Chem. J. Chinese Universities ›› 2019, Vol. 40 ›› Issue (11): 2388.doi: 10.7503/cjcu20190378

• Polymer Chemistry • Previous Articles Next Articles

CAI Lei1,ZHAO Yuanjin1,ZHANG Xingping1,HE Aihua1,*( ),DING Tao2,LI Xiaohong2,ZHANG Zhijun2

),DING Tao2,LI Xiaohong2,ZHANG Zhijun2

Received:2019-07-07

Online:2019-11-10

Published:2019-10-24

Contact:

HE Aihua

E-mail:aihuahe@iccas.ac.cn

Supported by:CLC Number:

TrendMD:

CAI Lei,ZHAO Yuanjin,ZHANG Xingping,HE Aihua,DING Tao,LI Xiaohong,ZHANG Zhijun. Structure and Properties of SSBR/BR/Surface-modified SiO2 Green Tire Tread Stock †[J]. Chem. J. Chinese Universities, 2019, 40(11): 2388.

| SiO2Brand | 1165MP | HB 2105N | HB 2205N | HB 2200D |

|---|---|---|---|---|

| Functional group in the modifier | None | Amino | Amino | Double bond |

| Contents of modifier/(mmol·kg-1) | 0 | 90 | 140 | 260 |

| Apparent density/(g·mL-1) | 0.88 | 0.28 | 0.13 | 0.16 |

| Mass loss at 950 ℃(%) | 4.50 | 7.52 | 8.17 | 5.61 |

| Oil absorption/(mL·100 g-1) | 160 | 168 | 196 | 207 |

| Specific surface area(BET)/(m2·g-1) | 155 | 151 | 125 | 121 |

| SiO2Brand | 1165MP | HB 2105N | HB 2205N | HB 2200D |

|---|---|---|---|---|

| Functional group in the modifier | None | Amino | Amino | Double bond |

| Contents of modifier/(mmol·kg-1) | 0 | 90 | 140 | 260 |

| Apparent density/(g·mL-1) | 0.88 | 0.28 | 0.13 | 0.16 |

| Mass loss at 950 ℃(%) | 4.50 | 7.52 | 8.17 | 5.61 |

| Oil absorption/(mL·100 g-1) | 160 | 168 | 196 | 207 |

| Specific surface area(BET)/(m2·g-1) | 155 | 151 | 125 | 121 |

| System | S/B-1165MP | S/B-HB 2105N | S/B-HB 2205N | S/B-HB 2200D |

|---|---|---|---|---|

| Mooney viscosity | 72 | 79 | 74 | 80 |

| Boundrubber(%) | 16 | 23 | 20 | 22 |

| Green strength/MPa | 0.41 | 0.40 | 0.39 | 0.41 |

| Modulus at 100%/MPa | 0.40 | 0.39 | 0.36 | 0.41 |

| Modulus at 300%/MPa | 0.36 | 0.37 | 0.35 | 0.32 |

| Elongation at break(%) | 935 | 1119 | 662 | 695 |

| Shore A hardness/(°) | 32 | 32 | 33 | 31 |

| System | S/B-1165MP | S/B-HB 2105N | S/B-HB 2205N | S/B-HB 2200D |

|---|---|---|---|---|

| Mooney viscosity | 72 | 79 | 74 | 80 |

| Boundrubber(%) | 16 | 23 | 20 | 22 |

| Green strength/MPa | 0.41 | 0.40 | 0.39 | 0.41 |

| Modulus at 100%/MPa | 0.40 | 0.39 | 0.36 | 0.41 |

| Modulus at 300%/MPa | 0.36 | 0.37 | 0.35 | 0.32 |

| Elongation at break(%) | 935 | 1119 | 662 | 695 |

| Shore A hardness/(°) | 32 | 32 | 33 | 31 |

| System | S/B-1165MP | S/B-HB 2105N | S/B-HB 2205N | S/B-HB 2200D |

|---|---|---|---|---|

| ML/(dN·m) | 2.53 | 2.96 | 2.83 | 3.10 |

| MH/(dN·m) | 20.2 | 24.7 | 23.7 | 24.4 |

| MH-ML/(dN·m) | 17.7 | 21.8 | 20.8 | 21.3 |

| tc10/min | 6.24 | 2.40 | 2.48 | 2.40 |

| tc90/min | 28.9 | 18.9 | 18.1 | 17.4 |

| Swelling ratio, Q | 1.75 | 1.45 | 1.52 | 1.45 |

| System | S/B-1165MP | S/B-HB 2105N | S/B-HB 2205N | S/B-HB 2200D |

|---|---|---|---|---|

| ML/(dN·m) | 2.53 | 2.96 | 2.83 | 3.10 |

| MH/(dN·m) | 20.2 | 24.7 | 23.7 | 24.4 |

| MH-ML/(dN·m) | 17.7 | 21.8 | 20.8 | 21.3 |

| tc10/min | 6.24 | 2.40 | 2.48 | 2.40 |

| tc90/min | 28.9 | 18.9 | 18.1 | 17.4 |

| Swelling ratio, Q | 1.75 | 1.45 | 1.52 | 1.45 |

| System | S/B-1165MP | S/B-HB 2105N | S/B-HB 2205N | S/B-HB 2200D |

|---|---|---|---|---|

| Dispersion(%) | 99.3 | 99.7 | 99.8 | 99.7 |

| White area(%) | 1.0 | 0.1 | 0.1 | 0.2 |

| System | S/B-1165MP | S/B-HB 2105N | S/B-HB 2205N | S/B-HB 2200D |

|---|---|---|---|---|

| Dispersion(%) | 99.3 | 99.7 | 99.8 | 99.7 |

| White area(%) | 1.0 | 0.1 | 0.1 | 0.2 |

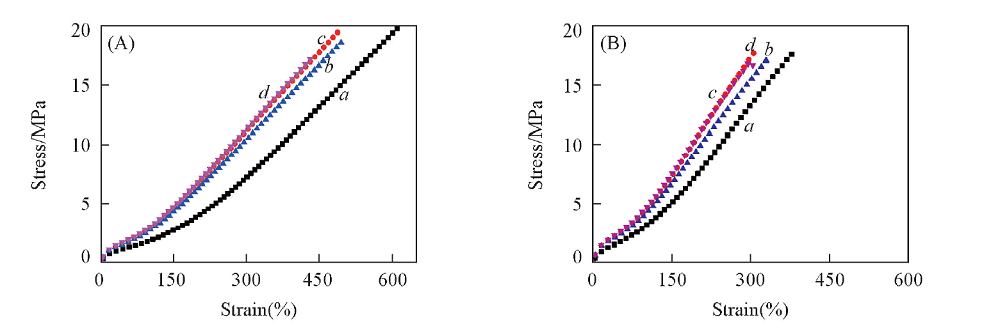

Fig.3 Stress-strain curves of SSBR/BR/SiO2 vulcanizates before(A) and after hot air ageing(100 ℃, 72 h)(B) a. S/B-1165MP; b. S/B-HB 2105N; c. S/B-HB 2205N; d. S/B-HB 2200D.

| System | S/B-1165MP | S/B-HB 2105N | S/B-HB 2205N | S/B-HB 2200D |

|---|---|---|---|---|

| Tensile strength/MPa | 19.9 | 19.5 | 17.7 | 17.6 |

| Modulus at 100%/MPa | 1.8 | 2.9 | 2.7 | 3.0 |

| Modulus at 300%/MPa | 7.2 | 11.2 | 10.7 | 11.3 |

| Elongation at break(%) | 613 | 487 | 460 | 438 |

| Shore A hardness/(°) | 63 | 72 | 70 | 72 |

| Tear strength/(kN·m-1) | 45.3 | 44.2 | 43.3 | 40.7 |

| DIN abrasion/(cm3·40 m-1) | 0.135 | 0.123 | 0.119 | 0.128 |

| Rebound(%) | 37.0 | 40.2 | 39.0 | 42.5 |

| Heat built-up/℃ | 31.5 | 29.4 | 27.8 | 29.0 |

| Compression set(%) | 5.00 | 5.19 | 4.93 | 5.69 |

| Tensile fatigue at 125% | 193×104 | >500×104 | >500×104 | >500×104 |

| tanδ at 60 ℃ | 0.142 | 0.130 | 0.123 | 0.131 |

| tanδ at 0 ℃ | 0.233 | 0.249 | 0.212 | 0.230 |

| Properties after hot air ageing(100 ℃, 72 h) | ||||

| Tensile strength/MPa | 18.0 | 18.1 | 17.1 | 17.4 |

| Modulus at 100%/MPa | 3.1 | 4.4 | 4.1 | 4.6 |

| Modulus at 300%/MPa | 13.3 | 17.4 | 15.5 | 17.1 |

| Elongation at break(%) | 386 | 311 | 330 | 304 |

| Swelling ratio, Q | 1.66 | 1.41 | 1.35 | 1.36 |

| Ageing coefficient(%) | 56.9 | 69.3 | 68.7 | 59.3 |

| System | S/B-1165MP | S/B-HB 2105N | S/B-HB 2205N | S/B-HB 2200D |

|---|---|---|---|---|

| Tensile strength/MPa | 19.9 | 19.5 | 17.7 | 17.6 |

| Modulus at 100%/MPa | 1.8 | 2.9 | 2.7 | 3.0 |

| Modulus at 300%/MPa | 7.2 | 11.2 | 10.7 | 11.3 |

| Elongation at break(%) | 613 | 487 | 460 | 438 |

| Shore A hardness/(°) | 63 | 72 | 70 | 72 |

| Tear strength/(kN·m-1) | 45.3 | 44.2 | 43.3 | 40.7 |

| DIN abrasion/(cm3·40 m-1) | 0.135 | 0.123 | 0.119 | 0.128 |

| Rebound(%) | 37.0 | 40.2 | 39.0 | 42.5 |

| Heat built-up/℃ | 31.5 | 29.4 | 27.8 | 29.0 |

| Compression set(%) | 5.00 | 5.19 | 4.93 | 5.69 |

| Tensile fatigue at 125% | 193×104 | >500×104 | >500×104 | >500×104 |

| tanδ at 60 ℃ | 0.142 | 0.130 | 0.123 | 0.131 |

| tanδ at 0 ℃ | 0.233 | 0.249 | 0.212 | 0.230 |

| Properties after hot air ageing(100 ℃, 72 h) | ||||

| Tensile strength/MPa | 18.0 | 18.1 | 17.1 | 17.4 |

| Modulus at 100%/MPa | 3.1 | 4.4 | 4.1 | 4.6 |

| Modulus at 300%/MPa | 13.3 | 17.4 | 15.5 | 17.1 |

| Elongation at break(%) | 386 | 311 | 330 | 304 |

| Swelling ratio, Q | 1.66 | 1.41 | 1.35 | 1.36 |

| Ageing coefficient(%) | 56.9 | 69.3 | 68.7 | 59.3 |

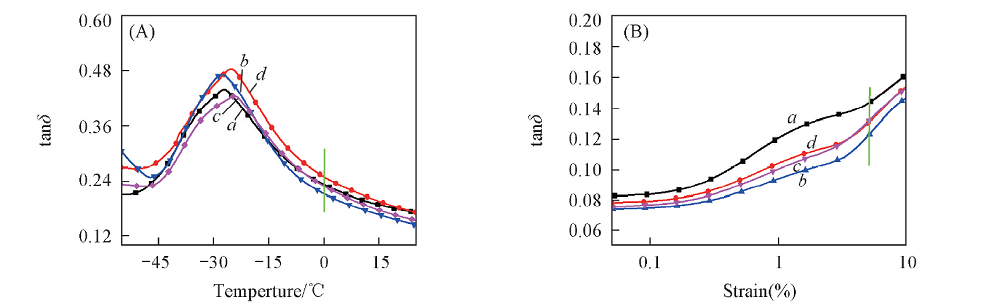

Fig.4 DMA curves of SSBR/BR vulcanizates filled with different SiO2 (A) tanδ versus temperature with a strain of 0.5%; (B) tanδ versus strain at 60 ℃. a. S/B-1165MP; b. S/B-HB 2105N; c. S/B-HB 2205N; d. S/B-HB 2200D.

| [1] | Panko J., Kreider M., Unice K., Non-Exhaust Emissions., 2018, 147— 160 |

| [2] | Schuring D. J ., Tire. Sci. Technol., 1994,22, 148— 161 |

| [3] | Georgios F., Samaras Z., Energ Policy., 2010,38, 1826— 1833 |

| [4] | Wang H., Song L. Y., Ma Y. S., Wang R. G., He A. H., Acta. Polym. Sin., 2018,3, 419— 428 |

| ( 王浩, 宋丽媛, 马韵升, 王日国, 贺爱华 . 高分子学报, 2018,3, 419— 428) | |

| [5] | Liu L., Zhang L. Q., Rubb. Ind., 1999,4, 245— 248 |

| ( 刘力, 张立群 . 橡胶工业, 1999,4, 245— 248) | |

| [6] | Ansarifara A., Azharb A., Ibrahima N., Shiaha S. F., Lawtonc J. M. D., Int. J. Adhes. Adhes., 2005,25(1), 77— 86 |

| [7] | Sombatsompop N., Thongsang S., Markpin T., Wimolmala E ., J. Appl. Polym. Sci., 2004,93(5), 2119— 2130 |

| [8] | Yang L. C., Ma H. W., Han L., Hao X. Y., Liu P. B., Shen H. Y., Li Y., Polym. Chem., 2017,9, 1— 15 |

| [9] | Rattanasom N., Saowapark T., Deeprasertkul C ., Polym. Test, 2007,26(3), 369— 377 |

| [10] | Liu X., Zhao S. H., J. Appl. Polym. Sci., 2008,109(6), 3900— 3907 |

| [11] | Shen M., Zhao F., Wang S. W., Zhao S. G., J. Macromol. Sci. Part B., 2013,52(2), 398— 406 |

| [12] | Wang Y. X., Wu Y. P., Li W. J., Zhang L. Q., Appl. Surf. Sci., 2011,257(6), 2058— 2065 |

| [13] | Ou Y. C., Yu Z. Z., Vidal A. Donnet J. B., J. Appl. Polym. Sci., 1996,59(8), 1321— 1328 |

| [14] | Yatsuyanagi F., Nozomu S., Masayoshi I., Hiroyuki K., Polym. J., 2002,34(5), 332— 339 |

| [15] | Wu Y. P., Dong J., Yuan R., Wan H. Q., Chen L., Li J. L., Zhou H. D., Chen J. M., Polym. Adv. Technol., 2018,29(10), 1— 9 |

| [16] | Wang H., Zhang X. P., Nie H. R., Wang R. G., He A. H., Compos. Part A: Appl. Sci. Manufac., 2019,116, 197— 205 |

| [17] | Yang L. C., Ma H. W., Han L., Hao X. Y., Liu P. B., Shen H. Y., Li Y., Polym. Chem., 2017,9, 1— 15 |

| [18] | Liu P. B., Ma H. W., Han L., Yang L.C., Shen H. Y., Li C., Li Y., Polymer, 2018,147, 153— 163 |

| [19] | Wang H., Zhang J. P., Ma Y. S., Wang R. G., He A. H., Chem. J. Chinese. Universities, 2017,38(11), 2095— 2101 |

| ( 王浩, 张剑平, 马韵升, 王日国, 贺爱华 . 高等学校化学学报, 2017,38(11), 2095— 2101) | |

| [20] | Zhang X. P., Cui H., Song L. Y., Ren H. C., Wang R. G., He A. H., Compos. Sci. Technol., 2018,158, 156— 163 |

| [21] | Ismail H., Suzaimah S ., Polym. Test, 2000,19(8), 879— 888 |

| [22] | Stöckelhuber K. W., Das A., Jurk R., Heinrich G., Polymer, 2010,51(9), 1954— 1963 |

| [23] | Ryu C., Yang J. K., Park W., Seo Y., Kim S. J., Kim D., Park S., Seo1 G., J. Appl. Polym. Sci., 2017,134(22), 1— 14 |

| [24] | Li Y., Han B. Y., Liu L., Zhang F. Z., Zhang L. Q., Wen S. P., Lu Y. L., Yang H. B., Shen J., Compos. Sci. Technol., 2013,88, 69— 75 |

| [25] | Stockelhuber K. W., Svistkov A. S., Pelevin A. G., Heinrich G., Macromolecules, 2011,44(11), 4366— 4381 |

| [26] | Ramier J., Gauthier C., Chazeau L., Stelander L., Guy L ., J. Polym. Sci. Part B., 2007,45(3), 286— 298 |

| [27] | Choi S. S., Kim I. S., . Eur. Polym. J., 2002,38, 1265— 1269 |

| [28] | Park S. J., Cho K. S., . J. Colloid. Interf. Sci., 200, 267(1), 86— 91 |

| [29] | Standardization Administration of the People’s Republic of China, GB/T 1332.1-2000, Rubber: Measurement Mooney Viscosity with Shearing Discvis Viscometer, Standards Press of China, Beijing, 2000 |

| ( 中国国家标准化管理委员会. GB/T 1232.1-2000, 橡胶用门尼粘度仪测定门尼粘度, 北京: 中国标准出版社, 2000) | |

| [30] | Standardization Administration of the People’s Republic of China, GB/T 25268-2010, Rubber:Measurement of Vulcanization Characteristics with RotorlessCuremeters, Standards Press of China, Beijing, 2010 |

| ( 中国国家标准化管理委员会. GB/T 25268-2010, 橡胶用无转子硫化仪测定硫化特性, 北京: 中国标准出版社, 2010) | |

| [31] | Standardization Administration of the People’s Republic of China, GB/T 9026-2007, Rubber:Measurement of Green-Strength, Standards Press of China, Beijing, 2007 |

| ( 中国国家标准化管理委员会.GB / T 9026-2007, 混炼橡胶的格林强度测试, 北京: 中国标准出版社, 2007) | |

| [32] | Standardization Administration of the People’s Republic of China, GB/T 528-2009, Vulcanized or Thermoplastic:Determination of Tensile Stress-train Properties, Standards Press of China, Beijing, 2009 |

| ( 中国国家标准化管理委员会. GB/T 528-2009, 硫化橡胶或热塑性橡胶拉伸应力应变性能的测定, 北京: 中国标准出版社, 2009) | |

| [33] | Standardization Administration of the People’s Republic of China,GB/T 529-2008, Vulcanized or Thermoplastic:Determination of Tear Strength, Standards Press of China, Beijing, 2008 |

| ( 中国国家标准化管理委员会. GB/T 529-2008, 硫化橡胶或热塑性橡胶撕裂强度的测定, 北京: 中国标准出版社, 2008) | |

| [34] | Standardization Administration of the People’s Republic of China, GB/T 1681-2009, Rubber:Determination of Rebound Reslience of Vulcanizates, Standards Press of China, Beijing, 2009 |

| ( 中国国家标准化管理委员会.GB/T 1681-2009, 硫化橡胶回弹性能的测定, 北京: 中国标准出版社, 2009) | |

| [35] | Standardization Administration of the People’s Republic of China, GB/T 9867-2008, Rubber: Determination of DIN Abrasion Resistance of Vulcanizates , Standards Press of China,Beijing, 2008 |

| ( 中国国家标准化管理委员会.GB/T 9867-2008 , 硫化橡胶DIN磨耗性能的测定, 北京: 中国标准出版社, 2008) | |

| [36] | Standardization Administration of the People’s Republic of China, GB/T 3512-2014, Vulcanized or Thermoplastic: Accelerated Ageing and Heat Resistance Tests: Air-Oven Method , Standards Press of China, Beijing, 2014 |

| ( 中国国家标准化管理委员会. GB/T 3512-2014, 硫化橡胶或热塑性橡胶热空气加速老化和耐热实验, 北京: 中国标准出版社, 2014) | |

| [37] | Standardization Administration of the People’s Republic of China, GB/T 1689-2016, Vulcanized or Thermoplastic: Determination of Tensile Fatigue, Standards Press of China, Beijing, 2016 |

| ( 中国国家标准化管理委员会. GB/T 1689-2016, 硫化橡胶或热塑性橡胶伸张疲劳性能测定(德默西亚), 北京: 中国标准出版社, 2016) | |

| [38] | Qi L. J., Zhao Z. C., Huang B. C., Spec. Rubb. Prod., 2009,30(6), 6— 9 |

| ( 齐立杰, 赵志超, 黄宝琛 . 特种橡胶工业, 2009,30(6), 6— 9) | |

| [39] | Zhang X. P., Wang H., Ren H. C., Wang R. G., He A. H., Ind. Eng. Chem. Res., 2019,58, 917— 925 |

| [40] | Gong K. C., Li G. J., Hu Q. X., J. Polym. Sci. Part A., 2010,29(9), 1225— 1230 |

| [41] | Suzana S. J., Vojislav J., Gordana M., Gordana M., Ivana Z., Milena M. C., Sci. World J., 2014,267(1), 1— 9 |

| [42] | Pourhossaini M. R., Razzaghi-Kashani M., Polymer, 2014,55(9), 2279— 2284 |

| [43] | Berriot J., Montes H., Lequeux F., Long D., Sottaet P ., Macromolecules, 2002,35(26), 9756— 9762 |

| [44] | Yan F. H., Zhang X. B., Liu F., Zhang Z. J., . Compos. Part B., 2015,75, 47— 52 |

| [1] | TONG Cheng, WU Wentao, WANG Ting. Preparation of Small Mesoporous SiO2 Particles with Asymmetric Tunnel Structure and Fabrication of the Resulting Hybrid Membranes [J]. Chem. J. Chinese Universities, 2021, 42(3): 946. |

| [2] | WANG Yong, DONG Biao, SUN Jiao, DONG Delu, SUN Liankun. Synthesis and Spectral Properties of Ag/SiO2-Al2O3 Composite Nanomaterial Based on Molecular Sieve Template [J]. Chem. J. Chinese Universities, 2021, 42(10): 3233. |

| [3] | WANG Tianqi,YU Qiongwei,FENG Yuqi. Analysis of Imidazole Propionic Acid in Serum of Patients with Type 2 Diabetes Based on NiO@SiO2 Solid-phase Extraction Coupled with Liquid Chromatography-Mass Spectrometry † [J]. Chem. J. Chinese Universities, 2020, 41(2): 262. |

| [4] | DONG Le, HUANG Xingliang, REN Junjie, DAI Xiaoping, LIU Zongyan, TIAN Hongfeng, WANG Zhidong, WU Xiaotong. Influence Mechanism of Particle Size and Distribution of Silica Sol in the Synthesis of Ferrierite Zeolite with High SiO2/Al2O3 Ratio [J]. Chem. J. Chinese Universities, 2020, 41(11): 2449. |

| [5] | WANG Xiaohui, WANG Kexin, LIU Junping, HONG Xia. Mesoporous-structure Enhanced Photothermal Effect of Fe3O4 Superparticles@mesoporous Silica [J]. Chem. J. Chinese Universities, 2019, 40(8): 1586. |

| [6] | CAI Jiao,YU Qiongwei,HE Xiaomei,XU Jing,DING Qiong,FENG Yuqi. Preparation of SiW11 Incorporated SiO2 Nanofibers(SiW11/SiO2) and Its Application in the Analysis of Polyamines in Arabidopsis† [J]. Chem. J. Chinese Universities, 2019, 40(5): 901. |

| [7] | QI Qi,LU Bingxin,CHE Yuping,WANG Yang,ZHAI Jin. Bimetallic Multi-core Nanoparticles with Dual SiO2 Layer Au@SiO2@Ag@SiO2 for the Detection of Glucose† [J]. Chem. J. Chinese Universities, 2019, 40(5): 887. |

| [8] | CHU Ming,ZHANG Jianfu,QU Lihang,LI Meiyuan,ZHU Dantong,LI Wenfei,YAO Zhanhai. Preparation and Properties of Grafted Polyethylene/GMS Grafted Modified SiO2 Blends† [J]. Chem. J. Chinese Universities, 2018, 39(12): 2781. |

| [9] | YUAN Jiayi, YE Baotong, WU Jing, LI Ying, CHEN Jinghua, CHEN Jingxiao. Study on Sulfated Glycosylated Fe3O4@SiO2 Nanoparticles Inducing Tumor Cells Apoptosis† [J]. Chem. J. Chinese Universities, 2018, 39(11): 2458. |

| [10] | SHI Huimin, WANG Hui, YIN Jinwei, ZHU Qingyun, WU Ping, Tang Yawen, Zhou Yiming, Lu Tianhong. Preparation and Lithium Storage Performance of MWCNT@SiO2 Coaxial Nanocables† [J]. Chem. J. Chinese Universities, 2015, 36(1): 175. |

| [11] | YAN Hui-Qiong, LI Jia-Cheng, FENG Yu-Hong, HU Wen-Tao, LIU Ruo-Lin, LIN Qiang. Stability and Release Properties of Drug-loaded Pickering Emulsions by the Modified Sodium Alginate Activated SiO2 Nanoparticles [J]. Chem. J. Chinese Universities, 2013, 34(9): 2164. |

| [12] | PAN Ai-Zhao, HE Ling, ZHANG Wen-Wei. Preparation and Film Properties of SiO2@P(MMA/BA/3FMA) Composite Nanoparticles [J]. Chem. J. Chinese Universities, 2013, 34(4): 1007. |

| [13] | LI Nan, HUANG Ya-Jiang, XIA Tian, YANG Qi, LI Guang-Xian. Phase Behavior of PS/PVME/SiO2 Blends Under Oscillatory Shear Flow Field [J]. Chem. J. Chinese Universities, 2013, 34(12): 2896. |

| [14] | LIU Ri-Jia, WANG Rui. Synthesis, Characterization and Catalytic Fuel Ultra-deep Desulfurization of Hollow Amino-SiO2 Supported Heteropoly Compound Catalyst [J]. Chem. J. Chinese Universities, 2013, 34(12): 2814. |

| [15] | ZHAI Shu-Bo, SUN Jing-Hui, GAO Shuang, YU Xue, HUO Wei-Tao, YAN Jian-Biao, LIU Yun-Ling, WANG Zhen-Lü. Catalytic Properties of SiO2 Supported ZnO Catalysts Prepared via Sol-gel and Impregnation Methods for Decomposition of Butan-2-ol [J]. Chem. J. Chinese Universities, 2012, 33(10): 2282. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||