Chem. J. Chinese Universities ›› 2016, Vol. 37 ›› Issue (11): 2060.doi: 10.7503/cjcu20160309

• Physical Chemistry • Previous Articles Next Articles

ZHANG Qian1,2, DING Mingyue1,*( ), ZHANG Yulan1,2, LI Yuping1, WANG Chenguang1, WANG Tiejun1,*(

), ZHANG Yulan1,2, LI Yuping1, WANG Chenguang1, WANG Tiejun1,*( ), MA Longlong1

), MA Longlong1

Received:2016-05-05

Online:2016-11-10

Published:2016-10-17

Contact:

DING Mingyue,WANG Tiejun

E-mail:dingmy@ms.giec.ac.cn;wangtj@ms.giec.ac.cn

Supported by:CLC Number:

TrendMD:

ZHANG Qian, DING Mingyue, ZHANG Yulan, LI Yuping, WANG Chenguang, WANG Tiejun, MA Longlong. Oligomerization of Biomass Cracking Gas to Gasoline Distillates over Amorphous Silica-alumina†[J]. Chem. J. Chinese Universities, 2016, 37(11): 2060.

| Run No. | t/℃ | p/MPa |

|---|---|---|

| R1 | 100 | 4.0 |

| R2 | 200 | 4.0 |

| R3 | 240 | 4.0 |

| R4 | 280 | 4.0 |

| R5 | 320 | 4.0 |

| R6 | 280 | 2.0 |

| R7 | 280 | 3.0 |

Table 1 Reaction conditions for ASA catalysis oligomerization of olefin-rich biomass syngas*

| Run No. | t/℃ | p/MPa |

|---|---|---|

| R1 | 100 | 4.0 |

| R2 | 200 | 4.0 |

| R3 | 240 | 4.0 |

| R4 | 280 | 4.0 |

| R5 | 320 | 4.0 |

| R6 | 280 | 2.0 |

| R7 | 280 | 3.0 |

| Catalyst | SBET/ (m2·g-1) | Average pore diameter/nm | Pore volume/ (cm3·g-1) |

|---|---|---|---|

| ASA(Fresh) | 467.2 | 4.33 | 0.73 |

| ASA-R1 | 279.9 | 4.31 | 0.37 |

| ASA-R2 | 330.8 | 3.83 | 0.43 |

| ASA-R3 | 307.4 | 3.81 | 0.44 |

| ASA-R4 | 320.9 | 4.32 | 0.49 |

| ASA-R5 | 249.1 | 3.81 | 0.35 |

| ASA-R6 | 361.1 | 4.29 | 0.55 |

| ASA-R7 | 335.1 | 4.32 | 0.52 |

Table 2 Physical and chemical characteristics of ASA before and after different reactions

| Catalyst | SBET/ (m2·g-1) | Average pore diameter/nm | Pore volume/ (cm3·g-1) |

|---|---|---|---|

| ASA(Fresh) | 467.2 | 4.33 | 0.73 |

| ASA-R1 | 279.9 | 4.31 | 0.37 |

| ASA-R2 | 330.8 | 3.83 | 0.43 |

| ASA-R3 | 307.4 | 3.81 | 0.44 |

| ASA-R4 | 320.9 | 4.32 | 0.49 |

| ASA-R5 | 249.1 | 3.81 | 0.35 |

| ASA-R6 | 361.1 | 4.29 | 0.55 |

| ASA-R7 | 335.1 | 4.32 | 0.52 |

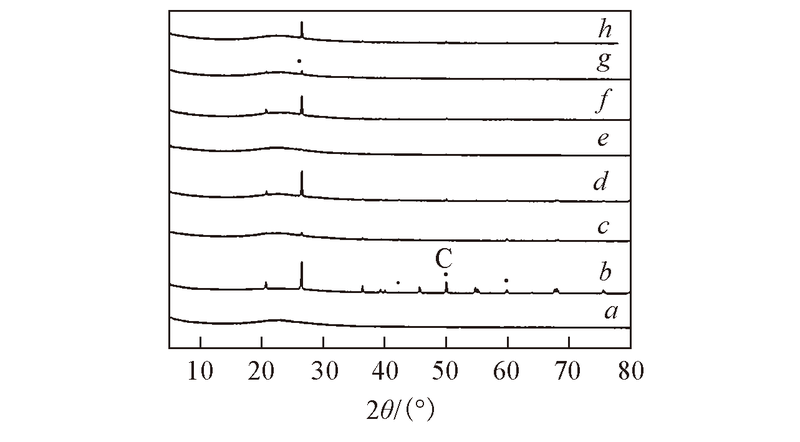

Fig.3 XRD patterns of ASA before and after different reactionsa. ASA-fresh; b. ASA-R1; c. ASA-R2; d. ASA-R3;e. ASA-R4; f. ASA-R5; g. ASA-R6; h. ASA-R7.

| Sample | Acid amount/(μmol·g-1) | T-peak/℃ | |||

|---|---|---|---|---|---|

| Weak acid | Strong acid | Total acid | LT-peak | HT-peak | |

| ASA | 77.29 | 530.34 | 607.63 | 230 | 500 |

Table 3 NH3-TPD data of ASA catalyst

| Sample | Acid amount/(μmol·g-1) | T-peak/℃ | |||

|---|---|---|---|---|---|

| Weak acid | Strong acid | Total acid | LT-peak | HT-peak | |

| ASA | 77.29 | 530.34 | 607.63 | 230 | 500 |

| Catalyst | Content of Brönsted acid/ (mmol·g-1) | Content of Lewis acid/ (mmol·g-1) | Catalyst | Content of Brönsted acid/ (mmol·g-1) | Content of Lewis acid/ (mmol·g-1) |

|---|---|---|---|---|---|

| ASA-fresh | 0.0304 | 0.1047 | ASA-R4 | 0.0168 | 0.0536 |

| ASA-R1 | 0.0212 | 0.0612 | ASA-R5 | 0.0244 | 0.0345 |

| ASA-R2 | 0.0156 | 0.0429 | ASA-R6 | 0.0227 | 0.0478 |

| ASA-R3 | 0.0199 | 0.0510 | ASA-R7 | 0.0234 | 0.0418 |

Table 4 Py-IR data of ASA catalyst

| Catalyst | Content of Brönsted acid/ (mmol·g-1) | Content of Lewis acid/ (mmol·g-1) | Catalyst | Content of Brönsted acid/ (mmol·g-1) | Content of Lewis acid/ (mmol·g-1) |

|---|---|---|---|---|---|

| ASA-fresh | 0.0304 | 0.1047 | ASA-R4 | 0.0168 | 0.0536 |

| ASA-R1 | 0.0212 | 0.0612 | ASA-R5 | 0.0244 | 0.0345 |

| ASA-R2 | 0.0156 | 0.0429 | ASA-R6 | 0.0227 | 0.0478 |

| ASA-R3 | 0.0199 | 0.0510 | ASA-R7 | 0.0234 | 0.0418 |

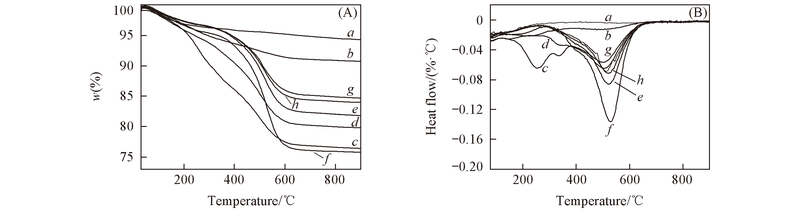

Fig.6 TG(A) and DTG(B) analysis curves of catalyst deposited with carbona. ASA-fresh; b. ASA-R1; c. ASA-R2; d. ASA-R3; e. ASA-R4; f. ASA-R5; g. ASA-R6; h. ASA-R7.

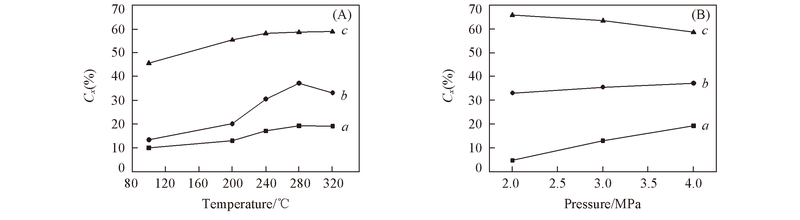

Fig.8 Carbon conversion of olefin oligomerization under different reaction conditions a. C2H4; b. C3H6; c. C4H8. (A) 4.0 MPa, 100—320 ℃; (B) 2.0—4.0 MPa, 280 ℃.

| Run No. | Carbon yield of liquid(%) | Product distribution(%, mass fraction) | ||||||

|---|---|---|---|---|---|---|---|---|

| C5 | C6 | C7 | C8 | C9 | C10 | |||

| R1 | 2.14 | 1.30 | 0.99 | 39.81 | 1.08 | 1.27 | 51.56 | 3.99 |

| R2 | 7.94 | 5.03 | 8.61 | 47.99 | 7.96 | 4.09 | 22.20 | 4.12 |

| R3 | 17.56 | 5.07 | 13.89 | 49.92 | 12.33 | 4.71 | 12.23 | 1.86 |

| R4 | 22.91 | 4.21 | 16.17 | 56.12 | 13.46 | 1.41 | 6.80 | 1.83 |

| R5 | 20.16 | 5.73 | 18.65 | 55.61 | 8.61 | 4.46 | 4.47 | 2.17 |

| Run No. | Carbon yield of liquid(%) | Product distribution(%, mass fraction) | ||||||

|---|---|---|---|---|---|---|---|---|

| C5 | C6 | C7 | C8 | C9 | C10 | |||

| R1 | 2.14 | 1.30 | 0.99 | 39.81 | 1.08 | 1.27 | 51.56 | 3.99 |

| R2 | 7.94 | 5.03 | 8.61 | 47.99 | 7.96 | 4.09 | 22.20 | 4.12 |

| R3 | 17.56 | 5.07 | 13.89 | 49.92 | 12.33 | 4.71 | 12.23 | 1.86 |

| R4 | 22.91 | 4.21 | 16.17 | 56.12 | 13.46 | 1.41 | 6.80 | 1.83 |

| R5 | 20.16 | 5.73 | 18.65 | 55.61 | 8.61 | 4.46 | 4.47 | 2.17 |

| [1] | Tomov A., K. , Gibson V., C. , Britovsek G. J., P. , Long R., J. , Meurs M., V. , Jones D., J. , Organometallics, 2009, 28( 24), 7033- 7040 |

| [2] | 王俊, 杨光, 李翠勤, 施伟光. 高等学校化学学报, 2014, 35( 7), 1536- 1540 |

| Wang, J. , Yang, G. , Li C., Q. , Shi W., G. , Chem. J. Chinese Universities, 2014, 35( 7), 1536- 1540 ( | |

| [3] | Corma, A. , Melo, F.V. , Sauvanaud, L. , Ortega, F. , Catal. Today, 2005, 107, 699- 706 |

| [4] | Park Y., K. , Lee C., W. , Kang N., Y. , Choi W., C. , Choi, S. , Oh S., H. , Park D., S. , Catal. Surv. Asia, 2010, 14, 75- 84 |

| [5] | 纪华, 吕毅军, 胡津仙, 相宏伟, 李永旺. 化学进展, 2002, 14( 2), 146- 155 |

| Ji, H. , Lü, Y. J. , Hu J., X. , Xiang H., W. , Li Y., W. , Progress in Chemistry, 2002, 14( 2), 146- 155 ( | |

| [6] | 王俊, 霍宏亮, 李翠勤, 马立莉, 施伟光, 陈帅. 高等学校化学学报, 2015, 36( 9), 1813- 1818 |

| Wang, J. , Huo H., L. , Li C., Q. , Ma L., L. , Shi W., G. , Chen, S. , Chem. J. Chinese Universities, 2015, 36( 9), 1813- 1818 ( | |

| [7] | Zhang, H. , Cheng Y., T. , Vispute T., P. , Xiao, R. , Huber G., W. , Energy Environ Sci., 2011, 4, 2297- 2307 |

| [8] | Gayubo A., G. , Valle, B. , Aguayo A., T. , Olazar, M. , Bilbao, J. , Industrial & Engineering Chemistry Research, 2009, 49( 1), 123- 131 |

| [9] | Bjorgen, M. , Svelle, S. , Joensen, F. , Nerlov, J. , Kolboe, S. , Bonino, F. , Palumbo, L. , Bordiga, S. , Olsbye, U. , J. Catal., 2007, 249, 195- 207 |

| [10] | Bradin, D. , Production of Polypropylene from Renewable, Resources , WO, US8916661, 2014 |

| [11] | Antonio, M. , Polymer Reviews, 2009, 49( 2), 79- 84 |

| [12] | Qi, Y. , Liu, Z. , Lv, Z. , Wang, H. , He, C. , Xu, L. , A Process for Producing Lower Carbon Olefins from Methanol or/and Dimethyl, Ether , EP, WO 2008106841 A8, 2009 |

| [13] | Yang G., H. , Tsubaki, N. , Shamoto, J. , Yoneyama, Y. , Zhang, Y. , J. Am. Chem. Soc., 2010, 132, 8129- 8136 |

| [14] | Corma, A. , Iborra, S. , Velty, A. , Chem. Rev., 2007, 107, 2411- 2502 |

| [15] | Cheng, J. , Hu, P. , Ellis, P. , French, S. , Kelly, G. , Lok C., M. , J. Catal., 2008, 257, 221- 228 |

| [16] | George, W. , Huber, P. , Corma, A. , Angew. Chem., 2007, 46( 38), 7184- 7201 |

| [17] | Vispute T., P. , Zhang, H. , Sanna, A. , Xiao, R. , Huber G., W. , Science, 2010, 330( 6008), 1222- 1227 |

| [18] | Gong, F. , Yang, Z. , Hong, C. , Huang, W. , Shen, N. , Zhang, Z. , Bioresource Technology, 2011, 102( 19), 9247- 9254 |

| [19] | Yuan, Y. , Bi, P. , Fan, M. , Zhang, Z. , Jiang, P. , Li, Q. , Journal of Chemical Technology & Biotechnology, 2014, 89( 2), 239- 248 |

| [20] | de Klerk, A. , Energy & Fuels, 2006, 20, 1799- 1805 |

| [21] | Lin, S. , Shi, L. , Zhang, H. , Zhang, N. , Yi, X. , Zheng, A. , Microporous & Mesoporous Materials, 2014, 184( 2), 151- 161 |

| [22] | Bleken F., L. , Barbera, K. , Bonino, F. , Olsbye, U. , Lillerud K., P. , Bordiga, S. , Journal of Catalysis, 2013, 307( 6), 62- 73 |

| [23] | 谭伟, 侯珂珂, 刘民, 李文慧, 刘海鸥, 宋春山, 郭新闻. 石油学报, 2002, 21( 7), 955- 957 |

| Tan, W. , Hou K., K. , Liu, M. , Li W., H. , Liu H., O. , Song C., S. , Guo X., W. , Acta Petrolei Sinica, 2002, 21( 7), 955- 957 ( | |

| [24] | Helveg, S. , Lopez, C. , Schested, J. , Nature, 2004, 427, 426- 429 |

| [25] | Martí, nez C. , Doskocil E., J. , Corma, A. , Topics in Catalysis, 2013, 57( 6-9), 668- 682 |

| [26] | 胡津仙, 李晓波, 李英, 王锋, 任杰, 李永旺. 分子催化, 2005, 19( 1), 17- 21 |

| Hu J., X. , Li X., B. , Li, Y. , Wang, F. , Ren, J. , Li Y., W. , J. Mol. Catal., 2005, 19( 1), 17- 21 ( | |

| [27] | Bjorgen, M. , Olsbye, U. , Kolboe, S. , Journal of Catalysis, 2003, 215( 1), 30- 44 |

| [1] | GUO Biao, ZHAO Chencan, LIU Xinxin, YU Zhou, ZHOU Lijing, YUAN Hongming, ZHAO Zhen. Effects of Surface Hydrothermal Carbon Layer on the Photocatalytic Activity of Magnetic NiFe2O4 Octahedron [J]. Chem. J. Chinese Universities, 2022, 43(11): 20220472. |

| [2] | DONG Yanhong, LU Xinhuan, YANG Lu, SUN Fanqi, DUAN Jingui, GUO Haotian, ZHANG Qinjun, ZHOU Dan, XIA Qinghua. Preparation of Bifunctional Metal-organic Framework Materials and Application in Catalytic Olefins Epoxidation [J]. Chem. J. Chinese Universities, 2022, 43(11): 20220458. |

| [3] | WANG Zumin, MENG Cheng, YU Ranbo. Doping Regulation in Transition Metal Phosphides for Hydrogen Evolution Catalysts [J]. Chem. J. Chinese Universities, 2022, 43(11): 20220544. |

| [4] | HE Jianyun, JIANG Yunbo, ZHANG Aimin, TANG Zhenyan, LI Hongpeng. Preparation and application of a novel porphyrin-based porous organic polymer COP-180 supported palladium catalyst [J]. Chem. J. Chinese Universities, 0, (): 20220535. |

| [5] | XIA Wenwen, YU Hongjing, WANG Shiye, YAO Li, LI Xiangyuan. Combustion Mechanism Construction Based On Minimized Reaction Network: Combustion of Aromatic hydrocarbon [J]. Chem. J. Chinese Universities, 0, (): 20220616. |

| [6] | LI Huaike, YUE Guichu, XIE Haiyun, LIU Jing, GAO Songwei, HOU Lanlan, LI Shuai, MIAO Beibei, WANG Nü, BAI Jie, CUI Zhimin, ZHAO Yong. Application of Electrospun Hollow Nanofibers in Catalysis [J]. Chem. J. Chinese Universities, 0, (): 20220625. |

| [7] | KUANG Huayi, CHEN Chen. Synthesis methods and electrocatalytic performance of noble-metal nanoframes catalysts [J]. Chem. J. Chinese Universities, 0, (): 20220586. |

| [8] | . Ni-La/SiO2 Catalysts Prepared by Dielectric Barrier Discharge Plasma Applying in the Dry Reforming of Methane [J]. Chem. J. Chinese Universities, 0, (): 20220503. |

| [9] | ZHU Jipeng, LIU Runhui, SONG Gonghua. Application of Bisoxazoline Grafted Amino Acid Polymer as Chiral Catalytic Center in Asymmetric Henry Reaction [J]. Chem. J. Chinese Universities, 0, (): 20220569. |

| [10] | LI Xueyu, WANG Zhao, CHEN Ya, LI Keke, LI Jianquan, JIN Shunjing, CHEN Lihua, SU Baolian. Enhanced Catalytic Performance of Supported Nano-gold by the Localized Surface Plasmon Resonance for Selective Hydrogenation of Butadiene [J]. Chem. J. Chinese Universities, 2022, 43(10): 20220174. |

| [11] | SUN Jinshi, CHEN Peng, JING Liping, SUN Fuxing, LIU Jia. Synthesis of Hierarchical Porous Aromatic Frameworks for Immobilization of Thiourea Catalyst [J]. Chem. J. Chinese Universities, 2022, 43(10): 20220171. |

| [12] | CHENG Yuanyuan, XI Biying. Theoretical Study on the Fragmentation Mechanism of CH3SSCH3 Radical Cation Initiated by OH Radical [J]. Chem. J. Chinese Universities, 2022, 43(10): 20220271. |

| [13] | SONG Jiaxin, CUI Jing, FAN Xiaoqiang, KONG Lian, XIAO Xia, XIE Zean, ZHAO Zhen. Preparation of mesoporous silica supported highly dispersed vanadium catalyst and their catalytic performance for selective oxidation of ethane [J]. Chem. J. Chinese Universities, 0, (): 20220532. |

| [14] | TANG Quanjun, LIU Yingxin, MENG Rongwei, ZHANG Ruotian, LING Guowei, ZHANG Chen. Application of Single-atom Catalysis in Marine Energy [J]. Chem. J. Chinese Universities, 2022, 43(9): 20220324. |

| [15] | LIN Zhi, PENG Zhiming, HE Weiqing, SHEN Shaohua. Single-atom and Cluster Photocatalysis: Competition and Cooperation [J]. Chem. J. Chinese Universities, 2022, 43(9): 20220312. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||