Chem. J. Chinese Universities ›› 2017, Vol. 38 ›› Issue (11): 1974.doi: 10.7503/cjcu20170249

• Analytical Chemistry • Previous Articles Next Articles

FENG Jianguo1, YANG Guantian1, YUAN Xiaoyong2, CHEN Qicheng1, SUN Chencheng1, YUAN Shuzhong1,*( )

)

Received:2017-04-19

Online:2017-11-10

Published:2017-10-30

Contact:

YUAN Shuzhong

E-mail:szyuan@yzu.edu.cn

Supported by:CLC Number:

TrendMD:

FENG Jianguo, YANG Guantian, YUAN Xiaoyong, CHEN Qicheng, SUN Chencheng, YUAN Shuzhong. Preparation, Characterization and Release Properties of β-Cypermethrin Microcapsules†[J]. Chem. J. Chinese Universities, 2017, 38(11): 1974.

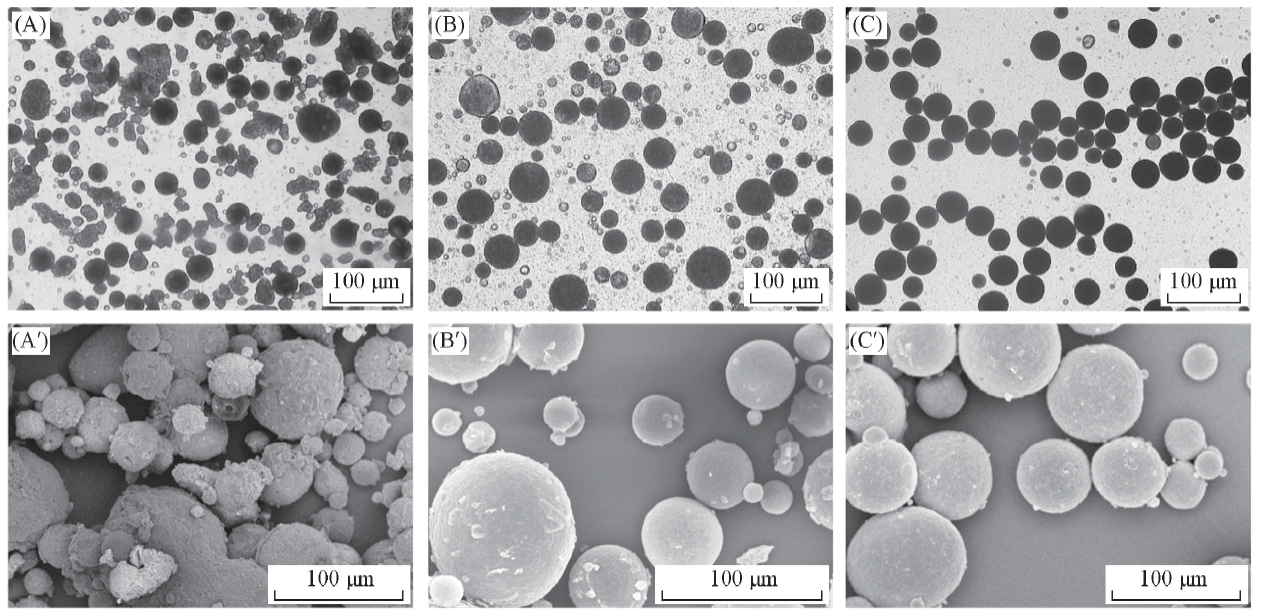

Fig.1 OM images(A—C) and SEM images(A'—C') of the β-cypermethrin microcapsules prepared with different emulsifiersEmulsifier: (A, A') Tween-20; (B, B') Tween-40; (C, C') Tween-80.

| Sample No. | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| Amount of β-cypermethrin(%) | 1 | 1 | 1 | 1 | 1 |

| Amount of dichloromethane(%) | 30 | 30 | 30 | 30 | 30 |

| Amount of ethyecellulose(%) | 1.25 | 1.5 | 1.75 | 1.75 | 1.75 |

| Amount of emulsifier(%) | 3 | 4 | 5 | 6 | 8 |

| Shearing time/min | 8 | 8 | 8 | 8 | 8 |

| Shearing rate/(r·min-1) | 12000 | 12000 | 12000 | 12000 | 12000 |

| Mean particle size/μm | 67 | 63 | 64 | 43 | 25 |

| Loading content(%) | 45.2 | 40.7 | 34.8 | 35.3 | 36.4 |

Table 1 Preparation parameters of microcapsule samples for release experiments

| Sample No. | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| Amount of β-cypermethrin(%) | 1 | 1 | 1 | 1 | 1 |

| Amount of dichloromethane(%) | 30 | 30 | 30 | 30 | 30 |

| Amount of ethyecellulose(%) | 1.25 | 1.5 | 1.75 | 1.75 | 1.75 |

| Amount of emulsifier(%) | 3 | 4 | 5 | 6 | 8 |

| Shearing time/min | 8 | 8 | 8 | 8 | 8 |

| Shearing rate/(r·min-1) | 12000 | 12000 | 12000 | 12000 | 12000 |

| Mean particle size/μm | 67 | 63 | 64 | 43 | 25 |

| Loading content(%) | 45.2 | 40.7 | 34.8 | 35.3 | 36.4 |

| Sample No. | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| k | 0.119 | 0.102 | 0.089 | 0.118 | 0.149 |

| n | 0.473 | 0.490 | 0.522 | 0.464 | 0.431 |

| R2 | 0.988 | 0.991 | 0.979 | 0.987 | 0.990 |

Table 2 Ritger-Peppas model fitting of the cumulative release amount of β-cypermethrin*

| Sample No. | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| k | 0.119 | 0.102 | 0.089 | 0.118 | 0.149 |

| n | 0.473 | 0.490 | 0.522 | 0.464 | 0.431 |

| R2 | 0.988 | 0.991 | 0.979 | 0.987 | 0.990 |

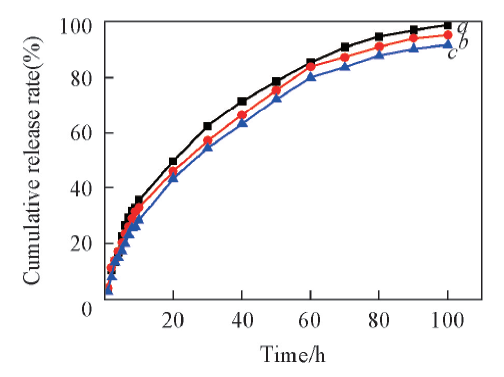

Fig.7 Effects of the loading content with similar particle size on the release behavior of β-cypermethrinLoading content: a. 45.2%; b. 40.7%; c. 34.8%.

| [1] | He X.K.,T. Chin. Soc. Agri. Eng., 2004, (1), 13-15 |

| (何雄奎. 农业工程学报, 2004, (1), 13-15) | |

| [2] | Yuan H. Z., Yang D. B., Yan X. J., Zhang L. N., Plant Prot., 2011, 37(5) , 14-20 |

| (袁会珠, 杨代斌, 闫晓静, 张琳娜. 植物保护, 2011, 37(5), 14-20) | |

| [3] | Xu D., Pan J. L., Liu W. Q., Jiang F. P., Dong J. X., Wang H. L., Asian J. Ecotox., 2013, 8(6), 897-902 |

| (许迪, 潘竟林, 刘万强, 姜福平, 董俊霞, 王会利. 生态毒理学报, 2013, 8(6), 897-902) | |

| [4] | Zhao Y. Y., Pei Y. S., Procedia Environ. Sci., 2012, 13(1), 1739-1747 |

| [5] | Yu C., Fan T. F., Guo X. Y., Wu X. M., Chem. J. Chinese Universities,2010, 31(2), 306-309 |

| (于迟, 范腾飞, 郭鑫宇, 吴学民. 高等学校化学学报, 2015, 36(2), 306-309) | |

| [6] | Lu X. Y., Modern Agrochemicals., 2013, 12(2), 4-9 |

| (卢向阳. 现代农药, 2013, 12(2), 4-9) | |

| [7] | Tsuda N., Ohtsubo T., Fuji M., Adv. Powder Techno., 2012, 23(6), 724-730 |

| [8] | Yuan H. Z., Li G. X., Yang L. J., Yan X. J., Yang D. B., Chem. J. Chinese Universities,2010, 31, 149-154 |

| [9] | Zhao D., Han Z. R., Du Y. C., Mu W., Liu F., Chem. J. Chinese Universities,2010, 31(12), 2753-2758 |

| (赵德, 韩志任, 杜有辰, 慕卫, 刘峰. 中国农业科学, 2007, 40(12), 2753-2758) | |

| [10] | Gu X. L., Zhu X. L., Zhang Z. G., Tan Y. B., Kong X. Z., Liu W. P., Chem. J. Chinese Universities,2010, 31(6), 1247-1254 |

| (顾相伶, 朱晓丽, 张志国, 谭业邦, 孔祥正, 刘维鹏. 高等学校化学学报, 2008, 29(6), 1247-1254) | |

| [11] | Li B. X., Wang K., Zhang D. X., Zhang C. G., Guan L., Liu F., Chin. J Pestic. Sci., 2013, 15(6), 692-698 |

| (李北兴, 王凯, 张大侠, 张灿光, 管磊, 刘峰. 农药学学报, 2013, 15(6), 692-698) | |

| [12] | Li J., Liu H. Y., Wang S. J., You L., Wang X. K., J. Chem. Ind. Eng.(China), 2011, 62(6), 1716-1722 |

| (李杰, 刘红研, 汪树军, 游龙, 王肃凯. 化工学报, 2011, 62(6), 1716-1722) | |

| [13] | Li B. X., Zhang D. X., Zhang C. G., Guan L., Wang K., Liu F., Chin. J. Pestic. Sci., 2014, 16(5), 483-496 |

| (李北兴, 张大侠, 张灿光, 管磊, 王凯, 刘峰. 农药学学报, 2014, 16(5), 483-496) | |

| [14] | Feng J. G., Xu Y., Luo X. R., Yan H., Wu X. M., Chin. J Pestic. Sci., 2011, 13(6), 568-575 |

| (冯建国, 徐妍, 罗湘仁, 严寒, 吴学民. 农药学学报, 2011, 13(6), 568-575) | |

| [15] | Li D., Liu B. X., Yang F., Wang X., Shen H., Wu D., Carbohyd. Polym., 2016, 134 , 341-349 |

| [16] | Liu B. X., Wang Y., Yang F.,Wang X., Shen H., Cui H., Wu D., Colloids and Chem. J. Chinese Universities,2010, 31, 38-45 |

| [17] | Huang Q. L., Li G. Z., Zhang W. J., Zhe D. M., Li F. M., Zhang H. C., Chem. J. Chinese Universities,2010, 31(6) , 1173-1178 |

| (黄啟良, 李干佐, 张文吉, 折东梅, 李凤敏, 张春华. 中国农业科学, 2006, 39(6), 1173-1178) | |

| [18] | Guo Y. F., Yin M. M., Chen F. L., Chin. J. Pestic. Sci., 2010, 12(1), 79-84 |

| (郭勇飞, 尹明明, 陈福良. 农药学学报, 2010, 12(1), 79-84) | |

| [19] | Du H. J., Liu J. Z., Zhang P., Ma L., J. Toxicol., 2016, 30(3), 218-220 |

| (杜宏举, 刘建中, 张鹏, 马玲. 毒理学杂志, 2016, 30(3), 218-220) | |

| [20] | Sun X. J., Ma L. M,, Gong B. T., Agrochemicals,2010, 49(1), 16-18 |

| (孙小静, 马利民, 龚本涛. 农药, 2010, 49(1), 16-18) | |

| [21] | Fan T., Feng J. G., Ma C., Yu C., Li J., Wu X., J. Porous Mater., 2014, 21(1), 113-119 |

| [22] | Xiao C. D., Shen X. C., Tao L., Int. J. Pharm., 2013, 252(1/2), 227-232 |

| [23] | Liu Z. T., Lü Z. F., Chen Y. Z., J. Guangdong Coll. Pharm., 2007, 23(5), 596-600 |

| (刘志挺, 吕竹芬, 陈燕忠. 广东药学院学报, 2007, 23(5), 596-600) | |

| [24] | Fuminori I., Hiroyoshi K., Chem. J. Chinese Universities,2010, 31, 734-739 |

| [25] | Tan T. B., Yussof N. S., Abas F., Mirhosseini H., Nehdi I. A., Tan C. P., Food Chem., 2016, 194, 416-423 |

| [26] | Liu R., Ma G. H., Wan Y. H., Su Z. G., Chem. J. Chinese Universities,2010, 31, 144-153 |

| [27] | Sergio F., Hans P. M., Bruno G., Chem. J. Chinese Universities,2010, 31(2), 313-332 |

| [28] | Xu Y. L., Su. Z. Y., Yang C. Q., Yu X., J. Tianjin Agr. Univ., 2011, 18(3), 28-30 |

| (许艳玲, 苏智扬, 杨春强, 于鑫. 天津农学院学报, 2011, 18(3), 28-30) | |

| [29] | Zuo J. D., Dong B. Q., Xing F.,Luo C., Chen D., Adv. Powder Techno., 2016, 27, 1086-1092 |

| [30] | Wang C. Y., Ye W. H., Zheng Y., Liu X., Tong Z., Int. J. Pharm., 2007, 338(1/2), 165-173 |

| [31] | Cui K. D., Li B. X., Huang X. P., He L. M., Zhang D. X., Mu W., Feng L., Chem. J. Chinese Universities,2010, 31, 80-87 |

| [1] | HUANG Mingxin, ZHOU Lei, WANG Xuezhong. Measurement of Particle Size Distribution of Battery Slurries Using Ultrasonic Attenuation Spectroscopy [J]. Chem. J. Chinese Universities, 2022, 43(6): 20220040. |

| [2] | DONG Le, HUANG Xingliang, REN Junjie, DAI Xiaoping, LIU Zongyan, TIAN Hongfeng, WANG Zhidong, WU Xiaotong. Influence Mechanism of Particle Size and Distribution of Silica Sol in the Synthesis of Ferrierite Zeolite with High SiO2/Al2O3 Ratio [J]. Chem. J. Chinese Universities, 2020, 41(11): 2449. |

| [3] | XIAO Biyuan,QIU Jiangyuan,QIN Fanghong,WAN Ting,XU Yaqun,NONG Xiaohui,HUANG Zaiyin. Study on Particle Size Effect on Adsorption Thermodynamics and Kinetics of Cubic Nano-Cu2O † [J]. Chem. J. Chinese Universities, 2019, 40(10): 2214. |

| [4] | ZHANG Guoqiang, ZHENG Huayan, HAO Zhiqiang, LI Zhong. Effect of Activated Carbon Surface Chemistry on the Properties of Cu Particles and the Catalytic Performance for Oxidative Carbonylation of Methanol† [J]. Chem. J. Chinese Universities, 2016, 37(7): 1380. |

| [5] | HUANG Zhaoliang, GAO Fangyuan, WANG Boliang, ZHANG Weibing. Simulation of the Formation and Fission of Charged Droplets in Electrospray Ion Source† [J]. Chem. J. Chinese Universities, 2016, 37(4): 633. |

| [6] | SUN Haijie, CHEN Lingxia, HUANG Zhenxu, LIU Shouchang, LIU Zhongyi. Particle Size Effect of Ru-Zn Catalysts on Selective Hydrogenation of Benzene to Cyclohexene† [J]. Chem. J. Chinese Universities, 2015, 36(10): 1969. |

| [7] | WANG Yanen, CAO Shuang, WU Weihong, WU Min, TANG Yawen, LU Tianhong. Effect of Particle Size on the Electrocatalytic Activity of Pt/C Catalysts for Oxidation of Formic Acid† [J]. Chem. J. Chinese Universities, 2014, 35(11): 2455. |

| [8] | HUANG Chaofan, QU Guanxiong, WEI Zhenhua, XU Bin, DING Jing, DOU Hongjing, SUN Kang. Fabrication and Medical Imaging of Ultrasonic Imaging Nanocaspsules† [J]. Chem. J. Chinese Universities, 2014, 35(1): 191. |

| [9] | SUN Mei-Yu, PANG Xiu-Jiang, MA Xiu-Ming, HOU Wan-Guo. Preparation and Particle Size Controllability of Mg-Al Layered Double Hydroxides via Coprecipitation Method Using T-type Microchannel Reactor [J]. Chem. J. Chinese Universities, 2013, 34(7): 1691. |

| [10] | JIA Ruo-Kun, JIN Xin, LIN Song-Zhu, GAO Feng, HE Ai-Min, YU Hai-Hui, BAI Yu-Bai. Preparation of Anisotropic Conductive Metal Regular Arrays by Solvent Evaporation Self-assembly [J]. Chem. J. Chinese Universities, 2013, 34(5): 1203. |

| [11] | JIA Ruo-Kun, ZHOU Shi-Yu, LIN Song-Zhu, HE Ai-Min, BAI Yu-Bai. Preparation of Electrostriction of PANI/PU Concave Lens Array by Solvent Evaporation Self-organization [J]. Chem. J. Chinese Universities, 2013, 34(12): 2834. |

| [12] | GAO Xia, ZHANG Fu, CHEN Zhi-Chun, LIN Xian-Fu. Hepatic-targeting Microcapsules Construction by Layer-by-layer Self-assembly of Lactose-branched Polyelectrolyte [J]. Chem. J. Chinese Universities, 2011, 32(4): 957. |

| [13] | YU Yi-Xuan, LIU Jian, NAN Hai-Ming, LIU Xi, CAI Qiang*, LI Heng-De. Synthesis and Characteristic of Pore Size-tailored Self-supporting Mesoporous Film via Solvent Evaporation Induced Self-assembly [J]. Chem. J. Chinese Universities, 2010, 31(11): 2136. |

| [14] | TONG Wei-Jun, ZHU Yi, GAO Chang-You*. Fabrication of Protein Microcapsules by Controlled Precipitation and Cross-linking [J]. Chem. J. Chinese Universities, 2008, 29(8): 1694. |

| [15] |

TONG Wei-Jun, GAO Chang-You*.

Layer-by-Layer Assembled Microcapsules: Fabrication, Stimuli-responsivity, Loading and Release [J]. Chem. J. Chinese Universities, 2008, 29(7): 1285. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||