Chem. J. Chinese Universities ›› 2018, Vol. 39 ›› Issue (2): 397.doi: 10.7503/cjcu20170417

• Polymer Chemistry • Previous Articles

WANG Xuan1, JIN Tao2, WANG Haowei2, LIAO Shengzhi2, YANG Huaiyu1,*( )

)

Received:2017-06-29

Online:2018-02-10

Published:2017-12-04

Contact:

YANG Huaiyu

E-mail:hyyang@imr.ac.cn

CLC Number:

TrendMD:

WANG Xuan, JIN Tao, WANG Haowei, LIAO Shengzhi, YANG Huaiyu. Preparation and Characterization of Polysulfide Sealant Microcapsules Based on in situ Polymerization of Urea and Formaldehyde†[J]. Chem. J. Chinese Universities, 2018, 39(2): 397.

| Type of dispersion stabilizer (1%, mass fraction) | Effect of emulsifying and dispersion for polysulfide sealant |

|---|---|

| Tween 80 | Not dispersed, and reunited after standing |

| Span 80 | Spherical particles with clear boundary, but largely difference in particle size and adhesion between particles |

| TX-100 | Not dispersed, agglomerated into a block after standing |

| SDBS | Uniformly dispersion, the particles were spindle type |

| Methylcellulose | Mostly spherical particles with clear boundary and partial particles were spindle type, small difference in particle size |

| Arabic gum + gelatin | Non-uniformly dispersion, irregular shape and largely difference in particle size, partially reunited after standing |

| PVA-124 | Uniformly dispersion, well-defined spherical particles with clear boundary, little difference in particle size |

| PVA-1799 | Uniformly dispersion, spherical particles with clear boundary, but largely difference in particle size |

| PVA-1750 | Poor dispersion, irregular shape, largely difference in particle size |

Table 1 Effect of different dispersion stabilizers on the result of emulsifying and dispersion for polysulfide sealant

| Type of dispersion stabilizer (1%, mass fraction) | Effect of emulsifying and dispersion for polysulfide sealant |

|---|---|

| Tween 80 | Not dispersed, and reunited after standing |

| Span 80 | Spherical particles with clear boundary, but largely difference in particle size and adhesion between particles |

| TX-100 | Not dispersed, agglomerated into a block after standing |

| SDBS | Uniformly dispersion, the particles were spindle type |

| Methylcellulose | Mostly spherical particles with clear boundary and partial particles were spindle type, small difference in particle size |

| Arabic gum + gelatin | Non-uniformly dispersion, irregular shape and largely difference in particle size, partially reunited after standing |

| PVA-124 | Uniformly dispersion, well-defined spherical particles with clear boundary, little difference in particle size |

| PVA-1799 | Uniformly dispersion, spherical particles with clear boundary, but largely difference in particle size |

| PVA-1750 | Poor dispersion, irregular shape, largely difference in particle size |

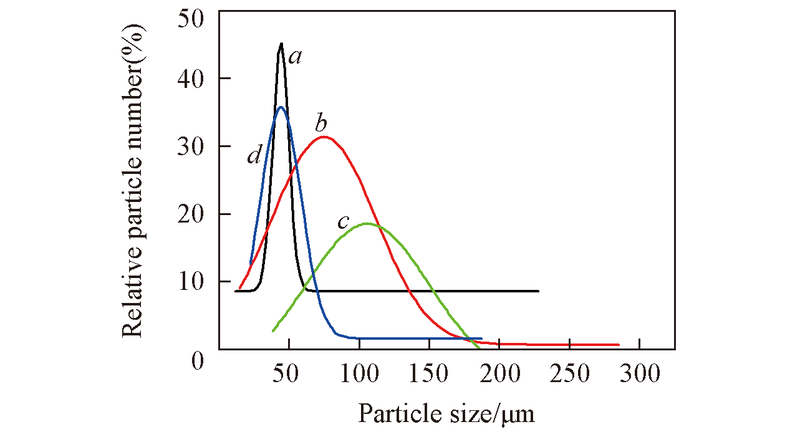

Fig.3 Particle size distributions of polysulfide sealant after emulsifying and dispersing in different PVA-124 solutionsMass fraction of PVA: a. 1%; b. 1.5%; c. 1.75%; d. 2%.

| Reaction temperature/℃ | Encapsulation effect of polysulfide sealant |

|---|---|

| 25 | Completely encapsulated, well-defined spherical particles with thick wall, little wall materials precipitated |

| 30 | Completely encapsulated, well-defined spherical particles with thick wall, little wall materials precipitated |

| 40 | Partially encapsulated, poor spherical particles with thin wall, little wall materials precipitated |

| 50 | Encapsulated, particle shape was irregular and large materials precipitated |

| 60 | Completely encapsulated, spherical particles with thin wall, large wall materials precipitated |

| 80 | Partially encapsulated, spherical particles with thin wall, large wall materials precipitated |

Table 2 Encapsulation effect of polysulfide sealant at different reaction temperature

| Reaction temperature/℃ | Encapsulation effect of polysulfide sealant |

|---|---|

| 25 | Completely encapsulated, well-defined spherical particles with thick wall, little wall materials precipitated |

| 30 | Completely encapsulated, well-defined spherical particles with thick wall, little wall materials precipitated |

| 40 | Partially encapsulated, poor spherical particles with thin wall, little wall materials precipitated |

| 50 | Encapsulated, particle shape was irregular and large materials precipitated |

| 60 | Completely encapsulated, spherical particles with thin wall, large wall materials precipitated |

| 80 | Partially encapsulated, spherical particles with thin wall, large wall materials precipitated |

| pH | Encapsulation effect of polysulfide sealant |

|---|---|

| 2 | Completely encapsulated, well-defined spherical particles with thick wall, but large precipitation and low utilization for the wall materials |

| 2.5 | Completely encapsulated, well-defined spherical particles with thick wall, but large precipitation and low utilization for the wall materials, and large difference in size |

| 3 | Completely encapsulated, well-defined spherical particles with thick wall and uniform size, little precipitation and high utilization for the wall materials |

| 3.5 | Completely encapsulated, well-defined spherical particles with thick wall and uniform size, little precipitation and high utilization for the wall materials |

| 4.5 | Well encapsulated, well-defined spherical particles with thick wall, but large precipitation and low utilization for the wall materials |

Table 3 Encapsulation effect of polysulfide sealant at different pH values

| pH | Encapsulation effect of polysulfide sealant |

|---|---|

| 2 | Completely encapsulated, well-defined spherical particles with thick wall, but large precipitation and low utilization for the wall materials |

| 2.5 | Completely encapsulated, well-defined spherical particles with thick wall, but large precipitation and low utilization for the wall materials, and large difference in size |

| 3 | Completely encapsulated, well-defined spherical particles with thick wall and uniform size, little precipitation and high utilization for the wall materials |

| 3.5 | Completely encapsulated, well-defined spherical particles with thick wall and uniform size, little precipitation and high utilization for the wall materials |

| 4.5 | Well encapsulated, well-defined spherical particles with thick wall, but large precipitation and low utilization for the wall materials |

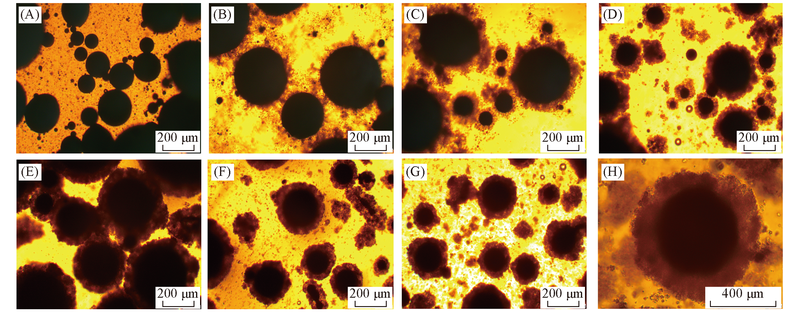

Fig.5 Optical photos of microspheres prepared at different polymerization timeTime/h: (A) 2; (B) 3; (C) 4; (D) 5; (E) 6; (F) 7; (G) 8. (H) repersentative microcapsule at 8 h.

| [1] | Farajpour T., Bayat Y., Keshavarz M., Zanjirian E., Materialwiss. Werkst., 2013, 44, 991—996 |

| [2] | Kemp T. J., Wilford A., Howarth O. W., Lee T. C. P., Polymer,1992, 33, 1860—18717 |

| [3] | Foster V. R., J. Chem. Educ., 1987, 64(10), 861—865 |

| [4] | Yang Y. F., Suo J. Y., Zhang J. Z., Wu S. H., Adhesion,2011, 32(3), 65—67 |

| [5] | Donskoi A. A., Baritko N. V., Zaitseva E. I., Polym. Sci. Ser. D, 2010, 3(1), 54—57 |

| [6] | Matsui T., Nakajima M., Nonaka T., J. Appl. Sci., 2004, 93(6), 2642—2649 |

| [7] | Zhang Y.K., Wu K., Zhang K., Wei X. R., Shen M. M.,Acta Polym. Sin., 2012, (7), 759—765 |

| (张延奎, 吴昆, 张卡, 魏续瑞, 沈敏敏. 高分子学报, 2012, (7), 759—765) | |

| [8] | Rong L., Ke T., Kang S., Hong J. D., Bin X., Colloid. Polym. Sci., 2010, 288(3), 353—357 |

| [9] | Teixeira R. F. A., Van Den Berg O., Nguyen L. T. T., Feher K., Du Prez F. E., Macromolecules,2014, 47(23), 8231—8237 |

| [10] | Fan G. Q., Tong W. J., Hu X. H., Gao C. Y., Chem. J. Chinese Universities, 2008, 29(10), 2086—2090 |

| (范国强, 仝维鋆, 胡小红, 高长有. 高等学校化学学报, 2008,29(10), 2086—2090) | |

| [11] | Zhang Q.X., Chen J. H., Lu H. B., Tang W., Lu Y., Gao Y. Z.,Acta Polym. Sin., 2015, (6), 692—698 |

| (张秋香, 陈建华, 陆洪彬, 唐伟, 陆玉, 高扬之. 高分子学报, 2015, (6), 692—698) | |

| [12] | Jiao X., Zhao D., Zhang Y., Wu Q., Shi X.D.,Acta Polym. Sin., 2016, (3), 345—351 |

| (焦鑫, 赵迪, 张姚, 吴倩, 石小迪. 高分子学报, 2016, (3), 345—351) | |

| [13] | Gong Y. F., Fu X. K., Zhang S. P., Zou K. D., Fu D., Fine. Chem., 2006, 23(2), 174—178 |

| (龚永锋, 傅相锴, 张树鹏, 邹旷东, 富丹. 精细化工, 2006,23(2), 174—178) | |

| [14] | Park S. J., Shin Y. S., Lee J. R., J. Colloid. Interf. Sci., 2001, 241, 502—508 |

| [15] | Shchukin D. G., Patel A. A., Sukhorukov G. B., Lvov M., J. Am. Chem. Soc., 2004, 126, 3374—3375 |

| [16] | Bai R. F., Fu X. K., Gong Y. F., Zou K. D., Fu D., Chin. J. Appl. Chem., 2007, 24, 694—697 |

| [17] | Cosco S., Ambrogi V., Musto P., Carfagna C., Macromol. Symp., 2006, 234, 184—192 |

| [18] | Li Y., Liang G. Z., Xie J. Q., Polymer,2006, 47, 5338—5349 |

| [19] | Wang D., Chen M., Wang C., Bai J., Zheng J., Mater. Lett., 2011, 65, 1069—1072 |

| [20] | Hao Z. X., Cheng Y. Y., Wang L. L., Wang X. G., Wang L. J., Zhu Z. R., Gan L. H., Xu Z. J., Chen L. W., Acta Chim. Sinica, 2012, 70, 331—338 |

| (郝志显, 程艺艺, 王乐乐, 王晓岗, 王利军, 朱志荣, 甘礼华, 徐子颉, 陈龙武. 化学学报, 2012, 70, 331—338) | |

| [21] | Hao Z. X., Guo B., Liu H., Gan L., Xu Z., Chen L., Micropor. Mesopor. Mat., 2006, 95, 350—359 |

| [22] | Liu X., Sheng X., Lee J. K., Macromol. Mater. Eng., 2009, 294(6/7), 389—395 |

| [23] | Yuan L., Gu A., Liang G. Z., Mater. Chem. Phys., 2008, 110(2/3), 417—425 |

| [1] | LI Lan,QIAN Yong,YANG Dongjie,QIU Xueqing. Preparation of Lignin/silica Nanoparticle Based Microcapsules and Their Application in Self-healing Coatings† [J]. Chem. J. Chinese Universities, 2019, 40(6): 1293. |

| [2] | CHEN Yuan,ZHAO Xuejing,LIANG Hongwei,WU Xiuwen,ZHANG Jinlin. Effect of Emulsification Process on the Thermal Properties of Stearic Acid Phase Change Microcapsules † [J]. Chem. J. Chinese Universities, 2019, 40(10): 2149. |

| [3] | YANG Hui, LI Tong, TONG Weijun, GAO Changyou. Fabrication of Microcapsules with Special Shapes by Layer-by-layer Assembly on CaCO3 Microparticles† [J]. Chem. J. Chinese Universities, 2018, 39(1): 172. |

| [4] | LI Xuehang, YU Huitao, WANG Weiren, BULIN Chaoke, XIN Guoxiang, ZHANG Bangwen. Preparation and Performance in Supercapacitor of Three-dimensional Functionalized Graphene/polyaniline Freestanding Electrode Materials† [J]. Chem. J. Chinese Universities, 2017, 38(12): 2306. |

| [5] | FENG Jianguo, YANG Guantian, YUAN Xiaoyong, CHEN Qicheng, SUN Chencheng, YUAN Shuzhong. Preparation, Characterization and Release Properties of β-Cypermethrin Microcapsules† [J]. Chem. J. Chinese Universities, 2017, 38(11): 1974. |

| [6] | YAO Jian, WANG Jianping, WEI Yao, WANG Xuechen, LI Wei, ZHANG Xingxiang. Synthesis and Characterization of Polyprrole Microcapcule Containing ZnCl2 Solution† [J]. Chem. J. Chinese Universities, 2016, 37(10): 1907. |

| [7] | ZHANG Jihua, FENG Huadong, ZAO Weitao, LING Mingbo, LIU Xiaoyan, ZHAO Yunfeng. Structures and Properties of in situ Polymethacrylates/Low-temperature Hydrogenated Butadiene-acrylonitrile Rubber† [J]. Chem. J. Chinese Universities, 2015, 36(7): 1447. |

| [8] | SONG Min, ZHANG Linping, ZHONG Yi, XU Hong, MAO Zhiping. Catalytic Properties of Manganese Complex of Cyclic Polyamine Encapsulated in Ethyl Cellulose Microcapsules† [J]. Chem. J. Chinese Universities, 2014, 35(9): 1941. |

| [9] | ZHANG Danfeng, FAN Louzhen, GUO Ruihua, FAN Zetan. Preparation of FGO/PBMA Composites with Improved Thermal Stability† [J]. Chem. J. Chinese Universities, 2014, 35(11): 2466. |

| [10] | ZHANG Qiuxiang, CHEN Jianhua, LU Hongbin, TANG Wei, LU Yu, GAO Yangzhi. Preparation and Properties of Paraffin Microencapsulated Phase-change Materials with Fine Particle Size† [J]. Chem. J. Chinese Universities, 2014, 35(10): 2258. |

| [11] | WANG Chun-Lei, YAN Jun-Tao, ZHONG Shuang-Ling, LI Zhan-Feng, CUI Xue-Jun, WANG Hong-Yan. Fabrication of Magnetic Protein Microcapsules by Sonochemical Method [J]. Chem. J. Chinese Universities, 2013, 34(2): 462. |

| [12] | GAO Xia, ZHANG Fu, CHEN Zhi-Chun, LIN Xian-Fu. Hepatic-targeting Microcapsules Construction by Layer-by-layer Self-assembly of Lactose-branched Polyelectrolyte [J]. Chem. J. Chinese Universities, 2011, 32(4): 957. |

| [13] | ZHANG Ying, YAN Shi-Feng, RAO Shui-Qin, ZHENG Yan-Zhen, YIN Jing-Bo*, CHEN Xue-Si*. Preparation of Melamine-formaldehyde Microspheres and Microcapsules Based on Poly(glutamic acid) by Template Method [J]. Chem. J. Chinese Universities, 2011, 32(10): 2447. |

| [14] | TONG Wei-Jun, ZHU Yi, GAO Chang-You*. Fabrication of Protein Microcapsules by Controlled Precipitation and Cross-linking [J]. Chem. J. Chinese Universities, 2008, 29(8): 1694. |

| [15] |

TONG Wei-Jun, GAO Chang-You*.

Layer-by-Layer Assembled Microcapsules: Fabrication, Stimuli-responsivity, Loading and Release [J]. Chem. J. Chinese Universities, 2008, 29(7): 1285. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||