Chem. J. Chinese Universities ›› 2015, Vol. 36 ›› Issue (2): 229.doi: 10.7503/cjcu20140845

• Articles: Inorganic Chemistry • Previous Articles Next Articles

CHEN Yanguang1,2,*( ), XIE Conghao1,2, HAN Hongjing1,2, ZHAO Fajun3, WANG Baohui1,2

), XIE Conghao1,2, HAN Hongjing1,2, ZHAO Fajun3, WANG Baohui1,2

Received:2014-09-18

Online:2015-02-10

Published:2015-01-22

Contact:

CHEN Yanguang

E-mail:ygchen79310@126.com

Supported by:CLC Number:

TrendMD:

CHEN Yanguang, XIE Conghao, HAN Hongjing, ZHAO Fajun, WANG Baohui. Preparation of NaP Zeolite with Low Si/Al Molar Ratio from Flying Ash†[J]. Chem. J. Chinese Universities, 2015, 36(2): 229.

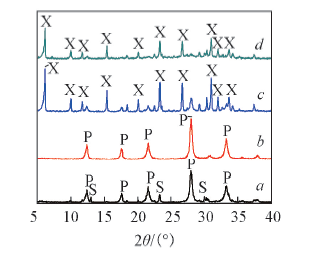

Fig.3 XRD patterns of products prepared with different molar ratios of H2O/SiO2 n(H2O)/n(SiO2): a. 96; b. 116; c. 136; d. 156. X, P and S represent X-type, P-type zeolites and SOD, respectively.

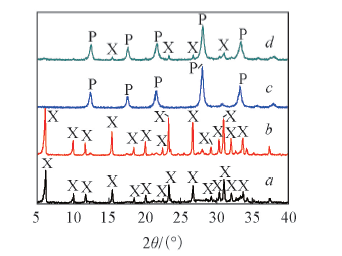

Fig.4 XRD patterns of products prepared with different reaction temperature X, P and S represent X-type, P-type zeolites and SOD, respectively. Reaction temperature/℃: a. 90; b. 105; c. 120; d. 135.

| Organic steric agent | Yield(%) | Average diameter/μm |

|---|---|---|

| 87.8 | 2.78 | |

| TEA | 80.2 | 1.64 |

| MEA | 81.8 | 2.25 |

| DEA | 78.4 | 2.65 |

Table 1 Yield and average diameter of NaP with different additives

| Organic steric agent | Yield(%) | Average diameter/μm |

|---|---|---|

| 87.8 | 2.78 | |

| TEA | 80.2 | 1.64 |

| MEA | 81.8 | 2.25 |

| DEA | 78.4 | 2.65 |

| NaX | pH(before reaction) | pH(after reaction) | Yield(%) |

|---|---|---|---|

| NaOH | 14.38 | 14.47 | 87.8 |

| NaCl | 14.22 | 14.11 | 89.7 |

| NaBr | 14.22 | 14.26 | 94.2 |

| NaNO3 | 14.23 | 14.19 | 90.1 |

Table 2 Variation of pH value of solution and yield of product

| NaX | pH(before reaction) | pH(after reaction) | Yield(%) |

|---|---|---|---|

| NaOH | 14.38 | 14.47 | 87.8 |

| NaCl | 14.22 | 14.11 | 89.7 |

| NaBr | 14.22 | 14.26 | 94.2 |

| NaNO3 | 14.23 | 14.19 | 90.1 |

| Treatment method | Pore volume/(cm3·g-1) | Average diameter/nm |

|---|---|---|

| Raw | 0.026456 | 22.00225 |

| NaBr addition | 0.043124 | 7.59387 |

| TEA addition* | 0.046964 | 4.31398 |

Table 3 Pore volume and diameter of zeolites

| Treatment method | Pore volume/(cm3·g-1) | Average diameter/nm |

|---|---|---|

| Raw | 0.026456 | 22.00225 |

| NaBr addition | 0.043124 | 7.59387 |

| TEA addition* | 0.046964 | 4.31398 |

| [1] | Yao Z. T., Xia M. S., Sarkerd P. K., Chen T., Fuel, 2014, 120(3), 74—85 |

| [2] | Musyoka N. M., Petrik L. F., Hums E., Baser H., Schwieger W., Catal. Today, 2012, 190(1), 38—46 |

| [3] | Zhong S. L., Zhang M. S., Su Q., Chem. J. Chinese Universities, 2005, 26(9), 1603—1606 |

| (钟声亮, 张迈生, 苏锵. 高等学校化学学报, 2005, 26(9), 1603—1606) | |

| [4] | Bohra S., Kundu D., Naskar M. K., Mater. Lett., 2013, 106(1), 182—185 |

| [5] | Kong D. S., Li Z., Li L., Fan J. X., J. Synth. Cryst., 2013, 42(4), 772—777 |

| (孔德顺, 李志, 李琳, 范佳鑫. 人工晶体学报, 2013, 42(4), 772—777) | |

| [6] | Kong D. S., Ji Y. H., Qin B. K., Fan J. X., Wu H., China Ceram., 2013, 49(3), 24—27 |

| (孔德顺, 籍永华, 秦丙克, 范佳鑫, 吴红. 中国陶瓷, 2013, 49(3), 24—27) | |

| [7] | Liu Z. L., Cao J. L., Liu X. W., Gao C. H., J. Synth. Cryst., 2009, 38(5), 1128—1133 |

| (刘振路, 曹吉林, 刘秀伍, 高长虹. 人工晶体学报, 2009, 38(5), 1128—1133) | |

| [8] | Du Y. C., Shi S. L., Dai H. X., Particuology, 2011, 9(2), 174—178 |

| [9] | Samadi-Maybodi A., Pourali S. M., Microporous Mesoporous Mater., 2013, 167(4), 127—132 |

| [10] | Zhang Q., Li C. Y., Shan H. H., Yang Z. H., Chem. J. Chinese Universities, 2011, 32(12), 2721—2726 |

| (张强, 李春义, 山红红, 杨朝合. 高等学校化学学报, 2011, 32(12), 2721—2726) | |

| [11] | Zhang Q., Xu S. J., Meng X. J., Yang W. H., Li C. Y., Shan H. H., Yang Z. H., Chem. J. Chinese Universities, 2013, 34(4), 782—787 |

| (张强, 徐少军, 孟晓静, 杨文慧, 李春义, 山红红, 杨朝合. 高等学校化学学报, 2013, 34(4), 782—787) | |

| [12] | Azizi S. N., Ghasemi S., Amiripour F., Electrochim. Acta, 2014, 137(8), 395—403 |

| [13] | Bohra S., Kundu D., Naskar M. K., Ceram. Int., 2014, 40(1), 1229—1234 |

| [14] | Chen Y. G., Xie C. H., Li Z. M., Han H. J., Li F., Song J., A Method of Using Fly Ash to Prepare P Zeolite, 201410501187.3, 2014-09-26 |

| (陈彦广, 解骢浩, 李治淼, 韩洪晶, 李锋, 宋军. 一种以粉煤灰为原料制备P型分子筛的方法, 201410501187.3, 2014-09-26) | |

| [15] | Zhang Q., Chen C. Y., Ding S., Zhang W. T., Xu D. O., Tang X. J., Wang R. W., Jiang R. H., Zhang Z. T., Qiu S. L., Chem. J. Chinese Universities, 2012, 33(3), 453—457 |

| (张前, 陈春影, 丁双, 张文婷, 许迪欧, 唐晓建, 王润伟, 姜日花, 张宗弢, 裘式纶. 高等学校化学学报, 2012, 33(3), 453—457) | |

| [16] | Lang W. Z., Ouyang J. X., Guo Y. J., East China University Sci. Technol.(Nat. Sci. Edition), 2010, 36(3), 334—339 |

| (郎万中, 欧阳洁霞, 郭亚军. 华东理工大学学报(自然科学版), 2010, 36(3), 334—339) | |

| [17] | Kim J. K., Lee H. D., J. Ind. Eng. Chem., 2009, 15(5), 736—742 |

| [18] | Hollman G.G.Steenbruggen G.Jurkoviěová J. M., Fuel, 1999, 78(10), 1225—1230 |

| [19] | Bonaccorsi L., Proverbio E., Microporous Mesoporous Mater., 2004, 74(1—3), 221—229 |

| [20] | Sun H., Shen B. X., Liu J. C., Dong J. H., East China University Sci. Technol.(Nat. Sci. Edition), 2008, 34(2), 172—177 |

| (孙辉, 沈本贤, 刘纪昌, 董霁虹. 华东理工大学学报(自然科学版), 2008, 34(2), 172—177) | |

| [21] | Bosnar S.,B., J. Cryst. Growth, 2004, 267(1/2), 270—282 |

| [22] | Bosnar S., ., Microporous Mesoporous Mater., 2011, 142(1), 389—397 |

| [23] | Li M., Fu J. Q., Beijing Institute Clothing Technol.(Nat. Sci. Edition), 2012, 32(4), 51—58 |

| (李猛, 傅吉全. 北京服装学院学报(自然科学版), 2012, 32(4), 51—58) | |

| [24] | GB 11910-89, Standards Press of China, Beijing, 1990(GB11910-89, 北京: 中国标准出版社, 1990) |

| (Ed.: F, K, M) |

| [1] | DAI Wei, HOU Hua, WANG Baoshan. Theoretical Investigations on the Electronic Structures and Reactivity of Heptafluoro-iso-butyronitrile Anion [J]. Chem. J. Chinese Universities, 2022, 43(6): 20220044. |

| [2] | LIANG Yu, LIU Huan, GONG Lige, WANG Chunxiao, WANG Chunmei, YU Kai, ZHOU Baibin. Synthesis and Supercapacitor Properties of Biimidazole-modified {SiW12O40} Hybrid [J]. Chem. J. Chinese Universities, 2022, 43(1): 20210556. |

| [3] | ZHANG Wanbin, WANG Yanmeng, WANG Shaowu, TONG Xin, HAN Xiaoqian, ZHANG Ce, ZHANG Guanghua, ZHU Xiuzhong. Synthesis of Poly(allyl glycidyl ether) Bearing Alkyl Functional Side Groups and Its Plasticizing and Antistatic Effects for PVC [J]. Chem. J. Chinese Universities, 2021, 42(9): 2961. |

| [4] | ZHUO Zengqing, PAN Feng. Progress of Key Electronic States in Lithium Ion Battery Materials Probed Through Soft X-ray Spectroscopy [J]. Chem. J. Chinese Universities, 2021, 42(8): 2332. |

| [5] | ZHANG Huishuang, GAO Yanxiao, WANG Qiuxian, LI Xiangnan, LIU Wenfeng, YANG Shuting. High-low Temperature Properties of Ni-rich LiNi0.6Co0.2Mn0.2O2 Cathode Material by Hydrothermal Synthesis with CTAB Assisted [J]. Chem. J. Chinese Universities, 2021, 42(3): 819. |

| [6] | WANG Ye, ZHANG Xiaosi, SUN Lijing, LI Bing, LIU Lin, YANG Miao, TIAN Peng, LIU Zhongyi, LIU Zhongmin. Morphology Control of SAPO Molecular Sieves under the Assistance of Organosilane [J]. Chem. J. Chinese Universities, 2021, 42(3): 683. |

| [7] | WANG Jianyu, ZHANG Qiang, YAN Wenfu, YU Jihong. Roles of Hydroxyl Radicals in Zeolite Synthesis [J]. Chem. J. Chinese Universities, 2021, 42(1): 11. |

| [8] | WU Qinming, WANG Yeqing, MENG Xiangju, XIAO Fengshou. Reconsideration of Crystallization Process for Aluminosilicate Zeolites [J]. Chem. J. Chinese Universities, 2021, 42(1): 21. |

| [9] | LIU Yabing,LI Mingyang,TIAN Ge,ALATENG Shaga,PEI Tonghe,NIE Jingsi. Syntheses, Structures and Catalytic Properties of Two Supramolecular Complexes Based on 2-Pyridylamine and Cluster † [J]. Chem. J. Chinese Universities, 2020, 41(5): 995. |

| [10] | ZHUO Mengning,LI Fei,JIANG Hao,CHEN Qianwen,LI Peng,WANG Lizhang. Preparation of SnO2/GDE Cathodes and Their Electrocatalytic Reduction of CO2 to Produce Formic Acid † [J]. Chem. J. Chinese Universities, 2020, 41(3): 530. |

| [11] | YANG Jin,CAO Yan,ZHANG Naidong. Co-sensitization in the Visible Light/H2O2 System † [J]. Chem. J. Chinese Universities, 2020, 41(3): 505. |

| [12] | FANG Mingliang,LIU Dong,HU Meishao,WANG Lei. Synthesis and Properties of Highly Branched Comb-shaped Poly(aryl ether sulfone)s/imidazolium-functionalized Graphene Oxide Anion Exchange Composite Membranes † [J]. Chem. J. Chinese Universities, 2020, 41(2): 365. |

| [13] | DONG Le, HUANG Xingliang, REN Junjie, DAI Xiaoping, LIU Zongyan, TIAN Hongfeng, WANG Zhidong, WU Xiaotong. Influence Mechanism of Particle Size and Distribution of Silica Sol in the Synthesis of Ferrierite Zeolite with High SiO2/Al2O3 Ratio [J]. Chem. J. Chinese Universities, 2020, 41(11): 2449. |

| [14] | ZHOU Hai, CHEN Hao, GUO Ya, KANG Min. Synthesis of Meso-porous Co3O4 Polyhedra and Their Electrochemical Properties† [J]. Chem. J. Chinese Universities, 2019, 40(7): 1374. |

| [15] | HU Xueyi, CHEN Miaomiao, FANG Yun, FENG Ruiqin, HAN Huihui. Investigation on Pseudo-polyanions of Cationic Cellulose-Sodium Dodecylbenzenesulfonate† [J]. Chem. J. Chinese Universities, 2019, 40(7): 1464. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||