Chem. J. Chinese Universities ›› 2019, Vol. 40 ›› Issue (5): 1058.doi: 10.7503/cjcu20180778

• Polymer Chemistry • Previous Articles Next Articles

DUAN Yajun, CHENG Yanyan, SUI Guanghui, ZHU Yanchao, WANG Xiaofeng, GUO Yupeng*( ), WANG Zichen

), WANG Zichen

Received:2018-11-17

Online:2019-03-09

Published:2019-03-09

Contact:

GUO Yupeng

E-mail:guoyupeng@jlu.edu.cn

Supported by:CLC Number:

TrendMD:

DUAN Yajun,CHENG Yanyan,SUI Guanghui,ZHU Yanchao,WANG Xiaofeng,GUO Yupeng,WANG Zichen. Lignin Impacts on the Lignin-urea-formaldehyde Copolymer Resin and the Reaction Mechanism†[J]. Chem. J. Chinese Universities, 2019, 40(5): 1058.

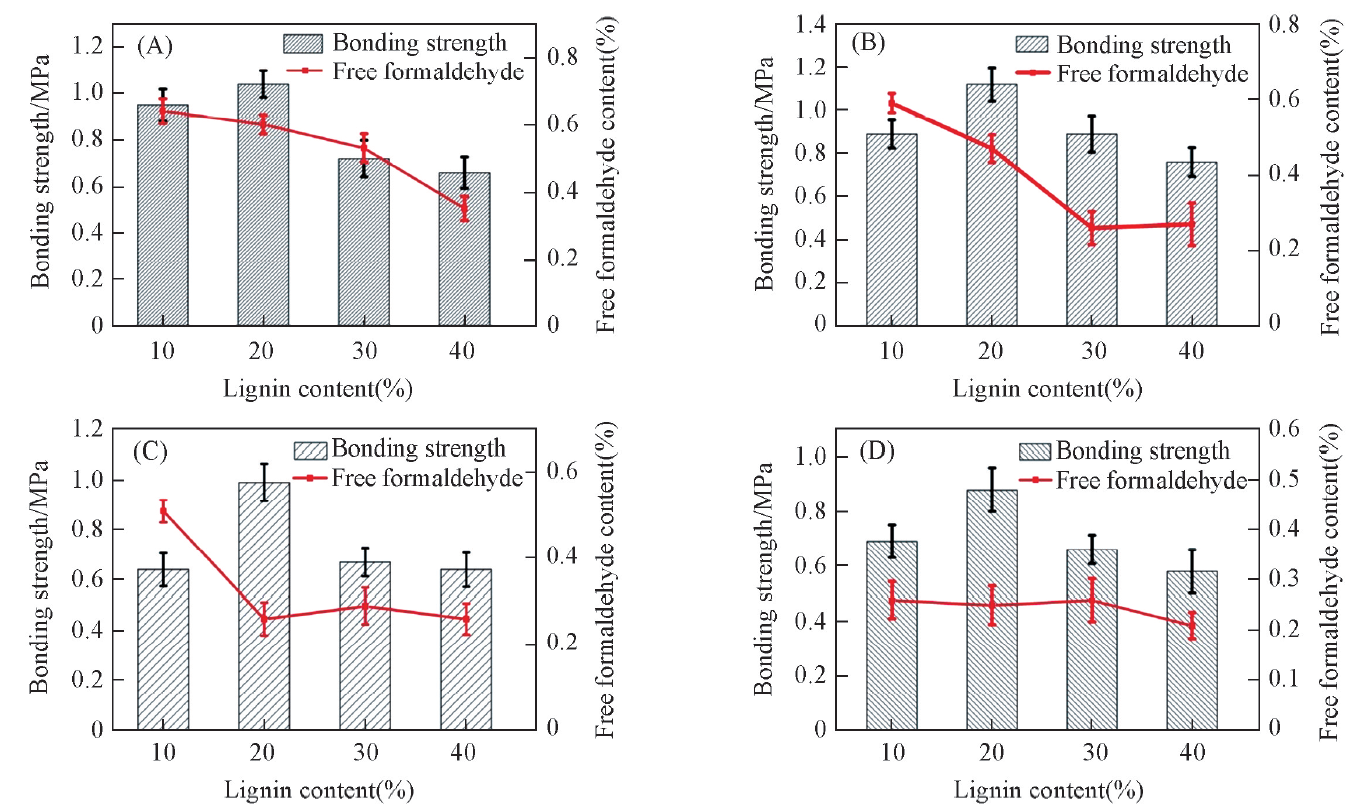

Fig.2 Effect of lignin content on the bonding strength and free formaldehyde content of LUF Molar ratio of F/U: (A) 1.17∶1; (B) 1.04∶1; (C) 0.91∶1; (D) 0.78∶1.

| Molar ratio of F/U | Lignin content(%) | Water resistance test | Bonding strength/MPa | Molar ratio of F/U | Lignin content(%) | Water resistance test | Bonding strength/MPa |

|---|---|---|---|---|---|---|---|

| 1.04∶1 | 0 | Fail | — | 0.91∶1 | 0 | Fail | — |

| 10 | Pass | 0.69 | 10 | Fail | — | ||

| 20 | Pass | 0.78 | 15 | Pass | 0.21 | ||

| 30 | Pass | 0.47 | 20 | Pass | 0.33 | ||

| 40 | Fail | — | 25 | Fail | — | ||

| 30 | Fail | — |

Table 1 Effect of lignin on the water resistance of the resin

| Molar ratio of F/U | Lignin content(%) | Water resistance test | Bonding strength/MPa | Molar ratio of F/U | Lignin content(%) | Water resistance test | Bonding strength/MPa |

|---|---|---|---|---|---|---|---|

| 1.04∶1 | 0 | Fail | — | 0.91∶1 | 0 | Fail | — |

| 10 | Pass | 0.69 | 10 | Fail | — | ||

| 20 | Pass | 0.78 | 15 | Pass | 0.21 | ||

| 30 | Pass | 0.47 | 20 | Pass | 0.33 | ||

| 40 | Fail | — | 25 | Fail | — | ||

| 30 | Fail | — |

| [1] | Borann S., Usta M., Gümüs-kaya E., Int. J. Adhes. Adhes., 2011, 31(7), 674—678 |

| [2] | Xia S. H., Li. L., Li J. Z., J. Beijing Fore. Univ.,2009, 31(4), 123—129 |

| (夏松华, 李黎, 李建章. 北京林业大学学报,2009, 31(4), 123—129) | |

| [3] | Gao X., Zhang X., Chem. Techno. Mar.,2008, 31(10), 19—23 |

| [4] | Yu L. Z., Gu T., Sun L. H., Sun C., Qiu F. X., China Adhes.,2012, 21(9), 1283—1286 |

| (俞丽珍, 顾婷, 孙乐花, 孙才, 丘凤仙. 中国胶粘剂,2012, 21(9), 1283—1286) | |

| [5] | Jun J., Lu X. N., Eur. J. Wood Prod.,2017, 75, 185—191 |

| [6] | Hu H.D., Study on Modified Alkali Lignin Synthetic Lignin Urea Formaldehyde Glue, Nanjing Forestry University, Nanjing, 2009 |

| (胡鸿达. 改性碱木质素合成木素脲醛胶的研究, 南京: 南京林业大学, 2009) | |

| 7 | [7] Pizzi A., Lipschitz L., Valenzuela J., Holzforschung,1994, 48(3), 254—261 |

| [8] | Du Y. J., Lin A. J., Du G. S., J. Fuzhou Univ.,2002, 17(2), 115—118 |

| (杜育江, 林爱娇, 杜光山. 福州大学学报,2002, 17(2), 115—118) | |

| [9] | Zhu H. L., Wu Y. Z., Sun W. S., J. Nanjing Fore. Univ.,2013, 37(1), 137—176 |

| (朱海龙, 吴玉章, 孙伟圣. 南京林业大学学报,2013, 37(1), 137—176) | |

| [10] | Lu L. N., Gu S. F., Zhang T., Zhou K., Yu L. Z., Fore. Prod. Industry,2015, 42(12), 36—39 |

| [11] | Yang J. Z., Xu L., China Adhes.,2006, 15(5), 31—33 |

| (杨建洲, 徐亮. 中国胶粘剂,2006, 15(5), 31—33) | |

| [12] | Liu X., Yu Q. Y., Yu L. Z., Gu S. F., Fan Y. C., China Adhes.,2014, 23(8), 39—42 |

| (刘璇, 于清洋, 俞丽珍, 沈丽梅, 顾顺飞, 樊玉昌. 中国胶粘剂,2014, 23(8), 39—42) | |

| [13] | Hamed Y. K., Antonio P., Eur. J. Wood Prod.,2018, 76, 871—876 |

| [14] | Esmaeili N., Zohuriaan-Mehr M. J., Mohajeri S., Kabiri K., Bouhendi H., Eur. J. Wood Prod.,2017, 75, 71—80 |

| [15] | Liu M., Wang Y., Wu Y. Q., He Z. Q., Wan H., J. Clean. Prod.,2018, 187, 361—371 |

| [16] | Lin Q. J., Liu J. H., Rao J. P., Scie. Silv. Sinic.,2005, 41(2), 129—135 |

| [17] | Hamed Y. K., Eur. J. Wood Prod., 2017, 75, 885—891 |

| [18] | Wu J.H., Sun W. H., Yan W. T.,Fore. Prod. Industry, 2016, 27—29 |

| [19] | Zhang H., Pu J. W., Hong L., Zhu M., Chem. Ind. Forest. Prod.,2016, 36(1), 99—104 |

| [20] | Mayers G. E., Forest Products Journal, 1984 , 34(5), 35—41 |

| [21] | Lu J. Z., Wu Q. L., Mcnabb H. S. J., Wood. Fiber. Sci.,2000, 32(1) , 88—104 |

| [22] | Forss K. G., Fuhrmann A., Fore. Prod.,1979, 29, 39—43 |

| [23] | Standard Administration of the People’s Repubic of China, GB/T14732-2017, Wood Adhesives: Urea-Formaladehyde, Phenol-Formaladehyde and Melamine-Formaladehyde Resins, Standards Press of China, Beijing, 2017 |

| (中国标准化委员会, GB/T14732-2017, 木材工业胶粘剂用脲醛、 酚醛、 三聚氰胺甲醛树脂, 北京: 中国标准出版社, 2017) | |

| [24] | Sha J.X., Preparation and Application of Lignin-Urea-Formaldehyde Resin, Jilin University, Changchun, 2017 |

| (沙金鑫. 木质素基脲醛树脂的制备及应用性能研究, 长春: 吉林大学, 2017) | |

| [25] | Mayers G. E., Wood Sci., 1982, 18(2), 95—107 |

| [26] | Zhong H., Zhang J., Gong F. H., Luo Y. C., China Adhes.,2010, 19(11), 32—35 |

| (仲豪, 张静, 龚方红, 罗永春. 中国胶粘剂,2010, 19(11), 32—35) | |

| [27] | Ghafari R., Doost H. K., Abdulkhani A., Mirshokraie S. A., Eur. J. Wood Prod.,2016, 74, 609—616 |

| [28] | Wang Y.X., Deng J. F., Adhesive Production Process, China Forestry Publishing House, Beijing, 1989 |

| (王毓秀, 邓介凡. 胶粘剂生产工艺, 北京: 中国林业出版社, 1989) | |

| [29] | Li D.G., Urea-Formaldehyde Resin Adhesive, Chemical Industry Press, Beijing, 2002 |

| (李东光. 脲醛树脂胶粘剂 北京,: 化学工业出版社, 2002) | |

| [30] | Tohmura S., Hse Y., Higuchi M., J. Wood Sci.,2000, 46, 303—309 |

| [31] | Taylor P., Hazarika A., Maji T. K., J. Wood Chem. Technol.,2013, 33, 103—124 |

| [32] | Chen H.Z., Study on Lignin and Its Composites in the Application of Epoxy Resin Adhesive, Jilin University, Changchun, 2016 |

| (陈洪卓. 木质素及其复合物在环氧树脂胶黏剂中的应用研究, 长春: 吉林大学, 2016) | |

| [33] | Zhang C. W., Liu Y., Han L. C., Forest. Sci. Technol.,2000, 25(5), 34—37 |

| [1] | LIU Xiaojin, LI Ting, WANG Yang, DONG Weifu. Preparation of Terpolymer Microspheres with Broad Band UV-blocking Performance [J]. Chem. J. Chinese Universities, 2021, 42(6): 1965. |

| [2] | YI Conghua, SU Huajian, QIAN Yong, LI Qiong, YANG Dongjie. Preparation of Lignin Nanocarbon and Its Performance as a Negative Electrode for Lithium-ion Batteries [J]. Chem. J. Chinese Universities, 2021, 42(6): 1807. |

| [3] | CHEN Xiangyun, ZHU Benqiang, YUAN Bing, YU Fengli, XIE Congxia, YU Shitao. Hydrogenation of α-Pinene Catalyzed by Ru Nanoparticles Stabilized by Magnetic Alkali Lignin Amine [J]. Chem. J. Chinese Universities, 2020, 41(8): 1826. |

| [4] |

HAN Hongjing,GE Qin,CHEN Yanguang,WANG Haiying,ZHAO Hongzhi,WANG Yizhen,ZHANG Yanan,DENG Jitong,SONG Hua,ZHANG Mei.

Production of Phenolic Compounds from Bagasse Lignin via Catalytic Pyrolysis of Ca1-xPrxFe |

| [5] | LI Lan,QIAN Yong,YANG Dongjie,QIU Xueqing. Preparation of Lignin/silica Nanoparticle Based Microcapsules and Their Application in Self-healing Coatings† [J]. Chem. J. Chinese Universities, 2019, 40(6): 1293. |

| [6] | ZHOU Lie, WU Qingyun, XU Ying, WANG Chenguang, MA Longlong, LI Wenzhi, CHEN Peili. Depolymerization of the Alkali Lignin for Aromatic Compounds over Ni/SiO2-Al2O3 Solid Acid Catalysts† [J]. Chem. J. Chinese Universities, 2018, 39(4): 735. |

| [7] | LI Changqing,YANG Dongjie,XI Yuebin,QIN Yanlin,QIU Xueqing. Synthesis and Electrochemical Performance of Silica/Porous Lignin Carbon Composites as Anode Materials for Lithium-ion Batteries† [J]. Chem. J. Chinese Universities, 2018, 39(12): 2725. |

| [8] | FU Fangbao,WANG Huan,ZHONG Ruisheng,QIU Xueqing,YANG Dongjie. Preparation of Lignin/ZnO Composite Nanoparticles and Its Application in Waterborne Polyurethane† [J]. Chem. J. Chinese Universities, 2018, 39(10): 2335. |

| [9] | LI Yuanyuan, YANG Dongjie, QIU Xueqing. Preparation and Characterization of pH-Responsive Lignin-based Colloidal Spheres [J]. Chem. J. Chinese Universities, 2017, 38(5): 880. |

| [10] | CHEN Yanguang, WANG Xinhui, HAN Hongjing, WANG Haiying, AN Hongyu, SONG Hua, GONG Xuzhong, ZHANG Jian. Production of Phenolic Compounds from Bagasse Lignin via Catalytic Pyrolysis of CaZr1-xFexO3† [J]. Chem. J. Chinese Universities, 2017, 38(2): 252. |

| [11] | CHAO Wei, YANG Xiaomin, ZHOU Yu, ZHU Yanchao, WANG Zichen. Lignin Impacts on the Preparation of Phenolic-resin/Lignin Block Copolymer Resin and the Reaction Mechanism† [J]. Chem. J. Chinese Universities, 2017, 38(2): 312. |

| [12] | WANG Wenliang, GENG Jing, LI Lufei, CHANG Jianmin. Catalytic Properties of Fast Pyrolysis Char Loaded with Cu-Zn on Alkali Lignin Pyrolysis for Monophenols† [J]. Chem. J. Chinese Universities, 2016, 37(4): 736. |

| [13] | YANG Dalei, ZHANG Niaona, HU Qiuxue, WEI Yingcong, YAN Ru, ZHANG Mingyao, ZHANG Huixuan, HU Wei. Synthesis of Lignin Based Epoxy Acrylate and Its UV-curing Research† [J]. Chem. J. Chinese Universities, 2016, 37(3): 426. |

| [14] | ZHANG Qing-Hua, ZHAN Xiao-Li, CHEN Feng-Qiu . Synthesis of Fluorinated Acrylate Ternary Copolymer Latex by Miniemulsion Polymerization and Characterization [J]. Chem. J. Chinese Universities, 2005, 26(3): 575. |

| [15] | GU Rui-Jun, XIE Yi-Min, ZENG Shao-Qiong, WU Hong, Seiichi-Yasuda . Carbon-13 Enrichment of Rice Stalk Lignin Traced by Solid State 13C NMR Spectroscopy [J]. Chem. J. Chinese Universities, 2002, 23(6): 1073. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||