Chem. J. Chinese Universities ›› 2022, Vol. 43 ›› Issue (3): 20210626.doi: 10.7503/cjcu20210626

• Review • Previous Articles Next Articles

YAN Wenqing1,2, ZHANG Zeyao1,3,4( ), LI Yan1,2,3,4(

), LI Yan1,2,3,4( )

)

Received:2021-08-31

Online:2022-03-10

Published:2021-11-18

Contact:

ZHANG Zeyao,LI Yan

E-mail:zeyaozhang@pku.edu.cn;yanli@pku.edu.cn

Supported by:CLC Number:

TrendMD:

YAN Wenqing, ZHANG Zeyao, LI Yan. Controlled Preparation of Carbon Nanotube Transparent Conductive Films[J]. Chem. J. Chinese Universities, 2022, 43(3): 20210626.

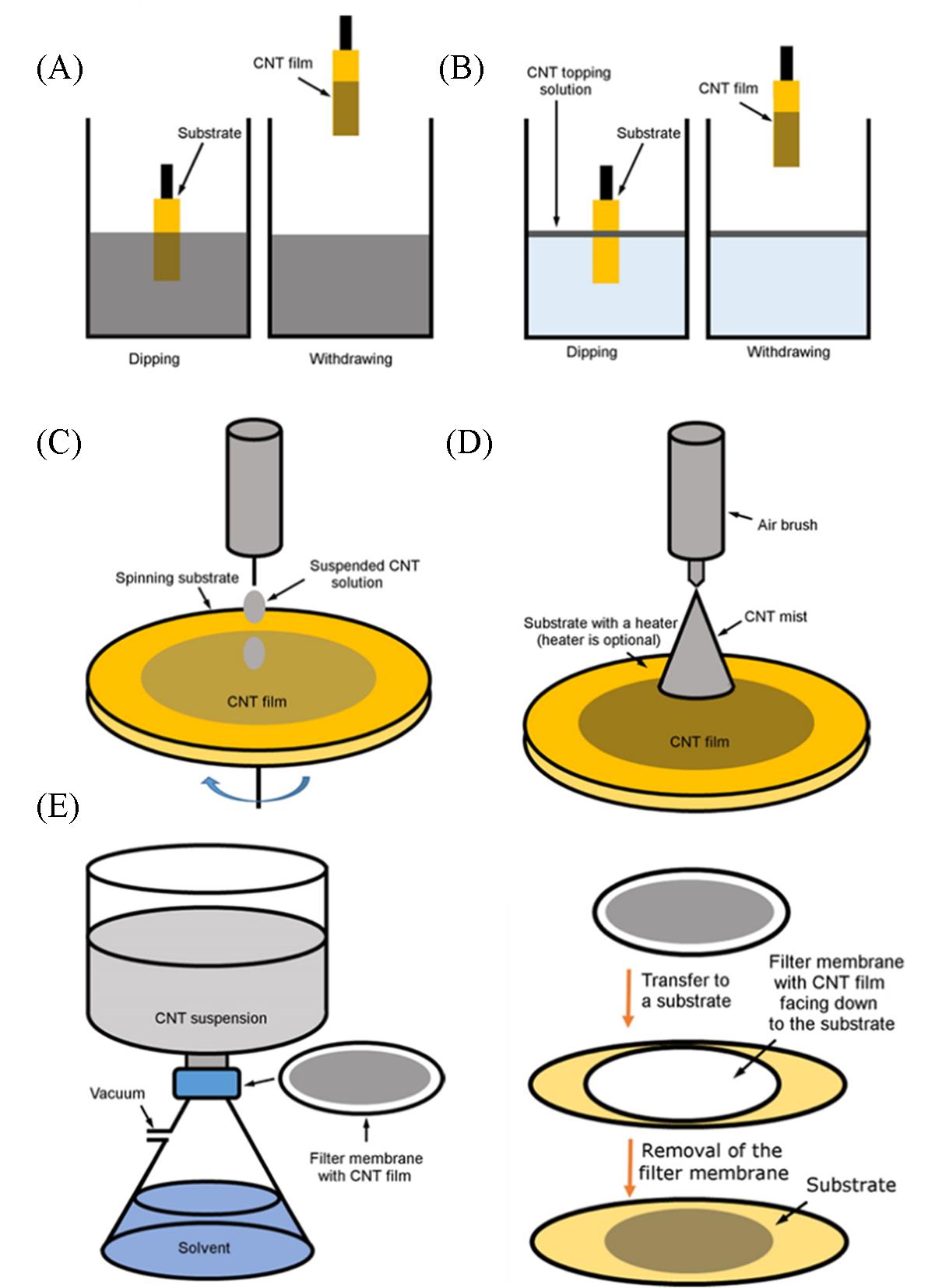

Fig.3 Schematic diagram of preparing carbon nanotube films by solution method[8](A) Dipping method; (B) LB method; (C) spin coating method; (D) spraying method;(E) vacuum filtration method. Copyright 2016, American Chemical Society.

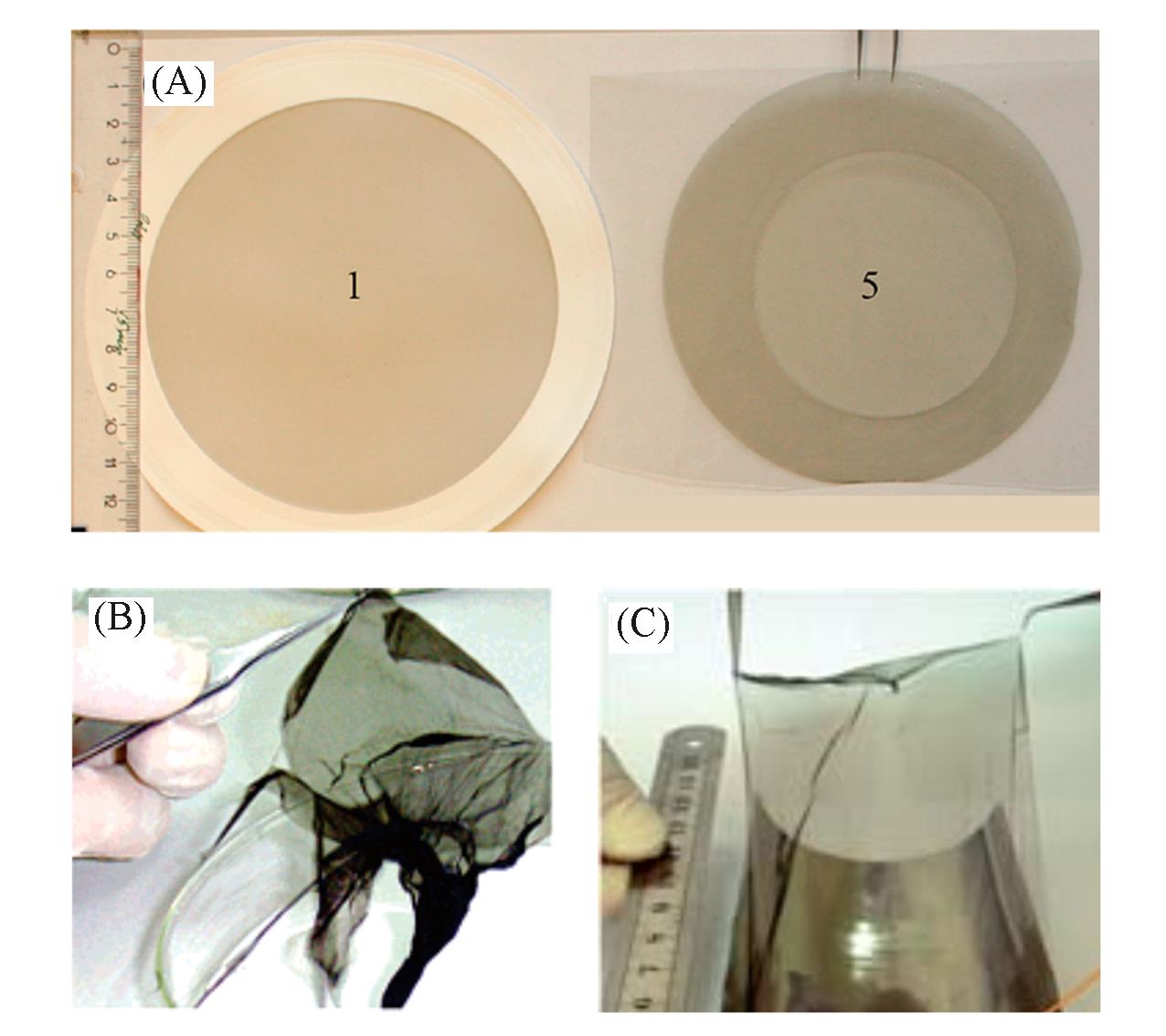

Fig.4 Carbon nanotube films prepared by FCCVD with different carbon sources(A) CO[53]. The left side of (A) is a nitrocellulose filter paper, and the right side is a polyethylene terephthalate film with holes. Copyright 2011, American Chemical Society. (B) Methane[50]. Copyright 2007, American Chemical Society. (C) Xylene[48]. Copyright 2010, the Royal Society of Chemistry.

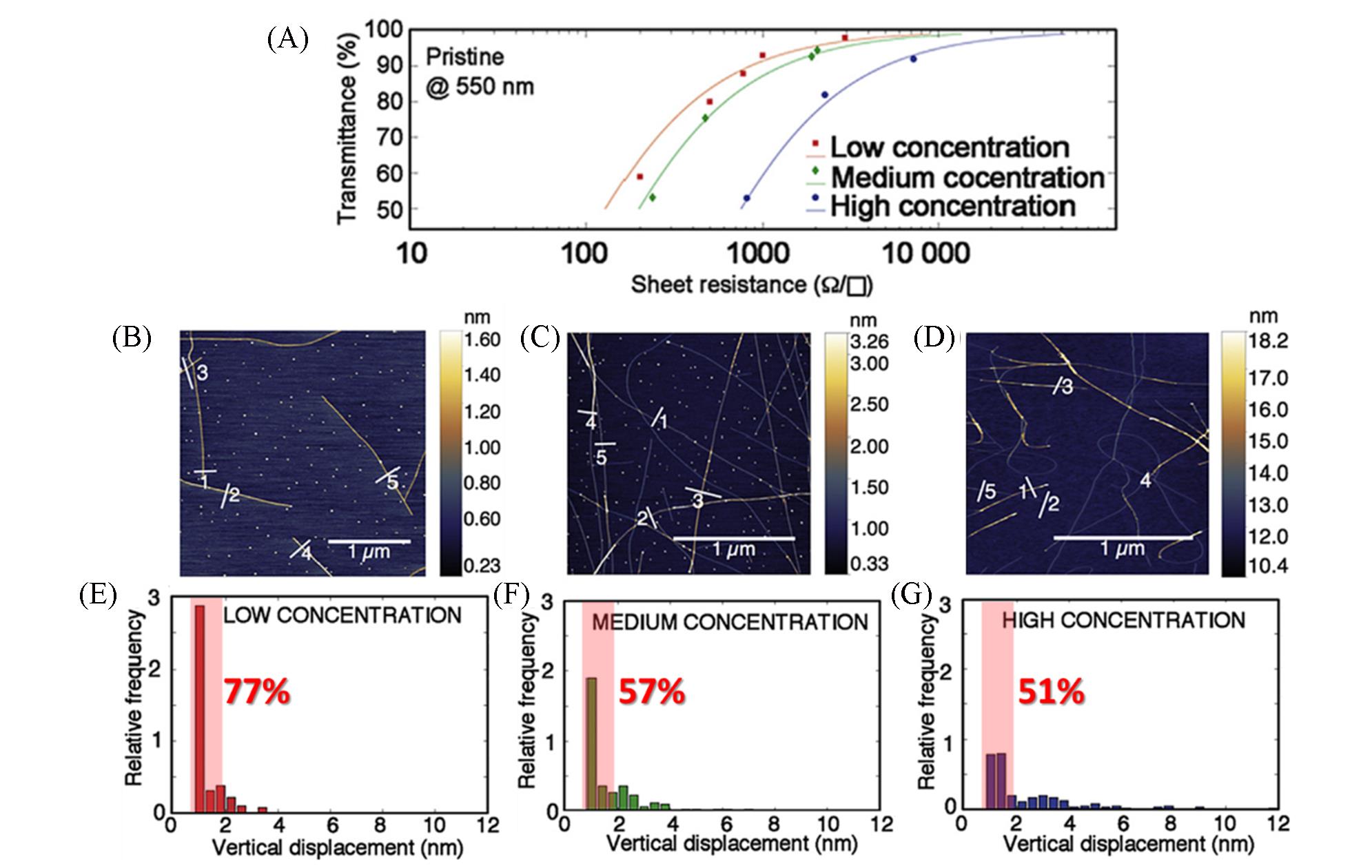

Fig.5 Effect of catalyst concentrations on carbon nanotube films[58](A) Transparent and conductive properties of carbon nanotube films grown with different catalyst concentrations; (B)—(D) AFM height maps of carbon nanotube films deposited with three catalyst concentrations; (E)—(G) corresponding statistical results of the height information of carbon nanotubes or tube bundles. The columns located in the red area represents individual carbon nanotubes, for the height of those nanotubes are below 1.8 nm. Copyright 2016, Elsevier Ltd.

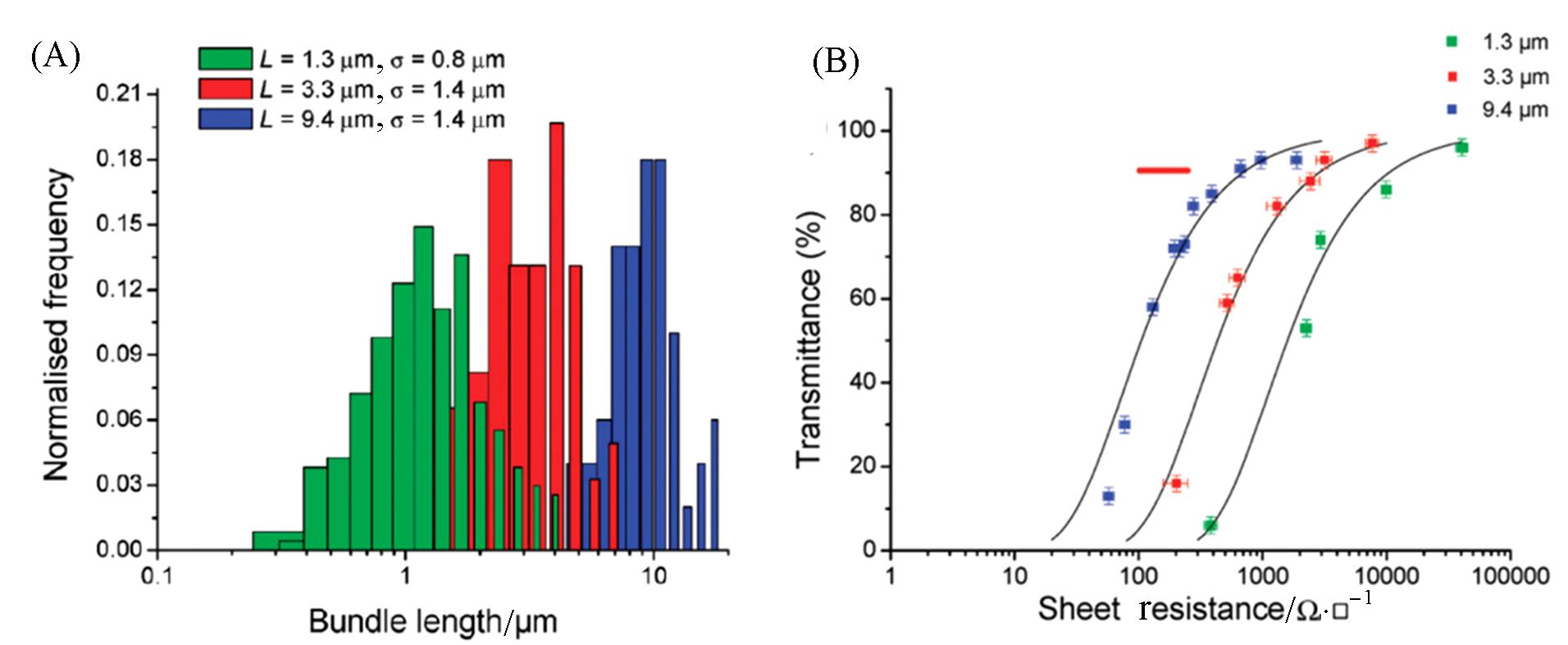

Fig.6 Effect of carbon nanotube bundle length on film properties[59](A) Statistics of the length of tube bundles in carbon nanotube films grown with different conditions; (B) corresponding film properties. Copyright 2010, American Chemical Society.

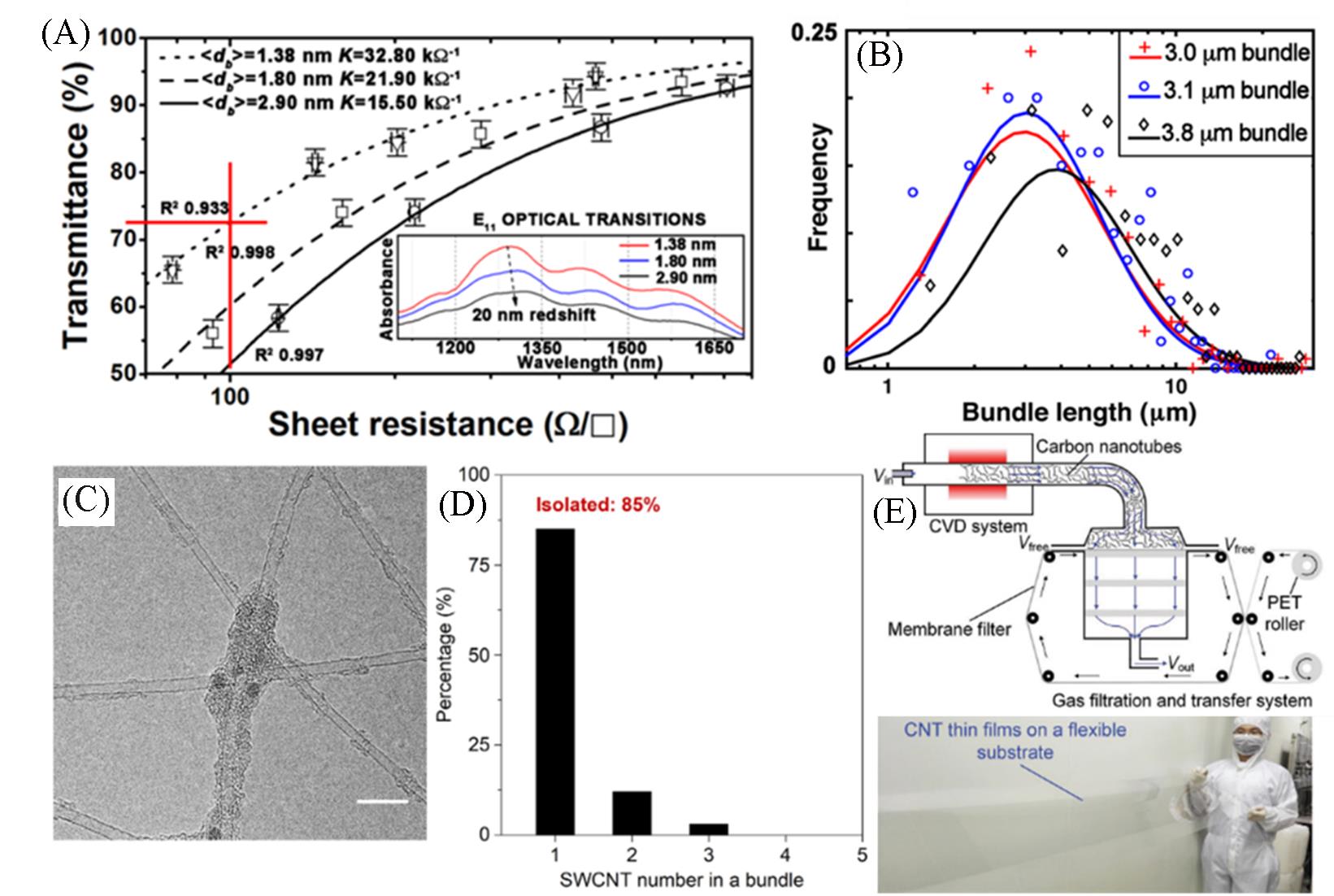

Fig.7 Effect of carbon nanotube aggregation degree on film properties(A) The transparent and conductive properties of the films with different carbon nanotube aggregation conditions; the inset is the absorption spectrum of the S11 region of the corresponding films; (B) corresponding to the length distribution of the carbon nanotube bundles in the three films[61]. Copyright 2015, American Institute of Physics. (C) Typical TEM image of carbon-welded isolated SWCNTs; (D) statistical data of the numbers of isolated and bundled SWCNTs in the network[62]. Copyright 2018, American Association for the Advancement of Science. (E) Continuous fabrication of meter-scale SWCNT films[63]. The upper part of the figure is a schematic showing the apparatus designed for the synthesis, deposition, and transfer of SWCNT films. Below that is a SWCNT thin film transferred on a flexible PET substrate with a length of more than 2 m. Copyright 2018, John Wiley & Sons Inc.

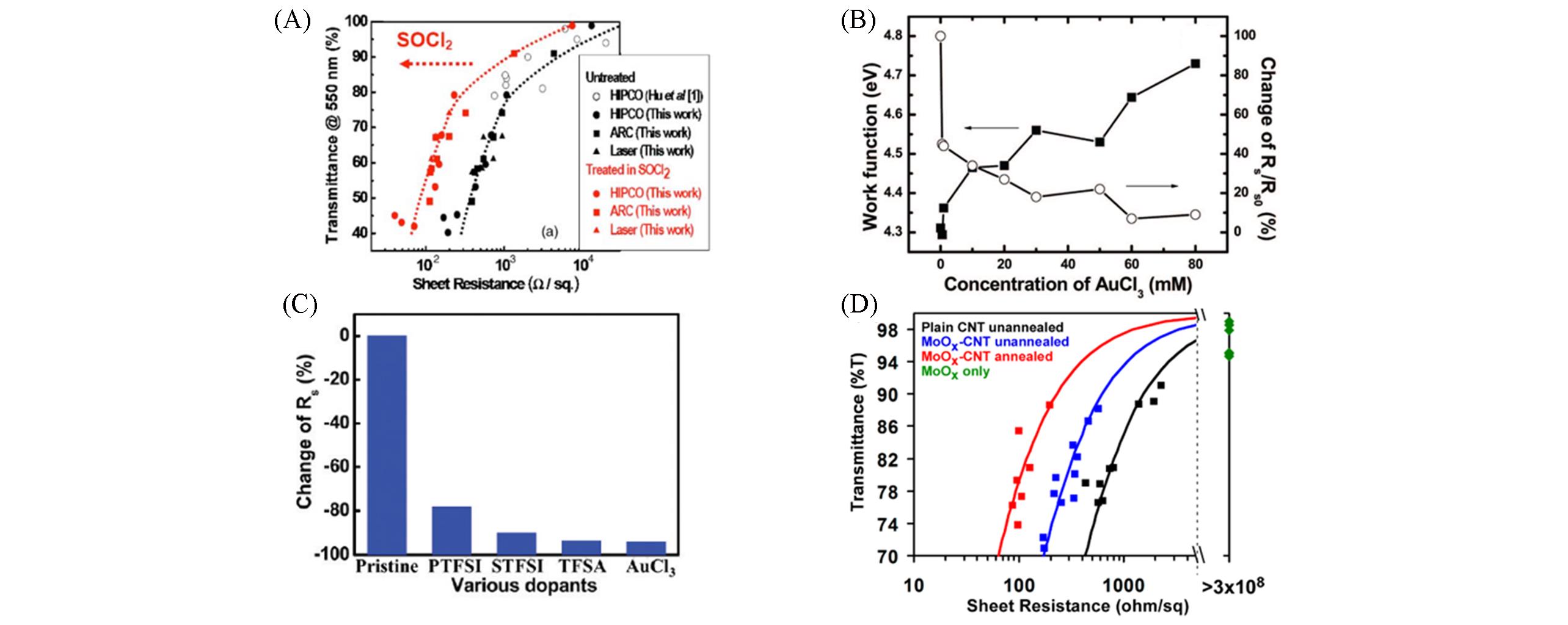

Fig.8 Effect of dopants on the properties of carbon nanotube films(A) The relationship between light transmittance and square resistance of carbon nanotube films before and after SOCl2 doping[68]. Copyright 2007, American Institute of Physics. (B) Effect of AuCl3 solution of different concentrations on the square resistance of carbon nanotube films[69]. Copyright 2008, American Chemical Society. (C) The change of resistance after the films doped with AuCl3 and three organic molecules with TFSI functional groups[76]. Copyright 2010, American Chemical Society. (D) Effect of MoO3 doping on the transparent conductivity of carbon nanotube films[72]. Copyright 2012, American Chemical Society.

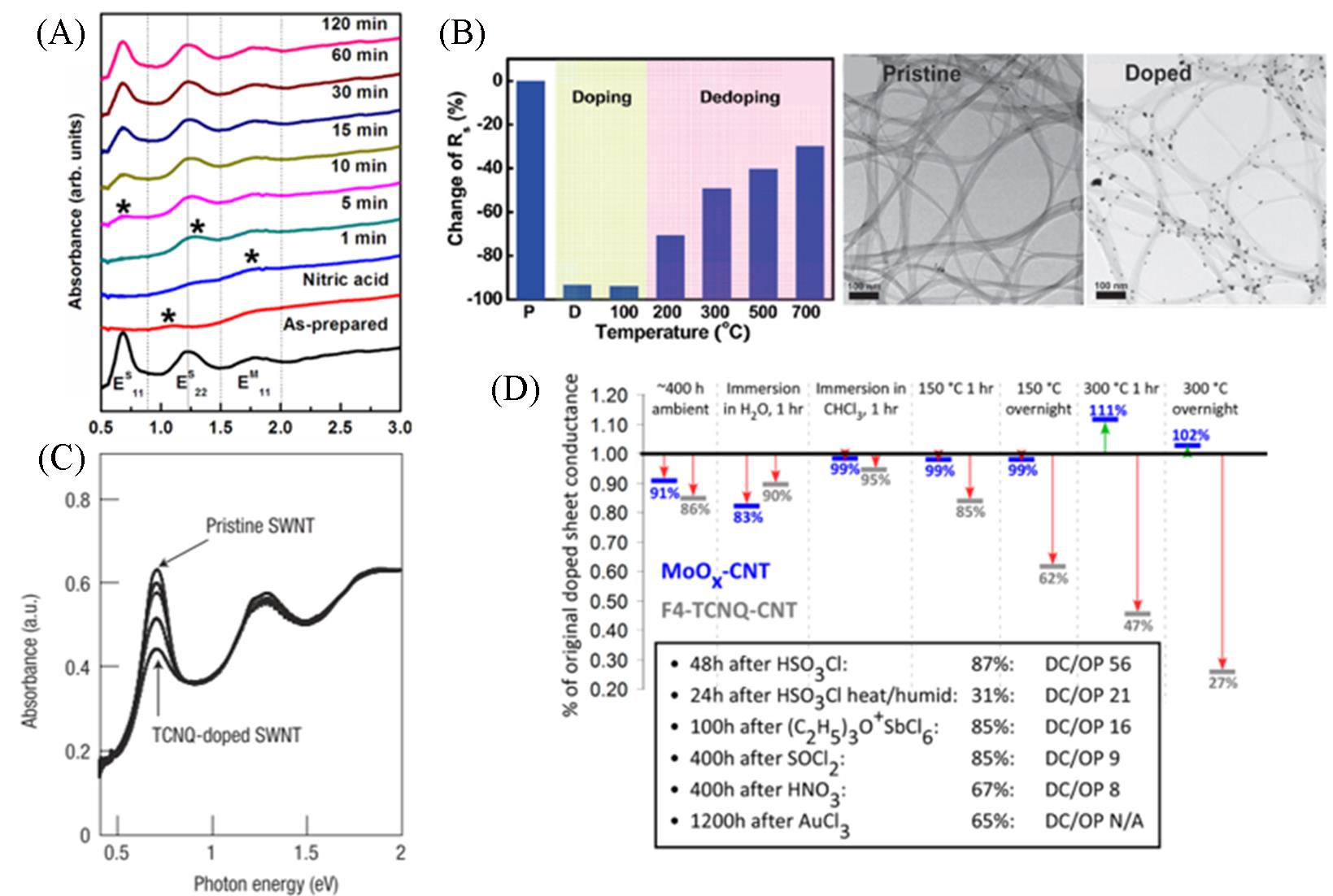

Fig.9 Limitations of existing dopants(A) The ultraviolet-visible-near-infrared absorption spectrum of carbon nanotube films doped by HNO3 with the increase of drying time[66]. Copyright 2009, IOP Publishing. (B) The picture on the left shows the change of the square resistance of AuCl3 doped carbon nanotube films annealed at different temperatures in Ar for 1 h. The two pictures on the right are TEM pictures of carbon nanotube films before and after doping[70]. Copyright 2011, American Chemical Society. (C) The absorption spectrum of the TCNQ doped carbon nanotube films after vacuum heating. The curves from bottom to top are: TCNQ doped carbon nanotube film, 200 ℃ heating, 250 ℃ heating, 300 ℃ heating and original absorption spectrum of carbon nanotube film[74]. Copyright 2003, Springer Nature. (D) Performance changes of carbon nanotube films doped with MoO3 and F4-TCNQ under different conditions. The inset shows the doping results of other dopants[72]. Copyright 2012, American Chemical Society.

| 1 | Hu L., Hecht D. S., Grüner G., Chem. Rev., 2010, 110(10), 5790—5844 |

| 2 | Cao Z., Wei B. B., Energy Environ. Sci., 2013, 6(11), 3183—3201 |

| 3 | Zhang Z., Wei L., Qin X., Li Y., Nano Energy, 2015, 15, 490—522 |

| 4 | Hirotani J., Ohno Y., Top. Curr. Chem., 2019, 377(1), 3 |

| 5 | Jeon I., Xiang R., Shawky A., Matsuo Y., Maruyama S., Adv. Energy Mater., 2019, 9(23), 1801312 |

| 6 | Hecht D. S., Hu L., Irvin G., Adv. Mater., 2011, 23(13), 1482—1513 |

| 7 | Du J., Pei S., Ma L., Cheng H. M., Adv. Mater., 2014, 26(13), 1958—1991 |

| 8 | Yu L., Shearer C., Shapter J., Chem. Rev., 2016, 116(22), 13413—13453 |

| 9 | Zhang Q., Wei N., Laiho P., Kauppinen E. I., Top. Curr. Chem., 2017, 375(6), 90 |

| 10 | Jiang S., Hou P. X., Liu C., Cheng H. M., J. Mater. Sci. Technol., 2019, 35(11), 2447—2462 |

| 11 | Güneş F., Shin H. J., Biswas C., Han G. H., Kim E. S., Chae S. J., Choi J. Y., Lee Y. H., ACS Nano, 2010, 4(8), 4595 |

| 12 | Cairns D. R., Witte R. P., Sparacin D. K., Sachsman S. M., Paine D. C., Crawford G. P., Newton R., Appl. Phys. Lett., 2000, 76(11), 1425—1427 |

| 13 | Green M. A., Prog. Photovolt: Res. Appl., 2009, 17(5), 347—359 |

| 14 | Jeon I., Yoon J., Ahn N., Atwa M., Delacou C., Anisimov A., Kauppinen E. I., Choi M., Maruyama S., Matsuo Y., J. Phys. Chem. Lett., 2017, 8(21), 5395—5401 |

| 15 | Cheng H. M., Li F., Su G., Pan H. Y., He L. L., Sun X., Dresselhaus M. S., Appl. Phys. Lett., 1998, 72(25), 3282—3284 |

| 16 | Nasibulin A. G., Kaskela A., Mustonen K., Anisimov A. S., Ruiz V., Kivisto S., Rackauskas S., Timmermans M. Y., Pudas M., Aitchison B., Kauppinen M., Brown D. P., Okhotnikov O. G., Kauppinen E. I., ACS Nano, 2011, 5(4), 3214—3221 |

| 17 | Moisala A., Nasibulin A. G., Brown D. P., Jiang H., Khriachtchev L., Kauppinen E. I., Chem. Eng. Sci., 2006, 61(13), 4393—4402 |

| 18 | Li Z., Kandel H. R., Dervishi E., Saini V., Biris A. S., Biris A. R., Lupu D., Appl. Phys. Lett., 2007, 91(5), 053115 |

| 19 | Bahr J. L., Mickelson E. T., Bronikowski M. J., Smalley R. E., Tour J. M., Chem. Commun., 2001, (2), 193—194 |

| 20 | Song Y. I., Yang C. M., Kim D. Y., Kanoh H., Kaneko K., J. Colloid Interface Sci., 2008, 318(2), 365—371 |

| 21 | Park C., Ounaies Z., Watson K. A., Crooks R. E., Smith J., Lowther S. E., Connell J. W., Siochi E. J., Harrison J. S., Clair T. L. S., Chem. Phys. Lett., 2002, 364(3), 303—308 |

| 22 | Mistry K. S., Larsen B. A., Blackburn J. L., ACS Nano, 2013, 7(3), 2231—2239 |

| 23 | Hecht D. S., Ramirez R. J. A., Briman M., Artukovic E., Chichak K. S., Stoddart J. F., Grüner G., Nano Lett., 2006, 6(9), 2031—2036 |

| 24 | Tardani F., Sennato S., J. Phys. Chem. C, 2014, 118(17), 9268—9274 |

| 25 | Wang H., Li S., Si Y., Sun Z., Li S., Lin Y., J. Mater. Chem. B, 2014, 2(28), 4442—4448 |

| 26 | Wang H., Li S., Si Y., Zhang N., Sun Z., Wu H., Lin Y., Nanoscale, 2014, 6(14), 8107—8116 |

| 27 | Khripin C. Y., Tu X., Heddleston J. M., Silvera⁃Batista C., Hight Walker A. R., Fagan J., Zheng M., Anal. Chem., 2013, 85(3), 1382—1388 |

| 28 | Wang J., Sun J., Gao L., Wang Y., Zhang J., Kajiura H., Li Y., Noda K., J. Phys. Chem. C, 2009, 113(41), 17685—17690 |

| 29 | Li X., Li Q., Chen G. X., Mater. Lett., 2014, 134, 38—41 |

| 30 | Jamnani B. D., Hosseini S., Rahmanian S., Rashid S. A., Mustapha S. A. B., Balavandy S. K., J. Nanomater., 2015, 2015, 149736 |

| 31 | Kim Y., Minami N., Zhu W., Kazaoui S., Azumi R., Matsumoto M., Jpn. J. Appl. Phys., 2003, 42(2), 7629—7634 |

| 32 | Pichumani M., Bagheri P., Poduska K. M., Gonzalez⁃Vinas W., Yethiraj A., Soft Matter, 2013, 9(12), 3220—3229 |

| 33 | Toolan D. T. W., Hodgkinson R., Howse J. R., J. Polym. Sci., Part B: Polym. Phys., 2014, 52(1), 17—25 |

| 34 | Tuukkanen S., Välimäki M., Lehtimäki S., Vuorinen T., Lupo D., Sci. Rep., 2016, 6(1), 22967 |

| 35 | King B., Panchapakesan B., Nanotech., 2014, 25(17), 175201 |

| 36 | White C. T., Todorov T. N., Nature, 1998, 393(6682), 240—242 |

| 37 | Purewal M. S., Hong B. H., Ravi A., Chandra B., Hone J., Kim P., Phys. Rev. Lett., 2007, 98(18), 186808 |

| 38 | Fuhrer M., Nygård J., Shih L., Forero M., Yoon Y. G., Choi H. J., Ihm J., Louie S. G., Zettl A., McEuen P. L., Science, 2000, 288(5465), 494—497 |

| 39 | Znidarsic A., Kaskela A., Laiho P., Gaberscek M., Ohno Y., Nasibulin A. G., Kauppinen E. I., Hassanien A., J. Phys. Chem. C, 2013, 117(25), 13324—13330 |

| 40 | Han J. H., Strano M. S., Mater. Res. Bull., 2014, 58, 1—5 |

| 41 | Anoshkin I. V., Nasibulin A. G., Tian Y., Liu B., Jiang H., Kauppinen E. I., Carbon, 2014, 78, 130—136 |

| 42 | Cheng H. M., Li F., Sun X., Brown S. D. M., Pimenta M. A., Marucci A., Dresselhaus G., Dresselhaus M. S., Chem. Phys. Lett., 1998, 289(5), 602—610 |

| 43 | Reynaud O., Nasibulin A. G., Anisimov A. S., Anoshkin I. V., Jiang H., Kauppinen E. I., Chem. Eng. J., 2014, 255, 134—140 |

| 44 | Wei J., Jiang B., Wu D., Wei B., J. Phys. Chem. B, 2004, 108(26), 8844—8847 |

| 45 | Wei J., Zhu H., Li Y., Chen B., Jia Y., Wang K., Wang Z., Liu W., Luo J., Zheng M., Wu D., Zhu Y., Wei B., Adv. Mater., 2006, 18(13), 1695—1700 |

| 46 | Wei J., Jia Y., Shu Q., Gu Z., Wang K., Zhuang D., Zhang G., Wang Z., Luo J., Cao A., Wu D., Nano Lett., 2007, 7(8), 2317—2321 |

| 47 | Jia Y., Wei J., Wang K., Cao A., Shu Q., Gui X., Zhu Y., Zhuang D., Zhang G., Ma B., Adv. Mater., 2008, 20(23), 4594—4598 |

| 48 | Li Z., Jia Y., Wei J., Wang K., Shu Q., Gui X., Zhu H., Cao A., Wu D., J. Mater. Chem., 2010, 20(34), 7236—7240 |

| 49 | Wei N., Laiho P., Khan A. T., Hussain A., Lyuleeva A., Ahmed S., Zhang Q., Liao Y., Tian Y., Ding E. X., Ohno Y., Kauppinen E. I., Adv. Funct. Mater., 2019, 30(5), 1907150 |

| 50 | Zhang Z., Liang X., Wang S., Yao K., Hu Y., Zhu Y., Chen Q., Zhou W., Li Y., Yao Y., Zhang J., Peng L. M., Nano Lett., 2007, 7(12), 3603—3607 |

| 51 | Hou P. X., Yu B., Su Y., Shi C., Zhang L. L., Liu C., Li S., Du J. H., Cheng H. M., J. Mater. Chem. A, 2014, 2(4), 1159—1164 |

| 52 | Hussain A., Liao Y., Zhang Q., Ding E. X., Laiho P., Ahmad S., Wei N., Tian Y., Jiang H., Kauppinen E. I., Nanoscale, 2018, 10(20), 9752—9759 |

| 53 | Tian Y., Timmermans M. Y., Partanen M., Nasibulin A. G., Jiang H., Zhu Z., Kauppinen E. I., Carbon, 2011, 49(14), 4636—4643 |

| 54 | Maruyama S., Kojima R., Miyauchi Y., Chiashi S., Kohno M., Chem. Phys. Lett., 2002, 360(3), 229—234 |

| 55 | Murakami Y., Miyauchi Y., Chiashi S., Maruyama S., Chem. Phys. Lett., 2003, 374(1), 53—58 |

| 56 | Ding E., Jiang H., Zhang Q., Tian Y., Laiho P., Hussain A., Liao Y., Wei N., Kauppinen E., Nanoscale, 2017, 9(44), 17601—17609 |

| 57 | Ding E. X., Zhang Q., Wei N., Khan A. T., Kauppinen E. I., R. Soc. Open Sci., 2018, 5(6), 180392 |

| 58 | Kaskela A., Laiho P., Fukaya N., Mustonen K., Susi T., Jiang H., Houbenov N., Ohno Y., Kauppinen E. I., Carbon, 2016, 103, 228—234 |

| 59 | Kaskela A., Nasibulin A. G., Timmermans M. Y., Aitchison B., Papadimitratos A., Tian Y., Zhu Z., Jiang H., Brown D. P., Zakhidov A., Kauppinen E. I., Nano Lett., 2010, 10(11), 4349—4355 |

| 60 | Reynaud O., Nasibulin A. G., Anisimov A. S., Anoshkin I. V., Jiang H., Kauppinen E. I., Chem. Eng. J., 2014, 255, 134—140 |

| 61 | Mustonen K., Laiho P., Kaskela A., Susi T., Nasibulin A. G., Kauppinen E. I., Appl. Phys. Lett., 2015, 107(14), 143113 |

| 62 | Jiang S., Hou P. X., Chen M. L., Wang B. W., Sun D. M., Tang D. M., Jin Q., Guo Q. X., Zhang D. D., Du J. H., Tai K. P., Tan J., Kauppinen E. I., Liu C., Cheng H. M., Sci. Adv., 2018, 4(5), 9264 |

| 63 | Wang B. W., Jiang S., Zhu Q. B., Sun Y., Luan J., Hou P. X., Qiu S., Li Q. W., Liu C., Sun D. M., Cheng H. M., Adv. Mater., 2018, 30(32), 1802057 |

| 64 | Nasibulin A. G., Brown D. P., Queipo P., Gonzalez D., Jiang H., Kauppinen E. I., Chem. Phys. Lett., 2006, 417(1), 179—184 |

| 65 | Tenent R. C., Barnes T. M., Bergeson J. D., Ferguson A. J., To B., Gedvilas L. M., Heben M. J., Blackburn J. L., Adv. Mater., 2009, 21(31), 3210—3216 |

| 66 | Shin D. W., Lee J. H., Kim Y. H., Yu S. M., Park S. Y., Yoo J. B., Nanotech., 2009, 20(47), 475703 |

| 67 | Dettlaff⁃Weglikowska U., Skákalová V., Graupner R., Jhang S. H., Kim B. H., Lee H. J., Ley L., Park Y. W., Berber S., Tománek D., Roth S., J. Am. Chem. Soc., 2005, 127(14), 5125—5131 |

| 68 | Parekh B. B., Fanchini G., Eda G., Chhowalla M., Appl. Phys. Lett., 2007, 90(12), 121913 |

| 69 | Kim K. K., Bae J. J., Park H. K., Kim S. M., Geng H. Z., Park K. A., Shin H. J., Yoon S. M., Benayad A., Choi J. Y., Lee Y. H., J. Am. Chem. Soc., 2008, 130(38), 12757—12761 |

| 70 | Kim S. M., Kim K. K., Jo Y. W., Park M. H., Chae S. J., Duong D. L., Yang C. W., Kong J., Lee Y. H., ACS Nano, 2011, 5(2), 1236—1242 |

| 71 | Yoon S. M., Kim U. J., Benayad A., Lee I. H., Son H., Shin H. J., Choi W. M., Lee Y. H., Jin Y. W., Lee E. H., Lee S. Y., Choi J. Y., Kim J. M., ACS Nano, 2011, 5(2), 1353—1359 |

| 72 | Hellstrom S. L., Vosgueritchian M., Stoltenberg R. M., Irfan I., Hammock M., Wang Y. B., Jia C., Guo X., Gao Y., Bao Z., Nano Lett., 2012, 12(7), 3574—3580 |

| 73 | Jeon I., Cui K., Chiba T., Anisimov A., Nasibulin A. G., Kauppinen E. I., Maruyama S., Matsuo Y., J. Am. Chem. Soc., 2015, 137(25), 7982—7985 |

| 74 | Takenobu T., Takano T., Shiraishi M., Murakami Y., Ata M., Kataura H., Achiba Y., Iwasa Y., Nat. Mater., 2003, 2(10), 683—688 |

| 75 | Chandra B., Afzali A., Khare N., El⁃Ashry M. M., Tulevski G. S., Chem. Mater., 2010, 22(18), 5179—5183 |

| 76 | Kim S. M., Jo Y. W., Kim K. K., Duong D. L., Shin H.⁃J., Han J. H., Choi J. Y., Kong J., Lee Y. H., ACS Nano, 2010, 4(11), 6998—7004 |

| 77 | Puchades I., Lawlor C. C., Schauerman C. M., Bucossi A. R., Rossi J. E., Cox N. D., Landi B. J., J. Mater. Chem. C, 2015, 3(39), 10256—10266 |

| [1] | ZHAO Runyao, JI Guipeng, LIU Zhimin. Efficient Electrocatalytic CO2 Reduction over Pyrrole Nitrogen-coordinated Single-atom Copper Catalysts [J]. Chem. J. Chinese Universities, 2022, 43(7): 20220272. |

| [2] | GAO Jing, HE Wentao, WANG Xinxin, XIANG Yushu, LONG Lijuan, QIN Shuhao. Preparation of DOPO Derivative Modified Carbon Nanotubes and Their Effect on Flame Retardancy of Polylactic Acid [J]. Chem. J. Chinese Universities, 2022, 43(3): 20210670. |

| [3] | LIU Jie, LI Jinsheng, BAI Jingsen, JIN Zhao, GE Junjie, LIU Changpeng, XING Wei. Constructing a Water-blocking Interlayer Containing Sulfonated Carbon Tubes to Reduce Concentration Polarization in Direct Methanol Fuel Cells [J]. Chem. J. Chinese Universities, 2022, 43(11): 20220420. |

| [4] | DING Qin, ZHANG Zixuan, XU Peicheng, LI Xiaoyu, DUAN Limei, WANG Yin, LIU Jinghai. Effects of Cu, Ni and Co Hetroatoms on Constructions and Electrocatalytic Properties of Fe-based Carbon Nanotubes [J]. Chem. J. Chinese Universities, 2022, 43(11): 20220421. |

| [5] | HOU Congcong, WANG Huiying, LI Tingting, ZHANG Zhiming, CHANG Chunrui, AN Libao. Preparation and Electrochemical Properties of N-CNTs/NiCo-LDH Composite [J]. Chem. J. Chinese Universities, 2022, 43(10): 20220351. |

| [6] | XU Xiaojian, LI Bo, LIN Mengxiao, ZHAN Shuo. Vacuum Freeze Drying to Prepare Porous Carbon Based Composite Membranes for Efficient Solar Steam Generation [J]. Chem. J. Chinese Universities, 2022, 43(10): 20220361. |

| [7] | MO Zongwen, ZHANG Xuewen, ZHOU Haolong, ZHOU Dongdong, ZHANG Jiepeng. Guest-responses of A Porous Coordination Polymer Based on Synergistic Hydrogen Bonds [J]. Chem. J. Chinese Universities, 2022, 43(1): 20210576. |

| [8] | CHU Mingyue, LI Fengbo, GAO Ning, YANG Xin, YU Tingting, MA Huiyuan, YANG Guixin, PANG Haijun. Construction of a Coronal Polyoxometalate-based Composite Film for Determination of Nitrite [J]. Chem. J. Chinese Universities, 2022, 43(1): 20210579. |

| [9] | ZHAO Lingyun, HUANG Hanxiong, LUO Duyu, SU Fengchun. Effect of Flexibility of Composites on Performances of Sensors with Micro-structured Inverted Pyramid Arrays [J]. Chem. J. Chinese Universities, 2021, 42(9): 2953. |

| [10] | WU Tonghua, YUE Xigui, MEI Xiaohan, LIANG Liubo, PENG Xin, MA Youmei, ZHANG Shuling. Preparation of MWCNTs/PEEK Electromagnetic Shielding Composites with Sandwich Structure [J]. Chem. J. Chinese Universities, 2021, 42(8): 2627. |

| [11] | XIE Fan, CHEN Shanshan, ZHUO Longhai, LU Zhaoqing, GAO Kun, DAI Qiyang. Fabrication of Poly(p-xylene) Nanofiber Arrays by CVD Liquid Crystal Template Method and Their Degradability [J]. Chem. J. Chinese Universities, 2021, 42(8): 2643. |

| [12] | LIANG Pingping, LIU Shuai, LI Hongyi, DING Yadan, WEN Xiaokun, LIU Junping, HONG Xia. Self-floating Porous PVDF-CNT Microbeads for Highly Efficient Solar-driven Interfacial Water Evaporation [J]. Chem. J. Chinese Universities, 2021, 42(8): 2689. |

| [13] | XU Mengyi, HUANG Xuewen, LI Xiaojie, WEI Wei, LIU Xiaoya. Fabrication of Biosensor Based on “Beads-on-a-String” Shaped Composite Nano-assembly Modified Screen Printed Electrode [J]. Chem. J. Chinese Universities, 2021, 42(6): 1768. |

| [14] | YANG Pengfei, SHI Yuping, ZHANG Yanfeng. Large-scale Syntheses and Versatile Applications of Two-dimensional Metal Dichalcogenides [J]. Chem. J. Chinese Universities, 2021, 42(2): 504. |

| [15] | LI Fei, LI Xiaoxuan, LI Yijun, HE Xiwen, CHEN Langxing, ZHANG Yukui. Preparation of Surface Oriented Magnetically Imprinted Polymers and the Selective Recognition of Quercetin [J]. Chem. J. Chinese Universities, 2021, 42(12): 3606. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||