | 0.018 | 21.5 | 48.3 | 0.05440 |

| Ce0.5Sr0.4Ca0.1Ox | 5.5 | 0.028 | 18.8 | 18.7 | 0.05438 |

Fig.4 XRD patterns of the catalystsa. CeO2; b. Ce0.5Sr0.5Ox; c. Ce0.5Sr0.4Ca0.1Ox; d. CaCO3, PDF No. 99-0022; e. CeO2, PDF No. 01-081-0792;f. SrCO3, PDF No. 01-084-1778.

| Catalyst | Eb/eV(FWHM*) | Amount of oxygen species(%) | n( n(O2-) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| O2- | C | O2- | C | |||||||

| CeO2 | 528.6(1.2) | 529.7(1.2) | 530.9(1.2) | 532.1(1.2) | 72.8 | 11.0 | 11.7 | 4.3 | 0.3 | |

| Ce0.5Sr0.5Ox | 528.4(1.7) | 530.3(1.7) | 531.3(1.7) | 23.6 | 65.5 | 10.9 | 2.8 | |||

| Ce0.5Sr0.4Ca0.1Ox | 528.2(1.6) | 530.5(1.6) | 532.0(1.6) | 22.7 | 66.1 | 11.2 | 3.0 | |||

Table 3 Curve-fitting results from XPS spectra for O1s of the catalysts

| Catalyst | Eb/eV(FWHM*) | Amount of oxygen species(%) | n( n(O2-) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| O2- | C | O2- | C | |||||||

| CeO2 | 528.6(1.2) | 529.7(1.2) | 530.9(1.2) | 532.1(1.2) | 72.8 | 11.0 | 11.7 | 4.3 | 0.3 | |

| Ce0.5Sr0.5Ox | 528.4(1.7) | 530.3(1.7) | 531.3(1.7) | 23.6 | 65.5 | 10.9 | 2.8 | |||

| Ce0.5Sr0.4Ca0.1Ox | 528.2(1.6) | 530.5(1.6) | 532.0(1.6) | 22.7 | 66.1 | 11.2 | 3.0 | |||

| [1] | Arndt S., Laugel G., Levchenko S., Levchenko S., Horn R., Baerns M., Scheffler M., Schlögl R., Schlögl S., Schomäcker R., Catal. Rev., 2011, 53(4), 424—514 |

| [2] | Hammond C., Conrad S., ChemSusChem., 2012, 5(9), 1668—1686 |

| [3] | Neumann B., Elkins T. W., Gash A. E., Hagelin W. H., Bäumer M., Catal. Lett., 2015, 145(6), 1251—1261 |

| [4] | Hou Y. H., Han W. C., Xia W. S., Wan H. L., ACS Catal., 2015, 5(3), 1663—1674 |

| [5] | Hou Y. H., Lin Y. L., Li Q., Weng W. Z., Xia W. S., Wan H. L., ChemCatChem., 2013, 5(12), 3725—3735 |

| [6] | Ferreira V. J., Tavares P., Figueiredo J. L., Faria J. L. Ind. & Eng. Chem. Res., 2012, 51(32), 10535—10541 |

| [7] | Yu Z., Yang X., Lunsford J. H., Rosynek M. P., J. Catal., 1995, 154, 163—173 |

| [8] | Xu F. Q., Shen S. K., J. Nat. Gas Chem., 1997, 6(4), 265—274 |

| [9] | Elkins T. W., Neumann B., Bäumer M., Hagelin W., Helena E., ACS Catal., 2014, 4(6), 1972—1990 |

| [10] | Serres T., Aquino C., Mirodatos C., Schuurman Y., Appl. Catal. A: Gen., 2015, 504, 509—518 |

| [11] | Palmer M. S., Matthew N., Olken A. M. M., J. Chem. Soc., 2002, 124, 8452—8461 |

| [12] | Iwamoto M., Lunsford J. H., J. Phys. Chem., 1980, 84(23), 3079—3084 |

| [13] | Osada Y., Koike S., Fukushima T., Appl. Catal., 1990, 59(1), 59—74 |

| [14] | Otsuka K., Komatsu T., Shimizu Y., Stud. Surf. Sci. Catal., 1989, 44, 43—50 |

| [15] | Otsuka K., Said A. A., Jinno K., Chem. Lett., 1987, 16(1), 77—80 |

| [16] | Dubois J. L., Rebours B., Cameron C. J., Appl. Catal., 1990, 67(1), 73—79 |

| [17] | Gellings P. J., Bouwmeester H. J. M., Catal. Today, 2000, 58(1), 1—53 |

| [18] | Ferreira V. J., Tavares P., Figueiredo J. L., Faria J. L., Catal. Commun., 2013, 42, 50—53 |

| [19] | Papa F., Luminita P., Osiceanu P., Birjega R. Akane M., Balint I., J. Mole. Catal. A Chem., 2011, 346(1/2), 46—54 |

| [20] | Holgado J. P., Alvarez R., Munuera G., Appl. Surf. Sci., 2000, 161(3/4), 301—315 |

| [1] | FAN Jianling, TANG Hao, QIN Fengjuan, XU Wenjing, GU Hongfei, PEI Jiajing, CEHN Wenxing. Nitrogen Doped Ultra-thin Carbon Nanosheet Composited Platinum-ruthenium Single Atom Alloy Catalyst for Promoting Electrochemical Hydrogen Evolution Process [J]. Chem. J. Chinese Universities, 2022, 43(9): 20220366. |

| [2] | HUANG Xiaoshun, MA Haiying, LIU Shujuan, WANG Bin, WANG Hongli, QIAN Bo, CUI Xinjiang, SHI Feng. Recent Advances on Indirect Conversion of Carbon Dioxide to Chemicals [J]. Chem. J. Chinese Universities, 2022, 43(7): 20220222. |

| [3] | JIANG Xiaokang, ZHOU Qi, ZHOU Hengwei. Synthesis and Luminescence Properties of Gd2ZnTiO6∶Dy3+, Eu3+ Single Phase White Light-emitting Phosphors [J]. Chem. J. Chinese Universities, 2022, 43(6): 20220029. |

| [4] | GONG Yanxi, WANG Jianbing, CHAI Buyu, HAN Yuanchun, MA Yunfei, JIA Chaomin. Preparation of Potassium Doped g-C3N4 Thin Film Photoanode and Its Application in Photoelectrocatalytic Oxidation of Diclofenac Sodium in Water [J]. Chem. J. Chinese Universities, 2022, 43(6): 20220005. |

| [5] | HAO Honglei, MENG Fanyu, LI Ruoyu, LI Yingqiu, JIA Mingjun, ZHANG Wenxiang, YUAN Xiaoling. Biomass Derived Nitrogen Doped Porous Carbon Materials as Adsorbents for Removal of Methylene Blue in Water [J]. Chem. J. Chinese Universities, 2022, 43(6): 20220055. |

| [6] | WU Zexin, ZHU Yuanjie, WANG Hongzhong, WANG Junan, HE Ying. Methyl-modified Carbazole/Diphenyl Sulfone-based AIE-TADF Blue Emitter and Its OLEDs [J]. Chem. J. Chinese Universities, 2022, 43(11): 20220371. |

| [7] | HOU Congcong, WANG Huiying, LI Tingting, ZHANG Zhiming, CHANG Chunrui, AN Libao. Preparation and Electrochemical Properties of N-CNTs/NiCo-LDH Composite [J]. Chem. J. Chinese Universities, 2022, 43(10): 20220351. |

| [8] | SUN Xingyu, LUO Jing, WANG Xiadi, ZHU Qing, ZHOU Hui, LYU Xiaobing. Synthesis and Characterization of Stereoregular and Discrete Oligo(cyclohexene carbonate)s [J]. Chem. J. Chinese Universities, 2022, 43(10): 20220204. |

| [9] | MA Lijuan, GAO Shengqi, RONG Yifei, JIA Jianfeng, WU Haishun. Theoretical Investigation of Hydrogen Storage Properties of Sc, Ti, V-decorated and B/N-doped Monovacancy Graphene [J]. Chem. J. Chinese Universities, 2021, 42(9): 2842. |

| [10] | TIAN Runsai, LU Qian, ZHANG Hongbin, ZHANG Bo, FENG Yuanyuan, WEI Jinxiang, FENG Jijun. Design and Construction of N-Doping Carbon in⁃situ Coated Cu2O/Co3O4@C Heterostructured Composite Material for Highly Efficient Lithium-ion Storage [J]. Chem. J. Chinese Universities, 2021, 42(8): 2592. |

| [11] | WU Qiliang, MEI Jinghao, LI Zheng, FAN Haidong, ZHANG Yanwei. Photo-thermal Coupling Water Splitting over Fe-doped TiO2 with Various Nanostructures [J]. Chem. J. Chinese Universities, 2021, 42(6): 1837. |

| [12] | JIANG Lei, YAN Shengdi, LIN Yu, WU Guozhang. Studies on Viscosity and Chemical Structure Changes in Polycarbonate Melts under Nitrogen Protection [J]. Chem. J. Chinese Universities, 2021, 42(3): 884. |

| [13] | LIU Zhigang, LI Jiabao, YANG Jian, MA Hao, WANG Chengyin, GUO Xin, WANG Guoxiu. Preparation of a Novel g-C3N4/Sn/N-doped Carbon Composite for Sodium Storage [J]. Chem. J. Chinese Universities, 2021, 42(2): 633. |

| [14] | DU Xinyao, WANG Wei, LIN Yu, WU Guozhang. Synthesis and Optical Properties of Polycarbonates Copolymerized with Bisphenol Fluorene Moiety [J]. Chem. J. Chinese Universities, 2021, 42(12): 3765. |

| [15] | WANG Yishu, LI Xue, YAN Li, XU Hongyun, ZHU Yuxin, SONG Yanhua, CUI Yanjuan. Photocatalytic Reduction Performance of Z-scheme Two-dimensional BCN/Sn3O4 Composite Materials [J]. Chem. J. Chinese Universities, 2021, 42(12): 3722. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||