Chem. J. Chinese Universities ›› 2018, Vol. 39 ›› Issue (10): 2335.doi: 10.7503/cjcu20180128

• Polymer Chemistry • Previous Articles Next Articles

FU Fangbao1, WANG Huan1, ZHONG Ruisheng1, QIU Xueqing1,2, YANG Dongjie1,2,*( )

)

Received:2018-02-01

Online:2018-09-29

Published:2018-09-29

Contact:

YANG Dongjie

E-mail:cedjyang@scut.edu.cn

Supported by:CLC Number:

TrendMD:

FU Fangbao,WANG Huan,ZHONG Ruisheng,QIU Xueqing,YANG Dongjie. Preparation of Lignin/ZnO Composite Nanoparticles and Its Application in Waterborne Polyurethane†[J]. Chem. J. Chinese Universities, 2018, 39(10): 2335.

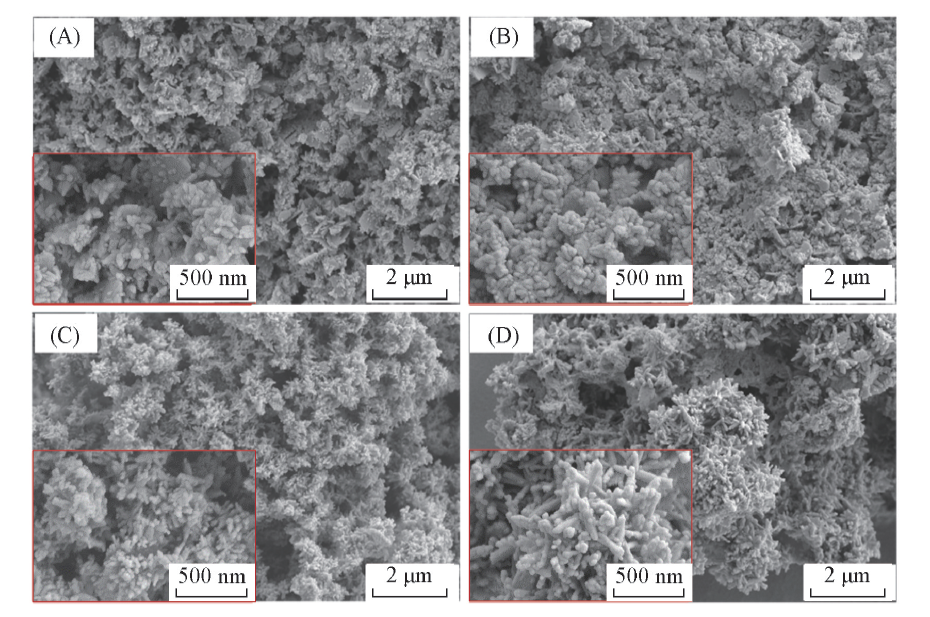

Fig.4 SEM images of LQAs/ZnO-0.8(A), LQAs/ZnO-1.2(B), LQAs/ZnO-1.6(C) and LQAs/ZnO-2.0(D) Insets are the higher magnification images of (A)—(D), respectively.

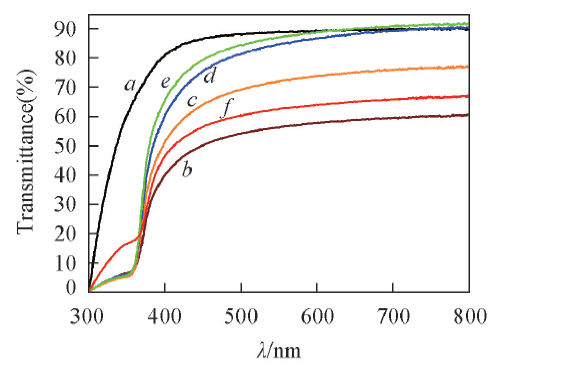

Fig.8 UV light transmittance curves of samplesa. WPU, UPF=5.21; b. WPU-LQAs/ZnO-2.0, UPF=38.55; c. WPU-LQAs/ZnO-1.6, UPF=38.19; d. WPU-LQAs/ZnO-1.2, UPF=32.46; e. WPU-LQAs/ZnO-0.8, UPF=31.93; f. WPU- ZnO-2.0, UPF=18.18.

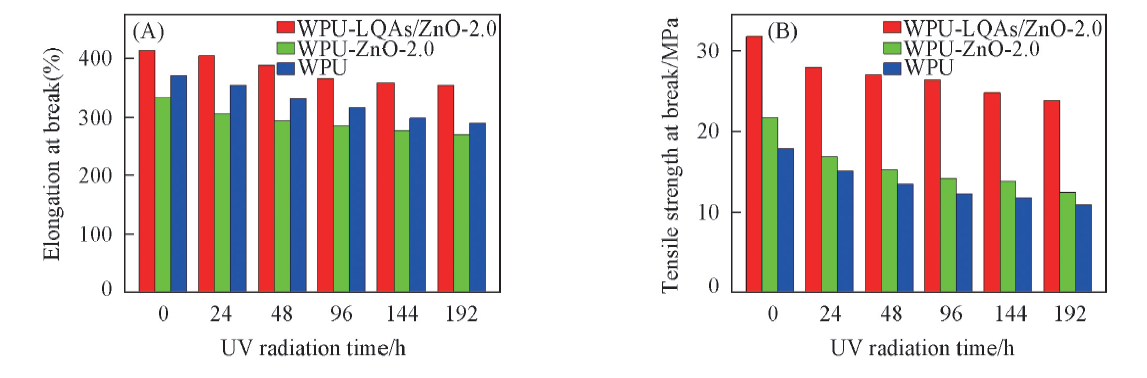

Fig.9 Mechanical properties of samples during UV aging process(A) Elongation at break vs. UV radiation time; (B) tensile strength at break vs. UV radiation time.

| [1] | Xiong W.L., Yang D. J., Zhong R. S., Li Y., Zhou H. F., Qiu X. Q., Ind. Crop. Prod., 2015, 74, 285—292 |

| [2] | Liu W.J., Jiang H., Yu H. Q., Green Chem., 2015, 17(11), 4888—4907 |

| [3] | Xue F., Zhang L.M., Feng X. L., Hu G. F., Fan F. R., Wen X. N., Zheng L., Wang Z. L., Nano Research, 2015, 8(7), 2390—2399 |

| [4] | Wang H., Yi G.B., Zu X. H., Qin P., Tan M., Luo H. S., Materials Letters, 2016, 162, 83—86 |

| [5] | Beek W.J. E., Wienk A. M. M., Janssen R. A. J., Adv. Funct. Mater., 2006, 16(8), 1112—1116 |

| [6] | Xiao B., Sun X.F., Sun R. C., Polymer Degradation and Stability, 2001, 74(2), 307—319 |

| [7] | Qian Y., Qiu X.Q., Zhu S. P., ACS Sustainable Chem. Eng., 2016, 4(7), 4029—4035 |

| [8] | Xiong W. L., Qiu X. Q., Yang D. J., Zhong R. S., Qian Y., Li Y. Y., Wang H., Chemical Engineering J., 2017, 326, 803—810 |

| [9] | Morsella M., d’Alessandro N., Lanterna A. E., Scaiano J. C., ACS Omega, 2016, 1(3), 464—469 |

| [10] | Liu S.G., Zhu G. Q., European Polymer Journal, 2007, 43(9), 3904—3911 |

| [11] | Kwak Y.S., Park S. W., Lee Y. H., Kim H. D., Journal of Applied Polymer Science, 2003, 89(1), 123—129 |

| [12] | Xue B.L., Wen J. L., Sun R. C., ACS Sustainable Chem. Eng., 2014, 2(6), 1474—1480 |

| [13] | Hsu S.H., Hsieh C. T., Sun Y. M., J. Mater. Chem.B, 2015, 3(47), 9089—9097 |

| [14] | Li Y.Y., Yang D. J., Qiu X. Q., Chem. J. Chinese Universities, 2017, 38(5), 880—887 |

| (李圆圆, 杨东杰, 邱学青. 高等学校化学学报, 2017, 38(5), 880—887) | |

| [15] | Hoffmann K., Kaspar K., Gambichler T., Altmeyeret P., Journal of the American Academy of Dermatology, 2000, 43(6), 1009—1016 |

| [16] | GB/T 1040B/T 1040.1—2006, General Administration of Quality Supervision, Inspection and Quarantine of the People republic of China, Determination of Tensile Properties of Plastics, China Standards Press, Beijing, 2006 |

| (GB/T 1040B/T 1040.1—2006, 国家质量监督检验检疫总局. 塑料: 拉伸性能的测定, 北京: 中国标准出版社, 2006) | |

| [17] | Sun Y., Qiu X.Q., Liu Y. Q., Biomass and Bioenergy, 2013, 55, 198—204 |

| [18] | Zhang W., Ma Y.F., Wang C. P., Li S. H., Zhang M. M., Chu F. X., Ind. Crop. Prod., 2013, 43, 326—333 |

| [19] | Klapiszewski Ł., Nowacka M., Milczarek G., Jesionowski T., Carbohydrate Polymers, 2013, 94(1), 345—355 |

| [20] | Velayutham T.S., Abd M. W. H., Gan W. C., Khorsand Z. A., Gan S. N., J. Appl. Phys., 2012, 112(5), 054106 |

| [21] | Sharma D., Sharma S., Kaith B.S., Rajput J., Kaur M., Applied Surface Science, 2011, 257(22), 9661—9672 |

| [22] | Zha R.H., Nadimicherla R., Guo X., J. Mater. Chem.A, 2015, 3(12), 6565—6574 |

| [23] | Donaldson L.A., Radotic K., Journal of Microscopy, 2013, 251(2), 178—187 |

| [24] | Paulsson M., Parkås J., Bio. Resources, 2012, 7(4), 5995—6040 |

| [25] | Ciobanu C., Ungureanu M., Ignat L., Ungureanu D., Popa V.I., Ind. Crop. Prod., 2004, 20(2), 231—241 |

| [1] | LI Cong, LIU Huanhuan, YANG Guihua, TIAN Zhongjian, YAN Jiaqiang, JI Xingxiang, HAN Wenjia, CHEN Jiachuan. Preparation and Performance Analysis of Extremely High Strength Self-repairing Waterborne Polyurethane Adhesive Based on Oxime-carbamate [J]. Chem. J. Chinese Universities, 2021, 42(8): 2651. |

| [2] | YI Conghua, SU Huajian, QIAN Yong, LI Qiong, YANG Dongjie. Preparation of Lignin Nanocarbon and Its Performance as a Negative Electrode for Lithium-ion Batteries [J]. Chem. J. Chinese Universities, 2021, 42(6): 1807. |

| [3] | CHEN Xiangyun, ZHU Benqiang, YUAN Bing, YU Fengli, XIE Congxia, YU Shitao. Hydrogenation of α-Pinene Catalyzed by Ru Nanoparticles Stabilized by Magnetic Alkali Lignin Amine [J]. Chem. J. Chinese Universities, 2020, 41(8): 1826. |

| [4] |

HAN Hongjing,GE Qin,CHEN Yanguang,WANG Haiying,ZHAO Hongzhi,WANG Yizhen,ZHANG Yanan,DENG Jitong,SONG Hua,ZHANG Mei.

Production of Phenolic Compounds from Bagasse Lignin via Catalytic Pyrolysis of Ca1-xPrxFe |

| [5] | LI Lan,QIAN Yong,YANG Dongjie,QIU Xueqing. Preparation of Lignin/silica Nanoparticle Based Microcapsules and Their Application in Self-healing Coatings† [J]. Chem. J. Chinese Universities, 2019, 40(6): 1293. |

| [6] | DUAN Yajun,CHENG Yanyan,SUI Guanghui,ZHU Yanchao,WANG Xiaofeng,GUO Yupeng,WANG Zichen. Lignin Impacts on the Lignin-urea-formaldehyde Copolymer Resin and the Reaction Mechanism† [J]. Chem. J. Chinese Universities, 2019, 40(5): 1058. |

| [7] | ZHOU Lie, WU Qingyun, XU Ying, WANG Chenguang, MA Longlong, LI Wenzhi, CHEN Peili. Depolymerization of the Alkali Lignin for Aromatic Compounds over Ni/SiO2-Al2O3 Solid Acid Catalysts† [J]. Chem. J. Chinese Universities, 2018, 39(4): 735. |

| [8] | LI Changqing,YANG Dongjie,XI Yuebin,QIN Yanlin,QIU Xueqing. Synthesis and Electrochemical Performance of Silica/Porous Lignin Carbon Composites as Anode Materials for Lithium-ion Batteries† [J]. Chem. J. Chinese Universities, 2018, 39(12): 2725. |

| [9] | HU Haixia, HU Shirong, DONG Peihui, TANG Yuanjun, HONG Kejun, WANG Songhua. Synthesis of New Type ZnO Nanomaterial and Its Application for Electrochemical Detection of p-Nitrophenol† [J]. Chem. J. Chinese Universities, 2017, 38(7): 1171. |

| [10] | LI Yuanyuan, YANG Dongjie, QIU Xueqing. Preparation and Characterization of pH-Responsive Lignin-based Colloidal Spheres [J]. Chem. J. Chinese Universities, 2017, 38(5): 880. |

| [11] | CHEN Yanguang, WANG Xinhui, HAN Hongjing, WANG Haiying, AN Hongyu, SONG Hua, GONG Xuzhong, ZHANG Jian. Production of Phenolic Compounds from Bagasse Lignin via Catalytic Pyrolysis of CaZr1-xFexO3† [J]. Chem. J. Chinese Universities, 2017, 38(2): 252. |

| [12] | CHAO Wei, YANG Xiaomin, ZHOU Yu, ZHU Yanchao, WANG Zichen. Lignin Impacts on the Preparation of Phenolic-resin/Lignin Block Copolymer Resin and the Reaction Mechanism† [J]. Chem. J. Chinese Universities, 2017, 38(2): 312. |

| [13] | LI Xingjian,JU Yunpeng,CHANG Degong,ZHANG Yiheng. Preparation and Properties of Flame Retardant Waterborne Polyurethane Nanocomposites via Click Reaction† [J]. Chem. J. Chinese Universities, 2016, 37(8): 1580. |

| [14] | GAO He, LIANG Daxin, LI Jian, PANG Guangsheng, FANG Zhenxing. Preparation and Properties of Nano TiO2-ZnO Binary Collaborative Wood† [J]. Chem. J. Chinese Universities, 2016, 37(6): 1075. |

| [15] | WANG Wenliang, GENG Jing, LI Lufei, CHANG Jianmin. Catalytic Properties of Fast Pyrolysis Char Loaded with Cu-Zn on Alkali Lignin Pyrolysis for Monophenols† [J]. Chem. J. Chinese Universities, 2016, 37(4): 736. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||